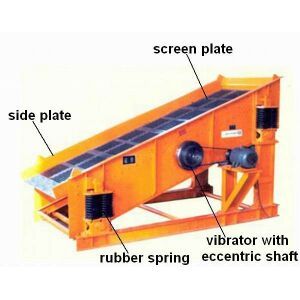

Vibrating Screen

Vibrating Screen are used to separate materials into various sizes for further processing. Or for end use. Depending on our need. The material is separated by passing it through a vibrating screen box which has a number of different sized screens, or meshes, which the material falls through like a sieve, the material falls onto attached conveyors which stock pile the end products. The end products can then be used in the building and construction industries. Vibrating screens are the most important screening machines primarily utilised in the mineral processing industry. They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size, and are applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above and directly connected to the screening surface.

...more

Stone Crusher

Stone crusher, including primary crusher and secondary crusher, is mainly used for crushing various ores and bulk materials with compression strength not more than 320Mpa into medium-sized grains. The series products have complete specifications and the feeding size ranging from 125mm to 750mm, which are the first choice for primary crushing. Jaw crusher or Stone jaw crusher is widely applied in mine, metallurgy, construction, road, railway, water conservancy, chemical industry, refractory material and ceramic, etc.

...more

Sand Mixer

Sand mixer can crush the materials and mix them at the same time, so that it is the ideal equipment for producing baking-free brick, lime-sand brick, cement brick and refractory brick and for crushing and mixing coal ash, boiler slag and tailing slag. The Structure Composition of Sand Mixer: This machine is composed of machine rack, driving mechanism and rolling mechanism. (1) Sand mixer 's machine rack is composed of machine plate, sand discharging door, sampling gate, air switch and air switching valve. (2) The driving mechanism consists of reducer, oil pump and stand column.

...more

Sand Maker

Sand maker is suitable for the crushing and shaping of soft, medium hardness and extremely hard materials, such as various ores, cement, refractory materials, aluminum soil clinker, emery, glass raw materials, building stone and gold slag. The Performance Characteristics of Sand Maker: 1. Large capacity, stable running.2. Low consumption of wearing parts.3. Perfect product shape, suit for sand making and stone reshaping.4. Thinning oil lubricant and automatic maintenance. Sand maker are widely used in crushing nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on. It is the indispensable machine in sand making industry and it is also the most ideal truing machine for mining and construction industries.

...more

Rotary Kiln

Rotary kiln is widely used in the fields of building materials, metallurgy, chemical industry, environmental protection, etc. It can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to the different materials processed. The cement kiln is mainly used to calcine cement clinker; In the process of non-ferrous and ferrous metallurgy, such as iron, aluminium, copper, zinc, stannum, nickel, wolfram, chromium, etc., the rotary kiln can be used to sinter and roast ore, concentrate, intermedium, etc.; The lime kiln is mainly used to calcine limestones. A rotary kiln is a device that supplies tremendous amounts of heat in order to change the chemical composition of an object. It is made up of a strong reinforced steel outer shell that is coated with a heat-resistant inner lining, support rollers and a drive gear to keep the contents in a continuous rotating motion and internal heat exchangers capable of producing temperatures well over 2732 degrees Fahrenheit (1500 degrees Celsius). Features: 1. Good calcination, high product quality;2. High capacity;3. Simple structure, reliable performance;4. Easy operation.

...more

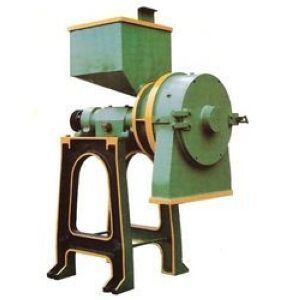

PULVERIZER

Pulverizer is used for grinding various kinds of items in different industries. These machines are manufactured in our advanced manufacturing unit by our experts using premium quality materials. These machines can be customized as per the requirements of the clients. These are highly appreciated for their superior quality, durability, excellent service, sturdy construction, high performance, reliability and efficiency. These machines are used to smash materials into tiny shards or granules. They can crush all types of items, including plastic, glass, aluminum, concrete, coal, rock, resin, tires, and medical waste. Pulverizer machines come in a number of different forms. Hammer mills, ring mills, double roll crushers, granulators, impactors, and shredders are all forms of machines. Pulverizers are available in various configurations like Single Mill Pulverizer, Twin Mill Pulverizer (Dual Mill Pulverizer) with various designs, sizes and shapes of pulverizer blades. Salient Features of Pulverizer: By using this machine you can manufacture 30-400 Kgs Master Batches p/h.The power consumption is very less compare to other pulverizing machines.Production cost will be cheaper.Low maintenance.Higher production capacity.Minimum man-power for operating the machine.High Quality and lower wastageEconomical and cost effectiveProduces fine micro PowderGives high output ratesA Single person can operate easily.

...more

Micro Powder Mill

Micro powder mill is suitable for the super fine crushing of all kinds of crisp materials whose Mohs hardness is below 5 such as calcium carbonate, barite, wollastonite, kaolin, rare earth ore, hematite, talc, feldspar and furnace slag. Micro Powder mill has the features of compact structure, adjustable product fineness, convenient maintenance, low energy consumption of unit product and low investment. The crushing and classification of the materials are completed in a closed system and the dusty gas is processed by the dust collector, so that it is the green and ideal equipment for environment protection. Features: 1. High-efficiency and low consumption With the same end-products fineness and motor power, its output can be doubled comparing with Jet Mill, Mix Mill, and Ball Mill. 2. Longer service life for wearing parts. The grinding roll and ring are made of special alloy. Generally, their service life is more than one year, but in certain condition which could up to over 3 years, like when it processes calcium carbonate and Calcite. 3. More secure and Reliable. There is no rolling bearings and screws in the grinding cavity, so no problems caused by the wear of bearings or screws 4. Good performance on Cleansing and Environment Protection This machine greatly reduces the industrial dust pollution and noise by applying Pulse dust collector and muffler, which reaches the National Standard.

...more

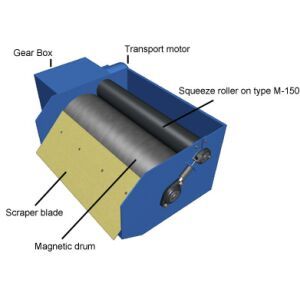

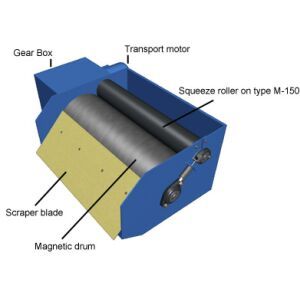

Magnetic Separator

Magnetic Separator is the high versatility machine, which is widely used in ore dressing, recycling, ceramic, chemical industry. The main function is remove iron from powdery material. Magnetic separator is suitable for material with particle size below 3mm, it can use wet seperation process for magnetite, pyrrhotite, calcination ore, ilmenite and other materials, but also can remove iron from coal, non-metallic minerals, building materials etc. Its magnetic system adopt high quality ferrite material or material compound with rare-earth magnet material, the magnetic strength of drum surface is 100-600mT. The advantage of magnetic separator is simple structure,large process capacity, easy operation and maintenance and so on.

...more

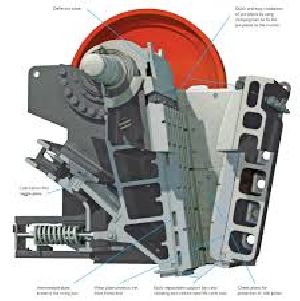

Jaw crusher

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do. A jaw crusher is generally used as a primary crusher in a crushing circuit. Product is fed into the top of the jaw crusher by an vibrating grizzly feeder. The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jaw. Jaw crushers are run on belt drives driven by an electric motor or diesel engine. Jaw crushers are used extensively throughout the aggregate and mineral processing industry. Jaw crushers are often used as primary crushers and are perhaps the most popular crusher worldwide. These compressive crushers are suitable for most any type of material. In this type of crusher, reduction takes place between a stationary jaw plate and a moving jaw plate. The moving jaw plate is mounted on the pitman, which is given a reciprocating motion. Crushing takes place when the pitman moves toward the stationary jaw, compressing the material. The Perfromance Characteristics of Jaw Crusher: 1. Crushing cavity is deep and there is no dead area, which improves feeding capacity and output; 2. High reduction ratio and uniform final product size; 3. Spacing piece type discharge-hole adjustment device is reliable and convenient; 4. Reliable and safe lubrication system, convenient replacement of parts and small work load of maintenance; 5. Simple structure, operational reliability and low operation cost.

...more

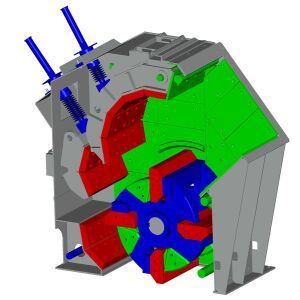

Impact Crusher

Impact crusher is a kind of crushing machine which is used for crushing of materials by using impacting energy. When the machine works, it drives the electro motor. The rotor will rotate with high speed. When the materials go into the action zone of the plate hammer, they will be struck & crushed on the plate of the rotor, and then crushed again. And they are thrown to the imapacting device, the material will bounce back from the impact lining board and go to the action zone of the plate hammer and are crushed again. This process will be proceeded repeatedly, and the materials go into the first, second & third impacting chamber to be crushed until they are crushed to the required granularity, and than discharged from the discharging mouth. Adjust the gap between the impacting rack and the rotor can change the discharging granularity and the shape of the materials. Impact crusher is used to crush materials which size is between 100 and 500 mm, and the hardness of the materials is no more than 350 MPa. The Impact Crusher is used for primary, secondary, fine crushing mining and rocks (for example, the granite, marble, and limestone) materials with compressive strength less than 350 MPa. The impact crusher is widely used for sand and rock producing in the industry of roads, railways, reservoir, electricity power and building materials and so on.

...more

Hammer Crusher

Hammer crusher (hammer mill) is applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150 Mpa. Hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials and compound fertilizer, etc. And hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure. The hammer crusher is mainly used in such industries as cement, coal separation, electricity generation, building materials and compound fertilizer. The hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure. The hammer crusher has the advantages of reliable mechanical structure, high productivity and favorable applicability.

...more

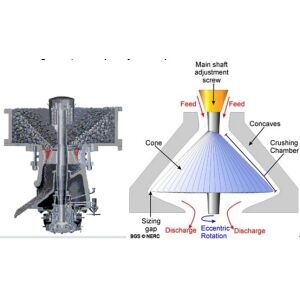

Cone Crusher

Cone Crusher machine is used in ore secondary crushing plant. It is widely used for all kinds of medium and fine crushing rocks with compressive strength under 350MPa in mining, cement industry, sand industry, metallurgy and other fields. It is especially suitable for materials with Mohs hardness under the range of 5-16, such as iron ore, non-ferrous metallic ore, granite, limestone, quartzite, sand stones, pebbles, etc. The cone crusher plays an important role in different industries, such as construction industry, chemical industry and metallurgical industry. It can be used to crush both hard and medium hard materials, such as limestone, iron ores and copper ores. When it comes to its production cavity, it is based on the types of the materials. The Benefits and advantages of Cone crusher: 1. Higher capacity and less wear costs.2. Wide range of application suitability.3. Easy to maintain, reduce the downtime and maintenance costs.4. Stable running performance and easy operation.

...more

Belt Conveyor

Belt Conveyor is a kind of machine that to transfer the material continuously. The belt works under the effect of frictional force. It is not only the components to transfer the material, but also the components to transfer the force. The Belt Conveyor is advanced and simple in structure, easy to maintain. Its transfer capacity is high, transfer distance is long. They are widely used in mining, metallurgical and coal industry to transfer sandy or lump material, or packaged material. In many situation, it Is a very important component of nonstandard machinery. Belt conveyors are the most commonly used powered conveyors because they are the most versatile and the least expensive. Product is conveyed directly on the belt so both regular and irregular shaped objects, large or small, light and heavy, can be transported successfully. These conveyors should use only the highest quality premium belting products, which reduces belt stretch and results in less maintenance for tension adjustments. Belt conveyors can be used to transport product in a straight line or through changes in elevation or direction. In certain applications they can also be used for static accumulation or cartons. Belt conveyors have proven to be a reliable method of conveying bulk materials. Industry standards for the design of belt conveyors have been developed by the Conveyor Equipment Manufacturers Association(CEMA). Features of belt conveyor: It mainly consists of frame rack, belt, roller, transmission part. The frame rack is made of steel; the belt is made of cotton or nylon as the core. It has the advantages of big conveying capacity, simple structure, convenient repair and standard parts.

...more

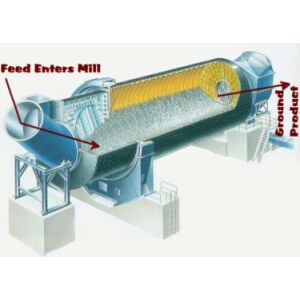

Ball Mill

Ball Mill – A Grinding Or Mixing Unit The ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix metals or raw materials for further processing. Various materials are placed into the mill drum and rotated with the mined materials that are to be crushed. The ball mill contains materials meant for crushing and grinding, such as balls of ceramic, small rocks, or balls made from stainless steel. The internal device of the ball mill grinds material into powder-like substances, and can rotate continuously for optimal grinding and refinery production.A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mill 's rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls. An internal cascading effect reduces the material to a fine powder. Industrial ball mill 's can operate continuously, fed at one end and discharged at the other end. Large to medium-sized ball mill 's are mechanically rotated on their axis, but small ones normally consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit rotary motion). Ball mill 's are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation of some pyrotechnic mixtures such as flash powder because of their sensitivity to impact.

...more

Hematite Iron Ore

Diatomaceous Earth Powder

Calibrated Iron ore

Magnetite Iron Ore

Be first to Rate

Rate ThisOpening Hours