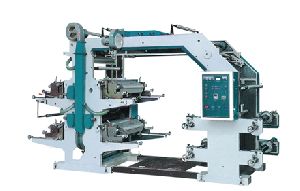

Woven bag Printing making machine

DESCRIPTION : This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, glass paper and roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc. Characteristics: 1. Easy operation, flexible starting, accurate colour register. 2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the set quantity or when the material is cut off. 3. Lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting. 4. The printing ink is spread by the knurled cylinder with even ink colour. 5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6. 3600 continuous and adjustable longitudinal register device. 7. The imported frequency control of motor speed adapts to different printing speeds. 8. There are inching/stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

...more

Woven bag Handle Fixing Making machine

This machine adopts the newest technology, it can make and fix the PP non-woven fabric handle loop on the bag fully automaticlly This machine is a newly improved handbag maker machine, it adopts a unique structure, utilizing step motor for feeding material, realizing precise transferring, combining interactive interface with all complete parameters, easier and more intuitive.

Thickness : 40-100g

...more

Semi Automatic Punching Machine

PYQ203 Creasing & Cutting Machine is a special equipment of creasing and cutting all kinds of Paper,such as ordinary paperboard, corrugated paperboard, plastic and leather products. It is suitable for printing, packing decoration and plastic industry. FEATURES: 1) Main part of the machine is made of top quality material with high strength. 2) One-piece casting makes the machine run smoothly and steadily. 3) Operational height is arranged reasonably and moving bed opens at its optimum angle. 4) Electrical system is designed according to IEC standard 5) Three functions, single & continuous operation and opening dwell, ensure that safety system is reliable. ( dwell range is adjustable)

...more

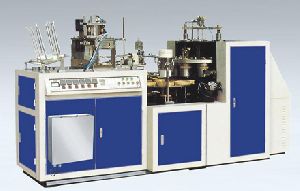

Rectangular paper cup Forming machine

We have national patent for the square/rectangular/coniform paper cups/bowls making machine JPC-Q33 model automatic square/rectangular paper cup making machine is a multi-positon machine, which can manufacture paper beverage cup, ice cream cup and other cone vessels for food stores through a series of automatically paper feeding, sealing, oiling, punching, heating, knurling, protruding rolling, edge curling, finished cups discharging and so on.

...more

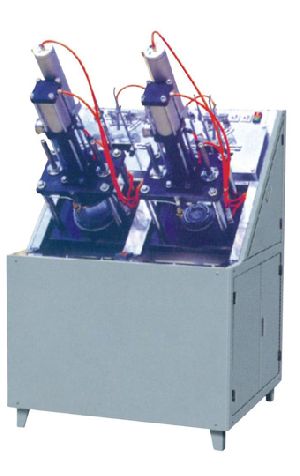

paper plate forming machine

DESCRIPTION ( Paper Meal Box Dish Forming Machine) DB-L300 With two independence working positions, is type semiautomatic machine can produce paper containers various in size. This machine is applied to process so many containers in different size and different shape, like paper meal box, paper bowl, paper plate and paper dish by changing moulds. MAIN TECHNICAL PARAMETER : The Production Capacity: 15-20gsm (pcs per minute) Required Paper: 150-300gsm(Grey and white paper) Specification of dish & box: Box:14oz 21oz (Produce different boxes’size by changing moulds) Dish: 205oz to 11oz (Produce different dishes’size by changing moulds) Total Power: 220v 50hz 2kw Weight:150kg Overall Dimensions(L×W×H):1200×600×1500mm.

...more

Paper Die Cutting Machine

DC6 high Speed Automatic Reel Die-cutting Machine is the professional equipment which uses for cutting various kind of popular paper and PE coated paper,be applicable to printing, packaging, paper cup and other to the die-cutting area, cutting lengh can be setted in touch-screen, it is convention and precise. And it can die-cut the blank paper and printed paper. Clutch is pneumatic clutch ,be fast and reliable.

Weight : 5.5T

...more

paper cup printing machine

DC6 high Speed Automatic Reel Die-cutting Machine is the professional equipment which uses for cutting various kind of popular paper and PE coated paper,be applicable to printing, packaging, paper cup and other to the die-cutting area, cutting lengh can be setted in touch-screen, it is convention and precise. And it can die-cut the blank paper and printed paper. Clutch is pneumatic clutch ,be fast and reliable.

...more

paper cup lid

Automatic paper cup plastic lid forming Machine is a new product that designed, improved and created by our technicians under the demand of market. It assimilates the advantage of al-plastic blister packing machine and vacuum forming machine, adopts medical vocationsGMP and food vocations QS standards. According to the special of the products required, this machine can adopts blow mold or vacuum forming, perforation, punching, full-automatic process running, and with advanced technical, safe and easy to operating, it avoid the labor consume of man made perforation and pollution of touching. Also ensured the quality from the producing. The special heat equipment of the machine can save electricity, economy practicality, with small overall and small covering area, it widely use in food, medicine, hard-ware line etc. Also widely used in the medicine plastic tray, petpspvc pe and another plastic products etc. And it is deeply favored by users from home and abroad.

...more

Paper Cup Forming Machine

DESCRIPTION : JKPLC-1000 Paper Cup Forming Machine is multi-station automatic machine. It has continuous automatic procedures like feeding, sealing, oil -filling, washing, heating, knurling, curling,unloading, etc. It is ideal equipment for producing paper testing-drinking cups, market cups, advertising cups, etc. It is widely used for hot drink and beverage. If you want to make two-side ( double) PE coated paper cups, we recommend you to use JKPLC-1000 or JPC-Q7 ultrasonic paper cup forming machine. FEATURES : 1) The main-frame of the machine is an incline. And the incline can help the cups easily drop into the plastic holes, the rate of which goes up to 99.99 %. 2) The shape of the head is oblate, which can seal the cups easily. It is much better than that is round. 3) The machine sends the bottom paper up to the cup automatically and adjusts itself because of a spring.

...more

Paper Cup Forming Machine

JPC-Q7 Paper Cup Forming Machine is multi-station automatic machine. It has continuous automatic procedures like feeding, sealing, oil -filling, washing, heating, knurling, curling,unloading, etc. It is ideal equipment for producing paper testing-drinking cups, market cups, advertising cups, etc. It is widely used for hot drink and beverage. If you want to make two-side ( double) PE coated paper cups, we recommend you to use JKPLC or JPC-Q7 ultrasonic paper cup forming machine. FEATURES : 1) The main-frame of the machine is an incline. And the incline can help the cups easily drop into the plastic holes, the rate of which goes up to 99.99 %. 2) The shape of the head is oblate, which can seal the cups easily. It is much better than that is round. 3) The machine sends the bottom paper up to the cup automatically and adjusts itself because of a spring.

...more

paper cone machine

The Paper Cone Forming Machine has a suction nozzle which sucks the printed and cut paper out from the paper shelf and then places the paper onto the conveying chains, which convey the paper further to the forming mould. The paper will be coated during this procedure with Heat Melt Adhesive, whose length and weight can be adjusted without stopping the machine if needed. After formed, the coated paper will become the cones which will be blown into the collecting device, where the cones will be automatically gathered, counted and transferred at a certain intended amount.

...more

paper cone forming machine

The Paper Cone Forming Machine has a suction nozzle which sucks the printed and cut paper out from the paper shelf and then places the paper onto the conveying chains, which convey the paper further to the forming mould. The paper will be coated during this procedure with Heat Melt Adhesive, whose length and weight can be adjusted without stopping the machine if needed. After formed, the coated paper will become the cones which will be blown into the collecting device, where the cones will be automatically gathered, counted and transferred at a certain intended amount. Features of Paper Cone Forming Machine: (1)High efficiency, 200pcs/min at the most. The products counted automatically. (2) With small overall, installed easily (Overall dimension 1850×1750×1800mm) (3)Low load power and high precise frequency control.(Power: about 5.5kw) (4)With the box-pattern and the high-quality steel, it has stable and precise transmission. (5)High level of automatism, easy to operate and debug, convenient maintenance and low cost (6)Lubricated by oil circulation. (7) With two modes. Standard Fitting of Paper Cone Forming Machine: (1)Complete electric-controlled case, including segment and non-segment speed regulating (2) Vacuum device and air-condensing device (3) Heat melt adhesive device (4) Products piling device (5) Fin refusing collecting device (6) A set of forming moulds (7) Ten fin knives. Technical parameters of Paper Cone Forming Machine: Adjustable model 1. Lowest height: 100mm 2. Highest height: 255mm 3. Angle: 15° -28° Producing Speed: 200pcs/min at its most Raw Materials: paper, combined aluminum foil paper, or dry stencil paper(<100g/m2) Other accessories: 1. Glue programmed controlling 2.Air compression engine Covering Area: 2m×2m Overall Dimension: 1.8m×2.5m×2.0m Weight: 800kg more or less (Net Weight)

...more

Paper Bucket Forming Machine

DESCRIPTION : JPC-Q24 is automatic equipment forming machine.Such as feeding, two-procedure preheating,sealing, oil-filling, washing,two-procedure under heating, knurling, curling, rolling watering line,unloading bowl and photoelectric checking, troubles warning, counting etc. Besides of these, it improve the speed and quality on the original basic, is the ideal equipment for producing bowl containers of large content or Kaperture like soup bowl, fast noodles bowl, etc. ESPECIALLY IT HAD PASSED CE authentication. If you want to make two side (double) PE coated paper cup,we recommend you use the ultrasonic paper bowl forming machin

...more

Paper bowl of outside packing Gluing Machine

Paper Bowl Making Machine of DEBAO-B1 type paper bowl of outside packing agglutinating machine is paper bowl machinery kit equipment. It has automatically pass paper, envelope, throw glue, unload bowls, outside packing automatically agglutinate with paper bowl and photo electricity examine, give an alarm when meeting with hitch, account etc, advanced craft, reasonable design, operation and maintenance convenience.

...more

Nonwoven Standard bag making machine

DESCRIPTION : This nonwoven bag making machine special designed for non woven bag making, this machine takes nonwoven as raw materials. This machinery can produce nonwoven bags of various sizes and shapes, such as nonwoven shopping bags, reticules, flat port bags, clothing bags, shoes bags, and other products packaging bags. This machine is electro mechanical integrative, once through fully automatic forming, touch screen operation is applied, photo electric trace, computerized deviation rectifying function, hence accuracy and smooth. Such automatic devices as slotting device, punching device and metering device are equipped. Finished products are produced at fast speed, in high efficiency, and in firm appearance after welding. This machinery is an optical choice for the nonwoven bag making enterprise and businessmen devoted to the production of nonwoven environment friendly bags. 1, local touch-screen computer configured to operate; 2, arbitrarily set a long-step electric track, a smooth, lost support from the standard parking 3, feed off automatic shutdown, auto-punch; 4, while at the end of the roll-ultrasonic welding, in particular, solid, smooth; 5, automatic temperature and automatically correcting leaks; 6, while cutting edge automatic closure, automatic nesting.

...more

Non Woven Bags Making Machine

DESCRIPTION : In then process, the machine takes nonwoven as raw materials. This machinery can produce nonwoven bags of various sizes and shapes, such as nonwoven shopping bags, reticules, flat port bags, clothing bags, shoes bags, and other products packaging bags. Features: This machine is electro-mechanical integrative, once-through fully automatic forming, touch screen operation is applied, photo-electric trace, computerized deviation rectifying function, hence accuracy and smooth. Such automatic devices as slotting device, punching device and metering device are equipped. Finished products are produced at fast speed, in high efficiency, and in firm appearance after welding. This machinery is an optical choice for the nonwoven bag making enterprise and businessmen devoted to the production of nonwoven environment-friendly bags. 1, local touch-screen computer configured to operate; 2, arbitrarily set a long-step electric track, a smooth, lost support from the standard parking 3, feed off automatic shutdown, auto-punch; 4, while at the end of the roll-ultrasonic welding, in particular, solid, smooth; 5, automatic temperature and automatically correcting leaks; 6, while cutting edge automatic closure, automatic nesting.

...more

lid forming machine

Automatic paper cup plastic lid forming Machine is a new product that designed, improved and created by our technicians under the demand of market. It assimilates the advantage of al-plastic blister packing machine and vacuum forming machine, adopts medical vocationsGMP and food vocations QS standards. According to the special of the products required, this machine can adopts blow mold or vacuum forming, perforation, punching, full-automatic process running, and with advanced technical, safe and easy to operating, it avoid the labor consume of man made perforation and pollution of touching. Also ensured the quality from the producing. The special heat equipment of the machine can save electricity, economy practicality, with small overall and small covering area, it widely use in food, medicine, hard-ware line etc. Also widely used in the medicine plastic tray, pet/ps/pvc /pe and another plastic products etc. And it is deeply favored by users from home and abroad.

...more

Fully Automatic Die Cutting Machine

JKP2012 Die Cutting Machine adopts the technology cutting of automatic punching. It can make the slitting, die cutting and clearing the waste of paper done together. So the machine has less steps than those with the traditional cutting technology, which can eliminate some loss of the raw material in cutting, and can improve the rate of the utilization of raw materials and finished goods effectively. The machine removes the waste clearing step in traditional procedures and cuts the pattern paper directly which are in good quality and looks nice. So it is a good machine which can not only largely reduce the consumption and manpower of worker's labor intensity. It is ideal equipment for cutting many kinds of paper container, such as disposable paper bowl, paper cup, paper meal, paper box, label paper, etc. It adopts professional high definition gas feeding paper structure, distinctive electronic protector and automatic feeding paper and collecting paper orderly. It is controlled by PLC, which makes the whole working procedures are automatic. And through the PLC control, the worker can get the whole data of the working machine, such as the speed, the power of motor, the amount of the pattern paper and so on. If you want to produce different pattern paper, what the woker an do is that changing the parameters on the interface of PLC. What's more, the important parts of machine are imported from Japan and Germany. From the above, this machine can run stably, locate correctly and operate safely, reliably and easily. Total power: 380V 50Hz 6.3kw Speed of sending paper: 40m/min(interval working) Main roller length: 1000mm Machine weight: 2100kg Machine size: 3000 x 1600 x 2000mm Control system: PLC control Watch Demo :

...more

Flex Printing Machine

DESCRIPTION : The flex machine can be with 1-6 colors 1. Adopt the creaminc anilox cylinder to transfer the ink 2. Unwinding and rewarding tension are auto-controlled by tension controller 3. Each printing unit adopts 3600 plate-adjustement 4. IR dryer (hot air type)for each printing unit (UV dryer is for option). 5. This machine has one die-cutting station, and keep running when the machine stopped 6. The ink rollers will be separated form the printing roller. And die cutting finished in one process 7. The machine can finished material -feeding printing varnishing drying lamimating die-cutting and rewinding in a lump. It is an ideal machine for printing note and top-grade adhesive label. Max. Unwinding diameter: 600mm Max. Rewinding diameter: 600mm Printing length :178-355mm/206-460mm/239-539 Precision of chromatography : ± 0.1 mm Dimensions: 1860mm x 560mm x 2500mm(L*W*H) Machine weight: about 2000kg Power supply: 380v. 50/60Hz, 3p

...more

Cat-5 and Cat-6 Cable

Aluminum Foil Container Making Molds

We coud design varied aluminum foil container mold, and we could also offer aluminum foil container machine and production line. Aluminum foil container mold Long life High precision and stable Short delivery time: 25 days to 40 days Great quality Aluminum foil container mold We adopt advanced technology on aluminum container mold producing,so our mold are long life,excellent in quality and reasonable in price. Features: Moulds are built with high quality steel. Flow area is heat treated for proper hardness,which ensure our mold in long life Moulds adopts pneumatic rebound device which makes the mold more flexible. Our excellent processing technical ensure that the mold can complete the cutting,shaping,blending and curring by one step. we can design and produce specially all kinds of aluminum container molds such as single cavity or multi-cavity mold,mold for the producion of various containers with different rims(G style, L style, IVC or Folded style) Mould has long service of life,stable and reliable quality,advanced high technology,high precision design make the aluminum foil vessel from cutting materials,forming,stretching,edge shape once completed,the perfect products,from smooth without knit to many cavity,various border(o edge, high edge, rotating edge or a side), all sorts of figure. According to the different needs of customers and the mold size or design appropriate treatment plan,The price is reasonable, making moulds faster cycle,Mould can be applicable requirements of users in ordinary punch,pneumatic punch,four-column machine installation.

...more

Aluminum foil container Makina Machine

Detailed Product Description : we coud design varied aluminum foil container mold, and we could also offer aluminum foil container machine and production line. Aluminum foil container mold Long life High precision and stable Short delivery time: 25 days to 40 days Great quality Aluminum foil container mold We adopt advanced technology on aluminum container mold producing,so our mold are long life,excellent in quality and reasonable in price. Features: Moulds are built with high quality steel. Flow area is heat treated for proper hardness,which ensure our mold in long life Moulds adopts pneumatic rebound device which makes the mold more flexible. Our excellent processing technical ensure that the mold can complete the cutting,shaping,blending and curring by one step. we can design and produce specially all kinds of aluminum container molds such as single cavity or multi-cavity mold,mold for the producion of various containers with different rims(G style, L style, IVC or Folded style) Mould has long service of life,stable and reliable quality,advanced high technology,high precision design make the aluminum foil vessel from cutting materials,forming,stretching,edge shape once completed,the perfect products,from smooth without knit to many cavity,various border(o edge, high edge, rotating edge or a side), all sorts of figure. According to the different needs of customers and the mold size or design appropriate treatment plan,The price is reasonable, making moulds faster cycle,Mould can be applicable requirements of users in ordinary punch,pneumatic punch,four-column machine installation. Subnavigation

...more

Aluminium Foil Making Machine

This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, glass paper and roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

...more

Automatic Reel Die-cutting Machine

DC6 high Speed Automatic Reel Die-cutting Machine is the professional equipment which uses for cutting various kind of popular paper and PE coated paper,be applicable to printing, packaging, paper cup and other to the die-cutting area, cutting lengh can be setted in touch-screen, it is convention and precise. And it can die-cut the blank paper and printed paper. Clutch is pneumatic clutch ,be fast and reliable.

...moreBe first to Rate

Rate ThisOpening Hours