Variable Frequency Drive

If you have an application that does not need to be run at full speed, then you can cut down energy costs by controlling the motor with a variable frequency drive, which is one of the benefits of Variable Frequency Drives. VFDs allow you to match the speed of the motor-driven equipment to the load requirement. There is no other method of AC electric motor control that allows you to accomplish this. VFDs are used in applications ranging from small appliances to the largest of mine mill drives and compressors. However, around 25% of the world's electrical energy is consumed by electric motors in industrial applications, which are especially conducive for energy savings using VFDs in centrifugal load service,[5] and VFDs' global market penetration for all applications is still relatively small. That lack of penetration highlights significant energy efficiency improvement opportunities for retrofitted and new VFD installations.

...more

Servo Drive Panel

Motor control centers are usually used for low voltage three-phase alternating current motors from 208 V to 600 V. Medium-voltage motor control centers are made for large motors running at 2300 V to around 15000 V, using vacuum contactors for switching and with separate compartments for power switching and control. Motor control centers have been used since 1950 by the automobile manufacturing industry which used large numbers of electric motors. Today they are used in many industrial and commercial applications. Where very dusty or corrosive processes are used, the motor control center may be installed in a separate air-conditioned room, but often an MCC will be on the factory floor adjacent to the machinery controlled.

...more

scada panels

Supervisory control and data acquisition (SCADA) is a system for remote monitoring and control that operates with coded signals over communication channels (using typically one communication channel per remote station). The control system may be combined with a data acquisition system by adding the use of coded signals over communication channels to acquire information about the status of the remote equipment for display or for recording functions. The term SCADA usually refers to centralized systems which monitor and control entire sites, or complexes of systems spread out over large areas (anything from an industrial plant to a nation). Most control actions are performed automatically by RTUs or by PLCs. Host control functions are usually restricted to basic overriding or supervisory level intervention. For example, a PLC may control the flow of cooling water through part of an industrial process, but the SCADA system may allow operators to change the set points for the flow, and enable alarm conditions, such as loss of flow and high temperature, to be displayed and recorded. The feedback control loop passes through the RTU or PLC, while the SCADA system monitors the overall performance of the loop.

...more

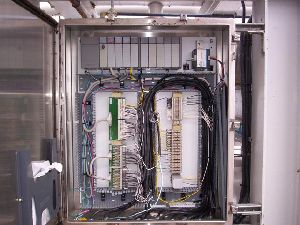

plc based control panels

In modern world most of the conventional controls of relay-contactor based logics are being replaced by PLC based systems. Being flexibility of operation and changing of logic PLC- Programmable Logic Controllers are extensively used in all type of industries Considering the preference of client from view of past experience, availability of support we offer our client any make of PLC such as Siemens, Allen Bradley, GE Fanuc, Mitsubishi, Schneider for making of PLC based control system panels. PC CONSOLES, SCADA CONSOLES, CONTROL DESK, CONTROL POST, HMI CONSOLE, OPERATOR DESK, SWIVELLING MONITOR.

...more

MCC Panels

Motor control centers are usually used for low voltage three-phase alternating current motors from 208 V to 600 V. Medium-voltage motor control centers are made for large motors running at 2300 V to around 15000 V, using vacuum contactors for switching and with separate compartments for power switching and control. Each motor controller in an MCC can be specified with a range of options such as separate control transformers, pilot lamps, control switches, extra control terminal blocks, various types of thermal or solid-state overload protection relays, or various classes of power fuses or types of circuit breakers. A motor control center can either be supplied ready for the customer to connect all field wiring, or can be an engineered assembly with internal control and interlocking wiring to a central control terminal panel board or programmable controller.

...more

Electrical Panels

Inside a switchboard there will be one or more busbars. These are flat strips of copper or aluminum, to which the switchgear is connected. Busbars carry large currents through the switchboard, and are supported by insulators. Bare busbars are common, but many types are now manufactured with an insulating cover on the bars, leaving only connection points exposed. The operator is protected from electrocution by safety switches and fuses. There may also be controls for the supply of electricity to the switchboard, coming from a generator or bank of electrical generators, especially frequency control of AC power and load sharing controls, plus gauges showing frequency and perhaps a synchroscope. The amount of power going into a switchboard must always equal to the power going out to the loads.

...moreBe first to Rate

Rate ThisOpening Hours