Drum Blender

45,000 Per Piece

1 Piece (MOQ)

Sterile Area Drum Blender

500,000 - 8,000,000 Per Piece

Best Deals from Drum Blender

Drum Blender

Get Price Quote

Originally developed for the homogenization of different grades of leaf Tea, this machine is adaptable for blending granular products efficiently and economically. A large diameter Drum rotates about its axis, supported on outboard Rollers, which are driven by independent motorized units. The special feature of this machine is that the loading and unloading of Product takes place while in motion, enabling a low blending cycle time. The full machine can be sealed and operation automated to meet hygiene and productivity requirements. Auxiliary feed and discharge equipment are provided as a support function.

Drum Blender

Get Price Quote

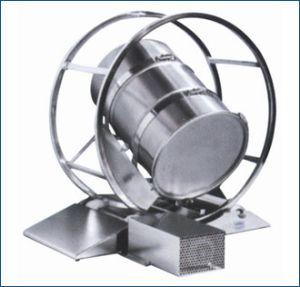

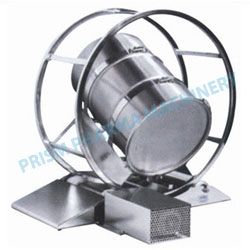

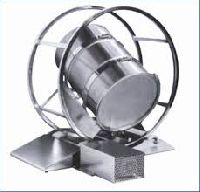

Drum blender is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter.This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained.

Drum Blender

Get Price Quote

The Drum Blender with its tumbling action ensures efficient blending. Its removable drum design makes transfer of material easy.

Drum Hoop Mixer

Get Price Quote

Our Drum Hoop mixer attachment is suitable for power and granule mixing. The Drum Hoop Mixer useful in research laboratory and also pharmaceutical, food, chemical and plastic fields having two parts, A. Main frame unit with Roller stand. B. Acrylic Mixing Drum with Rotating Arrangement. The Drum Hoop Mixer having drum capacity of 5 Kg. And operational capacity 2 to 3 kg. This Attachment is Suitable to Attached in our Both Main Drive.

Drum Blender

Get Price Quote

Drum Blender

Get Price Quote

DRUM BLENDER We are one of the pioneer Pharmaceutical Machinery Manufacturers from India, We manufacture Drum Blender, the blending achieved in Drum Blender is very good and it is one of most popular and conventional Blender used in the Pharma Industry.

Drum Mixer Blender

Get Price Quote

Drum Mixer Blender Dust free effective process technik of uniform mixing, lubricating & blending of dry powder & granules Application & Process : Drum/ Barrel mixer is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter. This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Available Capacity: 100 kg and 200 kg. This is a closed and contained system for blending and store. Main advantage of this system is that it is totally dust free. Controls panel with Cycle timer. Option for Variable speed.

Drum Blender

Get Price Quote

Drum blenders are excellent for rapid blending and mixing operation at low speeds. We make sure that at low speed the product's physical structure does not get disordered. They have a high demand all over the industry as they comprise the following features: • Blending occurs without any change in shape or size of particles • No possibility of generation of heat in the products

Drum Blender

Get Price Quote

Tumbling Mixers work on Diffusion Mixing Mechanism, in diffusive mixing, mobility of individual molecules is achieved by distributing particles over freshly developed surface. Materials are mixed by tumbling them in a partly filled container rotating about a horizontal axis. The rotary motion and gravitational force leads to cascade flow, which moves the material from side of the mixer to the middle of the mixer. When the material falls into the middle of the mixer, it spreads away developing fresh surface areas for efficient and homogeneous blending. This action continuously repeated during each rotation. Blending implies homogeneous distribution of fluid or particle. Blending requires definite degree and / or purpose to properly define the desired state of system. Tumbling Mixers work on Diffusion Mixing Mechanism, in diffusive mixing, mobility of individual molecules is achieved by distributing particles over freshly developed surface. Materials are mixed by tumbling them in a partly filled container rotating about a horizontal axis. The rotary motion and gravitational force leads to cascade flow, which moves the material from side of the mixer to the middle of the mixer. When the material falls into the middle of the mixer, it spreads away developing fresh surface areas for efficient and homogeneous blending. This action continuously repeated during each rotation. Tumbler blenders are of free flowing type and they provide a gentle mixing action. They can be incorporated with the following arrangement. Internal spray arrangement for introducing small amounts of liquid. Mechanically driven devices for breaking up Lumps. Vats & Vessels offers different distinct vessel shapes, the Drum, Octagonal, Double Cone and V/Y-shape. These shapes provide the ability to select a system best suited to your particular applications. All designs can be fitted with an internal agitator.

Drum Blender

Get Price Quote

The unit is specially made for dry mixing, blending etc. The mixer is supplied complete with 1No. Stainless Steel 316 drum having an airtight lid, with quick closing and opening clamps. The capacity of the drum is 200 liters, and it can mix 50 to 80 kgs. of material.

Drum Mixer Blender

Get Price Quote

Drum/ Barrel mixer is staple machinery used in pharmaceutical and chemical industry. Drum mixers are highly efficient mixing equipment used for mixing of powders. These mixers have gallon drums which rotate in order to mix powder. The mixing process involves loading the material into the drum, which is secured in a hoop and rotated thereafter. This equipment is very useful for mixing of ingredients or raw materials to be dispatched in barrels. Unlike other mixers, this mixer does not have any internal moving parts like blades or impellers; so the mixer avoids deterioration of material from friction-induced heating, since the drum has no dead space, so the material is uniformly blended. The drum mixers are powered by pneumatic or electric motors and available in various sizes. These mixers are configured in such a manner so that proper mixing and quality control of the end product is attained. salient Features : Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316 & non contact parts AISI 304. Available Capacity: 100 kg and 200 kg. This is a closed and contained system for blending and store. Main advantage of this system is that it is totally dust free. Controls panel with Cycle timer. Totally dust free. Option for Variable speed. Safety Features : Interchangeable Product Container AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station.

Drum Blender

Get Price Quote

hoop can be conviniently used for conveying the material to the storage site. flame proof motor (optional). quick mounting and dismantling the drum in hoop. replaceable drums can be used for even trasfering the material. drums available in SS 304 AISI construction, SS 316 drum optional.

Drum Hoop Mixer

Get Price Quote

This unit is suitable to attached Horizontal Main Drive [HMD], hoop mixer is suitable to research as well as industrial use in the pharmaceutical, chemical industries, food industries and plastic industries. Drum Hoop mixer comprises of two parts: The drive units with drum hoop support stand assembly. Acrylic mixing drum with rotating mechanism. The drum hoop mixer having drum capacity of 5 Kg. Operational capacity 3.00 Kg.

Rotary Drum Blender

Get Price Quote

Esteem Engineers Rotary Drum Blender is an ideal gentle mixer, with low speed and no moving parts inside the drum. Used all over the world for Powder/Granules blending, often with optional spray bar addition, the Rotary Drum Blender is perfect for delicate, friable or abrasive materials. Available in 15 Standard sizes from 100 L to 25,000 L, non standard and continuous versions are also produced to match your specification. A wide variety of options are available, we will design your Blender around the needs of your process.

Horizontal Twin Drum Blender

Get Price Quote

we are amongst the eminent horizontal twin drum blender manufacturer, supplier and exporters in chennai, tamil nadu. Our horizontal twin drum blender comes in customized specifications as well as with standard designs. Our horizontal twin drum blenders are simple to use and very effective for heavy duty. We produce constrict and technically advanced horizontal twin drum blender for various industries. This horizontal twin drum blender is effectively manufactured to get high productivity with a proper control on the caliber of mix. features this horizontal twin drum blender comes in variety of twin drum mixing systemsconsists of twin drums with two counter rotating rotors and specifically angled paddles, the rotors overlap in the centre of the mixer and the paddles completely sweep the bottom and mix all the material at the same timein zone b the materials have a main movement counter clockwise at the perimeter of the mixersimultaneously there are movements in the fluidized zone a both up and down, left and right and back and forth, all the time with space between the particles allowing free and random movementthe interaction of the two zones is the key to the unique mixing technology as all particles are transported into a highly homogeneous mixfrom our nominal filling level of 100% variations from 40% to 140% can be tolerated with the same perfect mixing results. The mixing time may be a few seconds longer than normal when mixing very small or very large batchesvery flexible in filling volume, the model number indicates the nominal filling level i.e., the level just above the rotor shafts, and is not to be mistaken for the total mixing volume mixing is movement of each particle to an exact position with other particles, and to prevent segregation of already mixed material. the fluidized zone provides homogeneous mixing independent of particle size and densityfree particle movementminimal heat generationgentle mixinglow chear large access doors ensure quick inspectioneasy cleaning large discharge doors give fast emptyingreduced segregationminimal residue steel fabrication various steel options available low power consumption guarantees low frictionminimal wearlow maintenancelow running cost twin mixer shafts provide overlapping paddlesoptimal particle movementfluidizationshort mixing timecontrol of main particle movementinsignificant dynamic forces on structural steel work and buildings fast and gentle high precision mixing the complete design of mixer combine fast mixing with slow shaft speed and gentle product handling which results in highly homogenous mixes after a short mixing timecarefully positioned paddles on two low speeds, counter rotating shafts create a fluidized zone with low power consumptionthis means very low shear and friction which in turn makes the mixer ideal for fragile products which cannot tolerate rough handling versatile for liquid additions liquids can be added at much higher rates than normally possible, due to the high particle movement capacity and fluidization of the particles. All the material surfaces are continuously exposed for maximum dispersion. It is possible to add small or large amounts of liquid, with high or low viscosity to powders, granules or pellets.

Drum Blender

Get Price Quote

The field of usefulness of Double cone for rapid, homogeneous blending and efficient drying is practically unlimited. As blender gently revolves a folding, spreading action ensures thorough uniform mixing, irrespective of material proportions or number of materials charged. Addition of liquid line & atomizer which remains stationary can give controlled uniform addition of liquid to dry powder. To avoid formation of lumps or re aggregation, internal lump breaker of different types can also be provided.

Drum Hoop Mixer

Get Price Quote

Drum Hoop Mixer is suitable for power and granule mixing. The Drum Hoop Mixer useful in research laboratory and also pharmaceutical, food, chemical and plastic fields having two parts, Acrylic Mixing Drum with Rotating Arrangement.

Drum Blender

Get Price Quote

The Drum Blender system has been designed as an integral cycle system from formulation to utilisation. It involves mixing & batch identification of the product during intermediate steps inside the same hermetically sealed container. This system allows that the G.M.P. is followed as closely as possible (no cross. contamination, no pollution of the environment) The machine consists of a fabricated MS Drum rotating at 20 RPM. It has an open able door in front, through which the SS Bins containing the products are loaded in the Drum. After the mixing, the Bins are removed and the Drum is recharged with another loaded Bin