Semi-automatic Hydraulic Shearing Machine

We are among the reputed organizations, highly engaged in offering an optimum quality range of Hydraulic Shearing Machine. The stable robust, all welded steel frame from ultra-sonically tested plates are of top quality. The top beam is guided by three point roller with replaceable hardened liners for least wear. In this machine, Raw and table designed with special inclined member and box type structure for maximum strength. FEATURES & ACCESSORIES FOR BASIC MODEL Rugged structure as per the international standards. Moving beam synchronized by differential cylinders. Hardened roller guiding beam for constant blade gap. Rake angle adjustable to suit thickness and material. Blade gap adjusted with levers for clean cuts. Sheets clamped hydraulically before cut starts. Shearing-clamping forces adjustable to suit job. Blades premium D2 HCHCr, four usable edges. Cutting length and position adjustable for short job. Beam returns on releasing foot switch for smaller cuts. Cutting area illuminated for clear view of blades First two hold-down spaced closer at both ends. Front gauging with stops, scale on squaring arm. Sheet supports 600mm long help support long plates. Ramp on rear slides out cut sheets outside shear area. Back gauge moves away to avoid trapping of cut sheet. Foot switch movable for operation from safe position. Finger safety guard with clear view of lighted cutting area. Dependable brands of hydraulics, and electricals. Efficient compact power-pack with minimal piping. Electricals neatly wired-labelled for trouble shooting. OPTIMUM Ranke angle adjustable for material thickness. Blade gap easily adjustable for clean cuts. All blades D2 HCHCr with 4 usable edges. Extra capacity to cut inconsistent material, Beam guided, synchronized for constant gap. Firm clamping of plates before cut starts and easier feeding gauging retrieval of sheets. Shearing at constant speed with cutting (rake) angle set to suit material, thickness minimizes the distortion of cut sheets. This facilitates quality in downstream operations viz. pressing, punching, bending and drawing. Shearing at correct blade gap with sheets firmly gripped help get clean burr-free edges and avoids re-working during welding and assembly.

...more

Pneumatic Under Crank Shearing Machine

KNTM Brand Pneumatic Shears fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. FRAME CONSTRUCTION Pneumatic Under Crank Shearing machine Frame fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. BED Super strong bed of closed box type construction, Street relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed area also provided for machined pas across the bed for convenient setting of front gauge brackets any desired spacing. Depressions in the top at the bed provide ample clearance for fingers in handling sheets narrower than the bed. UPPER BEAM Ram is also of solid steel plates, carrying the upper knife. Its minimum weight ensure lesser load on the bearings, The upper beam moves in flat heat treated steel guide plates to avoid plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. HOLD-DOWN MECHANISM Solid clamping by powerful spring loads hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of versions in thickness. Hold down pressure in easily adjustable for clamping soft material. Different thickness of material can be cut without future adjustment with consistently accurate and burr free results. ROLLING KEY CLUTCH Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. SHEAR KNIVES Knives are manufactured strictly as per standard material of D2 HCHCr. Every step from designing metallurgical specifications, heat treatment, grinding and inspection is carefully controlled. The blades are standards are standardized and are easily replaced. ACCURATE GAUGING The Rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. LUBRICATION Single shot lubricator provides oil to all the lubrication points, when necessary. Thus, all bearing parts and guide surface etc. DRIVE Drive through V-belts on flywheel and reduction gears are made of steel, hob cut for the smooth running and longer life.

...more

Pneumatic Over Crank Shearing Machine

KNTM Brand Pneumatic Shears fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. FRAME CONSTRUCTION Pneumatic Under Crank Shearing machine Frame fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. BED Super strong bed of closed box type construction, Street relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed area also provided for machined pas across the bed for convenient setting of front gauge brackets any desired spacing. Depressions in the top at the bed provide ample clearance for fingers in handling sheets narrower than the bed. UPPER BEAM Ram is also of solid steel plates, carrying the upper knife. Its minimum weight ensure lesser load on the bearings, The upper beam moves in flat heat treated steel guide plates to avoid plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. HOLD-DOWN MECHANISM Solid clamping by powerful spring loads hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of versions in thickness. Hold down pressure in easily adjustable for clamping soft material. Different thickness of material can be cut without future adjustment with consistently accurate and burr free results. ROLLING KEY CLUTCH Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. SHEAR KNIVES Knives are manufactured strictly as per standard material of D2 HCHCr. Every step from designing metallurgical specifications, heat treatment, grinding and inspection is carefully controlled. The blades are standards are standardized and are easily replaced. ACCURATE GAUGING The Rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. LUBRICATION Single shot lubricator provides oil to all the lubrication points, when necessary. Thus, all bearing parts and guide surface etc. DRIVE Drive through V-belts on flywheel and reduction gears are made of steel, hob cut for the smooth running and longer life.

...more

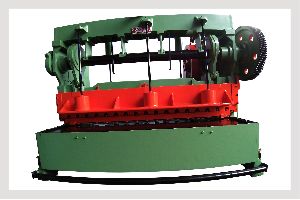

Piano Hinge Automation Line Machine

Given our in-depth domain specialization, we are offering a top-of-the-line piano hinge machine. At Keshav New Tech Machines (India) Pvt. Ltd, we manufacture the best quality piano hinge machines that are made of advanced technology in conformity with industry-laid norms. Piano Hinge Machine with Lowest Electricity Consumption Our piano hinge machines have gained immense popularity in the market because of their lesser power consumption. The machines are only delivered to our clients after passing through a quality test. If you are searching for a piano hinge machine manufacturer, call us immediately.

Voltage : 220V

Finishing : Powder Coated

Machine Weight : 100-1000kg

Packaging Type : Carton Box

Usage : Industrial

...more

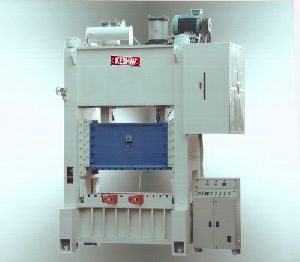

NC Press Brake Machine

Look no further than Keshav New Tech Machines (India) Pvt. Ltd when you have to purchase NC press brake machines in Bahadurgarh. Manufactured at state-of-the-art manufacturing units, the machines are known for their robust welded structure and toughness. Highest-Performing NC Press Brake Machine The machines can withstand constant stress even under full load at the slightest deflection. The highly-precise machines we offer can be delivered to your doorstep quickly and are made with proper guidance from manufacturing experts. To know more about the NC press brake machine, call us now.

...more

NC Hydraulic Shearing Machine

NC Hydraulic Shearing Machine by KNT Bending & Shearing exhibits the glimpse of marvelous quality and high performance attribute. The offered product is provided with stroke length, back gauge positions and stroke counting that ensure hassle free and efficient performance. The fast and accurate multi position back gauge system is very efficient and accurate. The machine productivity and accuracy are much improved with NC controlled back gauge. FEATURES & ACCESSORIES FOR BASIC MODEL Rugged structure as per the international standards. Moving beam synchronized by differential cylinders. Hardened roller guiding beam for constant blade gap. Rake angle adjustable to suit thickness and material. Blade gap adjusted with levers for clean cuts. Sheets clamped hydraulically before cut starts. Shearing-clamping forces adjustable to suit job. Blades premium D2 HCHCr, four usable edges. Cutting length and position adjustable for short job. Beam returns on releasing foot switch for smaller cuts. Cutting area illuminated for clear view of blades First two hold-down spaced closer at both ends. Front gauging with stops, scale on squaring arm. Sheet supports 600mm long help support long plates. Ramp on rear slides out cut sheets outside shear area. Back gauge moves away to avoid trapping of cut sheet. Foot switch movable for operation from safe position. Finger safety guard with clear view of lighted cutting area. Dependable brands of hydraulics, and electricals. Efficient compact power-pack with minimal piping. Electricals neatly wired-labelled for trouble shooting.

...more

Mechanical Under Crank shearing Machine

KNTM Brand Mechanical Shears fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. FRAME CONSTRUCTION Mechanical Under Crank Shearing machine Frame fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. BED Super strong bed of closed box type construction, Street relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed area also provided for machined pas across the bed for convenient setting of front gauge brackets any desired spacing. Depressions in the top at the bed provide ample clearance for fingers in handling sheets narrower than the bed. UPPER BEAM Ram is also of solid steel plates, carrying the upper knife. Its minimum weight ensure lesser load on the bearings, The upper beam moves in flat heat treated steel guide plates to avoid plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. HOLD-DOWN MECHANISM Solid clamping by powerful spring loads hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of versions in thickness. Hold down pressure in easily adjustable for clamping soft material. Different thickness of material can be cut without future adjustment with consistently accurate and burr free results. ROLLING KEY CLUTCH Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. SHEAR KNIVES Knives are manufactured strictly as per standard material of D2 HCHCr. Every step from designing metallurgical specifications, heat treatment, grinding and inspection is carefully controlled. The blades are standards are standardized and are easily replaced. ACCURATE GAUGING The Rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. LUBRICATION Single shot lubricator provides oil to all the lubrication points, when necessary. Thus, all bearing parts and guide surface etc. DRIVE Drive through V-belts on flywheel and reduction gears are made of steel, hob cut for the smooth running and longer life.

...more

Mechanical Over Crank Shearing Machine

Keshav New Tech Machines (India) Pvt. Ltd in Bahadurgarh is the name to trust for accurate and high-performing mechanical over crank shearing machines. We design and supply mechanical over crank shearing machines that were manufactured using structural analysis techniques for repeated production, reliability and accuracy. Order Mechanical Over Crank Shearing Machine Online The machines offered by us include multiple features like auto lubrication systems, hold down systems, hydraulic manual, ball transfers, etc. You can also discuss your requirements with our team to get customized machines at a low cost.

...more

H Type Pneumatic Power Press

FEATURES & ACCESSORIES FOR BASIC MODEL Rolling Key Material 20NM GR5 Tested. Wheel Bush Material 20NM GR5 Tested. Shafts Material EN18 Tested. ABB Make Main Motor of low Electricity consumption with installed IEC Technology. Motor Pulley 01 Nos. & “V” Section Belts 02 Nos. Gear & Flywheel Guard. Pneumatic Clutch & Brake with Non Inclinable Body. Flywheel mounting running on Bearing. Pinion Shaft mounting running on Bearing. Electrical Panel Console with Foot Switch. Pneumatic System of Janatics/Feisto. Automatic Centralized Lubrication Pump.

...more

H Type Mechanical Power Press

When it comes to manufacturing H type hydraulic power press, nobody does it better than us at Keshav New Tech Machines (India) Pvt. Ltd. Based in Bahadurgarh, we offer high-speed hydraulic power press for a broad base of industries. The machine can be manually operated and is useful in compressing materials into the optimum permissible limit. Cheaper and Efficient H Type Hydraulic Power Press You can choose from our vast range of H type hydraulic power press machines all of which are precisely designed at our modern manufacturing facility unit. The manufacturing process of our hydraulic power press machines is done as per the industry laid guidelines. Call us to have a look at our product and to place your order.

...more

H Type Hydraulic Power Press

FRAME CONSTRUCTION Frame is fabricated from IS-2062 graded rolled steel plates table and cutting beam deeply reinforced and fines machines after stress relieving. The interlocked design put the direct support to the frame. These frames are strain-free and eliminate welds at load supports. Thus the accuracy of the machine is never disturbed. TABLE & SLIDE (RAM) Table and Slide are made of high grade heavy duty cast iron / steel fabricated and properly seasoned. They are perfectly aligned, to each other to obtain high accuracy and precession press operation. CYLINDER The cylinder bodies are precisely made from forged steel material duly bored and fine honed for long sealing life. The piston rods are made From EN – 8 material having low carbon contents. The piston rod is hard chrome platted (0.200 micron). HYDRAULIC SYSTEM The compact Blocks eliminate the leakage chances and also reduces the hydraulic pipes. This low Noise hydraulic system is placed on the rear side of machine, on top between two side plates. Pressure relief value is provided to safe guard the system and Machine from overload. The hydraulic system is driven by an electric motor of reputed brand and is coupled with a pump capable of generating more than the required pressure. Pressure gauge for system pressure, back pressure and holding pressure are providing on top of oil tank for quick reference. ELECTRICAL CONTROL PANEL The electric control panel is located on the left hand side of the machine. It is assembled from the internationally reputed parts for consistent performance, reliability and availability, if needed to be replaced. It is wired cleanly and labelled/ferruled properly as per the international practices to help easily locate any fault and replace components conveniently.

...more

Cut to Length Line Machine

1 Piece (MOQ)

At Keshav New Tech Machines (India) Pvt. Ltd. we make sure to export cut to length line machines that were made with optimized advanced technology. The highest quality cut to length machines we offer is praised for their reliability and high-end structure. Professional Cut to Length Line Machine Exporters The machines are also popular for their robust construction. You can order our cut to length machines in various specifications and dimensions. The machines are used for instant cuts and even instant feeds. Feel to approach us if you need any information on our machines.

...more

CNC Press Brake Machine

The CNC or computer numerically controlled press brake machine that we offer at Keshav New Tech Machines (India) Pvt. Ltd, aren’t only easy to operate but also durable. Based in Bahadurgarh, we design all our CNC press brake machines to safeguard against unwanted deflections and breakage. This is the frame that is responsible for distributing the stresses and supports the bed directly on the frame. Accurately Designed CNC Press Brake Machines The CNC press brake machines ensure accurate bending, because of their perfect design. The machines also promise accurate dimensioning, thanks to the extremely precise back gauge. Our brilliant choice of hydraulics and electricals ensure overall dependability and reliability. Talk to our team to have a better understanding of our CNC press brake machines.

...more

Cnc Hydraulic Shearing Machine

High quality CNC Hydraulic Shearing Machine with ultra-heavy frame structure, squaring arm assists and accurate cutting feature. We are engaged in manufacturing and supplying of a comprehensive range of CNC Hydraulic Shearing Machines. These shearing machines are widely used in manufacturing sheet metal components and assemblies. Owing to the excellent shearing capacity and user-friendliness, these machines are highly demanded in the market. FEATURES & ACCESSORIES FOR BASIC MODEL Rugged structure as per the international standards. Moving beam synchronized by differential cylinders. Hardened roller guiding beam for constant blade gap. Rake angle adjustable to suit thickness and material. Blade gap adjusted with levers for clean cuts. Sheets clamped hydraulically before cut starts. Shearing-clamping forces adjustable to suit job. Blades premium D2 HCHCr, four usable edges. Cutting length and position adjustable for short job. Beam returns on releasing foot switch for smaller cuts. Cutting area illuminated for clear view of blades First two hold-down spaced closer at both ends. Front gauging with stops, scale on squaring arm. Sheet supports 600mm long help support long plates. Ramp on rear slides out cut sheets outside shear area. Back gauge moves away to avoid trapping of cut sheet. Foot switch movable for operation from safe position. Finger safety guard with clear view of lighted cutting area. Dependable brands of hydraulics, and electricals. Efficient compact power-pack with minimal piping. Electricals neatly wired-labelled for trouble shooting.

...more

C Type Pneumatic Power Press

FEATURES & ACCESSORIES FOR BASIC MODEL Rolling Key Material 20NM GR5 Tested. Wheel Bush Material 20NM GR5 Tested. Shafts Material EN18 Tested. ABB Make Main Motor of low Electricity consumption with installed IEC Technology. Motor Pulley 01 Nos. & “V” Section Belts 02 Nos. Gear & Flywheel Guard. Pneumatic Clutch & Brake with Non Inclinable Body. Flywheel mounting running on Bearing. Pinion Shaft mounting running on Bearing. Electrical Panel Console with Foot Switch. Pneumatic System of Janatics/Feisto. Automatic Centralized Lubrication Pump.

...more

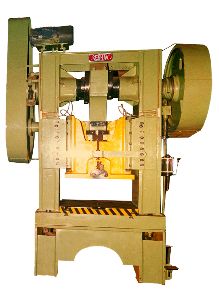

C Type Mechanical Power Press

features & accessories for basic model rolling key material 20nm gr5 tested. wheel bush material 20nm gr5 tested. shafts material en18 tested. spare 01 nos. rolling key. abb make main motor of low electricity consumption with installed iec technology. motor pulley 01 nos. & “v” section belts 02 nos. gear & flywheel guard. mechanical clutch & brake with non inclinable body. flywheel mounting running on bearing. pinion shaft mounting running on bearing.

...more

C Type Hydraulic Power Press

FRAME CONSTRUCTION Frame is fabricated from IS-2062 graded rolled steel plates table and cutting beam deeply reinforced and fines machines after stress relieving. The interlocked design put the direct support to the frame. These frames are strain-free and eliminate welds at load supports. Thus the accuracy of the machine is never disturbed. TABLE & SLIDE (RAM) Table and Slide are made of high grade heavy duty cast iron / steel fabricated and properly seasoned. They are perfectly aligned, to each other to obtain high accuracy and precession press operation. CYLINDER The cylinder bodies are precisely made from forged steel material duly bored and fine honed for long sealing life. The piston rods are made From EN – 8 material having low carbon contents. The piston rod is hard chrome platted (0.200 micron). HYDRAULIC SYSTEM The compact Blocks eliminate the leakage chances and also reduces the hydraulic pipes. This low Noise hydraulic system is placed on the rear side of machine, on top between two side plates. Pressure relief value is provided to safe guard the system and Machine from overload. The hydraulic system is driven by an electric motor of reputed brand and is coupled with a pump capable of generating more than the required pressure. Pressure gauge for system pressure, back pressure and holding pressure are providing on top of oil tank for quick reference. ELECTRICAL CONTROL PANEL The electric control panel is located on the left hand side of the machine. It is assembled from the internationally reputed parts for consistent performance, reliability and availability, if needed to be replaced. It is wired cleanly and labelled/ferruled properly as per the international practices to help easily locate any fault and replace components conveniently.

...more

Under Crank Shearing Machine

Hydraulic Shearing Machines

Back Mounted Hydraulic Press Brakes

H Frame Hydraulic Press

Pneumatic Clutch Power Press

High Speed Power Press

Complete Plant Piano Hinges

Be first to Rate

Rate ThisOpening Hours

Keshav New Tech Machines (India) Pvt Ltd, founded in 1989, is a manufacturer of a wide range of technical equipment utilised in many sectors. In the competitive area of Hydraulic Press Brake, Hydraulic Shearing Machines, Cut To Length Machine, and so on, we are a company to be reckoned with in Bahadurgarh, Haryana.

Our zealous attitude, stringent quality control processes, and scientific R&D activities have propelled us to a position that attests to the excellence of our product line.

We have held a leading position in the international Machine Industry by using the expertise and capabilities of our professional staff. Furthermore, our purposeful and planned progression has aided us in coping with diverse commercial procedures.

Our Infrastructure:

We have a robust infrastructure that aids in the modernization of our manufacturing operations. All of our units work tirelessly to provide our customers with an unrivalled selection of equipment that meets worldwide standards. Aside from that, our manufacturing plant is fully functioning and equipped with cutting-edge machinery.

Why Us?

Some of the causes why we are the customers\' first choice are as follows:

● Improved reporting system to keep customers informed on a regular basis so that they can plan their purchases.

● A group of competent engineers who are up to date on the latest innovations

● Constant process development in order to attain optimum client satisfaction