Water Softeners

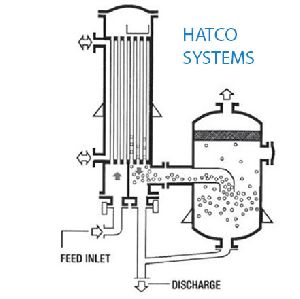

There are two types of Hardness present in water one is Temporary Hardness and another one is Permanent Hardness. Water is considered ‘hard’ (Temporary) when it has excessive levels of calcium and magnesium dissolved in it. Hard water increases the following Features Scale build-up in pipes, resulting in decreased flow rates. Scale build-up on heating and cooling systems, leading to increased electricity costs and breakdowns. White film on glass surfaces and staining on water taps. Increased laundry costs due to hard water reacting with soap and laundry detergents. Hatco Water Softening Plants are designed to produce treated water to suit for various applications. Treated water is of consistency quality with low residual hardness throughout the service cycle. Available at, FRP, Mild Steel, SS, FRP with inner lining of FRP/ Rubber/Epoxy Type: Vertical Flow rate: 01m3/hr to 200m3/hr The high synthetic resin is used to exchange Sodium ion with hardness forming Calcium and Magnesium ions. After producing desired output, the resin is regenerated with (NaCI) Sodium Chloride solution after which unit is again ready to deliver next batch. RWT Series units are available with different models. The difference between these models is in the capacity of the resin used for each model. These units are easy to operate and maintenance free.

...more

Vitro Sphere

General Details Hatco recommend and supply Glass media for certain application like swimming pool, fountain to give better quality of water. Glass filter „pearls“ with special surface made with nanotechnology will remove even the smallest impurities. The round shape provides for a smooth water flow in filter and high filtering efficiency. The special round surface allows easy separation of impurities from the pearls during filter backwash, making the backwash faster and with minimal water use and thereby reducing heating and water treatment costs. No calcium deposits on glass. Very hard material = longer lifetime. Recommended change interval = 5–8 years.

...more

Ultra Filtration Plants

HATCO offer wide range of UF systems as per customer requirement , we design Ultrafiltration plants for various applications like RO pre treatment, drinking water, ETP, STP and customised requirement. Ultrafiltration is a separation process using membranes with pore sizes in the range of 0.1 to 0.001 micron. Typically, ultrafiltration will remove high molecular-weight substances, colloidal materials, and organic and inorganic polymeric molecules. Low molecular-weight organics and ions such as sodium, calcium, magnesium chloride, and sulfate are not removed. Because only high-molecular weight species are removed, the osmotic pressure differential across the membrane surface is negligible. Low applied pressures are therefore sufficient to achieve high flux rates from an ultrafiltration membrane. Flux of a membrane is defined as the amount of permeate produced per unit area of membrane surface per unit time. Generally flux is expressed as gallons per square foot per day (GFD) or as cubic meters per square meters per day. Ultrafiltration membranes can have extremely high fluxes but in most practical applications the flux varies between 50 and 200 GFD at an operating pressure of about 50 psig in contrast, reverse osmosis membranes only produce between 10 to 30 GFD at 200 to 400 psig. Ultrafiltration, like reverse osmosis, is a cross-flow separation process. Here liquid stream to be treated (feed) flows tangentially along the membrane surface, thereby producing two streams. The stream of liquid that comes through the membrane is called permeate. The type and amount of species left in the permeate will depend on the characteristics of the membrane, the operating conditions, and the quality of feed. The other liquid stream is called concentrate and gets progressively concentrated in those species removed by the membrane. In cross-flow separation, therefore, the membrane itself does not act as a collector of ions, molecules, or colloids but merely as a barrier to these species. Conventional filters such as media filters or cartridge filters, on the other hand, only remove suspended solids by trapping these in the pores of the filter-media. These filters therefore act as depositories of suspended solids and have to be cleaned or replaced frequently. Conventional filters are used upstream from the membrane system to remove relatively large suspended solids and to let the membrane do the job of removing fine particles and dissolved solids. In ultrafiltration, for many applications, no prefilters are used and ultrafiltration modules concentrate all of the suspended and emulsified materials. There are several factors that can affect the performance of an ultrafiltration system. A brief discussion of these is given here. Flow Across the Membrane Surface: The permeate rate increases with the flow velocity of the liquid across the membrane surface. Flow velocity if especially critical for liquids containing emulsions or suspensions. Higher flow also means higher energy consumption and larger pumps. Increasing the flow velocity also reduces the fouling of the membrane surface. Generally, an optimum flow velocity is arrived at by a compromise between the pump horsepower and increase in permeate rate. Operating Pressure: Permeate rate is directly proportional to the applied pressure across the membrane surface. However, due to increased fouling and compaction, the operating pressures rarely exceed 100 psig and are generally around 50 psig. In some of the capillary-type ultrafiltration membrane modules the operating pressures are even lower due to the physical strength limitation imposed by the membrane module. Operating Temperature: Permeate rates increase with increasing temperature. However, temperature generally is not a controlled variable. It is important to know the effect of temperature on membrane flux in order to distinguish between a drop in permeate due to a drop in temperature and the effect of other parameters.

...more

TRAPPIRT Sewage Water Treatment

Hatco Systems now provides special TRAPPIST Combine treatment of Surface water and Ground water remediation. In combined remediation technologies such as mixing, diluting and GRAVITY DOSING and to treat and induction of Oxidative or Reductive conditions are very cost effective and time consuming. However, these applications are dependent on circumstances, and therefore TRAPPIST has proved to be cost prohibitive and very effective at contaminated sites without injection/ and mixing. Surface, Groundwater and waste water contamination poses a long-term risk to the environment and the value of your land. Hatco Systems can help you clean up test, safe and effective-without even buying any equipment or system. Our TRAPPIST the most environmental friendly product resolves the environmental issues of polluted lakes, Rivers and all industrial sites where hydrocarbons, metals, heavy metals or Organics have leeched into the water. TRAPPIST -Advance Sewage Treatment based on advance technology is most successful because of the following reasons. Sewage treatment Plants are the major source of releasing (EDCs) into the Environment and then into Surface water, rivers & lakes.

...more

Thermic Fluid Evaporator

These type evaporators are generates the heat from thermic fluid by heating up through heater power, Steam or gas. Mechanical evaporator incorporated with this exchanger to evaporate the waste water or polluted water to concentrate more. Thermic fluid Heat evaporator are not consider IBR / non IBR. Available capacity 100 LPH to 20000 LPH Model – Indoor or Outdoor

...more

Shock Wave Reactor

Hatco Systems, The Patented Next Generation Technology Using Cavitation for Extraction, Process Intensification, Mixing, Increased Mass Transfer and Scale-Free Heating. The ShockWave Reactor (SPR) technology harnesses the powerful force of cavitation to apply energy to fluids. The cavitation is controlled and is non-damaging to the equipment. The cavitation shockwaves can provide benefits in almost any industry with benefits in: Mixing Heating Extraction In heating the SPR can heat fluids without scaling or fouling. In mixing cavitation offers many advantages over conventional technology (such as shear/tank mixers) through its unique mixing mechanism. In extraction cavitation is similar to the more commonly known ultrasound technology, but with key advantage of being the ability to scale beyond the laboratory to large commercial flows.

...more

Sewage Treatment Plants

Sewage or wastewater is liquid from residences, institutions, commercial and industrial establishments, together with groundwater, surface and storm water. Nowadays, many hotels are not connected to a main sewerage hence installing sewage treatment plant for your hotels is a major criteria. Why because, Sewage treatment plant also called as wastewater treatment plant or water pollution control plant will take only few hours to remove most of the pollutants from sewage/wastewater before it is released into the natural environment or reuse. Sewage or wastewater from hotels undergoes few treatment processes to remove the majority of solid and organic material before it is clean enough to be safely discharged into waterways. After treatment, the treated water can be reused for gardening or can be disposed off. The major purpose of STP for hotels is to treat the wastewater influent so that it will not cause dangerous diseases to humans. Wastewater from the hotels is collected in the treatment plant, where it goes through several stages of treatment by means of drains and collectors. The effective sewage treatment plants for small, medium and large sized hotels and resorts are very small and compact which involves mechanical, chemical and biological treatments/techniques which would minimize environmental pollution (i.e. water pollution). Basic treatment steps involved in sewage treatment plant for hotels are as follows: 1. Preliminary Treatment: This treatment is the first step in processing waste water which is also called as mechanical/physical treatment process which needs to be done previous to primary treatment. During this stage, solids are removed through screening, sedimentation and skimming. It’s major objective is to remove coarse solids through screening. Incoming wastewater called influent passes through mechanical screens consisting of bars where rags, sticks, papers, drinking cans and other similar items will get removed. It involves grit chamber to remove sand and grit. This treatment also removes excessive amount of oils and greases. It is essential for preventing damages to the pumps and other equipments in rest of the treatment processes. 2. Primary Treatment: It is also known as physical-chemical treatment which is to be done prior to biological treatment called secondary treatment. It aims at removing organic and inorganic solids by the processes of sedimentation and floatation. Partially treated wastewater from preliminary treatment is allowed to pass through tanks called primary clarifier or sedimentation tank. During this treatment flow of wastewater is reduced to encourage sedimentation and thereby allowing the heavier solids to settle at the bottom and significant amount of floating material such as grease and oil will rise to the surface and be skimmed off. The settled solid is called as primary sludge which will be further subjected to sludge digestion process. This particular treatment removes about 50-60% of influent suspended solids and reduces BOD level up to 30-40%. The clarified water flows on to the next step of treatment. 3. Secondary Treatment: This treatment is referred as biological treatment process which generally uses one of the biological aerobic processes called “Activated sludge process” to degrade organic matter. During this process, primary effluent enters into aeration tanks, where it is mixed with microorganisms. Air is pumped into aeration tanks and hence bacteria growth will get increase to breakdown the organic matter that still present in the effluent. Now aerated wastewater flows into secondary clarifier where heavier particles and other solids settle to the bottom as secondary sludge. Some of the sludge will be re-circulated back to aeration tank to stimulate activated sludge process to remove as many pollutants as possible. The remaining sludge is removed from the tank and mixed with primary sludge in sludge processing system for further processing. This stage removes about 80-90% of organic solids. Once the water moves out of this stage, it enters into last stage called tertiary stage or disinfection stage. 4. Tertiary Treatment: It is the final stage in small sewage treatment plant which involves physical, chemical or biological processes to remove any residual or remaining suspended solids and dissolved solids. Even after primary and secondary treatment, treated wastewater may contain some disease causing microorganisms and that is why disinfection is required. Disinfection disinfects and kills harmful microorganisms from the effluent and it is done by using disinfectants like chlorine, ozone, UV light or other chemical disinfectants. Ozone and ultraviolet disinfection process is results in cleaner effluent than chlorination which contains residual chlorine that can damage the environment. Tertiary treatment is also called as disinfection treatment which is an essential step because it protects humans health.

...more

Scale Buster

Hatco supplies a wide range scale busters, To prevent scaling of any water. We are among the most trusted companies for providing Scale Buster to the clients. Our offered product Ion Scale Buster is stringently checked by the quality auditors on well defined parameters so as to make sure a hassle free operation and performance for long period of time and is widely appreciated by our esteemed clients. Features High accuracy Robust construction Easy control systems Product Description: Hatco technology has bee utilized for environmentally friendly, water conditioning by the residential, commercial and industrail markets for more than 15 years. The technology has been used by some of the world’s largest commercial and industrial companies to treat scaling, corrosion, and other water challenges. Over 300,000 units have been sold and installed worldwide. Scale and general corrosion form on equipment surface and restrict water flow, clog systems and reduce system efficiency resulting in costly equipment down time and increased maintenace coste. Using chemicals to treat these conditions results in high chemical disposal costs, pollution of the environment and related health and safety issues

...more

RO Membranes

We are in manufacturing, supplying and exporting premium quality RO membrane. Sourced from our trusted vendors in the branded name of Melbourn, high quality raw materials are used to design this membrane. Stringent quality control is maintained in the entire manufacturing process to ensure end product meets with international quality standards. Hatco Systems is India’s first company to supply high quality reverse osmosis membrane at market leading price. Based on our clients’ demands, we supply various type of RO membrane. We supply various type of membrane : 50 gpd, 75 gpd, 80 gpd, 100 gpd, 300 gpd, 400 gpd, 4″and 8″ industrial membrane. Key features of our Reverse Osmosis membrane: Better self life High salt rejection up to 98% TDS up to 2000 tds Ro membrane sheet manufacture by USA leading brand Ro membrane rolled by KOREAN machine for better performance In house testing facility

...more

Rising Film Evaporator

Rising Falling Film Evaporator Product Operation HATCO Falling Evaporator or Concentrator delivers high tube velocities which assures uniform product distribution and high coefficients of heat transfer. The rising falling film evaporator (RFC), or recirculating version, RRFC, works on uniform metered flow entering the bottom of the steamchest and rises through the first pass with rapidly increasing velocity. After leaving the first pass the flow of the vapor liquid mixture is reversed and directed downward through the second pass at extremely high velocity. The mixture then enters the separator where the vapor and liquid are separated. When not designed as a circulation unit, the rising falling film evaporator provides once through evaporation of heat sensitive materials, requiring minimum retention time. It is particularly adaptable to multiple effect systems but provides a lesser turn-down capability than the RRFC configuration. Rising Falling Film Evaporator Characteristics High tube velocity minimizes fouling. Able to achieve high concentrations at low temperatures. Risk of entrainment is greatly reduced since the major portion of the liquid passes directly out of steamchest rather than being re-entrained with vapor from the separator. System may be turned down without loss of efficiency or effectiveness. Holding time is a matter of seconds (RFC). Suitable for evaporation of a wide range of liquid concentrations. Low headroom requirement. Rising Falling Film Evaporator Product Applications Heat sensitive liquids requiring minimum process time. Pure or non-crystal forming liquids. Liquids having low to medium viscosities. Foamy liquids. Liquids containing fine suspended solids. Readily handles thixotropic materials. Rising Falling Film Evaporator Application Examples Ammonium- Nitrate Apple Juice Cane Sugar Syrup Caprolactam Corn Syrup Caustic Coffee Extracts Gelatin Glue Grape Juice Lemon Juice Orange Juice Pharmaceuticals, Heat-sensitive Pineapple Juice Tea Extracts

...more

Reverse Osmosis Plants

We offer a wide range of industrial reverse osmosis Plants, according to We need for tap water, brackish water & sea water application. The production range starts from 100 LPH (Liter per hour) to 100 M3 per hour for 100ppm to 45,000ppm TDS and reduce TDS @ 95-99% . All our industrial reverse osmosis Plants are carefully customized and configured to suit the individual requirement of the output water, which varies from normal drinking application to the specific usage, such as food Processing, pharmaceuticals and boiler feeding requirement. This is done through an in depth and complete chemical analysis of the feed water available to us in specific location. Reverse Osmosis has gained wide acceptance and popularity due to its simple operation and the ability to withstand variations in feed water quality. Produce high-quality dematerialized water Most modern membrane technology Modular design Low water-rejection rate Low operational and maintenance costs

...more

Pressure Sand Filter

HATCO Design & Develop the Pressure Sand Filter sizes based on water quality to make filtration velocity through Sand Filter Medias. These filters are mainly used to remove Turbidity, TSS and filter up to 50 micron Level. Filtration taking place through the filtration bed of pressure filters [known as fine filtration] removes especially turbidity, colloid substances, undesirable colour or odour, microbiological contamination, and some ammonia ions, precipitated iron, manganese from water and it reduces water acidity as well. Available at, FRP, Mild Steel, SS, FRP with inner lining of FRP/ Rubber/Epoxy Type: Vertical & Horizontal Flow rate: 01m3/hr to 100m3/hr For the purpose of a proper removal of these substances from water and to obtain the requested quality of output water it is necessary to propose a suitable filtration process. The actual filtration through pressure filters is complemented with aeration, clarification, coagulation, static mixers, disinfection… The kind of the filtration medium used is very important as well.

...more

Pilot Plant

Through our experience we know that in many cases the configuration of the future process plant can already be optimised through a standardised preliminary examination prior to installation. This will save you the cost for investment as well as for future operation. You can be assured of the quality of our service before placing your order. Advantages of a Pilot Plant Easy transportation and fast installation Very small footprint Optimum dimensions for a large-scale plant Optimisation prior to investment Proof of performance capacity prior to investing in large scale plant

...more

Packaged Sewage Treatment Plant

Hatco system provides packaged sewage water treatment plant. Features Offers high-load and expeditious treatment, and easy maintenance. Nitrogen can be removed through its anaerobic filter chamber. Sludge can be stored in high concentration in the separation box. The sludge only needs to be drawn once every 6-12 months. Comes in three styles and body types (capsule chamber, cylindrical chambers ofφ2170 andφ 2500) and this makes possible to meet various water quality criteria and installation space requirements. Energy-saving blowers keep running costs low. The most updated automated machinery ensures stable high-quality product anufacturing.

...more

oil skimmer belt

Hatco Systems Belt Skimmers are developed with a variable speed drive to provide an economical, corrosion-free, wide belt skimmer for central coolant tanks, wastewater and water treatment applications with high collection rates! Use in applications where desired oil collection rate is not known, where incoming oil rate may change, or where oil is needed to be removed faster/slower at different times. ! Simply Turn Knob to Adjust Oil Lift Rate or to dial it in for best recovery. Benefits: Economical Cost and Dependable Operation No Corrosion – All Stainless and Polymer Materials Std. Belt Lengths to 10 ft. – Can be made to 100 ft. down Handles Fluctuating Liquid Levels Takes Little Space & Easy to Install Furnished as a Complete System with Accessories Features: Uses Belts – Polyurethane or Stainless, Uses One to Four Belts, Baldor Permanent Magnet Gearmotor, UHMW Bearing-Grade Polymer Scraper Blade.

...more

mixed bed

HATCO design and make mixed bed polishing units to suit all of customer’s need. Cation and Anion resins are combined in a MSRL of FRP vessel to produce ultra pure water. Usually a mixed bed unit contains strong acid Cation (SAC) resin and Weak base Anion (WBA) resins combined to a ratio of approximately 40% Cation resin to 60% Anion resin. (All resin volumes are dependent upon the feed water analysis and the required quantity of treated water). Mixed bed polishers are typically installed when a water quality of less than 1 micro ohm conductivity is required. Normally mixed bed polishers are installed after a standard Reverse Osmosis or De mineraliser (DM Plant), to produce ultra high quality water. The Cation resins in mixed bed units are of a higher specific gravity and settle at the bottom of the vessel at the same time the Anion resin will automatically float to the top. Please note: The Cation resin must be a strong acid Cation type (SAC) and the Anion resin must be a strong base Anion resin (SBA) After a service cycle, each resin is regenerated as below: (SAC) : Strong Acid Cation resin is washed with approx. 30% hydrochloric acid. (SBA) : Strong Base Anion is washed with approx. 26% caustic. (WBA) : Strong Base Anion is washed with approx. 26% caustic. Please note: The above regenerate strengths refer to the values before being diluted by the mixed bed unit educator systems.

...more

Mini Dm Plant

Portable or Mini DM water plant: The flow rate of mini DM plant is 50 – 80 litre per hour and space required for it is very compact. These plants have a wide range of applications in food and pharmaceutical industry, automobiles industry, hotels, clubs, residential complexes, laboratories and so on. The plants are available in competitive prices. A pre-validated and pre-mounted skid mounted solution is offered by mini DM water plant. Application areas are Chemicals, industries, battery top-up and laboratory and research centres.

...more

Micron Media Filtration

Hatco Systems, Zeofine is a crystalline,hydrated aluminosilicate that has an infinite three dimensional structure.Zeofine contains extremely pure clinoptilolite (92% mass on average), which is one of the most effective Heulandite type of zeolite. Its highly porous structure (with porosity reaching 50%) provides an extremely large surface area on which chemical reactions and cation exchanges can take place at a veryhigh degree. provides a safe and economical solution for the most varied filter tasks. This filter medium has proved itself the best in many areas, including the chemical industry, food and drink production, in the pharmaceutical industry and in sewage treatment. Due to its high through put and precise filtration clearance, Zeofine is particularly economical. Alternative to sand Several differences set Zeofine apart from regular sand and make it an excellent filter medium. Most sand particles have relatively smooth surfaces and no porosity. They trap particles by straining and bridging them. As the dirt layer increases, sand will typically remove particles down to approximately 30- to 40 microns. Zeofine, by comparison, has large, rough, angular surfaces with chambers and cavities running throughout each particle. This structure allows it to remove suspended particles by straining and bridging between the granules, but aim to capture particles on the rough surface and in the internal pore spaces. This gives Zeofine the ability to remove particles as small as 3- to 5 microns, according to measurements taken with a scanning electron microscope. With its increased surface area, Zeofine dirt-loading capacity is significantly greater than silica sand. Application of Zeofine Ro pretreatment Surface water turbidity Domestic and industrial filtration Municipal drinking water Power plant filtration Cooling towers Pool filtration < 3 microns

...more

Micro Bubble Generator

Hatco Systems micro bubble generator is designed to pressurize water with air at 78 psig. The supply feed pipe is offset and positioned tangentially to the tube. Water pumped into the tube develops a rotating action. The combination of pressure and agitation causes air to dissolve into the water. A vortex forms at the central axis of the tube. Un-dissolved air collects at the vortex and is removed from the tube through a course air bleed off line. The flow rate through the micro bubble generator is determined by the pressure drop between two gauges located on the inlet feed pipe line to the tube and the other located at the end of AMT tube. Normal operating differential pressure is approximately 7 psig. Features Converts a pressure head to a velocity head. Flows can be modified. Operator can control the range of bubble sizes. No moving parts. Adjustable air to water ratios. Even control of air for uniform bubble size. Coarse air bleed off. Skid mounted tube, pump(s), electrical, trim, piping, air regulator, flow meter, pre-packaged ready for operation. Benefits Manufactured in different sizes to deliver flows from 1 to 3000 gpm. Units can also be installed in series for unlimited flows. Operator exercises control over creation of micro-bubbles of specific size for the application enhancing performance. Improves flotation and float mat in any type of cell. Improves TSS removal efficiencies. Reduces city sewer surcharge and chemical costs. Limited engineering costs for retrofits. User friendly.

...more

Electronic Magnetic Water Conditioner

Hatco Systems uses a series of controlled complex modulating high frequency waveform that ineffective the bonding ability of minerals that are contained in our water. This field effectively control & prevent different size molecules likely to form scale & to break the bonds between molecules & the water. This results the break down of large mineral crystals into tiny mineral particles & then prevent them from reacting with other minerals or bonding to any surface to from scales. The process is so effective that existing scales are progressively broken down & flushed away in due course of time. The conditioned and treated liquid ions results in non-corrosive & best solvent water. It also helps the plants to grow well & healthy. Electro-magnetic treatment is based on the principal of creating an Oscillating field of energy with the use of high frequency radio or square waves. The device produce a unique square wave current that sweeps all the frequency responses from 1000 to 15000 HZ at a rate of 10 times a second. When the strength of the oscillating field varies with time and changes direction an induced current is produced inside the pipe line, this is also known as FARADAY”S law of induction. In Simple Language:- As soon as the water pass through the device or softener, a certain in type of electro-magnetic field in developed in the machine and as a result of that two types of processes are done. 1.Breaking Process : During this process high mineral clusters of any size are being broken down into small and tiny particles and scattered. E.g . If any of the mineral ion in the water is in size of 40 micron, then it will be broken down and converted into 10 tiny parts of 4 micron and making them more bion-available. 2.Transforming Process : This process is very important in water. When minerals are being broken down and converted in to small and tiny particles, because of that nature of water molecules to travel together and sticking to each other or developing cluster are being ruined and transformed in to 100% non-sticking nature. Like that they cannot travel together or develop any cluster or layer in to water. Nature of water is changed. So with the help of join process of this device hard water is turned into “Best Solvent” compared to non – treated water. This is the only technology which does not remove useful and essential minerals/nutrient ions from water, but treat them and make them more bion-available.

...more

jet aerators

Biological Reaction Hatco, To provide the oxygen source for the biological reaction, a jet aeration manifold with multiple jet nozzle assemblies is connected to a pump and a blower. Each jet has a primary mixing nozzle and an outer secondary nozzle. The tank contents are re-circulated by the pump through the primary mixing nozzle. Low pressure air is mixed with the liquid in the outer secondary nozzle creating fine bubbles. By turning off the blower connected to the airline, Anoxic mixing can be achieved with the same equipment to promote biological nutrient removal. No separate mixer is needed. Energy Efficient Jets have high oxygen transfer and higher alpha values compared to other aeration devices. The design alpha for Hatco jet system is 0.9 with successful installations. Performance data has demonstrated alpha values above 1 in the use of some industrial wastewaters. Jet nozzle gassing rates can vary significantly without major changes in oxygen transfer efficiency. Jets also provide energy efficient off-bottom solids suspension. High Velocity Tank liquid is pumped through the liquid line and through the inner nozzle. High velocity is created by the inner nozzle forming a jet plume. Compressed air is forced through the air line into the air transfer duct and then the outer nozzle. The high velocity jet plume from the inner nozzle shears the air in the outer nozzle creating fine bubbles. These bubbles are carried by the jet plume into the tank liquid. As the jet plume disperses and velocity slows. The buoyant force of the bubble causes the bubbles to rise.

...more

Iron Removal Filters

A typical iron removal filter contains sand and MnO2 media to remove iron and manganese from groundwater. It follows the oxidation process of Iron and Manganese ions. As the raw water is passed through the bed, any soluble iron and manganese ions convert to rust particles (insoluble ferric state), allowing them to filter out through filtration process. Design Considerations of Iron Removal Plant Required flow rate per hour Your peak water demand Duration (hours) running par day Your water pressure Level of iron, manganese, ph etc Application of filtered water HATCO Iron Removal Filter HATCO water filters are great for removing iron and manganese ions from raw water and installed as a standalone unit or added to any water purification system as pre-treatment. These filters are known for their easy operation and give crystal clear water. Our iron removal filter plants are accurately designed to full fill our client’s specific requirements. HATCO series iron removal filters use Sand and MnO2 as filter media and purify water from sand without clogging the filter. Filter size, media quantity and piping are customized as specified by our clients. We provide full service iron removal plant installation anywhere in India and overseas including Asia, Africa and Middle East at competitive price. Available at, FRP, Mild Steel, SS, FRP with inner lining of FRP/ Rubber/Epoxy Type: Vertical & Horizontal Flow rate: 01m3/hr to 100m3/hr

...more

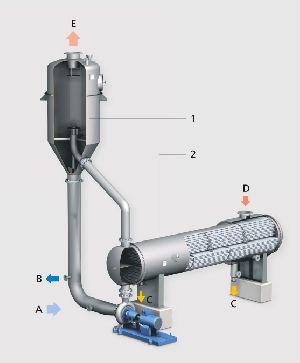

forced circulation evaporator

Forced Circulation Evaporator Operation As the name implies, force is used to drive the liquid through the evaporator tubes thus producing high tube velocities. A high efficiency circulating pump, designed for large volume and sufficient head, is used to supply the force. Proper design results in controlled temperature rise, controlled temperature difference and tube velocities that give optimum heat transfer. Forced Circulation Evaporators are recommended for viscous, scaling and salting liquids. As the liquid is only heated in the steamchest with flashing taking place in the separator and no boiling taking place within the tubes, fouling on hot tube walls is reduced. BUFLOVAK Forced Circulation Evaporators may be equipped with either horizontal or vertical steam chests. The circulating pump withdraws liquid from the lower part of the vapor-liquid separator and circulates it through the tubes at a high velocity. Boiling is suppressed in the tubes either by liquid head or an orifice plate. The heated liquid is discharged into the separator where the vapor flashes off due to the temperature difference and is removed through the top outlet. The liquid is discharged at a maintained liquid level. Forced Circulation Evaporator Characteristics Operates with extremely low temperature differences High tube velocity Velocity mechanically produced and controlled Gives high rate of heat transfer, rapid evaporation and high concentration without requiring high operating temperatures or large heating surface Maximum recovery of solids Can use horizontal or vertical tubes Tubes are readily accessible for cleaning and inspection Suitable for single or multiple effects Product Application Very viscous liquids Scaling liquids tending to produce scale Heat-sensitive materials Crystal producing liquids Forced Circulation Evaporator Application Examples

...more

Florides Arsenic Removal Filter

Hatco are engaged in offering wide are of Florides Arsenic Removal Filters. Our offered products are used to detect and remove arsenic and other impurities from water. Arsenic is found to be contaminated many water supplies used for drinking and farming. We are appreciated among the customers for offering products at industry leading prices. Features: High demand Effective Technically advanced

...more

Effluent Treatment Plant

HATCO offers an effectual range of Effluent Treatment Plants for recycling of wastewater to reduce water demand. The comprehensive treatment solution works at various levels and involves various physical, chemical, biological and membrane processes. HATCO also provides effluent treatment solutions for various types of industrial waste water. Customized systems to suit the wide variety of effluents and to maintain efficiency are provided to industries. These systems include physic-chemical treatment, biological treatment, tertiary treatment and membrane separation process to achieve the zero-discharge standards laid by statutory authority. We provide innovative and economical systems for waste from industries like chemicals, drugs, pharmaceutical, refineries, dairy, ready mix plants & textile etc. Process :- Screening/ Grit chamber: To remove floatable matter and sand, grit, stones in raw effluent. Oil & grease trap: To remove floatable oil and grease from raw effluent. Primary treatment: Includes chemical treatment (coagulation, flocculation, neutralization) and solid-liquid separation for removal of suspended solids. Secondary Treatment: Includes biological treatment for reduction of BOD/COD and solid-liquid separation. Biological treatment can be aerobic or anaerobic depends on quality of raw effluent. Aerobic- ASP (Activated Sludge Process), MBBR/FAB (Moving Bed Bioreactor/ Fluidized Aerated Bioreactor), SAFF (Submerged Aerated Fixed Film Bioreactor), MBR (Membrane Bioreactor) Anaerobic- UASB (Up-flow anaerobic Sludge Blanket Reactor) Tertiary treatment: Sand and carbon filtration for removal of suspended solids and organic material. Ultra-filtration and Reverse Osmosis are the advanced technologies to be implemented for zero-discharge system.

...moreBe first to Rate

Rate ThisOpening Hours