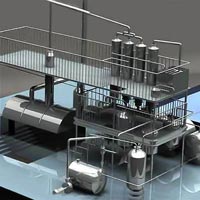

Fruit Juice Processing Plant

80,000 Per Piece

1 Set(s) (MOQ)

Tamarind Pulp Processing Plant

45,000 Per Piece

1 Piece (MOQ)

Best Deals from Fruit Processing Plant

mango pulp processing machine

2,000,000 - 8,000,000 Per piece

1 piece (MOQ)

Mango Pulp/Concentrate is perfectly suited for conversion to juices, drinks, jams, fruit cheese and various other kinds of beverages. It can also be used in puddings, bakery fillings, fruit meals for children and flavors for the food industry, and also to make the most delicious ice creams, yogurt and confectionery. The mango processing line typically includes a range of machines such as mango washing and sorting machines, mango peelers and pitting machines, mango cutting machines, mango pulping machines, mango slice drying machines (for dry mango chips production) mango pulp separating and concentrating machines, mango pulp/juice pasteurizers/sterilizers, filling machines, and packaging machines to facilitate the processing of fresh mangoes into various value-added products. The mango preparation process includes mango washing, cutting, de-stoning, refining and packing. In the case of aseptic products, the mango pulp is sterilized and packed in aseptic bags. The refined pulp is also packed in cans, hermetically sealed and retorted. Frozen mango pulp is pasteurized and deep-frozen in plate freezers. The process ensures that the natural flavor and aroma of the fruit are retained in the final product. The production process of a mango processing plant typically starts with the selection of fresh and ripe mangoes, followed by washing and peeling, pitting and pulping into a homogenous pulp, which is then pasteurized/sterilized, filled into various packaging forms such as bottles, aseptic bags, pouches, etc. The mango processing plant can produce concentrated juice/puree, NFC mango juice, mango dilution juice, dry mango chips, etc. according to different machine configurations. The Production line capacity is from 10 tons/day-2500 tons/day. Mango Juice yield: about 45%-55% (25%-45% for fruit peels and cores for the waste); Raw material solid content: 10-12Brix, Final concentrated juice concentration:65 ~ 72Brix, concentrated mango puree 28-30Brix. The whole mango processing line has the characteristic of high efficiency, automation, and flexibility, enabling it to process large volumes of mangoes with minimal labor, reduced processing time, and superior product quality. PLC control throughout the production process, all electrical components are imported products. Low-temperature vacuum concentration guarantees flavor substances and nutrients and greatly saves energy. The whole mango processing plant is equipped with CIP cleaning system, it can clean machines and pipelines fully automatically, and all material contact parts of the system are made of 304 stainless steel, which fully meets food hygiene and safety requirements.

Fruit Pulp Heating Cooling System

5,000,000 Per Piece

1 Piece (MOQ)

Fruit Juice Processing Plant

5,500,000 Per Unit

1 Unit (MOQ)

Fruit Juice Processing Plant

Get Price Quote

1 Piece (MOQ)

Fruit Juice Processing Plant

190,000 Per Piece

1 Piece (MOQ)

Mango Pulp Processing Plant

2,000,000 - 2,500,000 Per piece

1 p (MOQ)

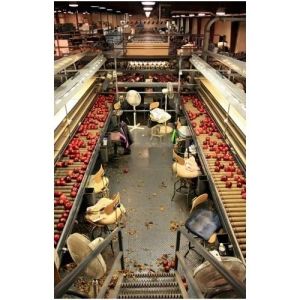

With such benefits, mangos are processed into a variety of products, such as mango pulp, mango juice and dried mango. And mango pulping become the most prevailing method for the simple process, high nutrition remain and high yield. The mango pulp processing includes mango cleaning, selecting, peeling and pitting, pulping, precook, blending, concentration, filling, sterilization and cooling. The mango pulp machine for pre-treatment includes fruit sorting machine, brush and spray cleaning machine, mango peeling and destoning machine, fruit pulping machine. M&T can provide you with customized mango pulp processing plant to make high quality mango pulp at high efficiency. We can offer you from 100Kg's to 10,000 Kg's/Hr Processing Line #mangopulp #mangojuice #mangoasepticpacking #mangobar #mangocanningline #Vegetableprocessingling #foodprocessingmachinery #apeda #packhouse #vegetablewasher #washer #dryers #industrialwashingmachines #vegetables #fruits #washingmachine #industrial #commercialprojects #ozone #ozone_production #mandtengineering For a detailed proposal: To see our other videos relating to the subject: subscribe to our channel and click the Bell icon for push notifications.

fruit processing plant

Get Price Quote

Most modern and world class processing plants are offered by SITCO at most genuine rates. All operations are automated and carried out flawlessly. There is a huge demand for processed fruits mainly because of the health benefits they bestow. Researches done worldwide reveal that processed fruits minimize the chances of heart disease, diabetes, strokes, obesity, hypertension, birth defects and even some types of cancer. You can get various superb quality fruit processing plants from SITCO, one of the most experienced manufacturers and suppliers of processing plants. SITCO maintains standard norms by focusing on all vital concepts including QA, SPC, HACCP, GMP, food safety and strict hygiene. SITCO also offers a lot of other processing plants according to the demand you have.

Fruits and Vegetable Preservation System by Aeolus

Get Price Quote

1 Piece(s) (MOQ)

Aeolus is most prominent supplier of 100% Made in India ozone generators. We have strong hold in Indian market in supplying Ozone based preservation systems. Vegetables and fruits have been recognized as a healthy and nutritive value food, with both a noticeable rise in consumption nowadays and greater frequency of foodborne illnesses associated with fresh produce. The microbial hazards associated with fruits and vegetables are contributed by: Microbial load of raw material Improper handling and storage Use of contaminated wash water Processing equipment, and transportation facilities Cross-contamination from other products Other foodborne illness can be attributed to complex pesticides and their preservatives like wax found on almost all fruits and vegetables. Most of the chemical pesticides are carcinogenic and indeed effect human health even at very low concentration. Disinfecting agents have widespread applications to assure safety and quality in the food industry. However, some of these agents, such as chlorine, are inefficient against some organisms, particularly at high pH or against spore-forming microbes. Furthermore, chlorine can react to form trihalomethanes, which are of concern for both human dietary safety and as environmental pollutants. Ozone is a viable alternative to traditional disinfectants. Ozone treatment has the potential to give encouraging results for some problems of the food industry like: Effective in inactivation of common and emerging pathogens, Removing toxic contaminants including chemical pesticides Leading to less loss in product quality; Adaptable to food processes Environmental friendly Hence Ozone extends the shelf life of a number of products including fruits and vegetables. And is quite efficient for such applications. Especially, ozone revealed promising results in solving the problems of the food industry like mycotoxin contamination and pesticide residues. Ozone is an effective sanitizer with great potential applications in the food industry. It decomposes into simple oxygen with no safety concerns about consumption of residual by-product. Due to its high oxidation capacity and microbial inactivation potential, ozone has prevented various kinds of microbial spoilages usually encountered in fruits and vegetables. We are capable of offering systems for vegetable & fruits disinfection and pesticide elimination for households, hotels & restaurants, community kitchens, super markets and malls, Indian Army and agriculture produce markets (APMC). We also deliver tailor made solutions with desired automation. At Aeolus, We strive to give effective and sustainable solutions to our customers. Contact Aeolus now with your requirements, we are happy to help!

Fruit Juice Processing Plant

Get Price Quote

we have with us extensive experience in successfully designing the fruit juice processing plant. the complete line of fruit juice processing plants are offered meet the processing needs of fruits like apple, mango , orange pineapple, papaya, guava, berry, grapes, lemon are made available in various operating capacities . the type of processing plant varies based on the product ,juice like apple,grape, lemon etc can be proceed with the plate of heat exchanger and viscous product like mango, guava, etc needs to be proceed with corrugated tubular heat exchanger 1. all equipment made up of ss 304. 2. low operating cost. 3. easy to handled. 4. we provide technical guidance.

Fruit Juice Processing Plant

Get Price Quote

We have with us extensive experience in successfully designing the fruit juice processing plant. The complete line of fruit juice processing plants are offered meet the processing needs of fruits like apple, mango , orange pineapple, papaya, guava, berry, grapes, lemon are made available in various operating capacities . The type of processing plant varies based on the product ,juice like apple,grape, lemon etc can be proceed with the plate of heat exchanger and viscous product like mango, guava, etc needs to be proceed with corrugated tubular heat exchanger 1. all equipment made up of ss 304. 2. low operating cost. 3. easy to handled. 4. we provide technical guidance.

Fruit Juice Processing Plant

Get Price Quote

We offers complete line for fruit processing and concentration. This plant is for processing of fruits like mango, orange, apple, pears, etc. and for making juice concentration, paste, jam, jelly, ketchup, etc. For Juice Concentration, vacuum evaporation is another step in fruit processing line. The final concentrate can be filled in aseptic bags in drums for export purposes. Clear Juices can be formulated, blended and spray dried at best conditions to convert them into readily soluble powders.

Fruit Juice Processing Plant

Get Price Quote

With our expertise in this domain, we are able to offer a superior quality range of Fruit Juice Processing & Packaging Plant. Our offered juice concentration plants are ideal for fruits such as pineapple, grapes, apple, mango and tomato. The increase in concentration can be achieved by passing the product through an evaporator. Further, these concentration plants are appreciated in the market for their optimum functionality and low maintenance cost. Send Enquiry

Fruit Juice Processing Plant

270,000 Per Units

1 Units (MOQ)

Fruit Juice Processing Plant

Get Price Quote

The Company is Specialized in undertaking Fruit Juice Processing Plant in the market. The fruit juice processing plant bought forth by us is available with (A) Processing Line for Fruit Pulp Juice, (B) Pulping section, (C) Processing Section, (D) Packaging Section. This includes Complete Process of Inspection, Sorting , Washing, Peeling, Cutting, Pulping (Pulper), Pasteurization, Blanching, Filling and Packing. These Processing Plants are easy to handle and have long durable Life. In addition to this, we are one of the most reputed fruit and Juice Processing Machine Manufactures in India.

fruit processing plant

Get Price Quote

fruit processing plant

Get Price Quote

Fruit Juice Processing Plant

Get Price Quote

Fruit processing plants to process mango, guava, papaya, pine apple, grapes, citrus fruits, pomegranate, bananas etc to convert the same to their respective purees of different concentrations and powders. Fruit juices are spray dried in order to have a long shelf life, reduces storage place requirement and lower cost of bulk packing. Fruit juice powders have many applications in food industry as additive like for sandwich cookies, instant soup, health food, jellies, puddings, biscuits, ice food mixes, breakfast cereals, confectionery, ready-to-drink mixes, bakery, milk powder mixes, flavorings in medicine, dietetic food & nutritional food etc.

fruit processing plant

Get Price Quote

Most modern and world class processing plants are offered by SITCO at most genuine rates. All operations are automated and carried out flawlessly. There is a huge demand for processed fruits mainly because of the health benefits they bestow. Researches done worldwide reveal that processed fruits minimize the chances of heart disease, diabetes, strokes, obesity, hypertension, birth defects and even some types of cancer. You can get various superb quality fruit processing plants from SITCO, one of the most experienced manufacturers and suppliers of processing plants. SITCO maintains standard norms by focusing on all vital concepts including QA, SPC, HACCP, GMP, food safety and strict hygiene. SITCO also offers a lot of other processing plants according to the demand you have.