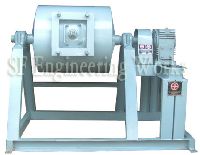

Ball Mill

We are offering Ball Mill. we manufacture and supply superior quality ball mills that are made from premium quality materials that offer sturdy structure and durability to them. the world class ball mills offered by us are designed by expert team of designer keeping the specific needs of our clients in mind. the wide demand of our ball mills in the market proves our claim of being the prime ball mill manufacturer and supplier from vasai, maharashtra. features made from premium quality materials designed by expert teamunique construction durable anti corrosiveanti abrasive widely used in chemical industriespaint industries food industries construction industries pharma industries steel industries beverages industries etc.

Ball Mill

Capacity : 1 Kg. With S.S. Jar.

Capacity(t/h): : 0.65-90

Application: : Grinding

Speed : 24.5 r/min

Ball loading : 15t

Max feed size : 25 mm

Weight : 31 T

Discharge size : 0.074-0.6 mm

Ball Mill

Country of Origin : India

Type : Ball Mill Machine

Application : For Grinding Materials

Color : Blue

Voltage : 220V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 1year

Body & Glaze Preparation

Condition : New

Ball Mill Machine

SIZE : 12x18,20x20

One of the oldest and safest methods for grinding of a wide range of materials of hardness upto 8 on mohs scale. Can be used for grinding of Practically any material wet,dry or sticky.Material Of Construction Mild Steel. Having Total Volume Capacity In Liters ---. Main Shell Will Be Fabricated In ---Mm Thick Plate And Side Plate Will Be --Mm Thick And Further Supported And Stiffened With Mild Steel Heavy Duty Ribs And Backing Plates To Withstand Heavy Loads From Outside. Main Shaft Will Be ---Mm Dia Located On Heavy-Duty Bosses And Rotate On Roller Bearings Complete With Plumber Blocks And Sleeve Nuts. A Discharge Door Main Hole Of The Cylinder Will Be ---------- For Liquid Or Solid Discharge Is Provided With The Mill Along With Manhole Cover If Required. Main Shaft Will Be Turned Through From One End To Another End. The Entire Mill Is Mounted On A Sturdy Frame Structure Made From ISMC Sections.

Vertical Planetary Ball Mill

Power Source : Electric

Usage/Application : Industrial

Material : Mild Steel

Packaging : Box

I Deal In : New Only

Ball Mill

95,000 - 300,000 Per Set

1 Set(s) (MOQ)

Finishing : Colouref

Machine Weight : 900-1000kg

Pressure : Low Pressure

Specialities : Excellent Functionality, Less Maintenance, Ruggedly Constructed, Durable, Easy To Use

Type : Ball Mill

Brand Name : Nirlaxson

Voltage : 440V

Condition : New

Power : 9-12kw

Driven Type : Electric

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Corrosion Resistance : Yes

Machine Structure : Horizontal

Operating Type : Manual

Size : 100 Ltr to 1000 Ltr

MOQ : MS, SS

Ball Mill

Ball Mill consists of cylindrical shell rotating on a horizontal axis mounted on a sturdy frame. The Ball Mill Shell is designed to withstand the rotational load of the mill charged with the grinding medium and the material to be gridded.

Ball Mill

Shape : Round

Application : Crushing Machine

Color : Silver

Feature : Compact Designs, High Strength, Optimum Quality

Finishing : Polished

Productivity : 40 pcs/min

Motor power : 1000 KW

ball mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a wet or dry state. ball mills are referred to by many names including pebble mills, tube mills and attrition mills, but no matter what the nomenclature they all operate on the same efficient principle. a horizontal cylinder is rotated at a predetermined speed that sets the balls into a tumbling and cascading motion which impact the solids in a very predictable and controllable fashion. because the process takes several hours, the particles will not only be finely milled, but will exhibit a narrow particle size distribution. tumble milling is efficient and puts more energy into milling and less into wasted friction which both reduces contamination and eliminates temperatures spikes. for very heat-sensitive products, a cooling jackets can be provided for temperature control. scale-up of tumble mills benefits greatly from the fact that they become more efficient with increasing size. tumble mills are designed for each application, taking into consideration all of the solids characteristics and whether the solids will be discharged wet or dry. features : high efficiency – due to the relatively slow rotational speed but large mass of media, more of the energy goes into milling and less wasted as heat. narrow particle distribution – solids milled in tumble mills are normally so fine and consistent in size that it’s rare to require classification. repeatable results – mill operating parameters including rotational speed, media size and milling duration can be independently controlled with known effect on the final results. low temperature – because of the high efficiency of milling and low heat generation, the solids will not be exposed to high temperatures. for extremely heat sensitive products, cooling jackets can be provided on the mill cylinder. chemical containment –solids are sealed and contained inside the mill, protecting the environment and operators. predictable scale up – scale up from small to large mills is very predictable. ball milling is one of the few unit operations that actual improve in performance and efficiency with increasing size. the abbe slice mill is the same as the product mill and can replicate all mill operating parameters but with very little product.

Ball Mill

Features of Ball Mill - Suitable for grinding material with high hardness The shape of the final products is circular No pollution for the powder with ceramic ball Stable performance Easy installation

Ball Mills

One of the oldest and safest methods for grinding of a wide range of materials of hardness upto 8 on mohs scale. Can be used for grinding of Practically any material wet,dry or sticky.

batch ball mill

Batch type Ball Mil is widely used in beneficiation, building material and chemical industries. It is suitable for dry-type grinding and wet-type grinding. It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries Features and Benefits Wet and dry intermittently to mill, mix, discharge material Used for ceramic raw material grinding, quartz, clay, etc. Large processing volume

Ball Mill

Type : Energy saving

Supply Ability : 1 Set/Sets per month

Port : Qingdao,Tianjin, Shanghai or others

Feed Size : Less than 30mm

Discharge Size : 0.4-0.047mm

Ball mill has very important position in the industrial production, especially is used for ore grinding in the ore beneficiation plant. Grinding mills are composed by the horizontal cylinder, feeding mouth, discharging mouth and the grinding head. The cylinder is made of steel plant, and inside the cylinder there fills steel balls. On the internal walls of the cylinder, lining board is equipped. During the working process of the ball grinding mill, the materials go into the grinding miller from the feeding mouth, and the cylinder will constantly rotate driven by the electric motor to bring the materials and the steel balls to a certain height and then they will fall down, and under the effect of the steel balls, the materials will be crushed, thus reaching the mineral grinding effect. The industrial grinding machines produced by CME Machinery are sold to many countries and areas in the whole world. Welcome to our company for visit and purchase.

Vertical Planetary Ball Mill

Power Source : Electric

Usage/Application : Industrial

Material : Mild Steel

Packaging : Box

I Deal In : New Only

Ball Mill

Technical features and advantages Suitable for grinding material with high hardness The shape of the final products is circular No pollution for the powder with ceramic ball Stable performance Easy installation The capacity and fineness can be adjusted by adjusting the diameter of the ball.

Ball Mill

Excellent for dry & wet fine grinding , mixing, reacting of colour paints, emulsifiers, enamels, refractoriies etc. Micro Ball Mills are provided with twin mouths for charging & discharging. Additional Gear & pinion are provided which results in power saving & smooth running.

Ball Mill

Container Capacity : 100 ltrs to 1600 ltrs

Ball mills are basically used for Particle reduction with the help of Grinding media. It consists of Cylindrical Shell made out of Mild Steel Sheet with or without lining of Steel or Rubber as per the application. The End plates are so designed to make sturdy with stiffners so as to withstand the rotational load of the Loaded Ball Mill. The Ball Mill is driven by pinion gear which drives the Ring Gear which is fitted on the Drum of the Ball mill. The Pinion gear is coupled to the Gear Box which is coupled to the Motor to ensure trouble free Performance. Bolted Flange covers are provided on the square opening of the Ball mill for loading and discharge of the material.

Ball Mill

Features Suitable for grinding material with high hardness The shape of the final products is circular No pollution for the powder with ceramic ball Stable performance Easy installation The capacity and fineness can be adjusted by adjusting the diameter of the ball. Description Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter. Application The ball mill is key equipment in grinding industry, especially in mineral ore dressing plants. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc.

Ball Mill Grinder Machine

We are working with a pool of professionals who are diligent at their work and make sure that the offered lot is packed in high quality material and timely dispatched. Our products are the most sought after in the market, as they are specifically made as per global and domestic quality managements.

Ball Mill

We are recognized as one of the chief Ball Milling Machine Manufacturers and Installers in India. Ball Mills are the equipments that are used for grinding and mixing of materials both dry and wet. Our Industrial Ball Mills are the essential components of many industries like chemicals, cement, Inks, Mineral Mixtures, Lime-Pazzolana, etc. the Planetary Ball Mill manufactured by us are designed to have special features which enables them to operate efficiently and smoothly like Replaceable Liners Heavy support stand Cylindrical shell has strong alloy steel trunnions. Cover, which can be easily removed. Our ball mills are efficient enough to work without assistance of any skilled labor. The machines are easy to operate and clean. Operational Advantages Uniform quality throughout the entire batch, batch after batch. Fineness accurately controlled by operating time, mechanical regulators being unnecessary. Ultimate fineness possible, less than 1 micron. Range of sizes for every production, semi-production or laboratiory problem. No workman's attention required while Mills is running. No skilled help needed at any time. Combined grinding & mixing accomplished most efficiently without loss of time. Equally suited for grinding both wet or dry products. Extremely low power consumption per unit of material. Easily cleaned.

Ball Mill

Color : all

Condition : New

Capacity : 1000

Voltage (V) : 440

Automation Grade : Semi-Automatic

Customisation : Customised

Ball Mill

ball mill is One of the oldest and safest methods for grinding of a wide range of materials of hardness up to 8 on mohs scale. Can be used for grinding of Practically any material wet,dry or sticky.

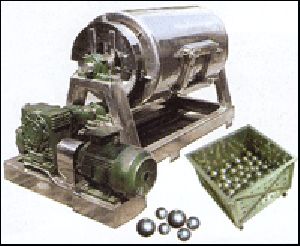

Ball Mill Motor Driven

Description :-For mixing & grinding, electrically operated having capacity of few gms to 1 KG & 2 KG. Fitted with geared motor with max speed of 80 rpm. The jar is made of SS and having steel balls of different sizes to be put in jar for mixing & grinding pesticides power. Jar is interchangeable and easily removable, light in weight and compact unit working on 220 V AC with 1 KG cap.— do — SS Drum 2 KG capacity— do — Aluminium Drum 1 Kg Capacity— do — Aluminium drum 2 KG capacity

Ball Mill

We are one of the leading Ball Mill Manufacturers & Suppliers in India. Our experts recommend only quality raw material to be used in the manufacturing of Small Ball Mill. Hence we provide optimum quality Industrial Ball Mill which is strong and durable. We strictly follow all the requisites to manufacture drive with motor and fluid coupling to input shaft. The inner shaft is coupled with the output shaft of the gear box.

Ball Mill

Voltage : 110V, 440V

Condition : New

Driven Type : Electric

Warranty : 5years

Application : Grinding Materials

Weight : 100-1000kg, 3000-4000kg, 4000-5000kg

Automatic Grade : Automatic

We are a celebrated Manufacturer, Exporter and Supplier of Packing Machine in Maharashtra, India. The Ball Mill that we bring to you has garnered wide acclaim due to its rugged construction, optimum quality and excellent productivity. In order to satiate variegated demands of the buyers, we proffer them out in tailored specifications as well. Our Ball Mill is offered at the discounted prices to all of you.

Ball Mills

We are one of the premier organizations involved in manufacturing and supplying of a wide range of ball mills in India.

Solid Carbide Ball Nose End Mills

1 Piece(s) (MOQ)

We are offering solid carbide ball nose end mills, solid carbide ballnose endmills available from sizes 1mm to 20mm with total length of upto 150mm available. Brands such as yg1 tiphoon, yg1 k2, hanita.

Ball Mill

We are well known for supplying of wide variety of Ball Mill.