Ultra Water Filtration System

01 Piece(s) (MOQ)

NeoTech supplies high effective smaller UF membrane skid system and bigger UF membrane system to our customers to treat different water and waste water. We collect much rich experience in installation, commission, and running of UF membrane system, our expert technical teams are supplying the all-around technical service. We do effort to give customers the highest effective system to solve their water problem. Details : We design and manufacture high effective containerized UF membrane system. The system is easy to be transported and operated by you, just connect your feed pump and give system a power. It can solve the wide range water problem, like surface water, well water, treated waste water, also as pretreatment of RO, to bring the user purified water. The system consists of pretreatment (sand, carbon, and micron filter), UF membrane modules, valves, pipes, automatic control system, backwash system, chemical cleaning system and air scouring system, all these are modularized in one container and fully automatic controlled, its convenient to operation, and it can be put everywhere users want to purify the water from. The filtration efficiency is high due to good quality hollow fiber membranes equipped on the system. The running cost is also low. Our expert technical team will track the running of your system, and supply you best technical support.

Country of Origin : India

...more

Ultra Filtration Plant

50,000 Per

Tube Settler System

100,000 - 1,000,000 Per Piece

01 Piece(s) (MOQ)

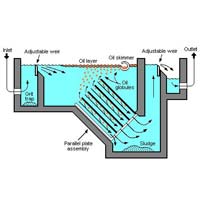

Conventional clarification equipment requires 10 times more physical area to even begin to approach the same settling capacity of a Neotech Lamella Gravity Settler. This means faster settling in one-tenth space because the effective gravity settling area of the inclined plate design equals each plate are projected on a horizontal surface. Up to ten square feet of settling area becomes available for each square foot of physical area occupied by the unit. Loading rates normally used for the design of conventional settlers can be applied to the sizing of a Lamella Settler by substitution projected area for the surface settling area of a conventional clarifier. The compact design minimizes hydraulic disturbances caused by wind or temperature changes. Balanced flow distribution ensures equal flow to each plate and across the plate surface area preventing short-circuiting. Units and plate packs arrive at the job site factory assembled which reduces installation time and lowers installed costs. Minimal moving parts mean low maintenance costs. How it Works:Influent enters the lamella system and flows downward through the inlet chamber in the center of the unit and enters the plates through side – entry plate slots. The countercurrent design, unlike typical bottom feed designs, reduces the risk of disturbing previously settled solids. As the liquid flows upward, the solids settle on the inclined, parallel plates and sludge into the sludge hopper at the bottom. Further thickening of the sludge is achieved in the hopper due to compression in the quiescent zone achieved by the side feed design. The clarified liquid leaves the plate assembly through orifices or weirs at the top and is distributed into the collection channels leading to the clarified water outlet. This creates a pressure drop across the collection channels which ensure uniform flow distribution across the plates in order to utilize the full area for settling.

...more

Static Mixer

30,000 - 50,000 Per Set

01 Piece(s) (MOQ)

Static Mixer function is simple, fluid flowing through a pipe is channeled through a geometric arrangement of mixing elements. The element geometry is such that the fluid flowing through the elements will divide, mix, divide again and mix again until complete mixing. The Static Mixer is an effective solution to your mixing requirements. Operating in-line, with no moving parts, this mixer blends and disperses the treatment chemical into wastewater streams. Compared to competitive mixers, its unique baffling design ensures complete mixing in a shorter length and lower pressure drop. Details : The Static Mixers can be easily installed in new or existing process lines. They are available in different pipe sizes. Construction Materials include Polypropylene, HDPE, Fiber Glass Lined, Stainless Steel, Carbon Steel, UPVC, CPVC etc. Sizes ranges from to 42or more depend on customer requirements. Applications : pH Control Chlorination Pulp Bleaching & Mixing Ink & Paint Blending Oil Blending Chemical Mixing Neutralization All Type of liquid to liquid, liquid to gas, liquid to solid mixing Features : Compact Design Easy installation Low capital cost Zero Maintenance 50 to 90% energy saving Excellent Process Versatility Highly Predictable Mixing and Dispersion

Brand Name : NeoStat

Material : Stainless Steels, PP , FRP, HDPE, UPVC , etc

Application : Online Mixing, Rapid Mixing

...more

sludge dewatering machine

300,000 Per Piece

1 Piece(s) (MOQ)

Usage : Industrial

Voltage : 440 V

Screw Press Dewatering/Juicing Machine

500,000 - 5,000,000 Per Piece

01 Piece(s) (MOQ)

Intro: The screw press is a device that uses physical extrusion to dewater the device. The device includes driven System, feed box, spiral auger, screen, pneumatic material blocking device, sump, rack, etc. The material enters into the equipment from the feeding box and is subjected to progressive pressure extrusion under the conveying of the spiral auger. Excess water is discharged from the liquid outlet through the screen, and the moisture-removing material is continuously transported by the spiral auger. The top opening and blocking device is discharged from the discharge port by the discharge port. It is truly low energy consumption, high output, low moisture, and secondary circulation for material to save a lot of processing costs. Working principle: The dewatering process of the screw press dewatering machine is divided into two stages. The first stage uses the screw auger to dehydrate. The spiral auger has three sections: the transmission section, the compression section and the discharge section, and the transmission space become smaller gradually to press the materials stronger and make the material extruded water. The second stage uses a material-blocking device to dewater. When the material enters into the discharge section of spiral auger, the spiral auger applies axial thrust to the material to push it out of the discharge port, while the pressure device is pressurized by the pneumatic device which applies a reverse force to the material to be pushed out, thereby forming a pressing force to the material to realize the dehydration.

...more

Plate-Frame Filter Press

100,000 - 500,000 Per Set

01 Piece(s) (MOQ)

Plate-frame filter press is a kind of intermittent solid-liquid separation equipment, which is composed of filter plate and filter frame to form a filter chamber. Under the pressure of the feed pump, the material liquid is sent to each filter chamber and the solid and liquid are separated by the filter medium. The equipment is widely used in chemical industry, dyestuff, petroleum, ceramics, pharmaceutical, sugar, starch, paint, metallurgy and sewage treatment, etc. It has the advantages of good separation effect, wide application range, simple operation and low investment, etc. In particular, the separation of sticky and fine materials has in comparable advantages. Advantages: Plate-and-frame filter press is a mature dewatering equipment with simple structure, easy operation, stable, flexible selection of filter area, less area per unit filtration area, large filter driving force, and low moisture of filter cake. Strong adaptability to materials, suitable for all kinds of sludge.

Type : Fully Automatic Filter Press

Material : SS304,carbon steel,ss316

Application : industrial

...more

Packaged Sewage Treatment Plant

700,000 - 5,000,000 Per Set

01 Piece(s) (MOQ)

The basic targets and main axes of the activities of Neotech Water Solutions are the development and construction of innovative systems which provide effective solutions to the problem of wastewater treatment and waste management in general. The systems and technical solutions which Neotech offer are designed and materialized with the most up-to-date methods of CAD/CAM while the technology that is used is the most advanced, reliable and innovative that is applied internationally for wastewater treatment. Details : With Packaged plants that Neotech manufactures, offers unique solutions to the increasing demand for the treatment of wastewater by small Municipalities and Communities as well as by Industry. The clever and functional design featured in these plants, together with the innovative technologies used (M.B.B.R. & M.B.R.) Lead to systems with a high performance rate and low running costs in a very compacted form. In order to develop innovative products and technical solutions Neotech cooperates with various academic bodies and specialized scientists. Also, to ensure that the performance and efficiency of the plants produced the company employs and operates special pilot plants which are monitored and checked by laboratory analysis on an intensive and scientific basis. The product range of Neotech Water Solutions can be supplemented as required with equipment and material from other first class constructors and suppliers with whom Neotech has close collaboration, so to provide a complete turn-key service.

Brand Name : Hydrox

Material : Carbon Steel or Stainless Steel

Capacity : 5 KLD to 500 KLD or more

...more

Oval Disk Type Liquid Solid Separator

300,000 - 1,000,000 Per Piece

01 Piece(s) (MOQ)

WAVE dewatering press is a solid- liquid separator machine with self-cleaning function by slits opposite continuous rotation, no vibration and noises.

...more

Oil Skimmer

35,000 - 75,000 Per Set

01 Set(s) (MOQ)

NeoSkim After a long period of testing, the ideal design was developed. A complete new design which ensures a high efficiency. The NeoSkim Belt Type Oil Skimmer is a dependable and effective means of removing oil from water and wastewater base solutions. Often, skimming by itself will reduce oil to an acceptable level of water purity. Depending on the characteristics of the liquid, it is possible for NeoSkim alone to reduce oil content to less than five parts per million in water. The unit can be used as a pretreatment before filtration, and in conjunction with coalescing systems.Features : Require Small Area Easy Mounting High Temperature Capability Custom Design Fast Cleaning Minimum Maintenance How it works? The NeoSkim Model utilizes a continuous belt and wiper to remove up to 150 liters of oil per hour from the fluid surface. The belt, operating on a motor and pulley system, runs through contaminated liquid to pick up oil from the surface. After traveling over the head pulley, the belt passes through tandem wiper blades where oil is scraped off both sides of the belt and discharged. The tail pulley has flanges which allow it to roll freely on the inside of the belt without becoming dislodged. It requires no bearings and does not need to be fastened to the tank. If turbulent conditions exist, an optional tether and cage assembly prevents the tail pulley from being dislodged. Oil skimming makes use of the differences in specific gravity and surface tension between oil and water. These physical characteristics allow the belt to attract oil and other hydrocarbon liquids from the surface of the fluid. The NeoSkim can be used in tanks with depths as shallow as one foot, or as deep as 100 feet.

...more

Oil Separator

500,000 - 800,000 Per Set

01 Piece(s) (MOQ)

The Coalescing Plate Interceptor employs a series of plate packs inclined at opposite angles in close proximity; the most effective technique for increasing setting area per unit volume. As a result, CPI Separators requires far less space than settling tanks. The units can be offered in fully certified pressure vessels, or atmospheric tanks. Process Technology Waste water enters the inlet nozzle into an enlarged coalescing section. This coalescing section is where heavier solids and sludge settle out of the waste water to the bottom of the vessel where it is discharged through the clean out nozzle. Waste water then flows through the perforated distribution baffle plate. After it is evenly dispersed, it flows down through the plate pack where oil rises to the top of the corrugations and coalesces with other oil droplets. The large oil droplets rise up through the plate pack to the oil/water interface. Coalesced oil will flow over an internally adjustable oil weir and is removed through the oil outlet nozzle. Light solids and sludge separation is simultaneously accomplished within the pack by settling to the bottom of the corrugations where solids are directed to the sludge drain. The flow out of the plate pack travels upward and spills over a fixed water weir, then exits the vessel through the water outlet nozzle for further downstream treatment or disposal. Our CPI Separators effectively remove oil droplets of 50 microns or larger, depending on fluid properties. Applications Oilfield production onshore and offshore Refineries Petrochemical Plants Industrial Plants Rainwater runoff Water treatment facilities

Brand Name : NeoSep

Country of Origin : INDIA

Warranty : 12 Months

...more

Mobile Sewage Treatment Plant

200,000 - 5,000,000 Per Set

01 Set(s) (MOQ)

General Description of Hydrox Sewage Treatment Plants- Mobile Sewage Treatment Plant The Hydrox System is based on the moving bed bio reactor and tube settling technologies, and is unique due to its compactness and performance with respect to Volumetric efficiency. These technologies are combined in prefabricated, skid mounted standardized tank system with variable length, suitable for overseas transportation. The overall size of the plants are based on the ISO freight containers. Neotech offer a number of standard model ranging from 20-500 m3/day, which are divided into two categories and two formats: Hydrox Series, introduces high rate bioreactors for efficient BOD removal (85- 95%), incorporated into a small compact pack. Hydrox Ultra Series, is a high efficiency membrane based technology, incorporated MBBR with MBR for higher BOD removal (90-95%), all in containerized packaged plants. Both Series are constructed in the Neomax Format for both indoor and outdoor location providing higher treatment capacity.

...more

Micro-screen Rotating Drum Filter

200,000 - 1,000,000 Per Piece

01 Piece(s) (MOQ)

Automatic micro-filtration equipment is used in solid-liquid separation in aquaculture water/water/sewage system.RDF is a reliable mechanical filtration method, it can separate solids, suspended substances(including feces, food waste and other organic water) over 30μm from water.

...more

Lamella Clarifier Parallel Plate Separator

300,000 - 1,500,000 Per Piece

01 Piece(s) (MOQ)

LAMELLA SEPARATOR: Conventional clarification equipment requires 10 times more physical area to even begin to approach the same settling capacity of a Neotech Lamella Gravity Settler. This means faster settling in one-tenth space because the effective gravity settling area of the inclined plate design equals each plate are projected on a horizontal surface. Up to ten square feet of settling area becomes available for each square foot of physical area occupied by the unit. Loading rates normally used for the design of conventional settlers can be applied to the sizing of a Lamella Settler by substitution projected area for the surface settling area of a conventional clarifier. The compact design minimizes hydraulic disturbances caused by wind or temperature changes. Balanced flow distribution ensures equal flow to each plate and across the plate surface area preventing short-circuiting. Units and plate packs arrive at the job site factory assembled which reduces installation time and lowers installed costs. Minimal moving parts mean low maintenance costs. How it Works: Influent enters the lamella system and flows downward through the inlet chamber in the center of the unit and enters the plates through side – entry plate slots. The countercurrent design, unlike typical bottom feed designs, reduces the risk of disturbing previously settled solids. As the liquid flows upward, the solids settle on the inclined, parallel plates and sludge into the sludge hopper at the bottom. Further thickening of the sludge is achieved in the hopper due to compression in the quiescent zone achieved by the side feed design. The clarified liquid leaves the plate assembly through orifices or weirs at the top and is distributed into the collection channels leading to the clarified water outlet. This creates a pressure drop across the collection channels which ensure uniform flow distribution across the plates in order to utilize the full area for settling.

...more

horizontal decanter centrifuge

1,000,000 - 5,000,000 Per Piece

01 Piece(s) (MOQ)

The solid phase particle size 0.005 ~ 15 mm, 1 ~ 40% concentration, temperature < 100 ℃ of all kinds of slurry solid phase dehydration, clear separation of liquid phase, sizing, etc. Especially suitable for regeneration of filter cloth have difficulty bigger suspending liquid separation and concentration, particle size change.

...more

Frp Tank

5,000 - 200,000 Per Piece

01 Piece(s) (MOQ)

Owing to its valuable features like leakage resistance and durable nature, FRP Tank is highly demanded in the market.

...more

floating aerators

110,000 Per Piece

Voltage : 220 to 440 V

Power : 2 HP/1.5 kW

Floating Aerator

45,000 - 1,000,000 Per Set

01 Piece(s) (MOQ)

Neomax is the third generation aerator. After a long period of testing, the ideal design was developed. A complete new design which ensures a high efficiency, a huge mixing effect and very smooth running with less vibration to the bridge and drive unit. The new surface aerator is designed on the basis of the latest know how on surface aeration and beats the old problem with this kind of aerators. Because of the strong mixing power of the Neomax, in most cases a system without sludge settlement can be guaranteed up to 5 meter water depth, even water depths up to 8 meter can be realized without the use of additional mixers. The NeomaxF consist of : Aerator impeller, vertical shaft and coupling. Foundation plate, gearbox, electric motor. Three numbers of Floats. (If Floating Aerator) The aerator impeller is a low speed, non-clogging and open type. The aerator is a heavy steel construction to withstand stresses created by mixed liquor motion and will be adequately anchored and supported to the bridge of the aeration tanks. The impeller consists of a flat plate with curved blades beneath the plate in order to obtain maximum efficiency and to suffer minimum friction losses between blades and water.

Brand Name : NeoMaxF

Power : 1 HP to 50 HP

...more

Fixed Surface Aerator

200,000 - 700,000 Per Set

01 Piece(s) (MOQ)

Neomax is the third generation aerator. After a long period of testing, the ideal design was developed. A complete new design which ensures a high efficiency, a huge mixing effect and very smooth running with less vibration to the bridge and drive unit. The new surface aerator is designed on the basis of the latest know how on surface aeration and beats the old problem with this kind of aerators. Because of the strong mixing power of the Neomax, in most cases a system without sludge settlement can be guaranteed up to 5 meter water depth, even water depths up to 8 meter can be realized without the use of additional mixers. The Neomax consist of : Aerator impeller, vertical shaft and coupling. Foundation plate, gearbox, electric motor. Three numbers of Floats. (If Floating Aerator) The aerator impeller is a low speed, non-clogging and open type. The aerator is a heavy steel construction to withstand stresses created by mixed liquor motion and will be adequately anchored and supported to the bridge of the aeration tanks. The impeller consists of a flat plate with curved blades beneath the plate in order to obtain maximum efficiency and to suffer minimum friction losses between blades and water.

Power : 0.5 HP TO 100 HP

...more

Effluent Water Treatment Plant

500,000 - 5,000,000 Per Set

01 Set(s) (MOQ)

NeoTech Water Solutions is a company engaged in water & wastewater management system. Our experience encompasses sewer collection systems, advanced wastewater treatment facilities, residuals management and handling of industrial wastewater treatment and reuse. We have significant expertise in all facets of wastewater liquid stream and solids stream treatment ranging from conventional plants for organic removals to complex nutrient removal/resource recovery processes covering scopes from compliance evaluations to turnkey delivery of completely operational facilities. We have also performed numerous wastewater treatment plant design upgrades to meet clients specific requirements. NeoTech Water Solutions is recognized for its products and technologies to treat wastewater to a safe sanitary water effluent quality discharge meeting effluent standards recommended by the Environmental Protection Agency.

Type : Conventional Or MBBR Effluent Treatment Plants

Driven Type : Electric

Warranty : 1year

Brand Name : Neotech

Application : Industrial Effluent Treatment

...more

Dissolved Air Flotation System

700,000 - 2,500,000 Per Set

01 Piece(s) (MOQ)

NeoTech DAF process consists of super saturation of discharge water from the effluent end of the system tank with air. The super saturated water stream is then mixed with the waste stream and pressurized in pressure tube. A sudden release of pressure from the saturated stream millions of microscopic bubbles form and attach themselves to the contaminants of oil and solids in the wastewater, thereby changing their buoyancy and floating them to the water surface where they can be skimmed and removed from the water. NeoTech also offer a combined chemical pretreatment to improve DAF solids removal efficiencies. Features : The use of chemical flocculants with DAF is based on system efficiency, application contaminant characteristics and cost. Chemical pretreatment often improves DAF solids removal efficiencies. The use of chemical flocculants with DAF is based on system efficiency, application (use of DAF) contaminant characteristics and cost. Commonly used chemicals include trivalent metallic salts of iron, such as FeCI2 or FeSO4 or aluminum, such as AISO4. Organic and inorganic polymers (cationic or anionic) are often used to enhance the flotation process. The most commonly used inorganic polymers are the polyacrylamides. Attachment of most of the bubbles to solid particles can be effected through surface energies while others are trapped by the solids or by hydrous oxide flocs as the floc spreads out in the water column. Colloidal solids are normally too small to allow formation of sufficient air-particle bonding. They must first be coagulated by a chemical such as the aluminum or iron compounds mentioned above and then absorbed by the hydrous metal oxide floc generated by these compounds. Frequently the coagulant is required in combination with the flocculant. Optional Facility : 304/316 Stainless Construction Emulsion Breaking System Chemical Pretreatment Sludge Pump out Float Pump out Effluent Pump out Influent Feed pH Adjustment System

...more

Containerized Sewage Treatment Plant

We are offering containerized sewage plants. Neotech water solutions is recognized for its products and technologies to treat wastewater to a safe sanitary water effluent quality discharge meeting and or exceeding effluent standards recommended by the environmental protection agency. the selection of a packaged waste water treatment plant offers the user a pre-engineered and pre-fabricated method of treating waste water with an aerobic process using mbbr & mbr processes. The final effluent can be released safely into the garden or drainage. Features : Compact plant with integrated tertiary membrane treatment High effluent quality suitable for reuse Innovative method combining MBBR & MBR technologies High Performance & Smaller foot print than conventional MBRs Fully automated, Quick installation and start-up

...more

Central Drive Clarifier

200,000 - 250,000 Per Set

01 Piece(s) (MOQ)

NeoTech Water Solutions supplying the industry highest quality and most reliable clarifier mechanisms for basic bridge or pier supported mechanisms to those with the most complex and demanding special requirements. Our drive units are high performance and delivers high torque. Standard Designs exist for basic mechanisms for a wide range of tank sizes. These standard mechanisms are effective, low cost and meet all design codes with minimal engineering costs. Bridge supported mechanisms are supported from a structural bridge that spans the tank diameter and are generally used for the lower end of the range of clarifier diameters. Features : High tourue drive Torque Alarms Hydraulic or Electrical Drive System Forward & Reverse (Optional) Variable speed (Optional) Manual or Motorised Central Pipe Lifting arrangement Low maintenance High quality components ndoor or Outdoor operation High torque settlings

...moreOpening Hours