aerosol filling machine

Get Price Quote

Rotary machine consisted of- Container Feeding Turn Table Indeed Conveyor. Automatic 2 Head Rotary Liquid Filling Unit. Single Head Crimping. Automatic 2 Head Gas Charging Unit. Technical Parameters : Pump Loading-Manual LPG Columns & Storage tank for Aerosol Containers Consisted of 6” dia. Column MS seamless pipe with pressure gauge & filtering unit & then after pass the filter 500Lit capacity of MS Storage tank to pass the filtered Gas. All Contact Parts-SS316 FLP Arrangement Filling capacity-10ml to 200ml Consisted of NO Container NO Liquid Filling & NO Container - NO Pump Loading (Pump loading by manually) as well as No Container No Crimping & No Container No Gas Charging. Consisted of Simple System for UHMW/CAST NYLON TURRET with Height Adjustment Any Change over for Varies as per dia. of the Containers in Crimping & Gas Charging unit. Gassing Head for Charging the LPG Gas which is applying with Booster Pump (Individually operation) & it’s operated with Two Stations ie. Initially filled with 40% & then after remaining 60% filled. Indexing with Pneumatic operation MANIFOLD separately for Rotary Liquid Filling as well as Crimping & Gas Charging Stations. Crimping Device-Pneumatic Operated Gassing Device-Pneumatic Operated Turn table Motor & Conveyor Motor with FLP (from Rotary Liquid Filling M/C to Gas Charging M/C) 0.5HP & 1HP respectively with Make - HINDUSTAN & with Suitable Gear Box Ratio Make - Bonfigloli as per requirement of Drive arrangement. LPG gas columns (will be kept at outside of the m/c) for molecules filtration before gas passing to the Gas charging stations via providing the storage tank. Operational Description : The Empty Containers Feed Manually onto the Feeding Turn Table which moves forward slowly up to the Filling Heads. It’s detect with FLP Sensors & after getting the feedback through the panel. Filling Nozzles will come down & filled the Containers as per settled Volume. This all operation will be done with Pneumatically operated. This Filled Containers moves forward & comes on to the further Line of Crimping & Gas Charging M/C Conveyor. During that time Pump Loading will be manually into the Filled Containers. It’s Moves forward to the Turret Cavity as per size of the Containers. This containers Index & rotate Clock wise with proper guiding & after indexing completion; Crimp the Pump with Pneumatic operated Cylinders. Crimping Setting will be done as per trial & error method which will set once a time with using Crimping & Checking the Depth Gauge as per standardise. After Crimping the pump; again Index the Turret with Crimped Bottle & Comes at Gas Charging station. At that time sense the container & give the signal to the Gassing Head. Gas will be fill into the Container which is pass through the Booster Pump ie. For Pressurize Gas filled into the Containers. For these operation we will provided Two separate Booster Pump due to easily filled the container with High Volume & for better accuracy as well as increase the productivity. These filled container moves forward to the next station & comes out at the Exit side conveyor. This whole assly. will be provided with Height Adjustable type due to Various Container sizes. Gas Charging will be operate as per requirement of Gas has to be charge & filled into the Containers ie. Either 2Nos OR 3Nos (As applicable) Gas charging will be applied as per depends upon the Filled quantity. These Gas Filled containers are moves forward from Gassing Exit Conveyor. This finish container comes out at the exit side of the Conveyor. This whole entire cycle repeat again & again with all sequence one by one & with Pneumatically as well as Electrically Logic operation (wherever applicable).

Paper Inserting Machine (top/bottom)

200,000 - 2,500,000 Per Piece

Best Deals from Industrial Machine

Semi-Automatic Pet Stretch Blow Moulding Machine

Get Price Quote

Semi-Automatic Pet Stretch Blow Moulding Machine SpecificationsPet bottle blow / blowing moulding / molding machine 1.Semi-automatic machine 2.Blow Capacity:1200-1600bph Pet bottle blow / blowing moulding / molding machine1.Semi-automatic machine 2.Blow Capacity:1200-1600bph 3.Max volume : 2L Semi-Automatic PET Bottle Blowing Machine 1. Controlled by MITSUBISHI touch screen computer. Operate consistently and simply. 2. Pneumatic elements from FESTO (German) and SMC (Japan) 3. Energy-saving and environmentally friendly design. Mechanical units are compact and rational. 4. Malfunction alert and diagnostic units allow easy maintenance. 5. Suitable for manufacturing a variety of PET bottles: mineral water bottles, edible oil bottles, soda bottles, medicine bottle, cosmetics bottles etc.. 6. Oven can be made according the different preform requirements of customers

Semi automatic plastic injection moulding machine

Get Price Quote

Owing to our enormous industry experience, we have been able to successfully cater to the varied needs of our clients by offering them quality assured range of semi auto plastic injection moulding machine. Our entire assortment is manufactured using best quality components and latest technologies. Further, this machine is fabricated with great precision by our experts in compliance with the set industry standards. Clients can avail this range from us at affordable prices. Features: precisely engineered reliable operation high functionality.

Industrial Cloth Dryer Machine

Get Price Quote

With a front loading design, robust construction. It has a distinctive appearance. Inside basket is made of stainless steel. Steam / electric or its combination, or thermic fluid heating is offered. Capacities varies from 6kg. to 100kg. Auto reverse & auto stop by digital timer.

Automatic Pan Feeding System For Broiler

Get Price Quote

Paper Ruling Machine

Get Price Quote

Leading Indian manufacturer of paper folding machine mfg, paper printing machine mfg, book binding machinery mfg, paper rulling machine mfg, automatic ruling machine, static, eliminator to neutralize paper, jogging arrangement, counting provided, speed increase and decrease in possible, self loading reel stand, no necessity of oiling in gears, high Pile. delivery. Send Online Query

Blindstitch Industrial Sewing Machine for Carry Bags

Get Price Quote

Leveraging the skills of our qualified team of professionals, we are instrumental in offering a wide range of Blind Stitch Sewing Machine to our clients. This Blind Stitch Sewing Machine has the mechanism to form single thread chain stitch by swinging hook thread take-off and penetrating the fabric with single arc needle.Features: Optimum performance Less maintenance Anti-corrosive

Servo Piston Filling Machine

Get Price Quote

Our Servo Piston Filling Machines are efficiently designed by the experts to provide a helping hand in the various hardcore industrial applications. These are renowned for giving hassle free operation in the small frame of time. Specifications Drip free nozzles with filling range of 100ml to 1000 ml to 500 ml to 5000ml (Different capacity available) Available from 4 head to 10 head Mitsubishi make plc system with 4" Touch Screen and VFD control for conveyor speed control. Contact parts in Stainless steel 304 quality Body frame made up of Stainless steel Capable of automatic intake of empty bottles in container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated Neck Entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage 12 feet conveyor with 4 Inches stainless steel slats Container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive Mechanically operated Nozzle Up-Down movement & Pneumatically stopper gates for bottle entry and exit. In built memory to store 25 filling slate Filling accuracy of el- 0.25% Power 415 Volts 3 phase 5EI Hz.

Poultry Feeding Machine

98,000 Per Piece

Paper Plate Making Machine

Get Price Quote

We offer highly efficient Paper Plate Making Machine which is ideal for producing paper plates. We offer Paper Plate Making Machines of different specifications and these Paper Plate Making Machines are easy to operate. We supply Paper Plate Making Machines as semi automatic and automatic. These Paper Plate Making Machines can even be operated by hand and can be used to produce plates and dounas of different sizes. These Paper Plate Making Machines are efficient and have a high productivity. Features : Available in different specificationsEasy to operateLow maintenanceIn Semi automatic and automatic optionsHigh outputEfficient Long service life

powder sieving machine

Get Price Quote

1p Piece(s) (MOQ)

Red Line RPS Series powder sieving machines are high performance machines. Models are available for capacities upto 240 kgs per hour.

Pressure Relief Valve

Get Price Quote

Our company holds expertise in offering quality Pressure Relief Valve. Designed with complete precision, our Pressure Relief Valve is known for superb quality, dimensional accuracy and exceptional durability. This valve is available in variegated specifications to meet diverse requirements of the buyers. Every valve is quality approved by the authorities after stringent quality tests. We take up bulk orders of Pressure Relief Valve and fulfill the same with utmost ease.

automatic shrink wrapping machines

Get Price Quote

Shrink wrapping machines suitable for gift's confectionery, bottle, cosmetics etc. It's a high speed of sealing machine and high equipment sealing. The complete process is visible & is furnish with L- sealer shaped. The automatic process of shrinkable pouch complete with web- sealer. We are provide very high quality of heat-sealing machine and branded shrink machines. It's very easily used.

Induction Cap Sealing Machine

Get Price Quote

Induction cap sealing machine, The Arshad Fluxosealer™ BREZO P is a manual induction cap sealing machine that is used for laboratory andor low production volumes. This machine consists of a hand held induction sealing head placed over the capped bottle. The Machine starts sealing upon activation by a switch. The sealing time is preset using the Timer on the machine panel. Input Voltage: 230 Volts AC, Single Phase 50 Hertz. 7 Amperes. Sealing Speeds: 4 – 6 bottles per minute. Neck Diameters: 20mm - 83mm. MOC: Mild Steel Powder Coated Enclosure. Max. Power Consumption: 300 Watts. Footprint Dimensions: 400mm x 400mm x 200mm (lxbxh).

Desilting Machine With Tipping Container

Get Price Quote

Mac Lifton Desilting cum dumper is a two in one machine a new concept in open drainage cleaning. The two in one machine is designed to clean open drains with the help of its excavator like arm. The silt is then loaded on to the container provided on the vehicle and then dumper at the dumping site.These machines are suitable for lifting and removing accumulated deposits of silt, debris, grit, pebbles. stones rubbles, grass, animal dung, twinge, vegetables, small branches of tree etc. for establishing the free flow in the drains.

Feeder Management Relay Machine

Get Price Quote

Shrink Chamber Machines

Get Price Quote

Semi Automatic Lid Placing & Pressing Machine

Get Price Quote

Features Smooth operations Long service life Minimum maintenance

Automatic Sleeve Shrink Wrap Machine

Get Price Quote

Automatic Sleeve Shrink Wrapping Machine" is distinguishable from other types of shrink wrapping equipment in that the two ends of the package have an opening (often called "bulls eyes") such as commonly seen for water bottle packaging where the openings can act a handles. In point of fact a sleeve wrapper is an excellent solution for bundling a wide variety of products and is often called a "bundler". Our Sleeve Wrappers are available in a wide range of size capabilities and configurations from manual feed to fully automatic with collating. Speeds generally decrease between cased product The Wraps manual two reel sleeve wrapping machine is the lowest cost method of producing a shrink wrap for transit purposes. The system consists of the FE sleeve wrapper and the M25.40T shrink tunnel. Each machine uses a 13 amp single phase electricity supply making it an extremely mobile wrapping solution. Shrink wrapping for transit purposes uses Polythene shrink film, the lowest cost shrink wrapping film available. One reel of film is mounted at a high level and the other is mounted at a low level. The two reels are joined by the sealing head, forming a curtain of film through which the product is pushed. The product to be wrapped is manually pushed through the curtain of film, enveloping the product. The sealing jaw is then brought down by hand, cutting and sealing the film producing a loose sleeve of film around the product. The next product to be wrapped then pushes the wrapped product into the heat shrink tunnel. In the tunnel the heat shrinks the film around the product leaving two open ends at the sides. The width of the film used compared to the width of the product determines how much of an open end is created. The Automatic Sleeve Shrink Wrapping Machine is suitable for products up to 550mm wide and 400mm high. Speed of operation is up to 400 products per hour. Additional features available with side feed sleeve wrap machines: Easy access and easy change of pusher - the pusher takes seconds to replace thanks to excellent access to the relevant part of the sleeve wrap machine. It’s also incredibly flexible; as many pusher plates as required are provided free of charge at the point of ordering Out-feed belt - the powered out-feed belt drives the pack automatically into the shrink tunnel, again useful for heavy or unstable collations. If it's an Automatic sleeve shrink wrapping machine that you need, then YPS can help. We supply a wide variety of sleeve sealers. We offer a range of high-speed sleeve wrappers aimed at the mineral water and soft drinks industry and specialist machines to wrap large items. Click start button below to view Video. All sleeve wrappers benefit from the following features: Fully safety guarded to exceed C.E. Marking regulations Heavy duty build quality to provide years of service Available in a variety of sealing sizes and in-feed arrangements Easy and intuitive to operate ‘Best in Class’, Heavy duty Teflon blade: this sealing system is more effective than a wire as it provides consistently strong seals and requires less maintenance than a three wire sealing system Pack clamp: fitted as standard on our sleeve wrap machines. This device clamps the pack securely in place while the film seals – absolutely critical for collation and unstable packs. Programmable pack counters to provide accurate shrink wrapping production and efficiency data, fitted as standard. All of our high speed sleeve wrappers offer the following benefits: High production speeds to reduce production time A heavy duty sealing blade for consistently strong seals Jaw / product safety device to protect the operator Perfect shrink tunnel air distribution for consistent, high quality results Automatic shrink film feed to both rolls for ease of use Automatic and manual cycle controls for convenience Programmable computer controlled memory for faster and effective operation Print registration options to enhance operations Variety of infeed arrangements for complete flexibility Heavy duty frame construction for years of continued use Side chains in the shrink tunnel for improved strength Sleeve wrap machines are more used in Mineral water manufacturing company Food industries like juice and jam making Pharma syrups bottle sleeve insertions Edilbe oil manufacturing companies And all pharma and non pharma companies

bright bar machines

Get Price Quote

The Bright Bar Division manufactures a wide range of bright bars, specialising in stainless steel, through different processes like heat treatment, quenching and tempering, pickling, cold drawing, peeling, smooth turning, centreless grinding and polishing.

Battery Sealing Machine

Get Price Quote

It is suitable for circumstances where the size of the cartons does not change frequently, which especially fits for continuous sealing of cartons in the same size. The machine is used in the fields of the domestic electrical appliances, foodstuffs, general merchandise, medicine & chemical industries.

Semi Automatic Carton Tapping Machine

86,000 Per Units

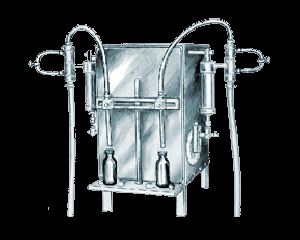

Liquid Filling Machine

Get Price Quote

• Precision and sturdy built Doube Head Machine. • Provided with two syringes. • Most accurate filling system. • Simplified changeovers. • Diving nozzle system for foamy liquids (optional). • 1000 to 2000 containers per hour. • Size: 60 cm. X 45 cm. X Ht. 75 cm. • Weight (approx.): 150 kg. • Electricals: 0.5 H.P. To 2 H.P. in 1 or 3 phase. According to the filling capacity.

Socket

128 Per Piece

Tube Filling Machine

Get Price Quote

We are offering tube filling machine. our tube filling machine is precision engineered by the authentic manufacturers, who use only latest technology and machinery. These tube filling machines are exceptional to fill and seal of both plastic and laminate tubes. Being an authorized aluminum tube filling machines suppliers in india, we offer customized solutions with all our products. Further, our range of tube filling machine is effectively used in food products, pharmaceutical and light industries. This tube filling machine range also consists of aluminum and plastic tube filling machines. features there is requirement of only one attendantdetachable tube holder chain reduces both the time for repairs (if any) and maintenance costonly specified quantity is filled in the tube that relates to the filling accuracythe perfect sealing solves the issues of leakage and damageit is the most desirable machine used to fill the laminate and plastic tubesthe tube holders are kept at a particular height for negating any kind of damage to the tube

Lug Capping Machine

37,500 Per Piece

Continuous Pickling Lines

Get Price Quote

Automatic Liquid Filling Machine

Get Price Quote

Rapid Prototype Machine

100,000 Per Unit

1 Unit (MOQ)