WELDING SEAMER

FEATURES Welding seamer is used for longitutanal welding of stainless steel vessels Can be customized as per customer need for length, diameter & thickness Welding Seamer Can be integrated with Tig, P+T, DP-Tig Wide application scope of SS material excellent in performance stability of high-quality Very fast compared to conventional process.

...more

welding controller

Welding controller CPU carries out the Feedback control during welding. It ensures the stable welding current even the fluctuation of power supply there. Guaranteed the welding quality. Count the welding spots. Detect the actual voltage of the power supply. Detect the actual welding current (CC mode).Automatic self-diagnosis, display Error number for any abnormal condition. Two type of current feedback: Welding transformer primary side and secondary side.

Frequency : 50/60Hz

...more

VERTICAL TIG CLADDING

FEATURES The installation is for internal vertical hole or valve line automatic cladding. Cold TIG/hot wire TIG welding processes. SEPCIFICATION BROCHURE The installation is for internal vertical hole or valve line automatic cladding. Cold TIG/hot wire TIG welding processes. Cladding hole diameter: ɸ50~800mm. Cladding depth:1000mm. Cone angle: 45°or 60°. AVC tracking and shutdown memory function.

...more

Transformer Radiators

Transformer radiators Use for power transformer radiator fin automatic production line, Full automatic and High quality.

...more

STRIP CLADDING DEVICE

FEATURES For pressure vessel manufactured pipe, tube sheet surface automatic cladding. Submerged arc welding and electroslag cladding process. Tiny strip cladding head - KSC-30 Strip type: 30mm wide, 0.4/0.5mm thickness Clad work: Outer cladding: OD>220mm Inner cladding: ID(after weld)>350mm(longitudinal) ID(after weld)>360mm(circum) Preheat temperature: above 250℃(forced water) Medium strip cladding head - KSC-60 Medium strip cladding head Strip type: 30~60mm wide, 0.4/0.5mm thickness Clad work: Outer cladding: OD>220mm Inner cladding: ID(after weld)>400mm(longitudinal) ID(after weld)>600mm(circum) Preheat temperature: above 250℃(forced water) Conventional strip cladding head - KSC-90 Strip type: 30~120mm wide, 0.4/0.5mm thickness Clad work: above ɸ800mm Preheat temperature: above 100℃(forced water) Magnetic control should be used when above 60mm strip

...more

Spm Welding Machine

SPM welding machine is a special purpose welding machine used for longitudinal welding of stainless steel vessels. Seamer having automatic clamping for hoiding vessel tightly to do welding with either TIG or Key hole plasma or DP-TIG.

...more

SMALL PIPE INNER

FEATURES Suitable for ɸ50-800mm pipe inner stainless steel cladding with MIG and TIG two processes. SPECIFICATION BROCHURE Cladding dimension: length≤1000mm TIG cladding diameter(ID): ɸ28~150mm (after cladding); MIG cladding diameter(ID): ɸ150~800mm. Weld parameterized HMI input AVC tracking and shutdown memory function.

...more

SINGLE PHASE AC SPOT

FEATURES Insulated upside is convenient for other device installation. Avoid short circuit happen during installing welding fixture. Epoxy-resin filled transformer ensured the welding quality. Water flow display is installed easy for checking the cooling water condition. Vertical type pressure mechanism has the advantage such as high speed, reduced the gas consumable, good following performance, low noise and long life. Pressure head up and down speed can be adjusted steplessly. It reduced the impact to the work piece and reduced noise also. Easy to switch the travel of the pressure mechanism. Integrated CPU controller. It has the voltage and current compensation function while the input voltage fluctuated. Ensure the stable welding current. Multiple welding parameters can be stored and easy change. It has failure warning function. Operate friendly and easy maintenance.

...more

ROLLER QUALITY TESTING MACHINE

FEATURES For the application of on line/off line testing for roller performance Can be integrated into production line, or be used alone as well. Radial runout error, Axial endplay error, Frictional resistance coefficient can be tested. Machine can automatically make sound-light alarm when over running. All the detected data can be generated and recorded on centralized-control system, easy for inspection and tracking from quality control.

...more

ROLLER PRESS ASSEMBLY

Used for the press assembly of the stamping bearing block, cast-iron bearing block, sealing and dustproof cap in sequence. The two self-stoping pressing device can press assemble the rollers without shaft shoulder concentrically. A complete set of tool heads is equipped to fit for the assembly of all kinds of rollers, which is widely applicable.

...more

ROBOTIC ROLLER WELDING machine

FEATURES Used for full automatic welding for inner and outer circumferential weld of roller bearing block. Double-robot + Torch clean and wire-cutter device, realizing unmanned full automatic welding. Provided with special water-cooling torches, which work reliably. The system can make automatic adjustment to adapt to different pipe length and diameter without human intervention. Can be integrated into Roller Automatic Production Line, so as to reduce secondary invested cost for customers

...more

REAR FRAME WELDING

FEATURES Used for the automatic welding of the main weld of the rear frame. Highly efficient tandem wire MIG/MAG welding, with high deposition efficiency. The automatic welding is done by weld tracking. The two sets of welding traveling devices are driven by steplessly adjustable AC servo motor. The AC geared-motor driven welding positioner can turn at 360 degrees freely and the workpiece can be welded conveniently at four positions.

...more

POLE MAST WELDING SYSTEM

FEATURES Used for the automatic shaping and submerged arc welding of general-purpose round pipe, cone-shaped pipes and multi-rhombus pipes. Tandem wire and multi-wire submerged arc welding with high efficiency. High endurance backing enable single side welding, both side formations. Parameters presettable and savableParameters presettable and savable. High efficient water-cooling system enables heavy current welding for a long time. Video monitoring system, easy to observe and operate.

...more

Pipe Welding Machine

Pipe welding machine is a special purpose welding machine used for longitudinal welding of stainless steel vessels. Seamer having automatic clamping for hoiding vessel tightly to do welding with either TIG or Key hole plasma or DP-TIG. Welding seamer is useful for manufacturing SS vessels for dairy equipments, pharma equipments,

...more

Orbital Welding Equipment

Orbital welding equipment used for longitudinal welding of stainless steel vessels. Seamer having automatic clamping for hoiding vessel tightly to do welding with either TIG or Key hole plasma or DP-TIG. Welding seamer is useful for manufacturing SS vessels for dairy equipments,

...more

NARROW GAP TIG

FEATURES Unique electrode oscillation to guarantee side wall penetration and increase weld efficiency High quality welding High efficiency welding. Low heat input welding. 3-directional AVC tracking, automatic operation.

...more

NARROW GAP SAW

FEATURES Oscillating tip, left-mid-right three position welding position, oscillating assembly is stable and reliable. Chromium Zirconium Copper contact tip, alloy copper material torch soft connection with good conductive, those can increase life span. Torch body is made of stainless steel and plasma paint technology, Automatic flux feeding and recovery and sensors to sense sidewall variations.

...more

HYBRID AUTOMATIC INTERSECTION

FEATURES Automatic positioning and clamping system, easy for pipe clamping. Five jaw chuck can center and clamp the pipe with high precision. The pipe is supported all along by roll carrier, and the pipe can be conveyed axially after cut off. Mature function,easy operation, it is suitable for precisely cutting large diameter and thick pipes.

...more

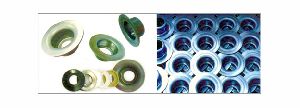

HIGH QUALITY BEARING HOUSING COMPONENTS

OVERVIEW Kaiyuan is a world leader in delivering high productivity automated solutions for the manufacturing of conveyor idler rollers of the highest quality. While Kaiyuan systems are known for their quality and reliability a key driver in achieving the desired quality and productivity levels in manufacturing is attributed by the input raw material. Bearing Housing Components are one of the important components of an idler roller, which play a major role in determining the quality and life of the idler rollers. Wrong selection of these components may result in the following. In-consistency in dimensions of idler rollers Reduced operational life of idler rollers Increased friction and jamming of the conveyor line Increase in cycle time of production i.e. decrease in productivity

...more

FOUR AXIS NC SADDLE WELDER

FEATURES For pipe or cap seal orthogonal or slanting nozzle saddle shape intersection line automatic submerged arc welding.

...more

FOUR AXIS NC SADDLE CUTTER

FEATURES For pipe or cap seal orthogonal or slanting opening or groove beveling, which is also suitable for pipe flange intersection line cutting. Round hole diameter: ɸ60~1600mm; Pipe diameter: ɸ500~6000m; Flame cutting max. thickness:200mm; Saddle drop height, torch lift stroke: 0~450mm; Torch angle: groove angle: 0°~60°; Cutting groove type: V, Y, X, K; Flange joint type: butt joint, insert, mount type.

...more

FIXED LENGTH CUTTING

FEATURES Suitable for fixed-length cutting and beveling steel tubes. Adopts four mechanical cutting tools, the cutting and grooving can be done in one time. I-shape,V-shape,U-shape (model A only) can be made, the cutting pecision is high. Provided with high-precision servo length fixing system, which can fix the cutting length accurately, it largely improves the production efficiency and guarantees the product quality. Equipped with automatic pipe loading/unloading system, which makes pipe conveying smoothly and this is suitable for large-quantity and high-efficient cutting. The automatic scheduling system can be integrated with host production management system or process system, it will sharply improve productivity.

...more

FITTING-UP MACHINE

FEATURES Used for assembling the straight pipe and flange by manual tack welding. The system can automatically fix the length according to the setting length. Provided with flange hole positioning device to ensure the precision of alignment angle. The self-centering chuck is provided with electric clamping, which has the functions of angle and center height adjustment. The axial and radial supports are used for centering the pipe, which can be adjusted electrically/manually.

...more

CHUCK AUTOMATIC INTERSECTION LINE

FEATURES The five jaw chuck can center and clamp the pipe with high precision. The base is manufactureed integrally to ensure the cutting precision. Simple structure, easy maintance.

...moreBe first to Rate

Rate ThisOpening Hours