SPINEL BALL

Spinel is also a well known single crystal being used in the optical industry. The main advantage being that spinel is a cubic single crystal. Spinel is a very hard material and its hardness is 8 on the mohs scale. The refractive index of Spinel material is 1.727 which makes it very interesting to be used as a Ball lens for optical telecom products. In addition to the optical properties of Spinel, it is also wear resistant and can withstand severe chemical corrosion. In terms of visual appearance, Our Spinel Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Spinel ball lens). Our Spinel raw material is produced by one of the oldest and most reliable supplier in the Swiss Industry. Each and every Spinel ball is checked 100% for Size, Accuracy, Polish level and Cleaning before delivery. All Spinel Ball products are cleaned and packed in Class 100 clean room area.

...more

SAPHIRE / SAPPHIRE BALL

Sapphire is one of hardest known material with consistent quality available on a commercially economical scale. With a hardness of 2300 HV it is much more harder then most of the known hard materials like ceramics, etc. Saphire raw material is grown in a factory by Melting ultra pure Al2O3 at temperature higher then 2000 deg. Celcius to create a single crystal. This hard material has the ability to be polished to a very good surface finish. The refractive index of sapphire is 1.760 which makes it very interesting to be used as a sapphire Ball lens for optical telecom products. In addition to the optical properties of Sapphire, it is also wear resistant and can withstand severe chemical corrosion. In terms of visual appearance, Sapphire Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Sapphire ball lens). Our Sapphire raw material is produced by one of the oldest and most reliable supplier in the Swiss Industry. Each and every Saphire ball is checked 100% for Size, Accuracy, Polish level and Cleaning before delivery. All Sapphire Ball products are cleaned and packed in Class 100 clean room area.

...more

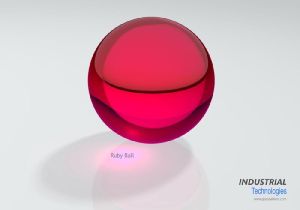

Ruby Ball

Ruby is one of hardest known material with consistent quality available on a commercially economical scale. With a hardness of 2300 HV it is much more harder then most of the known hard materials like ceramics, etc. Ruby raw material is grown in a factory by Melting ultra pure Al2O3 at temperature higher then 2000 deg. Celcius to create a single crystal. This hard material has the ability to be polished to a very good surface finish. Applications which need wear resistance to metals and chemicals use ruby balls for longer life. In terms of visual appearance, Ruby Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Ruby ball lens). Our Ruby raw material is produced by one of the oldest and most reliable supplier in the Swiss Industry. Each and every Ruby ball is checked 100% for Size, Accuracy, Polish level and Cleaning before delivery. All Ruby Ball products are cleaned and packed in Class 100 clean room area.

...more

Precision Brass Screw

MICRO BALL LENS

We Manufacture Micro Ball Lens range in diameter from 0.40mm to 8.0mm. They can achieve a very high level of surface finish depending on the application of the product. Our Micro Ball Lens can achieve a surface finish of Ra = 1.2nm. In terms of visual appearance, Our Micro Ball Lens can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Micro Ball Lens). The optical glasses used for making these Micro Ball Lenses are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, etc. which have a strict control on the nd and vd value of the glasses. Micro Ball Lenses are used to improve signal coupling between Emitters, Fibres, Transmitters, Receivers and Detectors depending on the application. STANDARD SPECIFICATION OF OUR MICRO BALL LENSES: Tolerance on Micro Ball Lens Diameter +/- 0.001mm Micro Ball Lens Surface Finish in Ra 1.2 nm Micro Ball Lens Roundness < 0.001mm No Scratch dig on Micro Ball Lens at 20X magnification Micro Ball Lens Cleaning Class 100 clean room Micro Ball Lens Packing in Waffle trays or Glass bottles Micro Ball Lens is checked 100% under microscope before Delivery. All Micro Ball Lenses are cleaned and packed in Class 100 clean room area.

...more

micro ball

We Manufacture Micro Ball range in diameter from 0.40mm to 8.0mm. They can achieve a very high level of surface finish depending on the application of the product. Our Micro Ball can achieve a surface finish of Ra = 1.2nm. In terms of visual appearance, Our Micro Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Micro Ball). The optical glasses used for making these Micro Ball are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, etc. which have a strict control on the nd and vd value of the glasses. Micro Balls are used to improve signal coupling between Emitters, Fibres, Transmitters, Receivers and Detectors depending on the application. STANDARD SPECIFICATION OF OUR MICRO BALLS: Tolerance on Micro Ball Diameter +/- 0.001mm Micro Ball Surface Finish in Ra 1.2 nm Micro Ball Roundness < 0.001mm No Scratch dig on Micro Ball at 20X magnification Micro Ball Cleaning Class 100 clean room Micro Ball Packing in Waffle trays or Glass bottles Micro Ball is checked 100% under microscope before Delivery. All Micro Balls are cleaned and packed in Class 100 clean room area.

...more

LOW TG BALL LENS

Industrial Technologies manufactures Low Tg ball lenses range in diameter from 0.40mm to 8.0mm They can achieve a very high level of surface finish depending on the application of the product. Our Low Tg ball lens can achieve a surface finish of Ra = 1.2nm In terms of visual appearance, our Low Tg ball lens can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the low Tg ball lens). The Low Tg optical glasses used for making these low tg ball lens are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, etc. Aspherical lenses / Low Tg Ball Lens are used to improve signal coupling between Emitters, Fibres, Transmitters, Receivers and Detectors depending on the application. STANDARD SPECIFICATION OF OUR LOW TG BALL LENSES: Tolerance on Low Tg Ball Lens Diameter +/- 0.0025mm Low Tg Ball Lens Surface Finish in Ra 1.2 nm Low Tg Ball Lens Roundness < 0.001mm No Scratch dig on Low Tg Ball Lens at 20X magnification Low Tg Ball Lens Cleaning Class 100 clean room Low Tg Ball Lens Packing in Waffle trays or Glass bottles Each Low Tg Ball Lens is checked 100% under microscope before Delivery. All Low Tg Ball Lenses are cleaned and packed in Class 100 clean room area.

...more

HIGH INDEX GLASS BALL

With higher coupling efficiency required for Transmitters and Receivers, the application of this High Index Glass Ball lens is becoming more and more popular. The use of High Index Glass Ball results in reduction of Back Focal Length, as a result the shorter distance simplifies fibre coupling. We manufacture High Index Glass Ball lens in diameters ranging from 0.40mm until 8.0mm They can achieve a very high level of surface finish depending on the application of the product. Our High Index Glass ball lenses can achieve a surface finish of Ra = 1.2nm In terms of visual appearance, our High Index Glass Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of theHigh Index Glass Ball). All our High Index Glass Balls are cleaned and packed in Class 100 clean room area. SOME OF THE MOST COMMON HIGH INDEX GLASSES ARE AS FOLLOWS: Sapphire nd = 1.760 K-VC89 (Sumita, Japan) nd = 1.810 S-LAH65 (Ohara, Japan) nd = 1.804 S-LAH71 (Ohara, Japan) nd = 1.850 S-LAH79 (Ohara, Japan) nd = 2.003 K-PsFn203 (Sumita, Japan) nd = 2.017 L-BBH1 (Ohara, Japan) nd = 2.102

...more

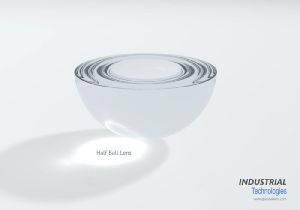

Half Ball Lens

These Half ball lenses range in diameter from 1.0 mm to 5.0 mm They can achieve a very high level of surface finish depending on the application of the product. Our half ball lens can achieve a surface finish of Ra = 1.2nm. In terms of visual appearance, our half ball lens can have a surface finish of 20/40 scratch dig. The optical glasses used for making these half ball lens are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, etc. which have a strict control on the nd and vd value of the glasses. Half ball lenses are used to improve signal coupling between Emitters, Fibres, Transmitters, Receivers and Detectors depending on the application. STANDARD SPECIFICATION OF OUR HALF BALL LENSES: Tolerance on half Ball Lens Diameter +/- 0.005mm Tolernace on half ball lens Thickness +/- 0.03mm Half Ball Lens Roundness < 0.001mm No Scratch dig on Half Ball Lens at 20X magnification Half Ball Lens Cleaning Class 100 clean room Half Ball Lens Packing in Waffle plastic trays Each Half Ball Lens is checked 100% under microscope before Delivery. All Half Ball Lenses are cleaned and packed in Class 100 clean room area.

...more

Glass Rod

Glass rods are being manufacture by us from diameter ranging from 0.60mm to 8.00mm in length ranging from 5.00mm to 100.00mm. Our glass rods can be achieve a very high level of surface finish depending on the application of the product. A surface finish of Ra=0.2um can be achieved in our glass rods. The diameter and both flat side of glass rod can be polished based on customer requirement. In terms of visual appearance, our glass rods can have a polish level of 20/10 scratch dig. The optical glasses used for making these Glass Rods are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, Hikari, etc. which have a strict control on the nd and vd value of the glasses. Glass rods can be used as preforms for glass molding application as well as rod lens. STANDARD SPECIFICATION OF OUR GLASS RODS: Tolerance on Glass Rod Diameter < 0.005mm Tolerance on Glass Rod Length < 0.05 mm Surface finish of glass rod < 0.20 um All Glass Rods are cleaned and packed in Class 100 clean room area.

...more

GLASS BALL LENSES

We Manufacture Glass ball lenses range in diameter from 0.40mm to 8.0mm. They can achieve a very high level of surface finish depending on the application of the product. Our Glass Ball lenses can achieve a surface finish of Ra = 1.2nm. In terms of visual appearance, Our Glass Ball Lens can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Glass ball lens). The optical glasses used for making these Glass ball lens are purchased from various renowned optical glass material makers like Ohara, Sumita, Schott, etc. which have a strict control on the nd and vd value of the glasses. Glass ball lenses are used to improve signal coupling between Emitters, Fibres, Transmitters, Receivers and Detectors depending on the application. STANDARD SPECIFICATION OF OUR GLASS BALL LENSES: Tolerance on Glass Ball Lens Diameter +/- 0.001mm Glass Ball Lens Surface Finish in Ra 1.2 nm Glass Ball Lens Roundness < 0.001mm No Scratch dig on Glass Ball Lens at 20X magnification Glass Ball Lens Cleaning Class 100 clean room Glass Ball Lens Packing in Waffle trays or Glass bottles Each Glass Ball Lens is checked 100% under microscope before Delivery. All Glass Ball Lenses are cleaned and packed in Class 100 clean room area.

...more

CUBIC ZIRCONIA BALL

The high refractive index of Cubic Zirconia material makes it very interesting to be used as a Ball lens for optical telecom products. In addition to the optical properties of Cubic Zirconia, it is also wear resistant and can withstand severe chemical corrosion. With higher coupling efficiency required for Transmitters and Receivers, the application of this cubic zirconia ball is becoming more and more popular. The use of High Index material results in reduction of Back Focal Length, as a result the shorter distance simplifies fibre coupling. We manufacture Cubic Zirconia balls in diameters ranging from 0.40mm to 3.0mm. In terms of visual appearance, Cubic Zirconia Ball can have a surface finish of No Scratch/Dig at 20x Magnification level (depending on the diameter of the Cubic Zirconia ball lens). Each and every CZ ball is checked 100% for Size, Accuracy, Polish level and Cleaning before delivery. All cubic zirconia ball products are cleaned and packed in Class 100 clean room area.

...more

Ceramic ball

The most common ceramic ball material is alumina oxide Al2O3. Alumina oxide balls resist corrosion and abrasion extremely well and maintain dimensional stability at temperatures up to 1734ºC (3180 ºF). Al2O3 balls may be used in many corrosive chemicals, salts and acids where a material that resists oxidation is required. Applications where alumina oxide balls are used include chemical pumps, down-hole pumps, valves, bearings, gages, flowmeters, etc. In terms of visual appearance, our ceramic Ball can have a surface finish of No Scratch/Dig at 30x Magnification level (depending on the diameter of the Ceramic ball lens). Each and every Ceramic ball is checked 100% for Size, Accuracy, Polish level and Cleaning before delivery. All Ceramic Ball products are cleaned and packed in Class 100 clean room area.

...moreBe first to Rate

Rate ThisOpening Hours