universal broing head

we are offering Universal Boring Heads

STRAIGHT SHANKS

STRAIGHT SHANKS PARALLEL SHANK RANGE 12mm 12.7 - 19.8mm 16mm 19 - 27.7mm 20mm 23 - 30.1mm 25mm 12.7 - 100.6mm 32mm 15.8 - 100.6mm 40mm 28.5 - 100.6mm Par Bars (2 Tool Bars 1-ANG, 1 SQU Mount) IMP Shanks from 1/2" - 3 1/4"to cut ranges 17/32" - 8.9/16"

...more

spindle tooling

We are offering spindle tooling.

Spindle Speed Increasers

Types 822-826 In contrast to the previous range, types 822-826 are designed for extremely high speeds. Smaller spindle bearings enable much higher speeds to be achieved. These spindle speed increasers retain, however, the advantages of hardened gear wheels and zero maintenance.

...more

Solid Carbide

Standard DIN Long Short / Double End High Performance Miniature Straight Flute Multiple Flute Sets

...more

short hole drills

The Microbore Indexable Short Hole Drill ranges offer a wide selection of high speed/high feed drills that will produce a hole from solid prior to finish boring. The whole range will machine to depths of of 3X diameter with through coolant for chip removal and long insert life. All drills throughout the range offer the following qualities: • Unique geometry for accelerated swarf evacuation• Composite shank for lathes and rotary tool holders• Self centering drilling, even on uneven surfaces• Low axial and balanced radial cutting forces• Quick and simple insert changing• Special drills made to customer specification

...more

Shell End Mills

Shell End Mills Hollow Mills Taper Shank End Mills-Standard Series Taper Shank End Mills-Long Series Parallel Shank End Mills Screwed Shank End Mills-Short Series(Metric Sizes) Screwed Shank End Mills-Long Series(Metric Sizes) Screwed Shank End Mills-Long Series(Inch Sizes) Roughing Shell End Mills Roughing Taper Shank End Mills Roughing Parallel Shank End Mills

...more

Sets of Boring Tools

bi-metal bandsaw blades

Bi-Metal Bandsaw Blades made of cobalt alloyed HSS-M42-, suitable for all kind of steels, also for high alloyed ones and for steels difficult to cut with a tension force of up to 1.400 N/mm2.The high content in the HSS-tooth tips permits the teeth to be fully hardened up to 67 - 69 H Rc, this leads to a higher resistance against heat and wear and at the same time to an impressive performance.

...more

precision tool system

We are offering precision tool system.

Precision Boring Heads - Vh

Precision Boring Heads are used for precision boring of cylindrical holes in the given range of diameter. Their accuracy of the boring diameter adjustment proceeds from the differential screw and subsidiary round nut. This nut is either carried by the screw and then they rotate together for coarse adjustment or this nut screws on the screw for fine adjustment. In this case, the nut is braked by tightening the screw. Boring heads are delivered with primary accessories in wooden boxes. The taper shank is exchangeable and it is not included in the primary accessories. The taper shank has to be ordered as a special item.

...more

Parallel Hand Reamers

Parallel Hand Reamers Long Fluted Machine Reamers Parallel Machine Reamers Machine Jig Reamers Chucking Reamers With Parallel Shank Chucking Reamers With Taper Shank Shell Reamers Shell Core Drills Shell Drills Parallel Shank Socket Hand Reamers Taper Shanker Socket Reamers Hand Taper Pin Reamers Machine Taper Pin Reamers Machine Bridge Reamers Counter Bores With Taper Shank Counter With Parallel Shank Centre Reamers

...more

Microset Tool Presetting Machines

We are offering microset tool presetting machines.

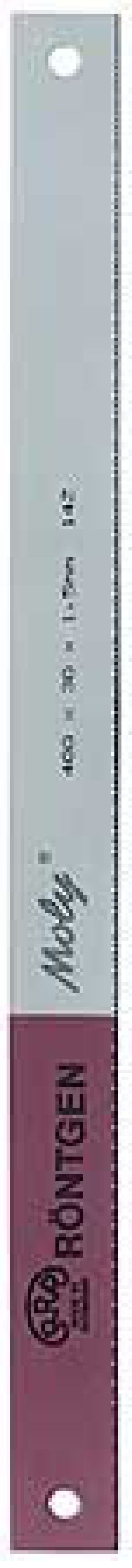

Metal Cutting Hacksaw Blades

ROENTGEN MolyThe heavy duty saw blade made of HSS DMo5, German material no. 1.3343, for the highest demands, recommended for materials with a tension force up to 1.400 N/mm2. ROENTGEN Moly 7The heavy duty saw blade made of HSS DMo5, German material no. 1.3343 with precision ground teeth and a cutting angle of 7°. Available with toothing 4 tpi and 6 tpi, most suitable for cutting high alloyed and long chipped materials. ROENTGEN Moly 13The heavy duty saw blade made of HSS DMo5, German material no. 1.3343 with precision ground teeth and a cutting angle of 13°. Available with toothing 3 tpi, suitable for cutting large diameters of high and highest alloyed materials. ROENTGEN 2-iksThe universal blade made of high speed steel suitable for general workshop use, insensitive to misuse. ROENTGEN bi-alfaThe saw blade made of bi-metal with tooth tips of HSS (M3).

...more

internal cylindrical grinder

We offer internal cylindrical grinders.

Internal Cylindrical Grinders

The MODEL 80 possesses high precision, quality and maintenance free design . It accommodated grinding of cylindrical, tapered and blind holes. It can be proved blessing for mass production industries, i.e. Antifriction Bearings, Tractors, Scooters, Automobiles, their spares and Defense etc. The technical characteristics as given below well tell the rest MODE OF OPERATION Fully automatic cycle with manual loading and unloading of the component .The grinding cycle is controlled with electro-hydraulic valve sequence . Any one of the following cycles can be chosen by the selector switch and a cam limit switch. The automatic cycle (Interval dressing , pre-dressing and skip dressing cycle) of the machine is as follows. By setting the counter value at 0004 ,this cycle will be operated 4 times without dressing . More –over any one of the above cycle can be selected to be operated once only with dressing. * CLEANING OF GRINDING WHEEL AT ONE SIDE (RIGHT TO LEFT) * * CLEANING OF GRINDING WHEEL BOTH THE SIDES (RIGHT TO LEFT & LEFT TO RIGHT) BASIC MACHINE FEATURES Work head with splash guard Hydraulic Diamond dresser Grinding wheel spindle (Belt driven) Compensation of grinding wheel wear Hand wheel for the displacement of the work head. Rough grinding variable feed control Finish grinding variable feed control Grinding allowance setting knob Quick unclamping foot switch Table speed control for wheel dressing Table reverse control Fast traverse control Starring and table speed control Oil level Hydraulic power pack Electric control cabinet Cycle cams and switches Electro-Hydraulic solenoid valve for manual/automatic cycle control Coolant tank with magnetic filter . DISTINCTIVE FEATURES OF MODEL 80 INTERNAL GRINDER Highest quality stress relieved castings ensure great rigidity and prolonged accuracy. Tow tables ( i.e. longitudinal table and feed table) mounted on hardened prisms and prestressed rollers . Work spindle running in special high precision HG or P4 class bearings. Grinding wheel head mounted on longitudinal table without cross slide, ensuring maximum rigidity. Entire machine is lubricated by oil mist . Variety of belt driven spindle .Changes over of the spindle is easy and less time consuming . Maintenance of this spindle is easy. ( Optional : Oil mist lubrication belt driven spindle {Integral motor construction} ) Extra sensitive feed control permitting separate progressive adjustment of roughing and finishing feed. Possibility to equip the machine with an electronic sizing device for direct measurement during grinding . Oversize electrical equipment mounted in a control cabinet and hydraulic power pack separate from the machine eliminating vibration and thermal distortion. Any one of the cycles can be chosen by selector switch and can limit switch. Programmable logic controller (PLC) along with high precision limit switches makes operation more accurate. There are many more special accessories like True chuck, Diaphragm Chuck and shock-centreless chuck ( magnetic )

...more

integral taper bars

AVAILABLE IN THE FOLLOWING SHANKS BT 40/50 (MAS 403-1975) 40/50 Din 69871 40/50 CAT Metric/ANSI ISO 60/50/40 NMTB Morse Taper 2/3/4/5/6 40/50 Flash Change Metric/Imperial Boring Ranges 13.5mm - 244

...more

Hydraulic Universal Cylindrical Grinders

Pick from our wide range of cylindrical grinders. Each model is different to suit individual production need. For higher productivity and greater profit, it is essential you pick a machine suitable for you. WorkheadThe work head spindle is made of nickel chrome EN-24 hardened and ground. It runs in gunmetal bush bearings. The drive to the workhead spindle which has MT-3, is by a step ‘V’ pulley. The speed obtained through this pulley can be reduced by another bigger size pulley provided in the workhead housing. The workhead is built for grinding operation both with stationary centre and revolving spindle. Oil holes are provided for lubrication. WheelheadThe rigid wheelhead spindle is made of nickel chrome steel EN-24 hardened and ground. It runs in white metal adjustable type bush bearings. The drive to the wheelhead is transmitted by two V-belts. Automatic wheelhead traverse in cross direction is on precision hand-scrapped ‘V’ and flat guide ways, and is hydro-mechanical type. The spindle is tapered (5o) at the front to receive the wheel flange. Oil holes are provided for lubrication of the bearing surfaces. Rapid approach is available in U-127 series and it is up to 40 mm. Tailstock The tailstock travels smoothly all along the length of table right upto the workhead. Hydraulic/Electrical System All standard equipments are used in both system. Swivel Table Table is arranged to swivel for taper grinding. For fine connections to be applied by the screw adjustment. nternal Grinding Attachment The hinged type Internal Grinding Attachment with its independent motor is conveniently located on the wheelhead. It has fast grinding action and it can be quickly swung into a grinding position. The work piece can be externally and internally ground in one setting. Taper hole can be ground by swivelling either workhead or table. There are so many standard and special accessories that can be added to the machine as per

...more

HSS Cutting Drills

Parallel Shank Twist Drills- Jobber Series Parallel Shank Twist Drills- Stub Series Parallel Shank Twist Drills- Long Series Parallel Shank Twist Drills- Extra Long Series Taper Shank Twist Drills Taper Shank Twist Drills- Long Series Taper Shank Twist Drills- Extra Long Series Taper Shank Core Drills Centre Drills Subland Drills

...more

Hand Taps and Short Machine Taps

Hand Taps and Short Machine Taps (Metric Coarse Pitch) Hand Taps and Short Machine Taps (Metric Fine Pitch) Hand Taps-B.S.W Form Hand Taps-B.S.F Form Hand Taps-U.N.C Form Hand Taps-U.N.F Form Hand Taps-BSCY Form Hand Taps-BS Conduit Form Hand Taps-BSP (Taper) Form RC Series Long Shank Machine Taps (Metric Coarse Pitch Threads) Long Shank Machine Taps (Metric Fine Pitch Threads) Nut Taps- Metric Coarse Pitch Threads Nut Taps-BSW Form Nut Taps-BSF Form Nut Taps-UNC Form Nut Taps-UNF Form

...more

Gear Cutting Tools

floor type milling machine

FS Model Axis: 4000 - 20000 mmY Axis: 2000 - 2800 mmZ Axis: 1250 - 1500 mmAutomatic indexing head 30/37kw FR Model X Axis: 4000 - 20000 mmY Axis: 3200 - 3600 mmZ Axis: 1250 - 1500 mmAutomatic indexing head 37Kw \FP Model X Axis: 4000 - 10000 mmY Axis: 1600 - 2000 mmZ Axis: 1200 mmAutomatic indexing head: 28kw

...more

Fixed Bed Moving Column Milling Centers

SL Model X Axis: 2500 – 8500 mmY Axis: 1000 - 1600 mmZ Axis: 1000 mmAutomatic indexing head: 28kw SP Model X Axis: 3500 - 10500 mmY Axis: 1600 - 2000 mmZ Axis: 1200 mmAutomatic indexing head: 28kw SM Model X Axis: 3250 - 10250 mmY Axis: 1600 - 2400 mmZ Axis: 1250 - 1500 mmAutomatic indexing head: 30/37kw

...more

Cylindrical Milling Cutters

Cylindrical Milling Cutters High Power Cylindrical Cutters Helical Cylindrical Cutters Side & Face Cutters Stagerred Tooth Side & Face Cutters Slotting Cutters Metal Slitting Saws Keyway Milling Cutters 50 Degree Shell End Single Angle Milling Cutters Single Angle Cutters Double Angle Cutters Equal Angle Cutters Convex Cutters Concave Cutters Single Corner Rounding Cutters Double Corner Rounding Cutters Rotary Form Relieved Involute Gear Cutters Face Cutters Taper Shank Slot Milling Cutters Parallel Shank Slot Milling Cutters Woodruft Key Slot Milling Cutters

...moreBe first to Rate

Rate ThisOpening Hours