Vibratory Finishing Machine

Our company is among the most trusted companies in the manufacture, supply and export of Vibro equipment. These equipment are well equipped by high experienced professional expert and are manufactured by supreme quality material. These equipment have no vibration transmission and are highly used in Automobiles Industries. Last but not the least these are best quality equipment and follow unique working principals. Features: Reasonable price International standard Widely used

...more

Vibration screen machine

Vibro Screens are designed to perform effective size based separation in coarse as well as fine sizes. Vibro Screens use wire mesh or perforated or slotted sheets for carrying out separation of material on basis of size. Vibro Screens are designed on the principle of gyrator motion and are one of the most versatile and universally adaptable machines working across spectrum of industries. Vibro Screens can carry out various duties including screening of any powder or granules, sifting and grading or classification, removal of oversize/ foreign material before packing your finished product, lump/ under-size chips/ dust removal from powder/ granules, solid liquid separation/ filtration/ grit removal from Slurry, Syrup or Oils, Fiber/ Husk Recovery from liquid stream. Vibro Screens are used by Industries like Agro, Agro Processing, Ceramic, Chemical, China Clay, Dehydrated Food, Dyes and Pigments, Ferro Alloys, Foundry, Engineering, Food, Mines and Mineral, Metal Powder Processing, Plastic, PVC, Petrochemical, Paper, Rot molding and many more.Vibro Screens are very versatile process equipment and provide reliable and economical solutions for spectrum of size based separation operations performed in most of the industry sector / applications due to its flexibility and distinctive advantages. Vibro Screens are your best bet for performing the operation of Classification, Grading, Oversize/undersize Removal, De-dusting, De-watering, De-lumping, Fiber Recovery, Fiber Separation, Continuous Filtration or any type of SIZE based separation

...more

Vertical Screw Mixers

Vertical Screw Blender are excellent design alternatives for product applications that are shear sensitive, voluminous and also where space on the plant floor is at a minimum. Nauta Mixers are widely used for mixing Dry Materials, Paste, Cream And Lotions. The principle of blending is based on the differential travel speeds of product particles in the conical section of the vessel. The material from the bottom section of vessel is lifted by the screw and spread over the upper sections.

...more

Ultrafine Pulverizer

Owing to years of experience, we are presenting a quality assured array of Ultrafine Pulverizer. The Ultrafine Pulverizer we offer is widely demanded amongst the clients for their safe use. Our products are available in various specifications and sizes that can be customized as per changing requirements of the clients. Offered products are recommended amongst the clients for their availability in various sizes and specifications. Features: Quality assured Reliable Safe use

...more

ultrafine machine

Item Code: V110Size: V25, V75, V110, V200 Our company is among the most trusted companies in the manufacture, supply and export of Ultrafine Machine.

...more

Ultrafine Grinder

The distinctive principle of Ultrafine Grinder V50 to V110 is based on a high air throughput in the grinding area. This high amount of air is converted in to a tremendous turbulence by the rotating & stationary parts of the machine as well as by an appropriate guidance of the air stream in the mill. The numerous air whirls in the grinding chambers accelerate the product up to the high velocity of the air. The direction & the speed of the particles is suddenly changed within extremely short periods. As a result of this principle the particles crash against each other so reaching a careful disintegration in high air stream. A small percentage of grinding taking place by impact with the rotating or stationary part of the mill. The creation of numerous air whirls in the single grinding chamber their increased turbulence by the inner grooved liner & the pulsation of the high air velocity make it micronics. Simple adjustment to the machine allow a narrow distribution range of out put particle our wet, dry, fibrous or heat sensitive materials.

...more

TURBO SIEVER

“Turbo Siever” has been manufactured in keeping with the numerous industrial needs in mind. The use of most advanced equipments has played the massive role in giving it an ultra-modern look. With the innovative impeller design along with the supremely sturdy construction, it has a unique appearance. The modern siever is capable of carrying out the task with amazing convenience as well as speed. Application In: Food, Pharma, Chemical, Minerals, Guar Gum / Starch / Cellulose etc

...more

Rotary Air Lock Valve

Our company is widely acclaimed in the manufacture and supply of Air Lock. These are used to remove or reduce dust from Cyclone Collectors. These are manufactured by high talented experts who have much knowledge in this type of domain. In addition to this these are tested under various challenging parameters and are using superb quality material. These Air Lock are available at reasonable price.

...more

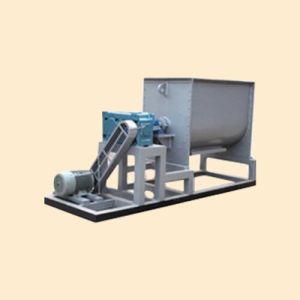

Ribbon Blenders

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of Chopper Blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon Blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

...more

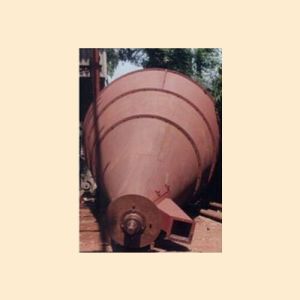

Reactor Blender

Our company specializes in the manufacture, supply and export of Reactor Blender. These Blenders are used in manufacturing companies to manufacture various products. These Blenders have Chopper Blades which have brilliant quality and are procured from our trustworthy vendors. Further these have great operation efficiency and are available at effective market price to suit the pocket requirement of clients. Features: Powerful application Applied in various applications Easy material loading

...more

Reaction Blenders

The design of the Reaction Blenders also makes suitable to dry stage reaction for the application such as Starch, Gum and cellulose derivatives. We also offer a various range of accessories such as Liquid Spray System, controlled rate discharge device, jackets to control or to vary the temperature of the mass. Application In: Food Pharmacy Chemical Minerals Guar Gum / Starch / Cellulose etc

...more

Pneumatic Flash Dryer Line

In order to maintain excellent quality standards, we are offering a quality assured assortment of Pneumatic Flash Dryer Line. The Pneumatic Flash Dryer Line we offer is widely demanded amongst the clients for their safe use. These products are tested for their quality before being introduced in the market. Moreover, one can get these products in committed time bound. One can get these products in committed time frame. Features: Quality assured Reliable Safe use

...more

Pneumatic Cyclone Dryer

Our domain expertise has enabled us to come up with an excellent collection of Pneumatic Cyclone. The offered range of cyclones is manufactured using high quality material and components that are sourced from reliable vendors of the market. To meet diverse requirements of customers, we offer these cyclones in a spectrum of specifications. Features: Rust-proof Fine finish Compact design

...more

Nauta Mixer

Our company has gained expertise in the field of the manufacture, supply and export of Nauta Mixer. These mixers are designed using advance technology and latest tools. These are used for mixing dry materials and to have excellent mixing capacity. In addition to this these have unique TRI blending action and high accuracy. These are available at competitive price. Features: Suitable for adhesive coating Short mixing time Trouble free

...more

Industrial Blower

Our company is the prominent company which deals in the manufacturing and supplying of Industrial Blower. Crafted in elegant designs and equipped with high precision machined components, these Industrial Blowers are in huge demand among the clients. These are primarily used for the purpose of providing a large flow of air to various industrial processes. Finally, these Industrial Blowers are available at market leading prices. Features: Robust construction Extensively used Nominal prices

...more

Guar Gum Plant Equipment

The plant has been configured and designed in such a way that minimum work force will require. The Guar Split will be fed in to the Pneumatic System to feed in to the turbo screen. The turbo screen is suggested at the high of plant. The screening will be employed for the removal of foreign matter. This screened material will be stored in a storage hopper. The Guar Split will fall from the screens by gravity to the storage hopper, which is configured below the screen. From storage hopper material can be taken in to double cone mixer as and when required by gravity for the re-hydrating of Guar Split. All the Re-hydrated Guar Split will be sent to the hopper of Flakers at a time by gravity. Flakers will crush the Guar Split and crushed Guar Splits will go into the Ultrafine Grinder at the uniform rate. Ultrafine Grinder is proposed for the grinding of crushed Guar Splits. This grinder has ability to grind the material without generating too much heat. Material will be fed into the dryer. Oil will be the media to convey the heat and deliver to the air. This hot air will take the material into the dryer line where actual drying will take place. Attached cyclone system will separate the material and hot air. To heat the oil Thermal boiler will be used. Capacity: As per RequirementMachinery : Pneumatic System Split Cleaning Split Washer Double Cone Mixer Water Tank Flaker Machine Flakes Dryer Ultrafine Pulverizer Boiler Heat Exchanger Pneumatic Flash Dryer Line Blower, Cyclone, Dust Collector with accessory Rotary Siever Nauta Mixer (Conical Blender) Misc. Pipe-lines Process :The indicative process of manufacturing Guar Gum (Food grade) is as under. The Guar Split will be purchased from the Guar Seed Processors. Selection of the split is a critical in the business. Various parameters of split selection have been derived by the client and will be purchased on that basis for the processing. The split will be screened to clean and then will be soaked to Rehydrate in a Double Cone Mixer. Re-hydrating stage is crucial in the process as it derives the rate of hydration of the final product. The soaked splits, which has reasonably high moisture content, will be passed through Flakers to take them. This stage helps to reduce the load at the grinder. The soaked splits are difficult to grind and direct grinding of those generates to much heat in the grinder which is not desired in the process as it results in insoluble or reduced hydration of the product. Both the material will be as a different grade and will be packed separately. Quality of the Guar Gum Powder-food grade is defined from its particle size, rate of hydration and the microbial in it.

...more

guar gum flaker machine

Flaker machine

Our company is the leading manufacturer, supplier and exporter of Flaker Machine. These machines are manufactured by high quality raw material and are designed by expert engineers. These machines have excellent technical specifications and have best quality. In addition to this these machines are highly durable and are available at cost effective prices to our leading customers. Features: Easy to install Pocket friendly Great functional capacity

...more

Double Cone Blender

A Double Cone Blender for the easy loading and discharge of the materials. Entire body of the Mixer Rotates and does not allow a single particle of the mass to stay at one place. The mass continuously tumbles and mixes. Double Cone Blender is unique equipment especially suitable for the small to medium capacities. The sizes of Double Cone Blender available are 50 liters to 3000 liters. Application In: Food, Pharma, Chemical, Minerals, Guar Gum / Starch / Cellulose etc

...more

Conical Screw Mixer

The Conical Screw Blenders we offer are widely demanded amongst the clients for their safe use. These products are made by using high grade material which is sourced from reliable vendors of the industry. Moreover, one can get these products in committed time frame. These products are highly reliable. Features: Safe use Reliable Durable

...more

Conical Screw Blenders

Our company is involved in offering a quality assured assortment of Conical Screw Blenders. The Conical Screw Blenders we offer are widely demanded amongst the clients for their safe use. These products are made by using high grade material which is sourced from reliable vendors of the industry. Moreover, one can get these products in committed time frame. These products are highly reliable. Features: Safe use Reliable Durable

...more

Centrifugal Sieves Machine

Air Screen Cleaner

We are leading manufacturer, supplier and exporter of cleaning plant. These are used to clean the environment and have great working capacity. These are used in many applications and are operated through a master control panel. Further these plants are manufactured by fine quality material which is purchased by our most reliable vendor. Last but not the least these plants are affordable and are easy to operate. Features: Easy installations Easy to maintain Low maintenance cost

...more

Air Lock Valve

Our company is widely acclaimed in the manufacture and supply of Air Lock. These are used to remove or reduce dust from Cyclone Collectors. These are manufactured by high talented experts who have much knowledge in this type of domain. In addition to this these are tested under various challenging parameters and are using superb quality material. These Air Lock are available at reasonable price.

...moreBe first to Rate

Rate ThisOpening Hours