shell moulding casting

Shell mold casting process is a technique in which liquid metal is poured into a cavity formed from a sand mixture. Shell molding process offers better surface finish, better dimensional tolerances, and higher throughput due to reduced cycle times and the fact that the process can be automated. These qualities of precision can be obtained in a wider range of alloys and with greater flexibility in design than die-casting and at a lower cost than investment casting.

...more

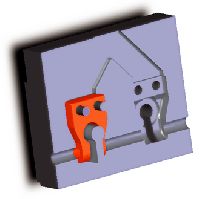

Self lubricating bushings

Self-lubricating bushingssliding pads are provided with solid lubricant (graphite base) inserted in holesgrooves. The solid lubricant forms a continuous lubricating film between the contact sliding surfaces and prevents metallic contact between the moving parts.

...more

permanent mold casting

The casting profile is machined into a specialty mould material (two or more depending on the complexity of the part), along with the gating system. The machined molds are then assembled along with required cores into a die assembly. The metal is poured into a die which then flows under gravity while being skillfully tilted to fill the mould appropriately. manufacture permanent mold castings ranging from a few grams to up to about 20 kilograms. While the smaller sizes are manufactured by manual process, the bigger sizes are manufactured on machine with automated PLC controlled tilting and mold coating facility.

...more

Mold Castings

Rapsri can manufacture permanent mold castings ranging from a few grams to up to about 20 kilograms. While the smaller sizes are manufactured by manual process, the bigger sizes are manufactured on machine with automated PLC controlled tilting and mold coating facility. The casting profile is machined into a specialty mould material (two or more depending on the complexity of the part), along with the gating system. The machined molds are then assembled along with required cores into a die assembly. The metal is poured into a die which then flows under gravity while being skillfully tilted to fill the mould appropriately. After the casting is removed from the cavity the moulds and cores are cooled in a proprietary solution which readies it for the next cycle.

...more

Centrifugal Casting

Centrifugal Castings are produced by pouring molten metal into a permanent mold that is rotated about its axis at high speeds (300 to 3000 rpm). The molten metal is centrifugally thrown towards the inside mold wall, where it solidifies after cooling. The axis of rotation may be horizontal or inclined at any angle up to the vertical position. The speed of rotation and metal pouring rate vary with the alloy and size and shape being cast. The casting is usually a fine grain casting with a very fine-grained outer diameter, the inside diameter has more impurities and inclusions, which can be machined away. The following operations include in centrifugal casting - rotation of mold at a known speed, pouring the molten metal, proper solidification rate, and extraction of the casting from the mold.

...more

carbon dioxide casting

The sand mixture used in this process is pure silica and sodium silicate. The molding mixture thus obtained is rammed around the pattern and gassed with carbon dioxide (CO2). The molding mixture gets hardened due to the formation of silica gel. After passing CO2, the pattern is removed and the mold cavity is ready for pouring. Properties of silicates vary according to the silica (SiO2)-soda (NaO) ratio of the sodium silicate base that is used to formulate the binder. Considerable care must be used when gassing with CO2 since overgassing and undergassing adversely affect the properties of the cured binding system. The amount of silicate binder used for cores and molds varies from 3% to 6% depending on the type of sand, grain fineness, and degree of sand contaminants.

...more

Bronze Bushings

The proprietary alloys of Rapsri conform or are equivalents of international standard specifications of ASTM, CDA, UNS, BS, DIN and ISO among others. Based on customer enquiry our engineering and R&D team will suggest suitable alternates or equivalents from our range for specific applications. The application of bronze bushings is in a wide range of areas where there is a requirement for wear. Rapsri has over 30 years of experience in this area and has provided valuable suggestions to end users on selection of material, type of lubrication, type of oil grooves and optimization of design for cost effective working.

...more

Bronze Bearings

bronze bushings manufacturer in India. Currently manufacturing approx. While most of the production is machined into bushes and bearings in the comprehensive machine shop in house, Rapsri also supplies customers with bars, tubes and profiles to specified sizes and material specifications.

...more

Bearing Bronze

Rapsri is perhaps the largest bronze bushings manufacturer in India. Currently manufacturing approx. 400,000 bushes per month, Rapsri has an installed capacity to manufacture approx. 600,000 bushes per month. While most of the production is machined into bushes and bearings in the comprehensive machine shop in house, Rapsri also supplies customers with bars, tubes and profiles to specified sizes and material specifications.

...more

Alloy Bushings

Heavy Commercial Vehicles: Engine Camshaft Bushings, Con-Rod Bushings, Piston Pin Bushings, Oil Pump Bushing, Thrust Washers, King Pin or Stub Axle Bushings, Brake Cam Shaft Bushings, Steering Gear Bushings, Leaf Spring Bushings, Gear Box Bushings. Stationary, Heavy and Locomotive Engines: Cam-shaft Bushings, Cam-Roller Pins, Governor Bushings, Thrust Bearings, Exhaust Valve Guides, Tappet Rod Guides.

...moreBe first to Rate

Rate This