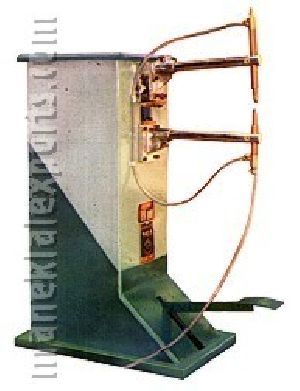

Spot Welding Machines

Get Price Quote

Features: - Electrodes, Electrode Holders and Arms water cooled. Water should be free from residue forming impurities and at a temperature below 30oC. (If water temperature is higher, increased water flow required) - One Pair Morse Taper 2 straight electrodes supplied as standard with the machine. (Other types available on request) - Pressure on the Job obtained by means of heavy spring on the pressure rod at the back of the machine - Adjustment of Electrode Force by means of a calibrated nut. Force is adjustable and gives a constant force from 100 - 200 kgf. with 30 kgf. applied on the foot pedal. - Adjustment of Electrode Stroke by vertical adjustment of the lower electrode holder - Current Control by means of 6 tap change links between 50% and 100% - Weld Initiation by means of mechanically coupled switch which initiates the weld only after preset pressure is built - Solid State Electronic Timer and Heavy Duty Electromagnetic Contactor provided as standard equipment with the machine - Timings: Short Range 5 - 50 cycles. Long Range 1 - 10 seconds (50 to 500 cycles) Applications: - Spot Welding, Electro-Brazing, Cross Wire Welding, Resistance Heating and Soldering - Capable of Welding Stainless Steel, Brass, Phosphor, Bronze, Alloy Steels, etc.

MIG Spot Welding Machine

65,000 - 85,000 Per piece

1 Piece (MOQ)

Best Deals from Spot Welding Machines

Spot Welding Machines For 20-200ltrs Barrel

Get Price Quote

1 Piece(s) (MOQ)

The rocker arm spot welding machine is an important machine in manufacturing Drums & Barrels. It is better to give some spots to the body sides before side seam welding operation. The machine can also be used for spot welding the handles etc.

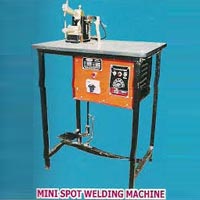

Spot Welding Machine

Get Price Quote

APPLICATIONS - Spot Welding, electro-brazing, cross wire welding resistance heating and soldering. The machines are also capable of welding stainless steel, brass, phosphor, bronze, alloy steels, etc. Specific details can be sought on request.

Spot Welding Machine

Get Price Quote

Our Spot Welding Machine is, precisely designed by experts in accordance with clients’ demands. For the convenience of clients, we also provide custom-built service of our Spot Welding Machine. Salient Features Pedal operatedProvided with thyristor controlModels from 6KVA to 300KVAMulti head welding with automationSuitable for pneumatic spot welding application

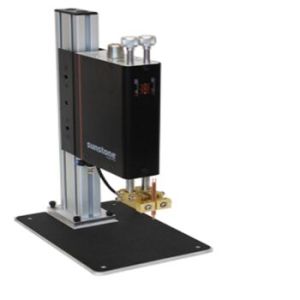

Digital Spot Welder

Get Price Quote

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. Based in Mumbai(India), we have gained wide appreciation owing to our high quality products and client-centric approach.

Spot Welding Machine

Get Price Quote

We offer quality spot welding machine, which is fabricated using latest technology. Our spot welding machine is best suitable of welding all kinds of metals. We have gained huge appreciation for high performance and durability of spot welding machine in both domestic and international markets. We are reckoned as one of the leading manufacturers and exporters of spot welding machine. Salient features small heat effect areawelding spot can be adjustedelaborate and clear spottoo much after-procession is not neededaccurate orientationno damage to the jewelryhigh welding speed with high quality no pollution uses can weld all kind of metals

Container Side Seam Welder machine

Get Price Quote

This welding machine is for tin sheets, black sheets and tin free sheets equipped with wire feed system, and one complete set of arm assembly consisting of z-bar , saddle, forming rollers etc. fully solid state thyristor weld control.

Spot Welding Machine

Get Price Quote

JK Spot Welding Machines are elegant in design, appearance and versatile in mass production lines of Engineering Industries, Sheet Metal containers, Drums, Barrels, Electrical and Electronic Instruments, Radio & Communication equipments, Furniture, Kitchenware, Automobile Assembly and Ancillary Lines, Toys, Air Conditioners, refrigerators, Electrical Machines and Switchgear manufacturing units. An accurate electronic timing device is provided in each Spot Welders. The timer is calibrated in two ranges. The short time range from 5 to 50 cycles and longer 1 to 10 seconds in steps which provides ease and comfort to operators for mass production. SPECIAL FEATURES: Designed for continuous and heavy duty production. Special pedal design ensures operation of machines from any convenient side. Ideal for welding M.S. and low carbon steel and slight modifications also suitable for Stainless Steel, Tin, galvanized Sheets, H.C. steel and Brass

Seam Welding Machine

Get Price Quote

APPLICATION :Spot welding, projection welding, cross wire welding, resistance heating, electro-brazing, With special attachments it is also possible to weld nonferrous material within certain limitions. USERS : Include - but are not limited to general engineering work-shop, makers of furniture, electrical instruments, containers, barrels and drums, telephone, radio communication devices, clocks, kitchen-ware,textiles machinery and spares automoblies-ancillaries,toys, air-conditions, refrigerators, motors, switchgear, etc. STANDARD FEATURES - ALL MACHINES :MAIN SUPPLY-415 Volts. Single Phase (2lines of 3 phase supply) 50 Hz. AIR OPERATION :Spring follow-double acting cylinder; Air line filter, lubricator, regular pressure gauge; Electric Solenoid Valve; Machine machanically capable of 125 operations/minute. ELECTRICAL - Foot Switch/Palm Button; Weld/No Weld Switch;Pressure Switch; Transformer in Class 'F' Insulation. provide with 8 current regulating taps between 55% and 100% output; Contrail circuits at less than 110 Volts. COLLING - By water with separate circuits for main Transformer, Secondary conductor and Electorder. die (in case of projection Welders) Thyristors. Each circuit to terminate in sight cup provide; wheel valves each circuit. PROTECTION - Transformer, Thyristors by themosate against water failure; Luminous overload indicator on panel. ELECTRONIC CONTROLS :Microprocessor based solid state Electronic Control with Thyristor Contact or unit.SPECIAL FEATURES AVAILABLE ON REQUEST : Actuation - Hydraulic-Motor H Air Reservoir h RTap Change Switch h Refrigerated or closed circuit cooling h Voltage/Current compensation h Other Voltages, Frequencies Special Purpose machines for /Special application, or Non Ferrous metals or Stainless and other exotic Steels electrodes h Special Tolong for projetion Welding Special Locating jigs for Spot /Switch Welding h Geneva Index \tablets h Automatic Feeders h Customer Ideas. We also manufacture :Arc, Butt and Seam Welding Machines; Salt Bath Furnace Transformer, Electronic Welder Controls, Electronic contractors etc.

Spot Welding Machines

Get Price Quote

Deepak Industries was established in the year 1951, a company with an experience of 62 years in the field of industrial machineries, situated in Byculla - Mumbai, around 2500 sqft size of the factory manufacturing Induction Heating Machines, Welding Machines, Spot Welding Machines, Butt Welding, Arc Welding, Seam Welding, Projection Machines, Transformers, Heating Coils, IGBTs, High Ampere-High Volt Heating Machines,Timers, etc...Best in quality and service, serving customers successfully from 53 year across India, Srilanka, China, Dubai and many more countries to be discovered. A family run business but incorporated and managed by professionals with management background and skills to make he products more and more innovative and customized. The top management consists of 2 partners one responsible for the marketing and customer relations and the other heading the manufacturing and quality division. Equipment used are high tech transformers, timers, heating equipments, etc. We deal with national as well as international clients some of them include Art D Inox, Jindal steel, Maggpie, Crompton Greaves, Fortune Steel, Anjali Kitchenwares, Marvell Housewares, Godrej & Boyce, Siemens India,etc. Our products can be used in Iron and steel industries, automobile industry, Utensil manufacturers, electronic equipments, etc.

Spot Welding Machine

Get Price Quote

We present premium spot welding machine, which is widely demanded in the market due to its high strength and superb quality. We are reckoned as a prominent spot welding machine manufacturer, exporter, and supplier from india. Our spot welding machine has set a bench mark in the drum manufacturing industries due to it unparalleled performance and cost effective prices. features : easy operation robust construction hassle free functioning tensile strength anti- corrosive maximum durability used for : spot welding of handles on top of the drums

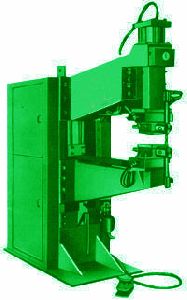

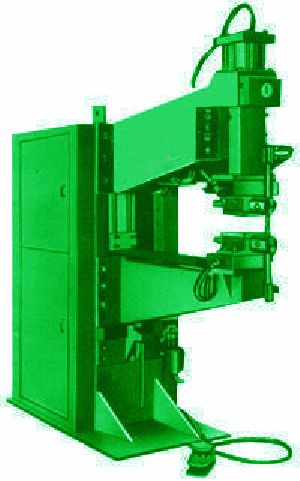

Press Type Projection Welders

Get Price Quote

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting.Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation. These machines are designed and manufactured conforming to the Indian Standard Specification No.IS:4804 Part I and III by a team of highly experienced engineers in welding technology. Specifications: Standard Ratings: 50, 75, 100, 150, 250 and 300 KVA @ 50% duty cycle. Type: Air operated, stationary press type projection welding machine with pneumatic cylinder mounted directly on the upper arm. Construction: Main frame of the machine is of heavy, rigidly reinforced welded steel construction, streamlined appearance with maximum resistance to deflection. Transformer enclosed in the main frame and pneumatic accessories mounted on the side of the machine and upper and lower arms mounted directly on the frame. Current is carried from the upper transformer terminal to the upper platen tooling through a 'U' shaped laminated copper flexible link designed to provide rolling action as the welding head reciprocates during operation. The welding head is of antifriction type. The pneumatic controls mounted on the side of the machine. The operating control station mounted on the machine is clearly visible and within easy reach of the operator. Standard Throat Depths: 300, 450, 750 mm. Welding Transformer: Transformer conforms to IS:4804 Part-I and RWMA Standards, water cooled, class 'F' insulation with thermo switch protection for overloading. Current Control: Welding current adjustable from 50 to 100% by means of a tap change links. Cooling System: Transformer, Bus Bars, Platens, Electrode and Thyristors are water cooled, followed by discharge to an open drain-pot for visual observation of flow. Water Flow Switch (Optional at Extra Cost): Water flow switches may be provided with the machine to ensure adequate flow of the water for Transformer and Thyristor circuits while operating the machine. Platens: Constructed from high quality copper alloy accurately machined, having 'T' slots to international standards. Dies Toolings: Machine can be provided with custom-designed projection welding dies to suit various sizes and shapes of work pieces, and suitable jigs and fixtures for holding, guiding and indexing of the work pieces, as required, at extra cost. Electrode Control System: Upper electrode actuated by a heavy duty 2-way cushioned pneumatic cylinder controlled by an electrically operated solenoid valve. Compressed air at 1.5 Kg/cm2 - 7.0 kg/cm2 (20 to 100 p.s.i.) acting on the pneumatic cylinder provides electrode force. Machine provided with air filter, air lubricator, air pressure regulating valve and air pressure gauge. High Lift Facility (Optional at Extra Cost): "High Lift" (retractable upper electrode) facility shall be provided by means of special cylinder. A hard/foot operated air valve causes the upper electrode to lift to the top most position for easy introduction of the job into the throat of the machine. The retraction as well as the working stroke is adjustable within a range. Dual Pressure System (Optional at Extra Cost) : Dual pressure system shall be provided by means of 2 sets of regulating and controlling devices and the necessary air circuits. Working in conjunction with special control units, this facility would enable application of a higher force on the job being welded at any point during the weld cycle. Air Reservoir (Optional at Extra Cost): An air reservoir of suitable capacity shall be provided to minimise pressure drop during welding. Adjustment of Welding (Electrode) Force: By adjusting the air pressure regulator provided on the machine. Adjustment of Throat Gap: By vertical adjustment of lower arm. Weld Initiation: By means of operator's foot switch / hand operated switch connected to a low voltage safe initiating circuit. Controls: Appropriate Control will be incorporated with the machine as per requirement. Service Requirements Power Supply: 415 V, single phase, 50 cycles, Machine suitable for connection to 2 lines of 3 phase supply. Main supply cables 2-core type, disconnect switch with fuses of size recommended to be provided by the customer. Compressed Air: Customer to provide air supply at recommended flow volume at a minimum pressure of 5.6 kg/cm2 (80 p.s.i.). Cooling Water: Cooling water at minimum 2.1 kg/cm2 pressure and temperature below 30oC at recommended flow rate to be provided by the customer.

Press Type Projection Welders

Get Price Quote

Wheel Aligner, BLUETOOTH WHEEL ALIGNMENT, VIDEOGRAPHIC WHEEL BALANCER

Capacitor Discharge Spot Welder

Get Price Quote

pneumatic butt welding machine

95,000 Per Piece

Spot Welder

Get Price Quote

Throat Depth (mm) 150 - 200 150 - 200 200 - 250 200 - 250 250 - 300 250 - 300 300 - 350 300 - 350, Models(KTS) 3 KVA 5 KVA 8 KVA 10 KVA 15 KVA 20 KVA 25 KVA 35 KVA Throat Depth (mm) 150 - 200 150 - 200 200 - 250 200 - 250 250 - 300 250 - 300 300 - 350 300 - 350 Throat clearance (TG) mm 150 200 250 250 300 300 350 350,Range of Welding Voltage 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V

Portable Suspension Type Spot Welder

Get Price Quote

Overhead suspension type transformers with portable spot welding guns are designed for high speed production to meet the needs of vast number of metal fabrication shops particularly for manufacture of automobile bodies and sub assemblies. Variety of guns viz. "C" type, Scissor type and Bell crank type with different throat depth and gap are available to suit simple or complex welding set up. The machine will be supplied with suitable Electronic Control depending upon the application.

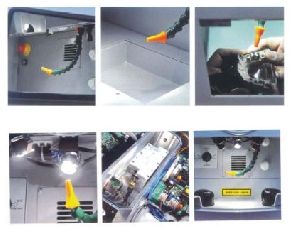

Forza Desktop Laser Spot Welding Machine

Get Price Quote

Focused towards delivering the utmost product range in terms of quality, we conduct frequent quality checks. Our customer-centric approach while making online or offline procedures makes us a reliable name. We keep a close eye on the transactions made to keep all the information shared by the clients safe and confidential. Technology : The new digital microprocessor incorporated in the FoRza works 100 times faster than traditional systems. and is able to measure the high energy precisely, analysing it and sampling it every 100 micro seconds. This makes welder FoRza a powerful machine while at the same time constant and very precise in the repetition of the shots. Features Real time and automatic regulations of the power supply. Double light LCD Touch Screen Shutter. Automatic control of the laser lamp, with consequent automatic adjustment of the energy. Integrated webcam Better cooling chamber & Efficient air cooling system. 6 preset pulse shaping programs Argon Gas nozzle directly on the welding point Air nozzle for cooling pieces in the working chamber Extractable drawer for the chamber cleaning Low noise and low maintenance 100memories parameters Frontal and big doors Optional on board LIVE Video Camera LASER APPLICATION Easily weld precious metals and other, including platinum, titanium, gold, silver and palladium. Repairs old jewellery perfectly. Repairs molding without removing the stones. Welds the elements using weld materials, and leaves them clear, sharp and without the need to clean again. Repairs casting defects such as porosity or breakages. by simply welding those areas with solder wire. Suitable for high-productive cycles Welding Samples Welding broken ring Welding on Jewellery joints Working directly on the models Welding of pins Repairs scratch and casting defect Reconstruction of stones setting

Laser Spot Welding Machine

Get Price Quote

We are offering laser spot welding machine. versatility of modulating power and speed in a nicer looking cabinet and improved reliability with added features: color touch-screen display for an easier access to working parameter and better machine-to-operator interfacing/messaging fully displaying basic working parameters power, time, frequency of repetition, spot size; and by the joystick inside the welding chamber memory cells to record permanent working settings for later use preset pulse-shaping programs for laser-welding alloys with special metallurgic characteristics halogen light adjustable by dimmer argon-gas supplied coaxially to the laser-beam over targeted object large integrated sealed circuit for cooling the flash-lamp specifically devised for longer laser-welding sessions by experience, the flash-lamp will last for at least 5 million pulses thanks to its reduced size and weight, this unit is easy transportable applications of clw – 100dt/ 60dt weld precious metals easily, including platinum, titanium, gold, silver & palladium repair perfect antique jewelry repair the frames without having to remove the stones repair watches & other components, even the glasses weld filler materials using the elements & lets you clear , crisp & with no need to clean up repair fusion defects such as porosity or fractures, only in those areas of the welding filler wire

Alternating Current Resistance Spot Welder

Get Price Quote

Functions : 1. Argon arc welding, good quality. 2. Autorotation welding. 3. It can adjust the center of a circle according to the tube diameter. 4. Tube diameter: below 25.4mm (can be custom-made) Main Technical Parameters 1. Power supply: single phase 220V+/- 10% 50Hz 2. Rated power: 5KVA 3. Efficiency: 4800pcs/8h 4. Size: 13S0*900*1900(mm) 5. Weight: 150KG.

Digital Ultrasonic Spot Welder

100,000 Per Piece

Seam Welding

Get Price Quote

APPLICATION : Spot welding, projection welding, cross wire welding, resistance heating, electro-brazing, With special attachments it is also possible to weld nonferrous material within certain limitions. USERS : Include - but are not limited to general engineering work-shop, makers of furniture, electrical instruments, containers, barrels and drums, telephone, radio communication devices, clocks, kitchen-ware,textiles machinery and spares automoblies-ancillaries,toys, air-conditions, refrigerators, motors, switchgear, etc. STANDARD FEATURES - ALL MACHINES : MAIN SUPPLY-415 Volts. Single Phase (2lines of 3 phase supply) 50 Hz. AIR OPERATION : Spring follow-double acting cylinder; Air line filter, lubricator, regular pressure gauge; Electric Solenoid Valve; Machine machanically capable of 125 operations/minute. ELECTRICAL - Foot Switch/Palm Button; Weld/No Weld Switch;Pressure Switch; Transformer in Class 'F' Insulation. provide with 8 current regulating taps between 55% and 100% output; Contrail circuits at less than 110 Volts. COLLING - By water with separate circuits for main Transformer, Secondary conductor and Electorder. die (in case of projection Welders) Thyristors. Each circuit to terminate in sight cup provide; wheel valves each circuit. PROTECTION - Transformer, Thyristors by themosate against water failure; Luminous overload indicator on panel. ELECTRONIC CONTROLS : Microprocessor based solid state Electronic Control with Thyristor Contact or unit. SPECIAL FEATURES AVAILABLE ON REQUEST : Actuation - Hydraulic-Motor H Air Reservoir h RTap Change Switch h Refrigerated or closed circuit cooling h Voltage/Current compensation h Other Voltages, Frequencies Special Purpose machines for /Special application, or Non Ferrous metals or Stainless and other exotic Steels electrodes h Special Tolong for projetion Welding Special Locating jigs for Spot /Switch Welding h Geneva Index \tablets h Automatic Feeders h Customer Ideas. We also manufacture : Arc, Butt and Seam Welding Machines; Salt Bath Furnace Transformer, Electronic Welder Controls, Electronic contractors etc.

battery spot welder

Get Price Quote

Spot Welding Machine

Get Price Quote

We are renowned Manufacturer, Supplier and Exporter of Spot Welding Machine in Maharashtra, India. Robust construction, high performance, corrosion resistant parts are the highlights of our Spot Welding Machine. In addition, it is wear and tear resistant too. Buyers are free to place bulk order and we make sure that it is duly delivered. We are well equipped with in-house testing lab for quality assurance where the product is stringently tested many a times. Moreover, we offer the Welding Machine at market-leading prices.

Spot Welding Robot

858,000 Per Piece

Spot Welder

Get Price Quote

Spot Welder, Co2 Laser Marker, diode end pump laser marking machine

INDUSTRIAL VACUMMING SPOTTING MACHINE

Get Price Quote

INDUSTRIAL VACUMMING SPOTTING MACHINE, Roll Press Machine

spot cum projection welder

Get Price Quote

spot cum projection welder, press type spot welder, Projection Welder

Multi Spot Welding Machine

Get Price Quote

Multi Spot Welding Machine, Spot Welding Extension Gun