Internal Gear Pump

Get Price Quote

We are offering internal gear pump. the function internal gear pumps belongs to family of positive displacement pumps where in driving gear with internal tooth drives the gear and turns in same direction inside the pump casing.during the rotation of the driving gear the liquid intake takes place at the suction and during the gear meshing, the liquid is displaced outside in the delivery side. Advantages of gear pumps self priming pumps steady deliveries without pulsation for clear liquids or with little pulsation but without vibration and noise speed directionally proportional to capacity highly suitable to handle viscous clear liquids and temperature up to 250 deg c can be offered with wide variety of material of construction to suit various corrosive media technical specification capacity : from 10 lph — 45,000 lph pressure : up to 10 kgcm2 viscosity : as low as 1.0 centre stoke — 300,000 centre stoke applications the internal ggear pumps are use to handle the following clear fluids furnace oil mineral oil edible oil petroleum gelly paints & varnishes solvents chemicals acids alkalis hot syrups type of industries using gear pumps brewery and distillers cattle feed chemical and process cosmetics and toiletries edible oil effluent treatment fertilizer fisheries man-made fibres marine oil exploration paint and varnish paper pulp and cellulose petrochemical and refinery printing ink soap and detergent starch steel sugar sewage and waste water treatment

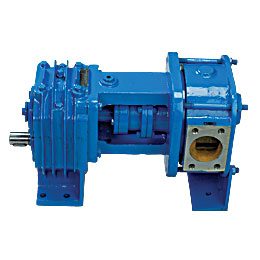

Internal Gear Pumps

10,000 - 150,000 Per 1

1 1 (MOQ)

The DIG series is modular developed with excellent interchangeability. The pump is available either as bracket mounted 'BM' or gearbox mounted 'GM" models.

Best Deals from Internal Gear Pump

Internal Bypass Gear Pump

Get Price Quote

We manufacture, export and supply precisely engineered Internal Bypass Gear Pump. Using high quality raw materials and hi-tech machines, our Internal Bypass Gear Pump is manufactured. The entire manufacturing process is carried out under the supervision of experts and thus there are minimal chances of flaws. We make available NSA /NSB series pumps with PRV & external bypass arrangement. Place bulk orders for Internal Bypass Gear Pump with us! Important Features : Hardened & ground internals of high quality steel : Offers better wear & tear resistance. Pump body of graded Cast Iron with additional alloying elements : Provides higher wear resistance and allows to handle high temperature fluids. Mechanical Seals of high quality sealing faces supported by suck back system : Sustains suction capability and avoid leakages. Shaft without any circlip groove : Delays fatigue means smooth, long trouble free operation. Needle roller bearings (Optional) : Avoids jamming, seizure and shearing resulting in smooth & efficient operation.

Internal Gear Pump

Get Price Quote

Delta DIG series employs proven Internal Gearing (Gear within Gear) principle for pumping. The main gear is keyed to the drive shaft, and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover maintains a small, but positive clearance to achieve perfect scaling between parts. As the gears come out of mesh, a partial vacuum is created, forcing the fluid to rush into the pump casing and fill in the voids between the teeth. Both gears rotating in the same direction of rotation gently transfer the fluid to the delivery port. The resulting action is a smooth-steady flow; low in pulsation, noise and vibration. Single shaft design well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. External bearing construction offers easy access the pump components i.e., rotor set and even pump casing simply by removing the front cover without disturbing drive parts, bearings etc., and in place. Block pump mounted integrally on hollow shaft gearbox automatically reduces the speed (in several ratios) and enables even the pump rotor to be pulled out without disturbing the drive! It is easily possible to jacket front and rear covers for products heating - thus making the design unique and versatile - ideally suited for process pumping.

Internal Gear Pump

Get Price Quote

Typical Applications Handling of fuel oil,& polymers, asphalt & bitumen,food products, Grease etc.

PGI103 Internal gear pumps

Get Price Quote

Medium Pressure Series PGI100PGI101PGI103 Internal gear pumps, medium pressure range Essential performance data: Available in sizes 2, 3, 5 and 6 5.4 cm³rotation - 100 cm³rotation Nominal pressure of up to 250 bar; maximum pressure of up to 320 bar Speed of up to 4000 rpm Also available as a multiple pump

TROCHOIDAL GEAR PUMP / INTERNAL LOBE PUMP

Get Price Quote

WORKING : There are two Pumping Elements with Gear in Gear Principle. The Rotors are mounted on single shaft well supported on both the ends. As the Shaft Rotates, they mesh & un-mesh displacing the liquid axially through its pumping elements. Axially flow through elements ensures better suction capabilities, very low noise level and nearly pulsation free flow. These pumps have low power consumption compared to other brands due to unique mounting rotors. Rotors are produced using sintered metal technology and the other components are produced using the advanced manufacturing techniques with all the necessary quality checks for repeated accuracies in dimensions, guaranteed interchangeability and near to perfect pumping characteristics. This Series is highly reliable when put to work on field, has longer service life, practically needs no maintenance and has reduced cost of the end product than the conventional equivalent to the customer. A standard pump would consists of Rotors in Sintered Iron, with built – In Relief Valve, Shaft in EN-8 / SS-304, Lip Seal in Nitrile and all other parts in Cast Iron. APPLICATION : Unloading and Transfer of Lubricating Oil from Tanks and Barrels Oil Circulation, Gearbox, Bearing and Pressure lubrication Transfer of Fuel Oils from Daily Service Tanks, Pre Heaters and Filters Transfer and Circulation of Oil in Transformer & Oil Cleaning Machines Fuel Injection Pumps and as Booster Pumps in Oil Burner Services Unidirectional Flow Designer and Reversing Shaft Duties as in Machine Tools, Gear Boxes and Crane Duties In Hydraulic Power Packs Low Pressure – Continuous and Intermittent duty application TYPICAL LIQUID LIST Lubrication Oils, Fuel Oils like HSD, LDO, Furnace Oil, Transformer Oils, Palm Oil, Hydraulic Oils, Additives, Shampoos, Coconut Oil and media having good lubricating properties OPTIONAL MOC Under Special Execution we can offer pump in Stainless Steel, Ball Bearing Construction and Seals in Viton or EPDM. MOUNTING Monoblock type Pump and Motor eliminating need of Coupling and Frame. Foot Mounted Pump Coupled with Motor on a Base Plate with Coupling Guard Flange Mounted Pump Coupled with Motor using a Bell Housing Bracket FEATURES Compact, Light Weight, Easy to Mountain and Neat Design Can be Serviced in place without disconnecting the pipelines & Motors (Applicable even for Mono Block Construction) Bi-Directional Integrated Shaft in Mono Block construction eliminating the shaft runs out for the improved life of the lip seal. Also, Shaft is supported on 2X Bush Bearing as well as 2X Ball bearing reducing the load on shaft as well as the pumps Pump Shaft Dynamically balanced and Heat Dissipation is improved in Mono Block Design Engineered to run at high Speeds and adaptability of Mechanical Seals for Critical Applications even for lower flow rates Advanced Metallurgical Composition for Better and Longer Rotor Life Lower Power Consumption & High Volumetric Efficiency Pump with steam Jacketing on Request With Built-In relief Valve Improved Rotor Profiles for Smooth Meshing minimizing the Internal Losses and for excellent Suction Capabilities

Internal Gear Pump

Get Price Quote

We are offering internal gear pump. Rotary internal gear pump has only two moving parts. “a gear within a gear”. The positive displacement of liquid is achieved by the complete filling of the spaces between the teeth of the rotor and idler gear. With every revolution of the pump shaft a definite amount of liquid enters the pump chamber through the suction port. This liquid fills the spaces between the teeth of the rotor and the idler. The crescent on the pump head splits the flow of liquid as it is swiftly moved towards the discharge port. The idler gear moves on hardened and ground eccentric pin. Pump is designed with built-in relief valve. pump capacity available from 10lpm – 1000lpm, pressure 15kgcm2

Internal Gear Pumps

Get Price Quote

FUEL INJECTION INTERNAL GEAR PUMPS ROTARY INTERNAL GEAR / LOBE TRACOIDAL PUMP

Internal Gear Pump

Get Price Quote

Internal gear pump consists of a rotor ad idler. Liquid travels between them through “gear-within-a-gear” principle. Pump head forces the liquid to move out of discharge port. A seal is formed between the discharge and suction ports. This pushes liquid out of the discharge port.Easy on maintenance with two moving parts and one stuffing part.

Internal Gear Pump

Get Price Quote

We are offering internal gear pump.the internal gear pumps that we offer have two moving parts and one stuffing box. The self-priming and bi-rotational internal gear pumps that we provide are ideal for high – viscosity applications. Besides, the internal gear pumps that we offer are fabricated from mild steel, pb10 material and stainless steel.

Internal Gear Pumps

Get Price Quote

The very first pump produced by Delta Group in 1968 was an Internal Gear Pump Model DIG-10 for low-pressure burner service - till this day it is in production with great success. Subsequently Delta Group had the foresight to introduce several other designs, to take care of growing industrial demands, thus placing themselves on the forefront in the field of Rotary Positive Displacement Pumps. Experience gained over years in designing and building Rotary Pumps combined with knowledge in Application Engineering has resulted in this development of New Stainless Steel Internal Gear Series specifically for food, chemical and pharmaceutical industry. Innovation, simple construction has ensured very easy maintenance and totally reliable hassle free installation. Working Principle Delta DIG series employs proven Internal Gearing (Gear within Gear) principle for pumping. The main gear is keyed to the drive shaft, and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover maintains a small, but positive clearance to achieve perfect scaling between parts. As the gears come out of mesh, a partial vacuum is created, forcing the fluid to rush into the pump casing and fill in the voids between the teeth. Both gears rotating in the same direction of rotation gently transfer the fluid to the delivery port. The resulting action is a smooth-steady flow; low in pulsation, noise and vibration.Single shaft design well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. External bearing construction offers easy access the pump components i.e., rotor set and even pump casing simply by removing the front cover without disturbing drive parts, bearings etc., and in place. Block pump mounted integrally on hollow shaft gearbox automatically reduces the speed (in several ratios) and enables even the pump rotor to be pulled out without disturbing the drive! It is easily possible to jacket front and rear covers for products heating - thus making the design unique and versatile - ideally suited for process pumping.Salient Features Smooth quite flow ReversibilityExcellent self priming Bracket/ Gear box mounting allows free expansion/ contraction - alignment not affectedInsensitive to viscosities Easy maintenanceAll metal construction, no contamination Built-in reducer offers ideal speed range 240~960 RPMSingle sealing, external bearing Slow speeds ensure better pumping & longer lifeLow noise and pulsation Reduced maintenanceConstruction The DIG series is modular developed with excellent interchangeability. The pump is available either as bracket mounted 'BM' or gearbox mounted 'GM" models. The bracket mounted casing construction provides stress free operation while handling products at higher temperatures. The major components are casing, front cover, rear cover, seal box (casing parts) and rotor set (rotor, idler and shaft). Most casing components are made by lost wax process for better finish and grain structure.'GM' version offers a choice of different speed ratios, making it easy to handle viscous products besides eliminating problems of alignment, extra set of coupling. Standard 4 pole or 6 pole motors can be directly coupled to such units making it very reliable, compact and clean drive. Another unique feature is the adjusting clearance between rotor set and cover by means of rotor positioning device enabling to restore pump capacity even after wear and tear after a long use.Pumps can be equipped with Heating/ Cooling Jacket on front cover/ rear cover and in some cases also Pump Housing. Choice of Mechanical Seal/ Stuffing box is available for shaft sealing.Typical ParametersCapacity upto 800 LPMPressure upto 14 kg/cm2Viscosity upto 100,000 cStTemperature upto 200°C

Internal Gear Pump

Get Price Quote

Internal gear pump, Gear pumps provide a comparably continuous, non-pulsating flow in relation to diaphragm pumps or peristaltic pumps. For this reason, gear pumps may be preferred in a number of applications from laboratory to petrochemical and marine applications, and processes involving hydraulic presses and dry pit steam power. Gear pumps are reliable when using media with heavier viscosities, however, build up or interference within the internal mechanisms may cause the gears to rotate more slowly. The addition of a pressure relief valve to the system may help to alleviate some of this slow down, and provide a longer life cycle as well.

CUTAWAY INTERNAL GEAR PUMP

Get Price Quote

Innovative yet simple design with internal gear and vane Can handle high or low viscosity material Symmetrical internal structure: can run in either direction. Can be provided with heating jackets, safety valves or other modifications. Can be made with cast iron, carbon steel, stainless steel (AISI 304 / 316), bronze.

internal rotary gear pump

Get Price Quote

internal rotary gear pump, Chemical Process Pumps, pvdf chemical process pump

Internal Gear Pumps

Get Price Quote

Internal Gear Pumps, Agitator Seals, Multi Spring Seal (LIE-701