Water Wash Spray Booth

The WATER WASH SPRAY BOOTH provides an extremely efficient means of removing paint particles from the exhausted air by using water as a filtration media; we have designed the WATER WASH SPRAY PAINTING BOOTHS for many finishing applications. We also offer both pump as well as no-pump versions in open type model, enclosed type model and conveyorised models. Standard WATER WASH SPRAY PAINTING BOOTHS are utilized for high volume paint usage, medium or large sized components and batch processes. Water Screen Type Water Wash Booth contains special features like water tank or over spray paint collection disposal tank, specially designed eliminators (baffles), saw tooth plates, washing chamber and high pressure exhaust blower. This type of painting booth is more popular where the paint consumption is 10-100 liters/shift , heavy paint consumption, high production and / for any component.

...more

Water Wash Downdraft Booth

Wet Downdraft Booth Pit Type DOWNDRAFT BOOTHS requires excavation and additional concrete work. DOWN DRAFT SPRAY BOOTH can be connected in line with air supply units or air replacement units for better performance. Large Downdraft Paint Booths:- Large Downdraft Painting Boothsare designed for hand spray of the largest types of work-earth moving equipment, tractors, locomotives, buses, cranes. Depending on the nature of the work, Large Downdraft Spray Booths may be either single sided or double sided and open partly enclosed of fully enclosed. Airflow is vertical from top to bottom through an either an open roof or through an air replacement system. Depending on the work to be carried out in Large Downdraft Paint Booth and Different material handling equipment. Open type Large Dry Downdraft Paint Booth is most popular & cost effective for all industrial products. Speciality of Autocoat Downdraft Booth fulfils. Complies to OPERATOR SAFETY Achieves FIRE SAFETY Fulfils POLLUTION NORMS. Helps to achieve QUALITY OF PAINT FINISH. Autocoat Engineering is the most experienced Dry Downdraft Paint booth Manufacturer in India since last 35 years. Autocoat Engineering have been manufacturing superior quality Water Downdraft Booth in India among other valuable products .We have wide experience of manufacturing Wet Downdraft Spray Booth with different material handling and different product size , and different production volume. Downdraft Booth Manufacturer in India & Downdraft Paint Booth Supplier in India Surface coating Plant Manufacturer in India & Painting Plant Manufacturer in India

...more

Water paint booth

Autocoat Water Curtain Booth is designed with Water curtain with pump for dust free paint shop or for plastic painting. Lab Water Booth is selected suitable for if application of different types of paints. Same way for large Painting Plant Conveyorised Water Wash Booth with paint sludge removal system is more popular. Autocoat Engineering is the most experienced Water booth Manufacturer in India since last 35 years. Autocoat Engineering have been manufacturing superior quality Water Paint booth in India among other valuable products .We have wide experience of manufacturing Water paint booth with different material handling and different product size , and different production volume.

...more

Water Downdraft Spray Booth

Autocoat Downdraft Booth are specially used for painting of heavy parts and large components, which are difficult to handle namely, wagons, earth moving machineries, chassis of vehicles, trailers, etc. In a DOWNDRAFT BOOTH air flows from top to bottom. And Air Draft is towards ground or to the exhaust chamber. The Wet Downdraft Booth can be single sided or double sided extraction chamber depending on the size of the component. Painter goes around the component to paint all sides of competence. The over spray paint particles exhausted are removed through grating & then to water tank. After turbulent action the paint particles are allowed to form a paint sludge & Paint Free air is exhausted to blowers and finally to atmosphere. Water Wash Downdraft Paint Booth is popular in mass production where paint consumption is very high. Such Downdraft Paint Booth requires Extensive civil work for Paint Booth as well as for Paint sludge removal system & hence are expensive. Pit Type DOWNDRAFT BOOTHS requires excavation and additional concrete work. DOWN DRAFT SPRAY BOOTH can be connected in line with air supply units or air replacement units for better performance.

...more

Water booth

The WATER WASH SPRAY BOOTHS designed and engineered by Autocoat, is available in three kinds of schemes, namely. Standard Water Screen Type Water Wash Booth also known as No-Pump Booth or Pumpless Booth. WATER WASH SPRAY BOOTH DESIGN with water curtain or water screen. Civil Excavated WATER WASH SPRAY PAINTING BOOTH. Conveyorised WATER WASH SPRAY PAINTING BOOTH etc. Water Wash Spray Booth For high volume paint consumption (more than 100 ltr/shift) Autocoat has developed Auto Paint Sludge Removers, (import substitution) to be used along with Paint Sludge Pit or Paint Sludge Sedimentation Plant. Such Auto Piant Remover will have to be incorporated in new painting plant or in existing painting plant with the modification in civil work & pumping system. System helps to remove online paint sludge removal so that efficiency of painting plant is maintained. In the Autocoat Water Booth Paint sludge can build up to within a couple of inches of the surface of the water tank without affecting the efficiency of the booth.& hence ideally suitable for any type of paint & any paint consumption is 10-100 liters/shift, as well as for mass production

...more

truck paint booth

autocoat large paint booth is designed with the side draft air flow (for medium sized component) is popular because of lower initial cost & lower operating cost. dry type large paint booth is ideally suitable for low volume production in which component or product can be rotated with the help of eot crane or underground turntable. & generally open type. dry type large spray booth is more popular with handling with eot crane or with floor trolley & generally open type is suitable for industrial products paint finish quality. open type large paint booth is to operate, easy to maintain & economical for low volume production & ideal when industrial paint finish quality is requirement (not like ultra quality of 4 wheeler automobile) paint booth cost? autocoat dry type large paint boothincorporates metal baffles & replaceable filters as per autocoat 4 level filtration to exhaust paint free air in the atmosphere to full fill pollution norms. autocoat dry type large spray booth with improved 4 level filtration system reduces recurring filter replacement cost to amazingly low when compared with competition. for bigger components like rail coach, earth moving machineries dry type or wet type, truck paint booth or rail coach painting boothcan be selected as per painting consumption & type of paint required. large paint booths are recommended for painting of heavy parts and large components, like wagons, chassis of vehicles, trailers, etc. in a large painting booth in which air flows from top to bottom or in a cross flow paint booth air draft is from one top corner to other end of the paint booth.for bigger products & mass production consuming large quantity of paint requiring water type large paint booth is recommended. paint booth is designed with central venture water washing system with online paint sludge removal system & sedimentation pit. such paint booths are expensive & most suitable for high volume of paint consumption. autocoat engineering is the experienced large spray paint booth,truck paint booth,rail coach painting, railway painting plant ,rail coach painting booth manufacturer in india since last 35 years.

...more

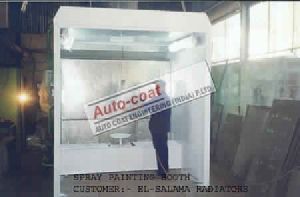

Std Painting Booth

We are offering std painting booth. we offer best quality paint booths, that are compatible for heavy & voluminous components which are difficult to handle. These paint booths are based on a modular concept and can be customized to suit clients' specific demands.

...more

Standard Paint Booth

We are offering standard paint booth. we manufacture of standard paint booth and painting booth featuring various standard booth models and specializing in custom designs for unique paint booth applications, our flexible, state-of-the-art paint booths may be used for production batch finishing as well as high production finishing on a large conveyor line

...more

Spray Pretreatment System

We are offering spray pretreatment system. spray pretreatment system (msp) is a complete pretreatment system which combines a spray zone and full dip zone. These spray pre-treatment systems can be customized as per our customer specifications.

...more

Spray Painting Equipment

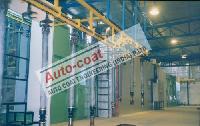

Spray Painting Booths, Spray Painting Plants

We are offering spray painting booths, spray painting plants. These spray painting booths and plants results into increased production rates & can be met easily by mere adjustment of the existing equipment within the existing area. Once installed spray painting plant can operate round the clock without any increase in capital equipment. A plant with an overhead conveyor for transportation of components will normally leave the floor area clear for storage and other movement of material. The objects to be sprayed are moved at a predetermined speed and convenient height. this reduces operator fatigue, and results in greater efficiency and increased output.the cost of painting would be greatly reduced as the output of the paint is increased by the operation of additional shifts. If you wish to expand your paint shop and space is a problem, it will pay you to investigate this type of installation. Autocoat engineering is the most experienced spray booth manufacturer since last 50 years in india. Autocoat engineering have been manufacturing superior quality spray booth among other valuable products .we have wide experience of manufacturing painting booths with different material handling and different product size , and different production volume.

...more

Spray Paint Booth

autocoat engineering is specialized in the manufacturing of all kinds ofspray booth standard or customized, suitable for batch or conveyorised application for small or very large component.many satisfied customers in india are using autocoat spray paint booth because of superior designing & selection of bought out items (design is most critical). All products are manufactured, assembled & tested for performance before dispatch and & commissioned at site. Training, after sale service & specialized instruction manual along with laminations for sop for maintenance & tpm activity are autocoat expertise. Most of our customers are corporate companies with iso certification and with their stringent quality requirements. having 35 year experience & expertise autocoat spray paint booths are more precisely autocad engineered & manufactured in-house & fulfils. it also takes care to reduce dust problems, reduces over spray problems, and removes waste spray paint & solves paint sludge disposal, helping for added value to the final product. Since it is the last operation prior to packing. Paintings in a clean paint booth normally have better finish & thus higher customer satisfaction value. operator safety. fire safety. pollution norms. improvement in quality of paint finish.

...more

Spray Booth

We are offering spray booth. autocoat engineering have been manufacturing superior quality spray booth among other valuable products. We have wide experience of manufacturing paint booth with different material handling and different product size , and different production volume. autocoat engineering is one of the most renowned company when it comes to spray booth manufacturers in india & spray booth suppliers in india autocoat engineering painting booth is designed (most critical is spray booth design), manufactured , assembled & tested for performance before dispatch and commissioned at site to achieve customer 100% satisfaction. Most of our customers are corporate companies with iso certification and with stringent quality requirements.

Type : Spray Booths

Application : Car Painting, Furniture Painting, Metal Fabrication, Truck & Bus Painting

Country of Origin : India

...more

Small Conveyorised Paint Plant

We are offering small conveyorised paint plant. the small conveyorised paint plant is designed for specially suitable for powder coating of high volumes of components, large in size or small in size or any kind of product. These kind of conveyorised powder coating plant are mainly helpful where synchronization of product input verses product output is to be maintained without any time lag. These conveyorised powder coating plant are very elaborate in size which can accommodate two or more than two painters, automated painting guns or reciprocators etc. These are available with or without filter air set-up.

...more

SMALL CONVEYOR PLANT

Conveyor Painting Plant are used for painting of components for mass productions & generally upgraded from batch painting to conveyor painting because of following distinct advantages Saving in manpower cost Better process control & hence Saving in rejection cost Useful to add accelerated drying or curing oven Payback in 2 to 3 years if volume is more than 100 200 Nos. per shift (Smaller & medium component ) In conveyor painting plant, each part moves through the manufacturing process at the same rate. If graphed, conveyor painting would be a straight line moving from start to finish. There is no wait time or down time because progress is happening constantly. Conveyor painting is well-suited for manufacturers with a large volume of parts, as they do not be required to manually move the parts into the next phase of the finishing process. However, it is important to note that the continuous flow of a conveyor system is not suited for lines containing parts of different size & shape.

...more

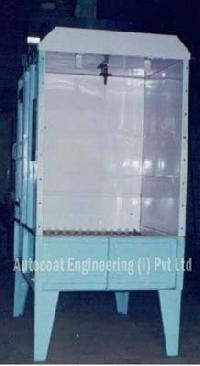

Side Draft Spray Booth

Autocoat has designed & developed wide series of LAB BOOTH designed to fulfill stringent pollution norms as well as with amazingly low running cost. Autocoat is Manufacturer & Exporter of LABORATORY BOOTHS . Autocoat Lab booths are built to last: with the quality appearance, 100% assembly & Trials in-house ensure guarantied performance as well as at customers place. Autocoat computer generated labels & lamination, detailed drawings and well documented Manual will save you time and money when it comes to use of Laboratory Paint Booth effectively during its lifetime.

...more

Side Draft Booth

side draft spray booth autocoat has designed & developed wide series of lab booth designed to fulfill stringent pollution norms as well as with amazingly low running cost. Autocoat is manufacturer & exporter of laboratory booths . autocoat lab booths are built to last: with the quality appearance, 100% assembly & trials in-house ensure guarantied performance as well as at customers place. Autocoat computer generated labels & lamination, detailed drawings and well documented manual will save you time and money when it comes to use of laboratory paint booth effectively during its lifetime. autocoat water lab booth is designed with the pumpless miniature washing chamber which with the turbulent action sparest paint particles. The best advantage of water type lab booth is that lumps of waste paint are collected in the collection tank thereby helping the user to dispose it easily. Autocoat water lab booth is ideally suitable for samples of all types of baking or air dry paint / water base or solvent based paint / primer or sealer or undercoat & finishing coat / epoxy or alkyd or acrylic or polyurethane etc autocoat dry lab booth is ideally suitable for samples of all non-sticky overspray like air dry paint / quick drying polyurethane paint or similar paint which produces non-sticky over-sprayed paint particles. autocoat rubber bonding spray booth is also popular with design changes & many rubber bonding paint booths are in use oem in india. autocoat new series of dry back lab booth design incorporates: - specialty 4 level filtration. suitable for low paint consumption & for pu & air drying paint (non sticky paint). specialty metal baffle design insures filter replacement cost at amazingly low. meets pollution norms of particulate matter. capital cost less than water wash booth. unlike autocoat dry back paint booth competitors paint booth are often provided with paint filters which chocks in no time (for chocking of filters can be 1 week if paint consumption 10 ltrs. Per/shift) and must be replaced to get same performance in the paint booth & if not replaced then painter will be uncomfortable & resist carrying on painting production loss while submission of quote autocoat insists to collect office room plan for technical suitability of performance especially if the lab room is closed type with the starving for air intake. Each quote is given with autocad drawing. autocoat engineering is the most experienced laboratory booth manufacturer in india since last 35 years. Autocoat engineering have been manufacturing superior quality lab booth in india among other valuable products .we have wide experience of manufacturing lab booth with different material handling and different product size , and different production volume. lab booth & laboratory booth in india manufacturer in india & lab spray booth supplier in india

...more

Pvc Enclosure

We are offering pvc enclosure. we offer high performing plastics enclosures, which are made from superior quality polycarbonate, frp and other raw materials. These enclosures are used for protecting electronic & pneumatic components.

...more

Powder Spray Booth

We are offering powder spray booth. autocoat engineering specializes in making the powder spray booth which are been made with the mild steel and stainless steel. Powder spray booths are been fitted with the quality spray guns and the powder hoppers. The processes that can be carried out in these powder spray booth in a variety of custom made designs. Powder spray booth are been used for spray coating the parts with multiple color shades and the capacity can be customized as per the client's need. autocoat engineering is the most experienced powder booth manufacturer since last 50 years in india. Autocoat engineering have been manufacturing superior quality powder spray booth among other valuable products. We have wide experience of manufacturing powder booths with different material handling and different product size , and different production volume. autocoat engineering is one of the most renowned company when it comes to powder booth manufacturers in india & powder coating booth manufacturer in india. autocoat engineering powder coating plant is designed (most critical is powder booth design), manufactured , assembled & tested for performance before dispatch and commissioned at site to achieve customer 100% satisfaction. Most of our customers are corporate companies with iso certification and with stringent quality requirements.

...more

Powder Coating System

We are offering powder coating system. autocoat engineering provide specialized powder coating system which can take care of the color change problem (i.e. Pigments) in minimum time , so that the production is unhampered . We can manufacture, erection, commissioning of any type of painting system, powder coating system as a turnkey powder coating system including , pretreatment plant both dipping type and spray type and both conveyorised and batch type, ovens for paint . Powder coating system has become very popular in the industry for outdoor durability products also, thus now it is not restricted to household products only. Powder coating plant manufactured by autocoat engineering can give best results to handle any type of color or powder. powder coating solutions : autocoat engineering is best powder coating solutions for spray booths which are been made with the mild steel and stainless steel. Powder coating spray booths are been fitted with the quality spray guns and the paint tank. There are a lot of difficulties faced by the operator or the customer, to how to maintain a clean room concept while using powder coating equipment. Other difficulties faced by the user is the curing of the powder after it is been sprayed over the component. Autocoat engineering is one company that provides complete powder coating solutions to customers, all guiding parameters to how to use the powder coating equipments, what should be the gun pressure , sewing arrangement etc.

...more

Powder Coating Plant

We are offering powder coating plant. we offer powder coating plant, which is commonly used surface finishing technique and widely used in plant and machinery industry. Our range helps in flexible and tough powder coating systems on different industrial equipment. Further, we also offer powder coating solutions on turnkey basis. Our powder coating plants are provided with smooth interior wall surface and anti static panels that minimizes the attraction of powder coating making the booth more efficient and easy to clean. These booths are designed to offer adequate flow of clean air at breathing level of the operator. We can manufacture, erection, commissioning of any type of painting system, powder coating system as a turn key project including , pretreatment plant both dipping type and spray type and both conveyorised and batch type,ovens for paint

...more

Powder Coating Booth

Plastic Painting Booth

We are offering plastic painting booth. autocoat engineering has experience in plastic painting booth which is complex object geometry and spray plastic coating surface should be of ultra finish. We have also supplied paint booths for spray plastic furniture coating plants, paint booth for gift articles, plastic painting for helmets.

...more

Phosphating Plants

Be first to Rate

Rate ThisOpening Hours