Weld Gun Arm, Shank, Electrode, Cap & Tip

Our pursuit of perseverance to register ourselves amidst the elite companies in this domain encourages us to manufacture and supply a commendable range of Weld Gun Arm. These have minimum rockwell hardness of 90B and a minimum electrical conductivity of 45% IACS. Offered products are made available in scores of designs and sizes to meet the diverse needs of the clients. Manufactured at our production unit, the offered products are properly tested before delivering to clients. Features:• Rugged design• Durability• Excellent strength

...more

Water Cooled Sub Jumper Cable

To meet the connector needs in resistance welding electromech offers a broad variety of secondary connector. Each cable, secondary shunts are designed and built to perform with maximum efficiency & economy in its intended application. Electromech air cooled jumpers cables are required to be electrically connecting distant points which move in relation to each other. Such as The movable gun–arm of certain types of welding guns to electromech cable. On multiple spot welding machines Electromech air cooled jumpers are extra more flexible rope type secondary conductors with connector, swage- formed on each end for maximum flexibility & cooling. The standard terminal width is 32 mm. if wide terminal is required, please specify when ordering. Terminals Terminals are made for soft electrolytic copper tube. Wire construction: - This made from 0.05 mm2 electrolytic grade copper wire each bunch of herringbone construction to reduce that the rate of wire fracture by providing the lateral surface wear areas. It is a total sectional area shall not be less than the appropriate sectional area per MCM/mm2 rating Wire connection to Terminals: - Wires are brazed crimped in the soft electrolytic copper Tube. Wire can not melt out during brief overheads. Flexible cover: - A loosely fitting rubber impregnated sheath encases most Cable styles for mechanical protection. Optional feature Protection sleeves: - In order to eliminate breakage of strands due to the frequent acute bending operation, protection sleeves are, provided on the area of both the terminals joints.

...more

water cooled kickless cables

3,000 Per Meter

Specification of Water Cooled Kickless Cable : 1. Design of Cable as per Customers Specification with very less tolerance. 2. Special type of rubber hose with the High flexibility, more than 10 Kg/cm2Capacity and to protect to high temperature water for safe operation. Excellent cooling effect even in continued welding operation. 3. Copper wire size is 33 Gauge for 300 MCM & 400 MCM as per standard of RWMA. 4. Accurate copper straight lugs or copper bend lug with 99% conductivity of Electrolytic Copper. Little Impedance & little Reactance drop. 5. Fantastic water testing units with Pressure 10 to 12 Kg/cm2, each and every Cable are tested. 6. Good Quality product with Long Life and very competitive rate. Long cable life reduces cable cost per weld - the true measure of cost cable. 7. We have good team of engineers with more than 10 Years experience in same field. 8. Strict Quality Control during production, delivery as per schedule. 9. Easy for check & replacement & maintenance. 10. We have own Quality Assurance Plan of our products.

Type : Kickless Cables

Application : Welding Machines

Certification : ISO 9001:2008 Certified

Application : Industrial Use

Conductor Material : Copper

Feature : Compact Design, Excellent Finish, Long Working Life

...more

Water Cooled Kickless Cable

1. Design of Kickless Cable as per Customers Specification & Requirement and drawings. 2. High flexibility for good working efficiency. 3. Special type of Rubber hose with the good flexibility and its Pressure Capacity more than 10 Kg/cm2 and protect to high temperature water for safe operation. Covering of good pressure resistance, heat resistance, wear resistances. 4. Excellent cooling effect even in continued welding operation. 5. Fantastic water testing units with Pressure 10 to 12 Kg/cm2, Each & every cable is tested. 6. Little Impedance & little Reactance drop. 7. Copper wire size is 33 Gauge for 300 MCM & 400 MCM as per Standard of RWMA 8. Accurate copper straight lug or copper bend lug with 100% Conductivity of copper. 9. High resistance of repeating kicks & bending caused by electro magnetic force introduced by the welding current & welding operation, according long life. 10. Good Quality product with Long Life and reasonable rate. Long cable life reduces cable cost per weld – the true measure of cost cable. 11 Easy for check & replacement & maintenance. 12 The kickless cable is consuming part required to be inexpensive. 13 Expertise staffs’ are working in Electromech Corporation, last 15 Years experience in same field. 14 Immediately service is our motto. Unique Technical Features: 11 extra operations on each end of Electromech Kickless Cable These operations are necessary where wires are again crimped in an exclusive male and female pattern to position the wires to achieve the best alternate polarity design. This ultimately, results into less Kicks in Kickless Cable without any shorting of inside wires while in weld operation and hence increases the life by two to three times as per the feed back received form the industry sources. Operation 1 & 2 : Copper strip using for Wire crimping in Hydraulic press & then soldering on both end lugs. Operation 3 & 4 : Blanking of Non magnetic S.S. sheets - 2 times (One Male & One Female). Operation 5 & 6 : Forming of straight Pipe (male) and taper Pipe (female) Operation 7 & 8 : Spot Welding straight pipe (male) and taper Pipe (female) Operation 9 & 2 : Crimping into male type and other into female type. Operation 11 : Covering the male pipe with high quality imported heat shrink sleeve.

...more

water cooled jumper sub cables

2,800 Per Meter

Specification of Water Cooled Jumper / Sub Cable : 1. Design of Cable as per Customers Specification with very less tolerance. 2. Special type of rubber hose with the High flexibility, more than 10 Kg/cm2Capacity and to protect to high temperature water for safe operation. Excellent cooling effect even in continued welding operation. 3. Copper wire size is 33 Gauge for 300 MCM & 400 MCM as per standard of RWMA. 4. Accurate copper straight lugs or copper bend lug with 99% conductivity of Electrolytic Copper. Little Impedance & little Reactance drop. 5. Fantastic water testing units with Pressure 10 to 12 Kg/cm2, each and every Cable are tested. 6. Good Quality product with Long Life and very competitive rate. Long cable life reduces cable cost per weld - the true measure of cost cable. 7. We have good team of engineers with more than 10 Years experience in same field. 8. Strict Quality Control during production, delivery as per schedule. 9. Easy for check & replacement & maintenance. 10. We have own Quality Assurance Plan of our products.

...more

Water Cooled Jumper Cable

These cables are used as supplementary cable to connect kickless cable and gun are of the single conductor only. To meet the connector needs in the resistance welding operation. Electromech offer a broad variety of secondary cable. Each cable is design and built to perform with maximum efficiency and economy in its in depended application. Electromech water-cooled jumper (Aid)cable to electrically connect distant points which move in relation to each other such as, The movable gun-arm of the certain types of welding guns to the electromech cable. On a multiple spot welding machines. Electromech water cooled jumper & sub cables are flexible rope types secondary connectors, assembling with high conductivity terminals. There are sheathed with reinforced abrasion & oil resistant hose. Free water passage is insured by means of an open spring core progressing the entire length of the cable. Thus permitting the cable to operate under the condition of acute bending without obstructing the water flow. TERMINALS Straight lugs are machined from high conductivity electrolytic Copper bar stock. Bends lugs are forged and machine from high conductivity electrolytic copper. WIRE CONSTRUCTION This is a made from 0.05mm2 electrolytic grade Copper wire. Each bunch or herringbone construction to reduce the rate of wire facture by providing lateral surfaces wears areas. The total sectional area shall not be less than the sectional area as per MCM/mm2 rating. Wire connection to terminal Water is terminated in a crimped in soft electrolytic tube and the soldered to the terminals. Wire cannot melt out during brief overloads FLEXIBLE HOSE COVER The outer rubber hose made of heat resistant on its inner Surfaces & abrasion resident on its outer surfaces. WATER FLOW Coiling water is passed at the rate of 3 lit/ min at the pressure of the 6kgf/ cm2 and the pressure drop does not exceed 0.7kg/ cm2 WATER PRESSURE The cable is tested at a pressure of 6 kgf/ cm2 (kcs) to ensure then there is no leakage or hose damage. Optional feature ROTECTION SLEEVES: - In order to eliminate breakage of strands due to frequent acute bending operation, projection sleeves are provided on the area of both the terminal joints.

...more

Water cooled Furnace Power Cables

3,000 Per Piece

We are the main supplier of this product.

resistance welding transformers

4,000 Per Piece

Custom manufacturer of resistance welding transformers specializing in automated resistance welding equipment featuring spot, projection, rocker arm, butt, seam, bench, gun, 3-phase, mil spec, MFDC & HFDC & miniature welders. Custom design of tooling & fixtures. Consumable products include electrodes, seam wheels, caps, shanks, holders, controls, cables, coolers, chillers & peripheral equipment. Remanufactured & special application equipment as well as service, training, parts & supplies. Resistance Welding Process Perfectors; Producers Of R/W Equipment. Wholesale Distributors Of All R/W Components & Raw Materials: RWMA Classes 1-14. Special Machined Parts & Tooling. Evaluations & Sample Welds Performed transformer design and characteristics would have been a rather controversial subject 15 years ago, as in those days the name-plate kilovolt-ampere rating of the transformer meant little other than that it was printed in English

...more

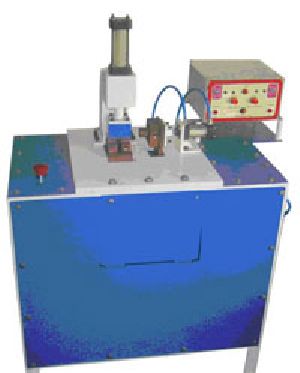

resistance spot welding machines

32,000 Per Piece

Our wide range of Spot Welding Machines that we manufacture and supply in many small and large scale industries are designed in order to complete the demand of various machine & instruments industries. Features:Adjustable length of armsChrome/Copper electrode holders for long life, designed for both straight and angled fittingPneumatic operated, synchronous step less current control by thyristors and synchronous timersAdjustable electrode strokeEpoxy coated, water-cooled transformerWater cooled arms, electrode holders and electrodesSynchronous SCR contactor insulated from water cooling circuitAdjustable electrode pressureAdjustable electrodes strokeWater-cooled transformer, with epoxy resin coated windingsFoot control adjustable in length

...more

resistance projection welding machines

32,000 Per Piece

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting. Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation. These machines are designed and manufactured conforming to the Indian Standard Specification No. IS:4804 Part I and III by a team of highly experienced engineers in welding technology. Specifications: Standard Ratings: 50, 75, 100, 150, 250 and 300 KVA @ 50% duty cycle. Type: Air operated, stationary press type projection welding machine with pneumatic cylinder mounted directly on the upper arm.

...more

One End Heating Machines

We are a team of qualified and experienced Engineers and Technicians. We are pleased to inform you that we have successfully come out with a unique – FIRST TIME IN INDIA – special purpose Resistance Heating Machine which is very useful for Engineers’ File manufacturers. This machine is used in place of existing Gas Burners for heating the file ends before forging. The special design used in this machine helps to heat the job faster with considerable less current. Since the Time and Current is less, the electrical energy consumption, which is proportional to the time and square of current, is considerably reduced and hence the operation cost of this machine is negligible compared to gas heating. Apart from the financial benefits, this machine is absolutely Eco friendly compared to gas heating We have successfully established this heating system with three of the following leading file manufacturers in India. » M/s HURRY NOTH AND CO. PVT. LTD » M/s UNIQUE STAR ALLIANCE PVT » M/s INDIAN FILLES MANUFACTURING COMPANY LTD (GARDEX GROUP) All of the above parties have removed the gas burners and have installed our heating machines in their forging plant. They are more than satisfied with the machine performance and the financial gain achieved after switching over to our heating machines

...more

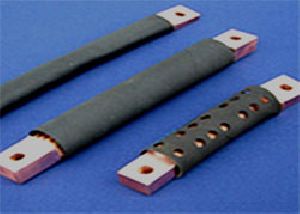

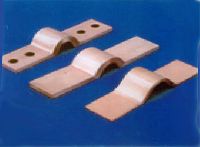

laminated copper shunts

We manufacture Copper Laminated Flexible Connectors, Shunts and Copper Laminated Flexible Jumpers using thin copper (Cu) foils or Aluminium Laminated Flexible, Shunts and Aluminium Laminated Flexible Jumpers made out of thin copper (Al) foils.Copper Laminated Flexible Connectors & Aluminium Laminated Flexible Connectors consist of several stacked strips with either riveted, soldered or fusion welded contact areas having a constant cross-section over the whole length. Copper Laminated Flexible Connectors and Aluminium Laminated Flexible Connectors with the same cross-section as that of a Bus-Bar can be loaded with the same current, providing beneficial connection capabilities. Design of the Copper Laminated Flexible Jumpers, Shunts and Connectors as well Aluminium Laminated Flexible Jumpers, Shunts and Connectors can be fully customizable upon our customers requirements.

...more

Laminated Copper shunt

Laminated Copper Shunts are secondary conductors made of this copper. Shunts are available in many standard sizes or more as per the customer specification. Shunts are normally supplied with their ends secured swaged and press welded connector. Resistance values are equal to more of flat Copper bar. As a result, voltage losses are minimized & maintaining the uniform flow of electrical current

...more

Kickless Cables

1. Design of Kickless Cable as per Customers Specification & Requirement and drawings. 2. High flexibility for good working efficiency. 3. Special type of Rubber hose with the good flexibility and its Pressure Capacity more than 10 Kgcm2 and protect to high temperature water for safe operation. Covering of good pressure resistance, heat resistance, wear resistances. 4. Excellent cooling effect even in continued welding operation.

...more

Fiber Insulation over the Gun

Extra features of Fiber Insulation over the Guns 1 100% Fiber Insulation with high Technology. 2 This is High technology process specially made for Resistance welding Guns, Arm Shank and Holders. 3 Superior quality material is used in process 4 Thickness of Fiber Insulation over the gun 3mm to 4mm thick 5 Color shade in Blue or any as per you expected. 6 80 to 90 degree in continuously temperature of water, nothing will happen any thing on Insulation 7 100% shunting effect problem will solve. 8 Sharp sheets will not remove that insulation easily 9 Increase the life of Guns, Arm, Shank and Holders….etc.

...more

ELECTROMECH CORPORATION MAKE FULLY AUTOMATIC ESR FURNACE MACHINE.

Electroslag remelting furnace (ESR furnace) provides optimal removal of sulphur, non-metallic inclusions and gases. ESR furnace/electroslag remelting furnace is a current production of heat using molten slag into the pool from the power level, the metal droplet liquid washing through the residue, after crystallization in water-cooled crystallizer Into the ESR of special refining equipment. As the slag to the mixture of liquid crystal effects and good conditions for ESR metal with good Purity, cast structure is uniform, no white spots and the ring-like segregation, very low sulfur content, inclusion of small dispersion and other fine performance.Therefore, ESR in the medium-sized forgings, rough blocks the production of a monopoly position in the high-quality tool and die steel, duplex steel billet, cold RollingElectroslag furnace is particularly Special steel production equipment is essential. Electromech electroslag furnace company making full use of the most mature technology design, manufacturing production stereotypes Products. Main Features ESR Transformer 120 KVA Plus 120 KVA double decors with common secondary. Total 240 KVAESR Transformer 150 KVA Plus 150 KVA double decors with common secondary. Total 300 KVA Heavy duty Water-cooled thyristor assembliesLatest Automatic Heat sequence electronic control panel.Latest operating control panel including with Ammeter, Voltmeter Secondary Ammeter, Voltmeter other switches for easy operation.Heavy diameter of Melting Rods.Constant melting continuously without voltage fluctuation.Quality Products is a result.

...more

Electrode Cap and Tip

CuCrZr material is best suited material of spot welding caps for both coated & non-coated sheets. The additional cost advantages of our (CuCrZr) Cap, Tip and Shank and Adaptor:- 1. RWMA – class 1 copper chromium zirconium (CuCrZr), Conductivity 85% and Hardness 83B. 2. Does not stick on Zr coated materials because the lower welding current and pressure used melt less of the Zr and thus reduce the diffusion of the Zr into the Cu. 3. Reducing the current by 15 - 20%, which is a big saving of energy & power consumption. 4. Reducing weld force by which weld splatters are minimized 5. Reducing dressing time to more than half that also if necessary, as the cap tip surface does not allow formation of any contamination like brass coating / carbon. 6. Reduce cap changing downtime. 7. Better weld quality. 8. Increasing Kickless & Aid Cable life.

...more

copper shunt

Copper Shunts are secondary conductors made of this copper. Shunts are available in many standard sizes or more as per the customer specification. Shunts are normally supplied with their ends secured swaged and press welded connector. Resistance values are equal to more of flat Copper bar. As a result, voltage losses are minimized & maintaining the uniform flow of electrical current

...moreBe first to Rate

Rate ThisOpening Hours