Plate Heat Exchangers

Get Price Quote

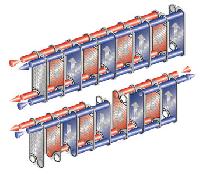

Compact, Expandable and easily cleanableThe Plate heat exchanger consists of a pack of corrugated metal plates, The corrugation of the plates provides the passage between the plates, the two fluids transfer the heat between the channels. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The gasket between the plates seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the design: the temperature program, flow rate, pressure drop and physical properties of the fluids,.

Plate Type Heat Exchanger

Get Price Quote

Plate Type Heat Exchangers consist of a series of alloy plates held together by a frame. The frame can be opened to add or repair the plates. One liquid flows through alternate plates and the other liquid flow the opposite direction through the opposite plates. Materials Used: Titanium, Tantalum, Zirconium, Nickel, Hastelloy, Inconel, Monel, Copper Nickel, Duplex, Super Duplex & Stainless Steel…Applications : Refineries, Petrochemicals, Pharmaceuticals, Caustic Chlorine Plants, Pulp & Paper, PTA, Acetic Acid Plants, Offshore, power Plants, Fertilizer Plants….Services : Retubing of Heat Exchangers, Repair Kit for Glass Lined reactor, Relining of equipment, Nickel Concentrator element repair, site work, etc…

Looking for Plate Heat Exchanger Services Providers

Plate Heat Exchangers

20,000 - 500,000 Per piece

100 piece (MOQ)

Plate Heat Exchangers

10,000 Per Piece

Plate Heat Exchangers

Get Price Quote

We maintain a steady supply of our products courtesy an ultramodern inventory management system and a high-tech storage facility. Our resources enable us to maintain year round products' availability. We have compartmentalized our facility into different units and one of them is packaging unit in which we meticulously pack our products to ensure safe and swift deliveries. Details : Ship your entire heat exchanger assembly to us. Plates will be removed, cleaned, tested and regasketed. The frame and other components can also be reconditioned. After reassembly, the unit will be hydro-tested. The completed unit can be quickly reinstalled and put into service with the assurance of leak-free operation.

Plate Heat Exchangers

Get Price Quote

We are main supplier of this product.

Plate Heat Exchangers

120,000 Per Piece

1 Piece(s) (MOQ)

plate heat exchanger services

12,089 Per 12089 Piece

25 Set(s) (MOQ)

Provide Advanced and exclusive service facilities Like Cleaning Refurbishment Gasket replacement Re-gasket Repair Modification Painting Re-structure Spares and accessories replacement machining and alignment service

Plate Heat Exchangers

Get Price Quote

Plate Heat Exchangers

50,000 - 150,000 Per Numbe

1 piece (MOQ)

Plate Heat Exchangers

Get Price Quote

Plate Type Heat Exchanger

Get Price Quote

A Plate Heat Exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluid. This has a main benefit above a square heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitate the transfer of heat, and deeply increase the speed of the temperature change. Plate Heat Exchangers are now general and very small brazed versions are used in the hot-water sections of millions of arrangement boilers. Plate Heat Exchangers have a high temperature move speed compared to extra types of heat exchangers due to their large surface area. They are composed of a number of thin metal plates compressed together into a ‘cover pack’ by two force plates. inside a plate heat exchanger, the fluid paths rotate between plates allowing the two fluids to interact, but not mix, several times in a small area. Each plate is grooved to boost the surface area and maximize heat transfer. Plate Heat Exchangers have a number of applications in the pharmaceutical, petrochemical, chemical, power, industrial dairy, and food & beverage industry.

Plate Heat Exchangers

Get Price Quote

We bring forth a broad line of Plate Heat Exchangers that are largely used in different domestic heating and hot water equipment. Our Plate Heat Exchangers are produced from quality metals and other raw materials with the employment of advanced technology. They are highly durable and require low maintenance. We are a distinguished Supplier of Plate Heat Exchangers from Gujarat (India). Backed by a huge distribution network, we can deliver our quality tested product safely and within a stipulated time-frame.

Plate Heat Exchangers

Get Price Quote

Plate Heat Exchangers

Get Price Quote

Plate Type Heat Exchanger

Get Price Quote

Raw material that we source is unprocessed and of excellent quality as we procure it from the trusted sources of the market. Before obtaining it, our experts check it thoroughly. Owing to our reliable transportation facilities, we are able to deliver the orders at the desired destination and on promised time. Features : Supreme quality High performance Reasonable rates

Plate Type Heat Exchanger

Get Price Quote

Plate Type Heat Exchanger

Get Price Quote

To keep a strict check on the quality of the products, we have hired professional quality analysts having rich domain experience. With the best in class raw material comes a remarkable finished product, thus we keep a stern check on the material used. Our quality auditors ensure that the products are up to the mark.

Plate Heat Exchangers

Get Price Quote

The Company is the noted Exporter & Supplier of durable Plate Heat Exchangers. Our Alfa Laval Heat Exchanger is appreciated for its flawless performance, low maintenance cost and longer functional life. Our quality inspectors thoroughly check our Plate Heat Exchangers against various quality parameters before procurement. We make available our Plate Heat Exchangers in safe packaging and at the most competitive rates.

Plate Heat Exchangers

Get Price Quote

1 Box (MOQ)

Condition : New Quality : High Usage : Heat Transfer Application : Industrial Place of Origin : Udaipur

Plate Heat Exchangers

10,000 - 3,000,000 Per piece

1 piece (MOQ)

Plate Heat Exchangers

Get Price Quote

Tranter is soon entering its fifth decade engineering, manufacturing and supporting gasketed plate heat exchangers. We have listened carefully to our customers. Beyond simply purchasing a plate heat exchanger that meets a spec, customers tell us they want an added-value solution with maintenance-friendly designs and life cycle support. We have responded with significant investments in global coverage with a local presence. We are committed to extending our support to you through our specialized Service Center network, with preventive maintenance services and emergency uptime restoration service devoted solely to plate-type heat exchangers.

Plate Type Heat Exchanger

Get Price Quote

Be it online or cash deposit, the financial operations are carried out only under the stern management, supervision of professionals. To make our payment procedures highly secured, we make use of the leading technologies to avoid any fraud. Due to our streamlined packaging system, we are capable to fulfill bulk and customized packaging requirements of the clients. In addition to this, we ensure complete safety of the products.

Plate Heat Exchanger Design services

Get Price Quote

The heart of a PHE is a pack of embossed plates with apertures. The plates are assembled in a 180° angle to each other, resulting in flow gaps on each side. Each plate is provided with a gasket, which securely seals the flow gaps from the atmosphere and separates the two media used in the heat exchange. The gasketed plate pack is mounted in a rack and is compressed with tightening bolts between the fixed plate and the movable plate. To guarantee maximum heat transfer, warm and cold media are normally fed through the PHE in one-pass or multi-pass counter flow.

Plate Type Heat Exchanger

25,000 Per Units

Plate Heat Exchangers

Get Price Quote

We manufacture and supply highest quality range of plate heat exchanger using the most advanced technology for a wide series of heat transfer applications used in various industries such as chemical industry, offshore, oil and gas, petrochemicals power plants, pulp and paper, steel, zinc and aluminium, sugar, vegetable oil, breweries / distilleries, dairy / beverages and others. The difference lies at plate design, sealing technology, capacity range, product range etc. We always continue to improve our Plate heat exchanger to give total customer's satisfaction. Plate Heat Exchanger Features High heat transfer coefficients Optimized heat recovery Compact constructions No mixing of product Flexibility to change plate arrangement and to add / remove plate Easy maintenance and suitable for CIP, plate pack easily accessible. Plate Heat Exchanger A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat system in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible. Plate Frame Heat Exchanger Application Plate Frame Heat Exchanger Cleaning Plate and Frame Heat Exchangers Animation Plate and Frame Heat Exchanger Approach Plate finned type Heat Exchanger Brazed Plate Heat Exchangers Plate Heat Exchanger Design The concept behind a plate heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger. The plate heat system (PHE) s was invented by Dr Richard Seligman in 1923 and revolutionized methods of indirect heating and cooling of fluids. Plate exchanger one is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat system. Advances in gasket and brazing technology have made the plate type heat system increasingly practical. In HVAC applications, large exchangers of this type are called plate-and-frame; when used in open loops, these heat system are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat system, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat systems also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves. Liquid foods such as milk, fruit juices, beers, wines, and liquid eggs are pasteurized using plate-type. Wine and fruit juices are normally deaerated prior to pasteurization in order to remove oxygen and minimize oxidative deterioration of the products. Plate Type heat exchanger consist of a large number of thin, vertical steel plates that are clamped together in a frame. So it may called as Plate and Frame. We manufacture Plate Heat Exchanger that are used in dairy, pharma and biotechnology, beverages, brewery, chemical and power sectors. PHE plates are available in MOC AISI 304, AISI 316, AISI 316L, Titanium, Hast alloy, Monel in range thickness from 0.5mm to 0.9mm. It is suitable for handling fluid from 100 LPH to 3.5 Million LPH. The plate heat exchanger sare available in herring bone, free flow and semi welded construction and depending on application respective plates are selected. Plate heat exchangers - Bolted design (plate and frame) Heat transfer plates are characterized by optimum embossing resulting in high heat transfer coefficients. This permits low-cost and optimum adoption to the respective application conditions Our product range includes single-pass and multi-pass plate heat exchangers with heat exchange surface up to 1500 m². Plate Heat Exchanger Technical data: heat exchange surface per plate: 0,04 - 2,50 m² max. design pressure: 25 bar max. design temperature: 170°C Plate Heat Exchanger Safety:Our plates are provided with double gaskets at the inlet and outlet which prevent mixing of the two media. If designed as safety heat exchanger, double plates are provided with a special sealing system. Plate material: standard: stainless steel 1.4301/AISI 304, 1.4401/AISI 316 optionally: 1.4539, 254 SMO, titanium Gasket material: NBR (nitrile-rubber) EPDM (ethylene-propylene-rubber) Viton (fluorine-rubber) Further materials on request Special series: Safety heat exchangers (FPSS) Stainless steel design for food and FDA applications Compact double PHE-units including cocks and valves Design with welded cassettes (FPG)

Plate Type Heat Exchanger

Get Price Quote

We are offering plate type heat exchanger. range of experiments 1. Determination of lmtd of heat exchanger. 2. Determination of heat transfer rate, heat transfer co-efficient and effectiveness of plate type heat exchanger

Plate Type Heat Exchanger

Get Price Quote

A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. It is not as common to see plate heat exchangers because they need well-sealed gaskets to prevent the fluids from escaping, although modern manufacturing processes have made them feasible. The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal, or another substance with a high thermal conductivity, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic or coated with thermal insulation, to discourage heat from escaping from the exchanger. The plate heat exchanger (PHE) was invented by Dr Richard Seligman in 1923 and revolutionized methods of indirect heating and cooling of fluids. Plate type heat exchanger one is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger. Advances in gasket and brazing technology have made the plate-type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type are called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasket type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat exchangers, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with “chevron” or other patterns, where others may have machined fins and/or grooves. Specifications : Liquid foods such as milk, fruit juices, beers, wines, and liquid eggs are pasteurized using plate-type heat exchangers. Wine and fruit sjuices are normally deaerated prior to pasteurization in order to remove oxygen and minimize oxidative deterioration of the products. Plate-type heat exchangers consist of a large number of thin, vertical steel plates that are clamped together in a frame. Applications : The plates produce an extremely large surface area, which allows for the fastest possible transfer. Making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange. The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger. A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved. Advantages : Easy maintenance and suitable for CIP, plate pack easily accessible High heat transfer coefficients Flexibility to change plate arrangement and to add or remove plate No mixing of product Compact constructions Optimized heat recovery

Plate Heat Exchangers

Get Price Quote

We are main supplier of this product.

Plate Heat Exchangers

Get Price Quote

Taj Heat Exchanger: Plate Heat Exchangers have become effective modern method of cooling or heating flowing liquids through the method of conduction. The application of the Plate Heat Exchangers is basically cooling the hotter liquid or heating the cooler liquid. The heat transfer plates are thin sheets having corrugations and patterns which increase the surface area of the plate hereby increasing the efficiency of heat transfer through conduction. The liquid is prevented from flowing sideways by thick gaskets which seals the PHE and also directs the liquid to flow in the appropriate alternate channel. The plates are supported and aligned by the guide bars and tightened by bolts between stationary and pressure frame. The equipment can adjust the number of plates to meet the heat duty. Heat Exchanger Mechanism: Heat Transfer plates L and R are of identical pattern. L when rotated 180 degrees become R and vice versa. The plates are arranged in LRLR or RLRL combination giving the PHE a honey comb pattern when looked from sideways. The first plate – E plate is having all port holes covered with the gaskets as this plate is touching the stationary frame. This double seal gasket prevents the flow between the stationary frame and the first plate Plate Press Patterns Herringbone pattern is adopted for the plate press because of its high heat transfer efficiency. Combining this plate together creates more contact points making it possible to obtain strong pressure resistance. In this way, a complex channel is formed creating highly turbulent flows to obtain excellent heat transfer performance.