Yarn Tension Sensor

100 Piece (MOQ)

The sensor is available in 3 main tension ranges: Low tension range: PA applications (0-60 cN) Standard range: PET applications (0-120 cN) High tension range: heavy counts and bulked continuous filament (BCF) applications (0-240 cN). Advantages : Highest requirements for economic and secure processes Innovative Hall digital sensor technology Electronics protected from environment Designed for highest reliability Optimal long-term drift, temperature drift and accuracy Tension overload protection to prevent damage to the sensor Protection against electrostatic discharge and machine vibrations Resistance to common spin finishes Simple installation and implementation into thread path Application in texturing and other industrial machines for tension surveillance

Brand Name : Retech

Material : Plastic

Color : Gray

Power : 15w

Application : Yarn Use

Type : Yarn Sensor

Country of Origin : India

Alarm Range : 1.5mtr

...more

Win-OLT Online Monitoring Sensor

10 Piece (MOQ)

Advantages Waste reduction due to early detection 100% quality control during production Cost-effective quality assurance Documented production process Wide range of facilities for fault detection, with user-defined parameters User-friendly computation using data graphics Analysis of production data by the program Recording of yarn tension at all positions, enabling long term analysis Optical indication of package quality by LED sensors Integral doff timer Optimized label printing options Simple connection to existing yarn cutting systems Guarantee Continuous tension monitoring Recording of yarn faults Quality classification by number of faults Display of events for error analysis Optical quality alarms Detection of surge speed Real-time fault recognition Detection of infrequently occurring faults Indications of type and source of fault by graphic presentation Optimization of spinning process

...more

Used Synthetic Filament and Fibre Machinery

All those who are looking for a responsible name supplying Used Synthetic Filament and Fibre Machinery can get in touch with us! We have automated systems to manage the sorting and packaging of all the products that are kept in the spacious warehouse. To look after this, we have hired veteran professionals. Features : Polyester filament - LOY, POY, FOY, FDY, SDY, R POY Recycled or Virgin PSF, RPSF Continuous Polymerization Plants - 5 Reactor, 3 Reactor, 2 Reactor process Nylon filament - LOY, POY,FOY, FDY, SDY

...more

Unheated Godet Rolls

100 Piece (MOQ)

Characteristics Ambient tempered roll surface Diverse surface materials available (chrome, ceramic or other) Diverse surface finishes available (for optimum frictional properties) Advantages High speed range Robust, simple modular design with installation from the front Low maintenance All electrical connections with ’plug-in’ facility No system balancing (roll exchange without rebalancing) No additional lubrication (lifetime bearings) Integrated cooling without additional cooling systems (water, oil mist, etc.)

Brand Name : Retech

Frequency : 50/60 Hz

Speed : Up To 6500 M/min

...more

TF-MX Melt Temperature Sensor

The TF-MX Series was developed in order to measure melt temperatures quickly and easily for all types of plastics. The temperature sensors are economical and versatile and impress with their robustness and reliability. The rheological characteristics of innumerable plastics were considered during the design procedure of the conical measuring tip, so that highly viscous medias can be ascertained without any greater problems. Major advantages regarding the life-span and reliability of the sensor in comparison to sword sensors are ensured due to the correct installation procedure. Robust metal construction Special material for measuring tip Plug connections with gold plated contacts Rheologically optimized sensor tip Applications up to 500°C (932°F) media temperature 100% market compatible Maximum melt pressure 2.000bar (29.000psi)

Certification : CE Certified, ISO 9001:2008

Application : Temperature Scaling

Feature : Non Conductive Liquid, Reservoirs Hoppers, Safety Interlocks, Solids In Storage Tanks, Suitable For Sensing Level, Visual Alarm System

Voltage : 0-15VDC, 15-30VDC

Frequency : 50Hz, 60Hz

Power : 0-5W, 5-10W

Ambient Temperature : 0-100deg C, 100-200deg C

...more

TF-CX Melt Temperature Sensor

The temperature sensors of the TF Series are ideal for exact temperature measurements in highly sensitive medias. The ceramic isolation guarantees a direct reading of the melt temperature independent of the flange or tool location. The ceramic encases the measuring element and isolates it from the surrounding area. The design of the TF conforms to the recommended guide lines of the Plastics and Rubber trade association according to EUROMAP 31. Measuring tip isolated with high-performance ceramic Highly precise temperature measurement Plug connections with gold-plated contacts Extremely robust conical measuring element (rheologically optimized) Applications up to 500°C (932°F ) media temperature 100% market compatible Conforms to EUROMAP 31

Certification : CE Certified, ISO 9001:2008

Feature : Non Conductive Liquid, Reservoirs Hoppers, Safety Interlocks, Solids In Storage Tanks, Suitable For Sensing Level, Visual Alarm System

Frequency : 50Hz, 60Hz

Power : 0-5W

Driven Type : Electric

...more

Synthetic Filament Spinning Machine Spare Parts

Synthetic Filament Spinning Machine Spare Parts that we provide is made from premium raw material. We offer a wide array of Synthetic Filament Spinning Machine Spare Parts such as Air Bearing Rollers, Quench Chambers, Interlacing Nozzle, Spinneret, Take Up and Winders. Regarded as prominent Synthetic Filament Spinning Machine Spare Parts Exporter, Importer and Supplier, we make sure that components conform to high quality standards of the industry. Highlights Of Our Filament Spinning Machine Spare Parts Sturdier built Easy to fix Flawless fabrication Affordable

...more

SFXmagnus Series Filter Screen Changer

The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application.Constant pressure and process consistency-The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application. This series is characterized by an extra large active screen surface area, its compact design, as well as extremely easy operation. Screen changes do not have any influence on the product quality.The advantages of the SFXmagnus Filtration System Economic-The extra large active screen surface area in relation to the screen changer size allows a unique economic efficiency of the SFXmagnus. The return on investment is realized within a very short period of time. Constant-By assuring a consistent active screen area, the pressure can be kept nearly constant during the whole production process. Melt temperature, viscosity and throughput are also free of variations at any time. Constant quality of the final product is guaranteed even during screen changes. Quality-Thanks to the optimized melt channel flow path and completely airtight encapsulated design, the requirements with regard to the purity and quality of the melt can be achieved and permamently maintained. Streamlined-The optimized rheological design of the melt channel flowpath ensures a minimized residence time (< 1 minute) thus ensuring for example fast material or color changes. Straightforward-The control system informs the operator in advance of an upcoming screen change. The screens can be changed quickly and easily and without any influence on the process or pressure consistency. Compact-The remarkably compact size of the SFXmagnus allows an easy and inexpensive integration even within limited space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low. Mode of operationWhen a pressure increase upstream of the filter is registered, the filter disk is indexed automatically by means of a pneumatic or hydraulic drive. The active screen area is always kept constant and the pressure upstream of the filter increases only slightly during the whole production process. After the cavities have passed through the melt flow, the screens can be removed without disturbing the production process.DesignThe filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

Thickness : 0-50cm, 100-150cm

Certification : CE Certified, ISO 9001:2008

Warranty : 2yrs

Flow Range : 0-200cfm, 200-400cfm

Country of Origin : India

...more

SFneos Series Filter Screen Changer

Patented Rotary Filter with simple and safe handling, suitable for almost all applications.Constant pressure and process consistencyThe SFneos Filtration Systems work continuously, process and pressure constant. They can be used for almost all applications and are characterized by their compact design and simple and safe handling. Several screens can be changed at the same time during a screen change process. Screen changes do not have any influence on the product quality.Specially designed for PVC processing and recycling applicationsThe Rotary Technology has been used successfully in PVC processing and PVC recycling applications for more than 30 years. The SFpvc Filtration Systems have been specially designed for thermally unstable and chemically aggressive processes such as those occurring in PVC recycling. The rheologically optimised filtration systems with their dead-zone free melt channel design and short flow path allow gentle processing.The advantages of the SFneos Filtration System Constant-By always keeping the size of the free active screen area constant, the pressure can be kept constant during the whole production process (max. pressure variations of ±1,5bar). Also, melt temperature and viscosity are permanently free from variations. Thus, the end product quality is always constant. Quality-Melt purity and quality downstream of the filtration system are permanently achieved. Rheologically optimized melt flow channels. Streamlined-Due to the optimal rheological flow channel design, the dwell time of all the melt in the filtration system is very short (< 1 minute). No danger of material burning in dead spots. Straightforward-The operator is informed in time about upcoming screen changes by the control system. Changing screens is a simple and quick procedure and does not have any influence on the process and product quality. Compact size-The compact design of the SFneos makes even in a very confined space a simple and cost-efficient integration possible. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low. Mode of operationWhen a pressure increase upstream of the filter due to contamination is registered, the filter disk is indexed by means of a pneumatic drive. This guarantees that the free screen area is always kept constant and that the pressure variation in front of the filter is < 1.5 bar.DesignThe filter disk – on which the screen cavities are located in a ring pattern – rotates between the two filter blocks. To change the screens, the safety cover has to be opened. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

Thickness : 0-50cm, 100-150cm, 150-200cm

Certification : CE Certified, ISO 9001:2008

Flow Range : 0-200cfm, 200-400cfm, 400-600cfm

Country of Origin : India

...more

Sea Island Composite Spinning Machine

With the aid of modern storage facility and diligent professionals, we are capable to fulfill quick and voluminous requirements of the clients. Also, we ensure complete safety of the stored products. All you need to do is place order with us; timely deliveries are our primary concern.

Type : Spinning Machines

Color : Metallic

Power : 7-9kw

Warranty : 2years

...more

RSFgenius Series Filter Screen Changer

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilitiesFully-automatic, pressure-constant, permanent process consistency-With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities. This fully-automatic and pressure-constant filtration system can be used in virtually any application, for automation of the production process and for the manufacture of a high quality final product. The RSFgenius is particularly well suited for ultra-fine filtration, the filtration of thermally-sensitive melts and the filtration of materials with a high contamination level.The advantages of the RSFgenius Filtration System- Fully-automatic-The filtration system operates fully-automatically and ensures a 100% availability of the line. Depending on the contamination level, a screen change (which takes approx. 20-30 minutes) is carried out approx. every 1-16 weeks and has no influence on the production process and product quality. Constant-By always keeping the size of the active screen area constant, pressure, temperature, viscosity and throughput of the melt remain constant, which guarantees the highest end product quality. Quality-Optimal flow channel design and encapsulation guarantee lasting purity and quality of the melt after the screen changer. The short dwell time of the melt in the filtration system (< 1 minute) permits quick material or color changes. Filtration finenesses down to 1 micron are possible. Simple-Screen changes do not expose personnel and environment to any danger. With the fully encapsulated design of the RSFgenius, influences from the environment (e.g. moisture, oxygen) during the filtration process are excluded. Due to the very effective screen cleaning with high pressure impulses, screens are automatically re-used 100-400 times (depending on the filtration fineness). Compact-The small and compact design of the RSFgenius makes a simple and cost-efficient integration possible even in a very confined space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low. Mode of operationA high pressure segmental backflushing system purges the screen packs clean, shortly before their re-entry into the melt channel. A small, measured „shot“ of filtered polymer is taken from the „clean“ (filtered) side of the screen changer and injected with an adjustable pressure of approx. 30 – 80 bar backwards across the screen pack. The backflush is then ejected through the screen changer inlet block to the outside. Only a small segment (approx. 1 %) of the screen area is cleaned at one time. A defined quantity of material delivers a high energy cleaning impulse.DesignThe filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.VersionsModel versions with special performance features are available to suit the respective application: Very high filter surface exchange rate for highly contaminated materials Continuous back-flushing for extremely sensitive processes and polymers and/or extremely contaminated materials

Thickness : 0-50cm, 100-150cm

Certification : CE Certified, ISO 9001:2008

Condition : New

Warranty : 2yrs

Country of Origin : India

Flow Range : 0-200cfm, 200-400cfm

...more

Polypropylene Industrial Yarn Spinning Machine

We believe in keeping transparency in the transactions and thus we offer an invoice to the clients stating all the necessary details. We undertake both online and offline payment processing methods. We keep in consideration that the inputs (raw material) used are of incredible quality and meet the set industrial norms. Thus, the final products are as per the globally accepted quality standards.

Type : Yarn Spinning Machine

Weight : 100-1000kg

Color : Metallic

Voltage : 380V

Automatic Grade : Automatic

Power : 3-5kw, 5-7kw

Warranty : 2years

...more

Polymerization Plant

Polymerization Plant is used to produce polymer products such as polyester RESINS or Directly to make POY/ FDY e, polyamide (nylon), etc. We offer premium Polymerization Plants/ Major Equipments from China that finds its application in diverse industrial sectors. Thus, we are regarded as prominent Exporter, Importer and Supplier of Polymerization Plant in the industry.Highlights of Our Polymerization Plant : Low maintenance Highly efficient Smooth and easy operations Made with high grade machinery Advantages : Production can be increased to maximum lever with an investment cost approximately 20% more The distillation column of Esterification, adopted pump reflux installation for distillation column, accurately controlled temperature Unique temperature control technology for poly condensation with EG steam eject system, able to save 60% energy required

Material : Metal

Application : Industrial Use

Color : Metallic

Feature : Durable, Dustproof

Finishing : Polished

Packaging Type : Wooden Box

Finishing : Polished

...more

Polyester Polyamide Composite Spinning Machine

We have well-maintained and capacious storage unit that includes all required facilities vital for a safe stacking of the products. We are working with experts and professionals and they supervise the range sternly ensuring zero damage to the stored items. In order to attain complete client credibility, we offer several options to the clients. Also, we make sure that the transaction is completely secure and confidential.

...more

Polyester Industrial Yarn Spinning Machine

From bulk to retail order fulfillment, we can do it all. Our company has a wide supply chain network to provide our buyers with the product all year round and make timely delivery. We are a prominent name offering quality-centralized array of products that are the perfect outcome of premium raw material and modern work methods. Also, we source the material from the reliable places only.

Type : Yarn Spinning Machine

Weight : 100-1000kg

Color : Metallic

Voltage : 380V, 440V

Automatic Grade : Automatic

Warranty : 2years

...more

Polyester FDY Spinning Machine

Our online and offline modes of payment are 100% secured and facilitate payment in cash and bank transfer. Thus, we are highly preferred by the clients. We are staffed with diligent packaging staff and they ensure that the packaging is designed to make certain that the products arrive at their destination in optimal condition. Usage :This machine is suitable for either direct or chip spinning to produce polyester FDY. Main product is 55~110D, 83~167D,167~330D, compared with traditional 8 ends/pos. production line, capacity can increase 50%~250%, and with low cost and energy consumption.Features : The extruder for chips spinning introduce LTM compenent. Bottom-mounted spin pack&spinneret,new type energy-saving spin beam with large gauge from 850-1500mm and manifold pipe with high efficient static mixer. Unique spinneret partition,one spinneret with single or double chanbers,which could convert 8 ends into 16 ends,12 into 24 ends. Special planetary metering pumps and individual drive for finish pump. Vertically top-mounted pump drive,dismountable drive shaft and individual stop control. GR is equipped with electric induction heating device,uniform temperature in surface of godet, and less energy consumed. Automatic winder facilities high successful switching rate,less waste and well developed package,max number of package up to 24 ends/pos.

...more

Polyamide Industrial Yarn Spinning Machine

Place orders with us, timely deliveries of the same are our prime responsibility! Keeping the quality standards high, we make certain that prior to production, the inputs (raw material) are examined by the professionals to make the final product free from defects.

Weight : 100-1000kg

Color : Metallic

Voltage : 230V, 380V

Automatic Grade : Automatic

Power : 3-5kw, 5-7kw, 7-9kw

Warranty : 2years

...more

Plate Heater and Oven

100 Piece (MOQ)

Characteristics : Contact or convection principle Resistance heated PT100 temperature sensor with monitoring sensor for over-temperature protection Alternative surface material (chrome or ceramic) Diverse surface finishes Specialties: double-sided hot plates Advantages : Accurate surface temperature Alternative lengths Extended surface life Recoverable surface

Brand Name : Retech

Length : 150 - 500 Mm

...more

Pet Recycling Plant

Key names: PET Recycling plant B to B PET Recycling plant Recycled POY Spinning machine Gneuss Filters Online Viscosity meter Viscosity meter Pet Flakes (Raw Material) Mechanical Recycling Semi chemical Recycling Chemical Recycling Application Area Pet Fibre Plant : In this case PET Bottles are collected from different sources and are washed and crushed into PET flakes. These flakes are put in to continuous or semi continuous dryer and then Extruder, CPF…and Tow is canned. In Drawing section these Tows are drawn and cut in to required staple length to make fibres. Pet Filament POY/FDY Plant : In this case PET Bottles are collected from different sources and are washed and crushed into flakes. These flakes are put in to continuous or semi continuous dryer and then Extruder, CPF and this filament is wound on winder. Semi Chemical Recycling Using (finisher/ Homogniser)System : We provide Finisher system from China from ZC POLY for Both PET Fibre and PET Filament. Finisher system is to remove the impurities about 70%~80% and increase and maintain the required IV hence improving the Fibre quality. Here we cannot use all types of pet raw material. E.g Color bottles, color yarn or fabric waste SSP: Solid state polymerisation with IRD under vacuum system for PET Flakes, where in PET Flakes IV can be increased upto 1.10 dl/g for B to B application or for High Tenacity Filament. The same can be used for making POY or FDY without using Finisher systems Special types of Extruder: We supply special extruders like Twin extruders, planetary Extruders depending on the Final product requirement. These type of Extruders can be used for making good quality POY and FDY Rotary Filters: Filtration play vital role in making good quality POY and FDY. 20 micron filtration is good for POY and FDY and this can offer constant Pressure and process which will enhance the quality and run ability 100% Chemical Recycling: We Represent NISCO Technologies for 100% Chemical Recycling. With this technology Customer can make PET chips from various types of Raw material having PET Component. The quality of PET Chips by this technology will be same as Virgin PET chips.

Type : Plastic Recycling Plant

...more

Online Viscometer Extrusion System

The Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process.Reliable viscosity measurementThe Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process.The viscometer is fitted between two flange connections. The melt channel can be designed according to the customer´s specifications between D = 20 mm (0.8 inches) and D = 110 mm (4.3 inches). The unit includes the pump drive, the pump, pressure transducers, temperature sensors and the control and evaluation electronics. Electric or liquid/vapor heating is available (optional). The setting of process parameters, the evaluation and the display is realized via a user-friendly touch screen panel or alternatively can be integrated into an existing control system.An easily exchangeable capillary permits the adaptation of the measuring device to different viscosities ranging from 1 mPas (0.01 poise) up to 20.000 Pas (200,000 poise). A subsequent change of the measuring range is also possible.Due to the special melt channel design and precise fabrication, dead spots or edges in which shear and temperature sensitive polymers could possibly stagnate can be avoided. The very short dwell time also prevents accumulations of degraded material. A further innovative feature is the possibility of completely cleaning all parts in contact with the melt without interrupting or disturbing the production process.ConfigurationBy means of a high precision metering gear pump, a small part of the polymer melt (max. 3 kg / h or 7 lbs / h) is separated from the main melt channel. This is pumped through a precisely manufactured slot capillary. The inlet and outlet pressures or the elastic properties which disturb the measurement are filtered out by means of length – optimized inlet and outlet zones in the capillaries for levelling out the laminar flow.Advantages of the Online Viscometer VIS No measurable temperature increase in the rheometer thanks to ample flow channels. Short dwell time, no dead spots, no remnants or material left in the melt channels. Through measurement in the rectangular capillary cross section – no elastic properties are recorded. Very compact design, flexible adaptation to the existing melt pipe or extrusion line. Fast adaptation and change of the measuring range through an exchangeable capillary plate. Polymer bypass, therefore no melt losses. High-precision measurement of the melt temperature directly during the viscosity measurement. High measurement accuracy through use of special high-precision pressure transducers. Complete cleaning of all surfaces and channels in contact with the melt without interruption or shutting down of the production process.

...more

Nylon FDY Spinning Machine

With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions. Only high-quality raw materials have been used for the production of our entire range. We check the raw materials against varied quality parameters before procurement. Main Features : The imported extruder or domestic XD-dual metal screw and barrels help stabilize melting and extend life span. New type of energy conserving spin beams,bottom-mounted spin packs and specially designed spin beam,easy for dismantling and cleaning. Spinneret has a vapor protective system to slow down cooling and crystallization of filament. The monomer suction device and saturated steam jet are specially suitable for producing nylon 6,66 micro-denier filament. New quenching has a honey-comb rectifier which features stable wind speed and better yarn evenness. GR3 is more helpful in improving package formation and dyablity. Precisely-controlled automatic winder enjoys extremely low ADF and excellent unwinding properties.

...more

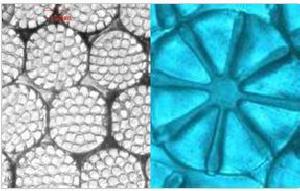

MRS Extrusion System

The patented MRS Extrusion System offers completely new possibilities with regard to the efficient degassing and extrusion of polymer melts.MRS Extrusion ConceptThe patented MRS Extrusion System offers completely new possibilities with regard to the efficient degassing and extrusion of polymer melts. Additionally, this system also offers excellent dispersion performance for the introduction of gases and / or all forms of additives.DesignThe MRS extruder is based on the conventional single screw extruder, but is equipped with a multiple screw section, for optimum devolatilisation. The polymer melt is delivered into a large single screw drum. The drum contains 8 small extruder barrels, parallel to the main screw axis. Installed in these small extruder barrels are the “satellite” screws, which are driven by a ring gear in the main barrel. The satellite screws rotate in the opposite direction to the main screw while they rotate around the screw axis. This disproportionately increases the surface exchange of the polymer melt. So that the volatiles can be freely evacuated, the MRS extruder is equipped with a large opening for venting (exposing the full length of the satellite screws) which is completely under vacuum. This provides excellent and unrestricted access to the polymer melt, the surface of which is constantly replaced at an extremely high rate by the action of the satellite screws in the multiple screw section. Further, precise control of the melt temperature is possible as the temperatures of all the surfaces in contact with the melt can be controlled accurately.Performance comparisonThanks to its Multi Rotation Section, the surface area – and the surface area exchange rate – available for devolatilization are far greater than in other extrusion systems available on the market.The surface area of the steel parts in contact with the melt is exchanged at a rate of more than 25 times greater than with a co-rotating twin screw extruder. Due to the opposite rotation direction and high speed of the satellite screws, the polymer surface area is increased by a factor of 100 compared to a single screw extruder and a factor of 40 compared to a twin screw extruder.Energy efficientThe specific energy requirement of the MRS system is typically 15 to 25 % less than for conventional technologies as it needs neither pre-drying nor powerful vacuum systems. Compared with the single screw extruder when processing PET, pre-treatment of the material in the form of drying and crystallizing can be avoided thereby saving operating and maintenance costs along with energy savings.The MRS also has a lower energy consumption when compared with corotating twin screw extruders. In the case of PET processing, there are additional savings with the MRS as this system requires neither a powerful vacuum system ( < 5 mbar) nor partial pre-drying of the material.Furthermore, the MRS delivers sufficient pressure that in most cases, a melt pump is not necessary to boost the pressure.

...more

Motor-Driven Separator Rolls

100 Piece (MOQ)

Characteristics Ambient tempered roll surface Diverse surface materials available (chrome, ceramic or other) Diverse surface finishes available (for optimum frictional properties) Advantages High speed range Robust, simple modular design with installation from the front Low maintenance All electrical connections with ‘plug-in’ facility No system balancing (roll exchange without rebalancing) No additional lubrication (lifetime bearings) Integrated cooling without additional cooling systems (water, oil mist, etc.)

Brand Name : Retech

Frequency : 50/60 Hz

...more

Mother yarn splitting machines

300,000 Per Set

10 Set(s) (MOQ)

Features: 1) no need to use mettalic bobbins if the customer has covering machine 2) motor: 1.025 kw 3) speed: 600 mpm 4) easy to load mother yarn 5) saves two process a) mother yarn to mono on metallic cops and b) rewinding machine 6) covering labours can be used to run the machine as simple to run 7) compact size machine.

Brand Name : SANTECHS

Application : MOTHER YARN SPLITTING MACHINE

Voltage : 1.025 KW

...more

PET Recycling Services

There are three types of Pet recycling available : Mechanical Recycling : Pet Fibre Plant : In this case PET Bottles are collected from different sources and are washed and crushed into flakes. These flakes are put in to continuous or semi continuous dryer and then Extruder, CPF and Tow is canned. In Drawing section these Tows are drawn and cut in to required staple length to make fibres. Semi Chemical Recycling : Pet Fibre Plant : Pet Filament ( POY/FDY) Plant : We provide Finisher system from China from ZC POLY for Both PET Fibre and PET Filament. Finisher system is to remove the impurities about 70%~80% and increase and maintain the required IV hence improving the Fibre quality. Here we cannot use all types of pet raw material. E.g Color bottles, color yarn or fabric waste 100% Chemical Recycling : We Represent NISCO TECHNOLOGIES for 100% Chemical Recycling. With this technology we can make PET chips from various types of Raw material having PET Component. The quality of PET Chips by this technology will be same as Virgin PET chips.

...more

Indenting Services

Opening Hours