compression proving rings

Get Price Quote

Proving rings are used for load measurements and are used in outfits of a number of Soil / Cement & Bitumen Testing Equipments like Direct Shear Test Apparatus, Triaxil Shear Test Apparatus, C.B.R. Test, Uncontined Test, Marshall Test etc. They are made out of special steel carefully forged to give maximum strength and machined to give highest sensitivity combined with stability to ensure long life and accuracy. When compressive or tensile load is applied within the elastic range, the proving rings get temporarily deformed. This deformation is measured by a sensitive dial gauge fixed co-axially at the center of proving ring. The dial gauge readings thus obtained versus load applied enable the operator to find out unknown load, just by noting the dial gauge reading for unknown load. The proving rings have high elasticity and on removing load they regain their original shape provided they are loaded in their elastic limits. Salient Features A Dial gauge and plunger anvil are mounted on brackets clamped to the ring body. The dial gauge is held perfectly rigid without the remotest chance of shifting due to inadvement shocks or pressures exerted on it. The dial gauge plunger rests on an adjustable anvil. Proving Rings , from 50 kg to 1,00,000kg capacity provided with 1/2 inch B.S.F femal threads. Loading bosses and a loading ball nipple and steel ball are supplied with each rings. Rings of capacity over 25000kg (or 25 Tonnes) are not thus threaded. Each ring is individually calibrated and supplied with works calibration chart and a carrying case. Calibration charts from Standard Laboratories for the Proving Rings ordered are also available at extra cost. All Proving Rings are Integral Type. Integral type Compressive Proving Rings of different capacities from 50kgf to 200000kgf are available. (a) above cap. 50 to 500kg. (b) above cap. 500 to 3000kg. (c) above cap. 3000 to 5000kg. (d) above cap. 5000 to 10000 kg. (e) above cap. 10000 to 20000 kg. (f) above cap. 20000 to 30000kg. (g) above cap. 30000 to 50000 kg. (h) above cap. 50000 to 100000 kg. (i) above cap. 100000 to 200000 kg. (j) above cap. 200000 to 300000 kg.

compression rings

Get Price Quote

We compete effectively in today's global business environment by constantly delivering high quality Compression Rings that are apt for all kinds of industrial & automotive engines, power generation engines, marine & heavy earth mover engines. Rings offered by us are manufactured from qualitative raw material and cutting edge technology. Being a quality driven company, we assure our clients that these rings are checked on different parameters.

Best Deals from Compression Rings

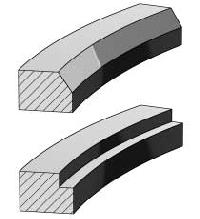

Stepped Compression Ring

Get Price Quote

By providing an edge relief on the top side of rectangular and taper faced rings a twist effect is achieved which, in all operating phases without gas pressure loading, brings the ring into bore contact only with its bottom outer edge while the inner edge contacts the bottom groove side (positive twist). This helps to improve oil consumption control. Under operating conditions the gas pressure forces the ring flat against the piston groove, creating an additional dynamic behavior of the ring. Rings of this kind are used in the top and second groove of passenger car gasoline and passenger car and truck diesel engines.

compression proving rings

Get Price Quote

Proving Rings, Compression Proving Rings (AIM 261 TO AIM 281), Tension Proving Rings (AIM 290 To AIM 298) & Tension Compression Proving Ring (AIM 284) The Proving Rings are made up of special steel, carefully forged to give maximum strength and machined to give high sensitivity commensurate with stability, ensuring long life and accuracy.All proving rings are integral type viz. the loading (outside) bosses are forged integral with the ring body. This ensures that there is no possibility of abutment shift and consequent loss of accuracy in reading that always exists with bolted abutments. Repeatability in these Proving Rings is as stipulated in IS:4169. The rings are supplied complete with dial gauge and Works Calibration Chart, individually packed in polished wooden boxes. National Physical Laboratory (NPL), (India)/ National Council for Cement & Building Material (NCCBM )Calibration can also be arranged for any proving ring at an additional cost. Proving rings to meet special requirements are also available on request.Separate polished and ground pair of Loading Pads for Compression Proving Rings and pair of Shackles for Tension Proving Rings are provided to suit each proving ring.We supply Compression Proving Rings, Tension Proving Rings & Tension Compression Proving Ring of different capacities. Application Compression and Tension Measurements Industry Chemical/Process Agricultural Civil Infrastructure Dams & Tunnels Geophysical/ Seismology Testing Geotechnical (soil/ rock) Testing Irrigation Mining Real Estate Roads, Highways & Bridges Education Architecture Building Technology Civil Department Geotechnical Mining Engineering Science Colleges Traffic & Transportation Railways Roads, Highways & Bridges

compression proving rings

Get Price Quote

Proving rings are used for load measurements and are used in outfits of a number of Soil / Cement & Bitumen Testing Equipments like Direct Share Test Apparatus, Triaxil Share Test Apparatus, CBR Test, Unicontained Test, Marshall Test etc. They are made out of special steel carefully forged to give maximum strength and machined to give highest sensitivity combined with stability to ensure long life and accuracy. When Compressive or tensile load is applied within the elastic range, the proving rings get temporarily deformed. This deformation is measured by a sensitive dial gauge fixed co-axially at the center of proving ring. The dial gauge readings thus obtained versus load applied enable the operator to find out unknown load, just by noting the dial gauge reading for unknown load. The proving rings have high elasticity and on removing load they regain their original shape provided they are loaded in their elastic limits.A Dial gauge and plunger anvil are mounted on brackets clamped to the ring body. The dial gauge is held perfectly rigid without the remote chance of shifting due to inadvertent shocks or pressures exerted on it. The dial gauge plunger rests on an adjustable anvil. Proving Rings , from 50 kg to 1,00,000kg capacity provided with 1/2 inch B.S.F female threads. Loading bosses and a loading ball nipple and steel ball are supplied with each rings. Rings of capacity over 25000kg (or 25 Tonnes) are not thus threaded. Each ring is individually calibrated and supplied with works calibration chart and a carrying case.

compression rings

Get Price Quote

The compression rings prevent leakage of gases in a combustion engine or leakage of pneumatic.hydraulic pressure in compressors hydraulic applications.

compression rings

Get Price Quote

We are offering compression rings

compression proving rings

Get Price Quote

Proving rings are used for load measurements and are used in outfits of a number of Soil / Cement & Bitumen Testing Equipments like Direct Share Test Apparatus, Triaxil Share Test Apparatus, CBR Test, Unicontained Test, Marshall Test etc. They are made out of special steel carefully forged to give maximum strength and machined to give highest sensitivity combined with stability to ensure long life and accuracy. When Compressive or tensile load is applied within the elastic range, the proving rings get temporarily deformed. This deformation is measured by a sensitive dial gauge fixed co-axially at the center of proving ring. The dial gauge readings thus obtained versus load applied enable the operator to find out unknown load, just by noting the dial gauge reading for unknown load. The proving rings have high elasticity and on removing load they regain their original shape provided they are loaded in their elastic limits.A Dial gauge and plunger anvil are mounted on brackets clamped to the ring body. The dial gauge is held perfectly rigid without the remote chance of shifting due to inadvertent shocks or pressures exerted on it. The dial gauge plunger rests on an adjustable anvil. Proving Rings , from 50 kg to 1,00,000kg capacity provided with 1/2 inch B.S.F female threads. Loading bosses and a loading ball nipple and steel ball are supplied with each rings. Rings of capacity over 25000kg (or 25 Tonnes) are not thus threaded. Each ring is individually calibrated and supplied with works calibration chart and a carrying case.Calibration charts from Standard Laboratories for the Proving Rings ordered are also available at extra cost.All Proving Rings are Integral Type.Integral type Compressive Proving Rings of different capacities from 50kgf to 200000kgf are available.(a) Above cap. 50 to 500kg.(b) Above cap. 500 to 3000kg.(c) Above cap. 3000 to 5000kg.(d) Above cap. 5000 to 10000 kg.(e) Above cap. 10000 to 20000 kg.(f) Above cap. 20000 to 30000kg.(g) Above cap. 30000 to 50000 kg.(h) Above cap. 50000 to 100000 kg.(i) Above cap. 100000 to 200000 kg.(j) Above cap. 200000 to 300000 kg.

compression rings

Get Price Quote

compression rings, Ring holding plier, Rocker arm bushing

plain compression ring

Get Price Quote

plain compression ring, Piston, Automobile Accessories, Wire Ropes

Compression Piston Rings

Get Price Quote

The company is one of the well-known Manufacturers and Exporters of Compression Piston Rings in Ahmedabad (India). The top Compression Rings is present in the first ring grooves. The Compression Piston Rings, offered by the company, has the primary function of sealing the combustion gases. The Compression Piston Rings are also the primary means for the transfer of the heat from the piston to the piston walls. Various types of Compression Piston Rings are designed in accordance to the specific applications they are used in. Common Types Of Compression Piston Rings Rectangular Ring : A Piston Ring with rectangular cross section. The Rectangular Ring is a simple shaped Piston Ring that performs the sealing in the normal operating conditions. The Rectangular Rings are used in marine and diesel engines, garden equipment, power plants, internal combustion engines, and rotary seals like industrial valves, shock absorber seals and blowers.Taper Faced Ring : A Piston Ring with tapered face. The Taper Faced Ring contacts the cylinder bore with the outer edge at the bottom. This particular feature of the Taper Faced Ring is useful in shortening the running-in time and improving the oil scraping. Taper Faced Rings are the primary installations in the second groove in various applications like Compressors, Marine Engines and Locomotives to name a few.Internally Bevelled or Stepped Ring : Provides edge relief to the top side of the Rectangular Ring and Taper Faced Ring. The design of the Internally Bevelled or Stepped Ring is such that it offers a twist effect which brings it into bore contact with the bottom outer edge only and that too, without gas pressure loading. The inner edge of the Internally Bevelled or Stepped Ring contacts the bottom groove side. The Internally Bevelled or Stepped Ring helps in improving the oil consumption control and is used in various industrial applications like Compressors, Hydraulic applications and Garden Equipments.Keystone Ring : Comes with both sides tapered and is used in if any kind of ring sticking is possible due to the wedge shape which may lead to some sort of radial movement. This can possibly alter the axial clearance and thus limit the combustion residue build up. These Keystone Rings are mainly used in the automobile engines where the chances of the occurrence of sticking are there.Half Keystone Ring : Have one tapered face which is usually facing the combustion chamber. The Half Keystone Ring also reduces the ring sticking. These types of Piston Rings find common usage in the various two stroke engines like snowmobiles. The Half Keystone Rings are also used in garden equipments and earth moving equipment.

compression provision rings

Get Price Quote

compression provision rings, dynamometers, Material Testing Equipment

Proving Ring Compression

Get Price Quote

Proving Ring Compression, compacting factor apparatus

compression proving rings

Get Price Quote

compression proving rings, force measuring devices, Soil Testing Equipment

compression rings

Get Price Quote

compression rings, braslat, studs tops, fine rind, Bangle, Necklaces

Compression Ring

Get Price Quote

Compression Ring

Piston Compression Rings

Get Price Quote

Piston Compression Rings

Tension And Compression Type Proving Ring

Get Price Quote

Tension And Compression Type Proving Ring, Metacentric Height Apparatus

compression rings

Get Price Quote

compression rings, lathe machine components, precision forgings

compression rings

Get Price Quote

compression rings, Cam Thrust Plates, oil control rings, Valve Body Covers

Compression Piston Rings

Get Price Quote

Compression Piston Rings, aluminum bearing, IROX Polymer Coated Bearings