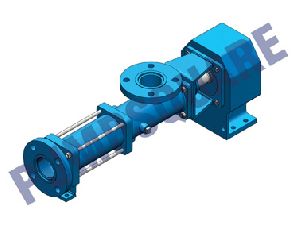

Twin Screw Pumps

PUMPSQUARE Twin Screw Pumps are designed for pumping contaminated or slightly abrasive liquid, lubricating and non lubricating media of low or high viscosity which do not chemically attack the pump materials. These are double entry pumps and the shaft spindle is axially held in position by ball bearings. Single unbalanced mechanical seal is used keeping the liquid pumped isolated from the bearings and gearbox. A spring loaded built in relief valve is used to protect the pump from overloading Option Heating and Cooling Jacket. Option of Horizontal and Vertical Mounting APPLICATIONS : Bilge/ballast Pumps General Service Pumps Cargo Pumps Transfer Pumps

Pressure : Δp

...more

Twin Screw Pump

Twin Screw Pumps are designed for pumping contaminated or slightly abrasive liquid, lubricating and non lubricating media of low or high viscosity which do not chemically attack the pump materials. These are double entry pumps and the shaft spindle is axially held in position by ball bearings. Single unbalanced mechanical seal is used keeping the liquid pumped isolated from the bearings and gearbox. A spring loaded built in relief valve is used to protect the pump from overloading.

...more

TROCHOIDAL GEAR PUMP / INTERNAL LOBE PUMP

WORKING : There are two Pumping Elements with Gear in Gear Principle. The Rotors are mounted on single shaft well supported on both the ends. As the Shaft Rotates, they mesh & un-mesh displacing the liquid axially through its pumping elements. Axially flow through elements ensures better suction capabilities, very low noise level and nearly pulsation free flow. These pumps have low power consumption compared to other brands due to unique mounting rotors. Rotors are produced using sintered metal technology and the other components are produced using the advanced manufacturing techniques with all the necessary quality checks for repeated accuracies in dimensions, guaranteed interchangeability and near to perfect pumping characteristics. This Series is highly reliable when put to work on field, has longer service life, practically needs no maintenance and has reduced cost of the end product than the conventional equivalent to the customer. A standard pump would consists of Rotors in Sintered Iron, with built – In Relief Valve, Shaft in EN-8 / SS-304, Lip Seal in Nitrile and all other parts in Cast Iron. APPLICATION : Unloading and Transfer of Lubricating Oil from Tanks and Barrels Oil Circulation, Gearbox, Bearing and Pressure lubrication Transfer of Fuel Oils from Daily Service Tanks, Pre Heaters and Filters Transfer and Circulation of Oil in Transformer & Oil Cleaning Machines Fuel Injection Pumps and as Booster Pumps in Oil Burner Services Unidirectional Flow Designer and Reversing Shaft Duties as in Machine Tools, Gear Boxes and Crane Duties In Hydraulic Power Packs Low Pressure – Continuous and Intermittent duty application TYPICAL LIQUID LIST Lubrication Oils, Fuel Oils like HSD, LDO, Furnace Oil, Transformer Oils, Palm Oil, Hydraulic Oils, Additives, Shampoos, Coconut Oil and media having good lubricating properties OPTIONAL MOC Under Special Execution we can offer pump in Stainless Steel, Ball Bearing Construction and Seals in Viton or EPDM. MOUNTING Monoblock type Pump and Motor eliminating need of Coupling and Frame. Foot Mounted Pump Coupled with Motor on a Base Plate with Coupling Guard Flange Mounted Pump Coupled with Motor using a Bell Housing Bracket FEATURES Compact, Light Weight, Easy to Mountain and Neat Design Can be Serviced in place without disconnecting the pipelines & Motors (Applicable even for Mono Block Construction) Bi-Directional Integrated Shaft in Mono Block construction eliminating the shaft runs out for the improved life of the lip seal. Also, Shaft is supported on 2X Bush Bearing as well as 2X Ball bearing reducing the load on shaft as well as the pumps Pump Shaft Dynamically balanced and Heat Dissipation is improved in Mono Block Design Engineered to run at high Speeds and adaptability of Mechanical Seals for Critical Applications even for lower flow rates Advanced Metallurgical Composition for Better and Longer Rotor Life Lower Power Consumption & High Volumetric Efficiency Pump with steam Jacketing on Request With Built-In relief Valve Improved Rotor Profiles for Smooth Meshing minimizing the Internal Losses and for excellent Suction Capabilities

...more

TRIPLE SCREW PUMPS / THREE SCREW PUMPS

GENERAL INFORMATION (TH 1X PUMPS) WORKING PRINCIPLE Triple Screw Pumps are positive displacement pumps of very simple design They consist of three rotating parts only the rotors" which turn in their precisely machined housing bores. The rotors are of double start screws, continuously meshing to form delivery chambers, which move constant y from the suction to the pressure / discharge side. Constant volume oi the chambers and the uniformity of the movement allow an even flow The pumps remain therefore near silent in operation and almost free of pulsation, even at high speed The Principle of screw pump and its accurate profiles warrant high suction power. Axial loads on the rotor are compensates by adequate design of the bearing part. All the radial loads are self-compensated. APPLICATION Triple Screw Pumps, type TH are used for die transfer of fluids with lubricating properties, as well as for generating pressure in hydraulic units or overcoming pressure in the hydraulic circuits. Main Industrial uses are in: Power Hydraulics Power Generation Lube industries Machine Tools Windmill Oil & Gas Compressor Lubrication Presses Marine Filtration TYPICAL LIQUIDS All kind of Bunker Oil, Engine oil, Furnace oil, Heating oil, Hydraulic Oils, High Viscosity Lubrication Oil, Mineral oil, Synthetic Oil, 0il Water Emulsions and Fuel 0ils, Diesel Oil, LSHS, LDO. MATERIAL OF CONSTRUCTION Pump Housing : Carbon Steel, Cast Iron, Stainless Steel Liner : Alluminium Alloy / Cast Iron / Copper Rotors : Main Screw : Alloy Steel, Hardened Steel and Surface Treated Steel Idler Screw : Hardened Steel, Surface Treated Steel Shaft Sealing : Mechanical Seal / Lip Seal with Elastomers in Viton, EPDM & Nitrile / Gland Pack/Graphoil Rings Mounting Frames : Fabricated Steel Relief Valve Parts : In Steel & Cast Iron EXECUTION The pumps here described may be incorporated in various housings and supplied as Foot, Flange or Pedestal Pumps. We also supply cast or welded housings to your specifications. To adapt the pumps to various applications, they can be fitted with the following seal variations: Radial shaft seals Gland packings (stuffing box) Mechanical seals PRESSURES Upto 120 bar are admissible. INSTALLATION Screw-Pumps work perfectly in any position, provided suction and pressure lines are arranged in a way that prevents emptying of the pump when at a standstill. DIRECTION OF ROTATION Clockwise from the Shaft End of the Pump (Standard) Anticlockwise from the Shaft End of the Pump (On Request / Non Standard) DRIVE In general the pumps are connected with a flexible coupling to a foot or flange mounted motor. Radial loads onto the shaft end are not permissible, unless when absorbed by an additional external bearing, e.g. in case of pump drive by belts or gears. SPEED OF ROTATION Shaft Speed Ranging from 500-3600 RPM Do not exceed 1500 RPM when pumping residual fuels, crude oil due to the presence of abrasives and contaminants. VISCOSITY Normal range 21,5 to 385 cSt. Depending on type, pressure, speed and suction conditions, fluids with viscosities ranging from 6 to 3800 cSt may be pumped. Regarding viscosities outside the normal range. Please consult us! TEMPERATURE RANGE When fitted with standard radial shaft seals, up to 90 Deg C. Depending on operating conditions, temperatures as high as 180 deg C are permissible. Please ask us! Cooling Jacket & Heating Jacket for the pump body & covers can be provided for easing the cold start of the pump and for continuously pumping liquids at high temperature. SUCTION LIFT OR INLET PRESSURE For speed between 1000 and 1700 r.p.m and viscosities below 385 cSt you may reckon with an absolute manometric suction lift of maximum 0,5 bar. For other speeds or viscosities. Please contact us! The inlet pressure should not exceed +0,5 bar, when radial shaft seals are used. For higher inlet pressures we offer gland packings or mechanical seals. If the suction lift condition exceeds the pump capability, cavitation will occur resulting in noise and possible pump damage. SUCTION AND PRESSURE LINES The cross section of the suction line should be such that fluid velocity nowhere exceeds 1 m/sec. In the pressure line velocity should not exceed 5 m/sec. PRESSURE RELIEF VALVE All housings described here may be obtained with or without pressure relief valve, which we supply at your option as by-pass valve, connected to the suction chamber, or as return valve, conducting the fluid by a separate connection to the tank. When a larger quantity should have to pass through the valve for more than 10 seconds, a return valve has to be fitted, to avoid an undue rise in temperature. FILTRATION The pumps must be protected against solid particles in the fluid by suitable suction filters. The mesh width should be 0.1 mm and care has to be taken that even with a contaminated filter the admissible suction lift capability is not exceeded.

...more

rotary lobe pumps

Rotary lobe pumps are designed to achieve maximum pump performance combined with minimal product damage. Specific attention is paid to the bearing construction and the rigidity of the shaft. The design is kept as compact as possible and the volume between the lobes is optimized.Capacity : 0,5 - 15 m3h, Pressure : up to 12 bar.

...more

Progressive Cavity Pumps

Progressive cavity pumps.

Peristaltic Pumps

Pump Sizes : SLP02 to SLP25, Capacity : 200 to 2500 Ih, Max. Suction Lift : up to 5 m Ws,Max. Pressure Head : approx. 2 bar, Max Temperature : approx. 100°C, FDA-conformable, Simple and Fast Demounting.

...more

MONOBLOCK GEAR PUMPS

Max Capacity: Up to 80 LPM Max Pressure: Up to 6 Bar Temperature: Up to 120 Degree C. Viscosity: 20 - 320 Cst. CONSTRUCTION & WORKING IL 2X series has been developed as a successor to the IL1X Series Generation, but with a modular design for the most rugged application. The users have peace of mind to an extent that all the pain points like coupling, coupling guards, alignment and shaft runout is eliminated. Furthur, the evolution of design is such that the bearings don't come in contact with the liquid and if need arises for maintenance, the pumps need not be disturbed from the pipe lines.The working principle is simple. There are two pumping elements with gear in gear principle. As the shaft rotates, they mesh & un-mesh displacing the liquid axially through its pumping elements. Axial flowthrough elements ensures better suction, very low noise level and nearly pulsation free flow. ADVANTAGE Just buy the pump head and easily fit it on your motor at your works. Monoblock Pump Head can be used across any type of motor & any brand motor as far as the Frame Size of the Motor remains same. With Built-In Relief Valve Improved Rotor Profiles for Smooth Meshing, minimizing internal losses and excellent suction capabilities. External bearing Design, Liquid doesn't come in contact with bearings. Low Power Consumption, Higher efficiency than traditional pumps. Eliminates the need of Mounting Frames & Coupling. Pump shaft is well supported on ball bearings to reduce the loads on the rotor as well as motor shaft. Hardened Shaft, Low Noise, no shaft run out, compact and light weight. Fit & Forget Design Reduced cost of your end product and monetary savings for you Value addition on your delivery of product as monoblock gear pumps with special motor ratings can be easily delivered MOUNTING & EXECUTION Horizontal Face Mounted Pumps for Close Couple Design with the Prime Mover. Pump mounting flanges to Suit B14 Face of standard Frame IEC Motor Electrical Motor to be of Foot + Face (B3 + B14 = B34)Type. Horizontal & Vertical Mounting as per your selection PRIME MOVER Three Phase AC Motor Single Phase AC Motor APPLICATION Unloading, Loading & Transfer of all types of Oils Circulation & Forced Lubrication in your Machines & Equipments As Filtration Pumps and Fuel Injection Pumps In Hydraulic Power Packs For all Low Pressure - Continuous & Intermediate Duty Applications. TYPICAL LIQUID LIST All types of Lubricating, Gear Oil, Water Emulsions & Transformer Oils Hydraulic Oil, Coolant Oil, Neat Cutting Oil, Mineral Oil, Furnace Oil & Fuel Oils like HSD & LDO Any media having good lubricating properties MATERIAL OF CONSTRUCTIONS (MOC) Pump Housing & Covers: Cast Iron Rotor Set: Sintered Iron Shaft: Hardened Alloy Steel Relief Valve Parts: In Spring Steel & Cast Iron Shaft Sealing Type: Lip Seal (Mechanical Seal Optional) Sealing Kit Elastomers: Nitrile (Viton Optional) Pump must be protected against solid particles in the fluid by suitable suction filters. Also, Running Dry or with Non-Lubricating Liquid will damage the pump.

...more

Marine Pumps Triple Screw Pumps

Used with low-viscosity fluids such as LSMGO and light gas oils with standard viscosities between 1.2 cSt and 10/15 cSt, typically used with Boiler systems with pressures up to 40 bar and flow rates of 560l/min (33.6m3/h). Its high self-priming strength and its capacity to operate at low viscosities make it very a suitable pump for applications with fluids that do not include lubricating properties among its main characteristics.

...more

Marine Pumps Double Station Systems

Double fuel pumping station typically applicable to diesel engine fuel Booster / Feeder systems. These systems include Zero leakage inlet and outlet valves, pressure control valves and systems to avoid fuel backflow through stand-by pump. Both pumping units can be used at the same time. Employed pump: PHS in its standard version, with traditional flexible coupling or with MAGNETIC DRIVE couplers.

...more

Internal Gear Pump

Proven Principle of Internal Gear is used in pumping. Rotor (Outer Gear) is keyed to drive shaft whereas idler (Inner Gear) is located eccentrically on a pin on the front cover. Both the gears are in mesh and the ports are sealed by a crescent located at the front cover. As the rotor and idler gear un-mesh, an under pressure is created and the liquid enters the new created cavities. Liquid is transported in sealed pockets to the discharge side. The walls of the pump casing and the crescent are creating a seal and separate suction from discharge side. The rotor and idler gear mesh pushing the liquid into the discharge line. Reversing the shaft rotation will reverse the flow through the pump as well.

...more

Peristaltic Hose Pumps

KIESEL hose pumps are conceived for dosing and filling of puniest volume. At the assortment of the materials the great importance is set to the abrasion resistance. ADVANTAGES : Without Lubricants All product touched parts in stainless steel Easy Cleaning Simple and Fast Demounting FDA-conformable Pump Sizes : SLP02 to SLP25 Capacity : 200 to 2500 I/h Max. Suction Lift : up to 5 m Ws Max. Pressure Head : approx. 2 bar Max Temperature : approx. 100°C

...more

Hose Pump

Hose pumps are conceived for dosing and filling of puniest volume. At the assortment of the materials the great importance is set to the abrasion resistance.Without Lubricants, All product touched parts in stainless steel, Simple and Fast Demounting.

...more

Heat Transfer Pump

PUMP APPLICATIONS Heating of baking ovens and large frying units Cooling of cold stores and refrigerated counters Tempering of tool moulds Production of edible oil and dry masses Heating of calanders, melting pots, agitators and mixing tanks in the leather, rubber and chemical industry and for the production of lacquers, colours and adhesives Heating of tank, fuel oil and bitumen chambers on stationary and mobile platforms as well as in tank ships, in crude oil production und processing Heating of coloring, coating, washing, pressing und ironing systems in the textile industry Heating of systems for bitumen production and processing, for drying applications and for the production of binders in the building industry Heating of systems for the production of liquid crystals in the pharmaceutical industry Heating of pipelines and treatment stations in the field of gas gathering Heating of temperature controllers in the die cast industry Design Features DESIGN FEATURES Horizontal, Single Stage, Closed Impeller, Single Entry Centrifugal Pumps with Volute Casing for Process Design Capacity - upto 200 m³h/hr Head - upto 550m Speed – upto 2900 RPM MAXIMUM OPERATING TEMPERATURE Heat Transfer Oil upto 350°C Hot Water upto 160°C COOLING METHOD - WITH AIR BEARING BRACKET SIZE -360 & 470 SEALING OPTIONS Mechanically Seal ( Single Acting Unbalanced) Magnetic Coupling for Zero Leakage Due to the back-pull-out design the complete bearing assembly including Impeller and casing cover can be dismantled without removing the volute casing from the pipe system PUMP SHAFT EXTREMELY RIGID TO MINIMIZE BENDING HYDRAULIC FORCES ARE BALANCED Radial Forces compensated by plain bearing close to Impeller and ball bearing on coupling side Pumps Painted with highly heat resistant aluminum paint ACCESSORIES (OPTIONAL) Quench Reservoir prevent oxygen from reacting with seal leakage, preserves seal life in long run

...more

flexible impeller pumps

KIESEL impeller pumps are self-priming, rotating pumps. They unite the characteristic of a rotary pump and a positive displacement pumps into one. ADVANTAGES : All parts in stainless steel. Casings in Cast Iron & Mild Steel can be provided on request. Gentle, almost Pulsation - free conveyance Easy cleaning Simple and fast demounting Compact design, Low Weight Liquids with solids are pumped without problems Complete accessories program available Pump Sizes : IP1 to IP30 Capacity : 1000 — 30 000 I/h Max. Suction Lift : up to 5 m Ws Max. Pressure Head : 4 bar Max. Temperature : up to 130°C

...more

EXTERNAL LOBE PUMPS

KIESEL rotary lobe pumps are designed to achieve maximum pump performance combined with minimal product damage. Specific attention is paid to the bearing construction and the rigidity of the shaft. The design is kept as compact as possible and the volume between the lobes is optimized. ADVANTAGES : Non-Contact run of the pumping elements Simple and Fast demounting Perfect for hygiene application Robust and authentic design CIP/SIP Cleaning Complete Design Different, Harmonized rotors for special products SPECIALS : Cover (in different materials) Available Capable for use with abrasive media Capacity : 0,5 - 15 m3/h Pressure : up to 12 bar Temperature : up to 150°C Viscosity : up to 160.000 mPas

...more

ECCENTRIC SCREW PUMPS / PROGRESSIVE CAVITY PUMPS

Flow upto 5000 LPM Pressure upto 24 Bar Temperature upto 150 c Shearless Pumping of Fluid Can Pump Solid Particles GENERAL INFORMATION : The progressive cavity pump is a positive displacement rotary pump. The actual pumping elements of the pump are the rotor and the stator. The single helical rotor rolls eccentrically in a double threaded helix stator of twice the pitch length. A series of sealed cavities 180,part are created that progress from suction and to discharge end. The opposing cavities fill and empty simultaneously resulting in a pulsation free flow. The fluid travels axially with relatively low velocity and minimal agitation of the fluid. This Pump has the Capability to transfer the liquid without Shear and no Churning of the Liquid takes place during Pumping. The stator is made of a resilient elastomers material and vulcanized to the stator tube providing a slide radial interference of the rotor in the stator. The important feature of the pumping principal is the ability to handle slurries and solid particles. The elastomers stator adds abrasion resistance beyond that of conventional rotary pumps. The particles tend to imbed rather than abrade the elastomers stator also allowing deformation to partially accommodate the solid particles. The compression fit of the rotor and stator enables the Progressive cavity pumps to handle gaseous liquids and low viscosity liquids. The pressure capabilities of the pump are a function of the nurnber of times the progressive seal lines are repeated. Our progressive cavity pumps are available in 1, 2, and 4 stage design. Each stage has a maximum pressure lirnit of 6 Bar. This pumps are available in a wide variety of materials and can be easily customized as per the fluid compatibility and requirements. Our progressive cavity pumps are versatile, rugged, compact and highly efficient. If the fluid is delicate, shear sensitive or abrasive, low or high viscosity, with fibers, high air content, or large solids, our progressive cavity pumps can solve the problem of moving the fluid. Pumps are available for Discharge pressure upto 24 Bar, flow upto 5000 LPM, temperature upto 150°C. SPECIAL FEATURES : Solid drive design provides strength for rigorous continuous operation. Unique Pivot-joint design extends service life and reduces replacement cost. Single, Two and four stage models for pressures upto 24 Bar Equal Wall Stator design available for some models which reduces pump slippage and increases pressure limit. Close coupled models with built on speed reducers offer a compact unit Stators are available in a wide range of elastomers. Suction lift to 28" w.c.

...more

CONSUMPTION MEASUREMENT - SCREW FLOW METERS

Screw-type volumetric flowmeter, compact, with in-line ports, very low head loss and high signal precision. Available with a broad variety of sensors and data reading, transfer and recording instruments.

...more

Horizontal Twin Screw Pump

Magnetically Couple Hot Oil Pumps

triple screw pumps

Flexible Impeller Pump

Be first to Rate

Rate ThisOpening Hours