Welded Steel Conveyor Chain

The Renold range of engineering class chain includes a complete line of welded steel mill and drag chains. The quality and performance of our welded steel chains have been the industry standard for decades. For the full range of welded steel chains available, please contact us. Type W Permaweld chains are normally of cranked link construction. The pins have a press fit into the side plates, thus eliminating unnecessary wear due to pin movement. Accurate punching of the plate, automated machine welding and assembly of the bushes to side plates ensures high quality and dimensional control. Steels of medium carbon grades are used for pin and plates and may be heat treated to produce greater strength and wear resistance. Bushes are of carburising grades of carbon steel which may be case hardened. Type WD Type WD Permaweld drag chains are furnished with heat treated pins and formed steel bushes. The bushes are shaped to provide maximum conveying capacity, shock resistance, toughness and higher yield strength in bending than many comparable cast and other welded links. Precise press fits of the pins in the side plates and single flats milled on the pin ends prevent unnecessary wear due to pin movement. Pins and side plates are made of medium carbon steels. Bushes are of carburising grade steels which are case hardened on the heat treated chains. Accurately punched holes and assembly procedures ensure dimensional control. The flexibility of welded construction provides a wider range of attachment links than is normally offered for similar cast chains.

...more

WASTE WATER TREATMENT CHAIN

We have the experience and can advise on installations and improvements that will keep this critical operation running. Renold supply all the specialised chain and sprockets for settlement and clarifier tanks at waste water treatment plants. High quality bar screen chain, 700 Series chain, non-metallic, cast and stainless steel chain and sprockets that are manufactured from 100% UHMWPE, combination of cast/steel hubs and UHMWPE segments, all Cast, and/or Steel construction. Fibreglass flights, laminated wood flights, UHMW wear strips, wear shoes, jaw clutches and wall bearings are also available.

...more

Vibratory Shaker Drives

For Use on Conveyors, Feeders, Screeners, Packing Tables and Other Vibratory Equipment Continuous Operation Long Life Dependency Low Maintenance Schedule Totally Enclosed Gear Driven Eccentrics 26 Sizes Throughout the world, Renold's Ajax Shaker Drives are recognised as energy efficient units, adaptable to countless new and unusual application possibilities. Standard applications include: Open and Enclosed Pan Conveyors Screeners Feeders Packaging Tables De-watering unit Tampers Electronic Test Tables Cable Laying Plows Six basic sizes are offered, each having a variety of eccentric weight selections. The force output range is from 115 to 11,000 lb, operating at low frequencies.

...more

Vibratory Fill Stations

Vibratory Tables / Packers: Automated Vibrating Weigh System Renold's custom engineered Vibratory Tables / Packers provide more materials in less space; while weighing, vibrating and filling simultaneously. Each unit is designed to insure the proper vibration, thus eliminating voids to increase the density of materials in Bags, Boxes, Drums, and Totes being packaged. Increases in density from 20% to 50% is achieved in minimal cycle time. Ancillary equipment such as in-line roller conveyors, pallet dispensers, slip sheet dispensers etc, including various PLC interfacing compliment the Station to make up the Turnkey System necessary to meet any specification.

...more

Vibratory Feeders

Brute Force and Two Mass Vibratory Feeders Renold's vibratory feeders meter bulk materials into the process at rates of 1,000 pounds per hour through 1,600 tons per hour. Our feeders are custom built to meet any application need. Feeders are built rugged to produce the consistent flow rates and trouble free operation needed for efficient processing. UL listed explosion proof motors are available capable of interfacing with variable frequency drives to carry the feed rate.

...more

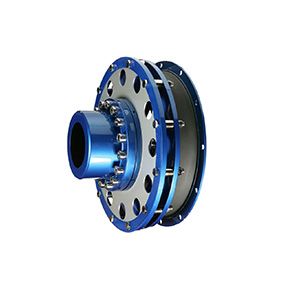

VF Coupling

The highly flexible VF coupling has been designed for diesel engines that are mounted separately from the marine gear and which can be placed on flexible mounts. These flexible mounts provide optimum isolation of the vibrations of the diesel engine from the hull. The VF Coupling can dampen torsional vibrations, tune the torsional response of the system and absorb the unavoidable substantial misalignments between the engine and the gear, it is specially suitable for high speed diesel engines with SAE flywheels from 14 to 21 and for power take offs up to a torque of 18.0 kNm. The standard range comprises Flywheel to shaft Shaft to Shaft Flywheel to flange Flexible Mounts Renold Hi-Tec Couplings can also supply a large range of flexible mounts to be used in conjunction with the VF Coupling, please click on the email icon below to email us your application details. Features Radial removal of rubber elements Low linear stiffness High misalignment capability Zero backlash Noise attenuation Tune the torsional response of the system Benefits Allows rubber elements to be changed without moving driven or driving machine Achieving low vibratory loads in the driveline component by selection of optimum stiffness characteristics Allows axial and radial misalignment between the driving and driven machines Eliminating torque amplifications through pre-compression of the rubber elements Giving quiet running conditions in sensitive applications by the elimination of metal to metal contact Achieving low vibratory loads in the driveline components by selection of optimum stiffness characteristics.

...more

Universal Joints Coupling

Renold's Ajax full line of universal joint assemblies range from 4 to 30+ inch diameters, with misalignment capabilities of up to 30 degrees. Renold offers both Metric and English designs with standard slip centre sections, or special long travel assemblies are also available. Extensive stock of standard components permits same day shipment for many designs if required. Closed eye, wing bearing and split eye designs are available. Four-point lubrication is optional on the smaller sizes and standard on the larger size assemblies. Specially developed seals retain the bearing lubricant, even under harsh conditions so extended grease intervals can be used without sacrificing reliability. Integral face pad flange connections reduce downtime during roll changes. Also available from Renold are heavy duty Pin and Block type universal joints, and constant velocity joint assemblies. Renold's Ajax full line of universal joint assemblies range from 4 to 30+ inch diameters, with misalignment capabilities of up to 30 degrees. Renold offers both Metric and English designs with standard slip centre sections, or special long travel assemblies are also available. Extensive stock of standard components permits same day shipment for many designs if required. Closed eye, wing bearing and split eye designs are available. Four-point lubrication is optional on the smaller sizes and standard on the larger size assemblies. Specially developed seals retain the bearing lubricant, even under harsh conditions so extended grease intervals can be used without sacrificing reliability. Integral face pad flange connections reduce downtime during roll changes. Also available from Renold are heavy duty Pin and Block type universal joints, and constant velocity joint assemblies.

...more

Tyreflex Coupling

A range of highly flexible couplings offering excellent misalignment capacity, and suitable to absorb both shock loads and vibrations. Coupling Capacity Maximum power @ 100RPM - 65.8kW Maximum torque - 6270Nm Features & Benefits High misalignment capabilities - high flexibility Shock absorbing - extending machine life Maintenance free - minimum number of wearing parts Standard fire retardant - anti-static elements up to size TY100 for use in flameproof environments Interchangeability means no re-engineering Pump spacer option for easy pump maintenance Taperbush bores available for ease of replacement Standard Range Comprises Shaft to shaft Pump Spacer Type Applications Compressors Generator Sets Pumps Roller Table Drives General industrial applications Construction Details Steel or S.G. Iron half bodies Urethane Tyres: Temperature Range -40°C to +80°C Rubber Tyres: Temperature Range -50°C to +50°C FRAS Tyres: Temperature Range -15°C to +70°C

...more

Transit Escalator Drive Solutions

Renold Gears designs and manufactures a full range of heavy duty transit escalator drive solutions. Design options include: Compact Drives The new WH Series escalator drives combine the benefits of worm and helical gearing in a compact design offering high efficiency, low noise and minimal maintenance. Direct Drives Slim line unit directly mounted on to the headshaft, eliminating lubrication and risk of contamination. Traditional Drives Renold supplies traditonal base plate arrangements designed for London Underground, Washington Metro and New York Subway. Double Drives Renold has developed a number of solutions ideal for in truss arrangements which can be configured as double drives. Replacement Drives Renold produces replacement drives and gearing for old and obsolete designs. Our design capabilities enable re-engineering from sample parts or drawings.

...more

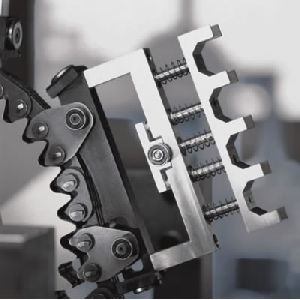

Tooth Chain drives

Special chains with all types and pitches are individually adapted to the indicated requirements.This is accomplished using state-of-the-art technologies and specialized expertise from a single source.We offer custom-made inverted tooth chain drives, including: Inverted tooth chains with integrated special links as drivers or incremental transducers Individualized versions through the easy integration of parts from other manufacturers using special link plates or adapter pieces Inverted tooth chains made of stainless steel, with specially treated surfaces for use in cleanroom applications, with special joints for inverted tooth chains without rigid backing Configurations for special applications with inverted tooth chains in special pitches, e.g. by combining inverted tooth chain components with special link plates or individualized, complex geometries Advantages at a glance Cost savings compared with in-house developments Extensive expertise from different industries in over 120 years of activity as a developer Higher quality tooth meshing and quieter running Less elongation Increased permissible speed Reduction of required lubrication and maintenance

...more

Tooth Chain Drive

Our product range offers the right drive concept for every application and its specific requirements, including matching sprockets to ensure optimum functioning. Advantages at a glance Industry-specific product innovations Components with needs-based additional equipment Customized overall solutions based on your specific requirements Long service life, easy assembly Quality for every applicationAll Renold drive solutions feature extremely even, gentle, and precise running. With high-quality materials and production processes, our products can even be used in harsh environments, at high temperatures, or with aggressive agents. Inverted tooth chain types and special formsHPCState of the art. – The HPC, the most powerful type of Renold inverted tooth chains, sets new standards for wrap drives. Faster, quieter, and more precise than all other inverted tooth chains, it meets the highest demands. BIFLEXThe highest flexibility possible – symmetrically toothed link plates on both sides yield equal performance and precision during bilateral use. This makes BIFLEX the ideal solution for changes in direction of rotation or for multi-shaft drives. Special formsIndividual – and always ready to meet your requirements. The maximum flexibility of the inverted tooth chain drive system allows it to be adapted easily to the most diverse requirements – from the individual special link plates to complete specialized inverted tooth chains, we have the right solution for your application! HDLImprovements to the link plate form and joint kinematics compared to the KH type help transfer larger forces within smaller spaces. HDL enables speeds up to 40 m/s.~ KHA tradition of quality – the KH inverted tooth chain was the first drive chain design to include a rolling pivot joint. This set the stage for the integration of inverted tooth chain drives in demanding applications. KH inverted tooth chains are still a safe and economical special solution for certain applications.

...more

Theme Parks Trident Chain

Renold has extensive experience in supplying theme parks around the world with conveyor chain for theme park rides, from roller coasters to water rides. Through continuous research and development and examining the common causes of chain failure in corrosive environments, Renold has developed the Trident Chain series to tackle the three main areas of failure in such environments: corrosion, seizure and wear. Tackling Corrosion Due to constant exposure to water, corrosion is often an issue on water ride chains. To address this, Renold has developed a dual process surface treatment to increase corrosion resistance. The zinc based specialised coating offers superior protection of the steel. Even when the coating is penetrated, the treatment continues to offer superior corrosion resistance. Eliminating Seizure Transfer and lift chain on rides can suffer from seizure of the bush and pin and significantly shorten the life of the chain. Through the development of a unique polymer sleeve, metal-to-metal contact is reduced, thereby eliminating the risk of the bush and pin seizure. This also provides lubrication-free operation and removes the need for any lubrication ports. Reducing Wear Development of a heavy wall bush design overcomes premature wear and failure of the bush, and in most cases a shell roller can also be incorporated which reduces wear on sprocket teeth; increasing life of both the sprocket and chain – and reducing maintenance time and cost.Additional Benefits Integral attachment design – eliminates attachment/plate corrosion issues Smoother and quieter operation than standard water ride chain Operates on the same sprockets and track as standard chain. Superior breaking load and working load *in salt spray testsNOTE: Polymer sleeve highlighted in yellow for illustration purposes onlyFor more information on Renold Trident and how it can reduce costs for your theme park rides, call us today on +44 (0) 161 498 4600 or use fill in our request form for more information.

...more

Theme Parks Conveyor Chain

Renold has extensive experience in the manufacture and supply of chain solutions for theme parks. From Roller Coasters to Water Rides, Amusement Parks around the world trust Renold to deliver chains designed to minimise downtime and maximise safety. Overview Supreme performance under high and shock loads Major suppliers to many original equipment manufacturers All Renold manufacturing and assembly processes are controlled in accordance with vigorous procedures and controls developed over many years Renold chain has proven reliability on leisure rides in theme parks around the world As applications are often specific, Renold offers a full bespoke design to customers' requirements. As standard, Renold provides: Excellent fatigue life High reliability Full technical service Basic coaster chain Cranked link design with breaking load up to 667kN, maximum speed of 1.8m/s and a fatigue of 1,000,000 cycles at 70kN. Maximum overload is 120kN with a wear life of 15,000 hours at 1% elongation. Features Blanked holes Good interference fits End softening Case hardened pin Stake Rivet Grease lubrication Welded bush versions available Enhanced coaster chain Cranked link design with breaking load up to 667kN, maximum speed of 2.7m/s and a fatigue of 1,000,000 cycles at 90kN. Maximum overload is 150kN with a wear life of 15,000 hours at 1% elongation. Features Machined holes High interference fits Cottered pins Induction hardened pins Honed bush bore Shot peened plates Individual inspection and tag Grease gun lubrication Super coaster chain Straight side plate chain with a breaking load of 700kN and a maximum speed of 3.0m/s. Fatigue life up to 1,000,000 cycles at 120kN with a maximum overload of 160kN and 15,000 hour wear life at 1% elongation. Features CNC machined holes Optimum interference fits Stake rivet / end softened pin Induction hardened pin Honed bush bore Shot peened plates Individual inspection and tag Grease gun lubrication Mega coaster chain Straight side plate chain with a breaking load of between 900 and 1200kN and a maximum speed of 3.5m/s. Fatigue life of 1,000,000 cycles at 180 – 270kN with a maximum overload of 230 to 320kN. Wear life of 15,000 hours at 1% elongation. Features CNC machined holes Optimum interference fits Stake rivet / end softened pin Induction hardened pin Honed bush bore Shot peened plates Individual inspection and tag Grease gun lubrication Water ride chain Conveyor chain with breaking loads of between 67kN and 900kN. Features Machined holes High interference fits Zinc plated Other surface treatments available Treated with special water resistant lubrication as standard To discuss your specific requirements, contact us on 0161 386 4600 or submit an enquiry via our website.

...more

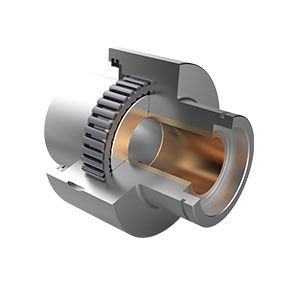

standard gear couplings

Renold Ajax carries a full line of standard gear couplings that conforms to the AGMA gear coupling specification number. They are offered in o-ring or metal seal designs, and include quality features such as fitted bolts, crowned and barreled teeth with tooth tip piloting, and forged steel components. The Renold Ajax metal seal design coupling uses a unique method of seal retention that will not allow the seal to separate from the ring gear during operation. This seal design also allows a metal seal ring gear to easily be converted to an o-ring seal configuration and back to metal seal if needed. Renold Ajax standard couplings also include a line of D- and DS-Series high misalignment couplings that are capable of operation at up to 6 degrees misalignment. The D-Series couplings use a piloted flange for connection while the DS-Series couplings have a detachable sleeve for connection in applications with a diameter restriction such as levelers.

...more

Standard Conveyor Chain

Conveyor chain, like transmission roller chain, can be manufactured to a number of different international standards. The main standards available are: British Standard (BS)This standard covers chain manufactured to suit the British market and markets where a strong British presence has dominated engineering design and purchasing. The standard is based on the original Renold Conveyor Chain design.ISO Standard ChainChain manufactured to ISO Standard is not interchangeable with BS or DIN Standard Chain. This standard has a wide acceptance in the European market, except in Germany. Chain manufactured to this standard is becoming more popular and are used extensively in the Scandinavian region. Renold has extensive experience in the manufacture of conveyor chain. The Renold specification of conveyor chain has taken many years in design and development to achieve the optimum product. In order to ensure this is translated into product performance, we strictly control: Materials Heat Treatment Processes Fits Attachment Assembly Lubrication Renold Ultimate Reliability The key to Renold chain reliability is consistency in design and manufacture. Maximum chain strength and resistance to wear are achieved by strict control of the material specification and by using state of the art heat treatment processes. The consistent overall tolerances of Renold chain make it ideal for conveying systems requiring precise alignment on multi-strand chain layouts. Breaking loads exceed the minimum international standards. Correct chain selection is essential for optimum performance. Renold’s experienced design team are always available to freely advise on particular products and applications. Standard and Deep Link conveyor chain is available to BS4116 Part 4 as well as ISO 1977, with both Hollow and Solid Bearing Pins. Extra Strength Standard Conveyor Chain To complement our standard range of British Standard Conveyor Chain, this extra strength chain is more suitable for conveyor applications selected on ultimate tensile strength (breaking load). Each chain is the same dimensionally as its normal counterpart, for example an extra strength 24000 lbs chain has basically the same dimensions as a normal 12000 lbs series chain. This chain is used extensively in the conveying of animal feed and bulk food stuffs such as grain, maize, wheat and raw food mixtures. Most of these applications use scraper type conveyor systems that normally have long centre distances between sprockets. Such systems are sometimes slow moving with little or no shock loading. Contact our technical sales staff for selection and applicational details.

...more

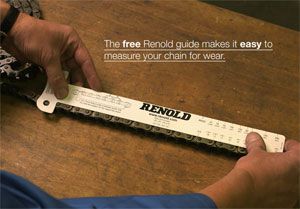

Standard Chain Wear Guide

The Standard Chain Wear Guide from Renold is a quick and easy way to measure chain elongation. You can clearly see that if your chain has reached or even exceeded the recommended limit of 2% wear extension then it is time for the chain to be replaced. Make sure that chain wear doesn't cause you problems like downtime, lost production and reduced profitability. Watch our video on the right to see how to use the Renold Chain Wear Guide correctly.

...more

Standard Attachments

Standard attachments are parts fitted to a base chain to adapt it for a particular purpose as a conveying medium. Attachments may form an integral part of the link plate or may be built into the chain as a replacement of the normal link. Other attachments (according to type) are fixed to the chain plates by projection or fillet welding, to either one or both sides of the chain. Standard attachments are described below: F AttachmentsOuter or Inner Links F Attachments provide a flat surface at right angles to the chain plate. They are used for securing pushers, scraper bars, etc. K Attachments Outer or Inner Links K Attachments provide a platform parallel to the chain line and bearing pin axis. They are used for securing slats, scrapers, buckets etc. to the chain. L Attachments L Attachments are integral with the chain outer plates. Normally they have one or two holes (L2 preferred), but for use on scraper applications they can be supplied without holes and with various box widths (LO Type). Outboard Rollers For use on Hollow Bearing Pin Chain Outboard rollers have two principal advantages; as direct load carriers they enable the chain rollers to be used solely for gearing purposes and in the event of outboard roller wear, they can be replaced easily without recourse to chain replacement. They are particularly useful when attachments prevent the gearing rollers running on support tracks on the return run or where the roller loading is high. Spigot Pins & Holed Link Plates Spigot pins may be assembled either through hollow bearing pins or link plates and are secured by a nut and spring washer. Single holing is primarily for use with spigot pins and is required on both sides of the chain. Double holing is provided for the assembly of special attachments on one or both sides of the chain. The holes in the inner plates are countersunk on the inside face to prevent the bolt heads fouling the sprocket teeth.

...more

Sprockets

Renold offer a comprehensive range of transmission chain sprockets for British Standard chain up to two inch pitch, ensuring maximum working life and productivity for your application. Other sizes of sprocket, including those to American Standard dimensions, are available on request. Special sprockets are also manufactured on request, in special materials or formats, normally to suit a specific applications in harsh or difficult drive situations, such as; Sprockets incorporating shafts Welded or detachable hubs Shear pin devices fitted Necklace sprockets made up of chain plates and individual tooth sections for turning large drums or tables. Combination sprockets (two or more sprockets combined having different pitch sizes and numbers of teeth). Sprockets in two or more sections, i.e. split sprockets or segmental sprockets. Sprocket and Chain CompatibilityMost drives have an even number of pitches in the chain and by using a driver sprocket with an odd number of teeth, uniform wear distribution over both chain and sprocket teeth is ensured. Even numbers of teeth for both the driver and the driven sprockets can be used, but wear distribution on both the sprocket teeth and chain is poor. Number of TeethThe maximum number of teeth in any driven sprocket should not exceed 114. This limitation is due to the fact that for a given elongation of chain due to wear, the working pitch diameter of the chain on the sprocket increases in relation to the nominal pitch diameter, i.e. the chain assumes a higher position on the sprocket tooth. The allowable safe chain wear is considered to be in the order of 2% elongation over nominal length. A simple formula for determining how much chain elongation a sprocket can accommodate is 200/N expressed as a percentage where N is the number of teeth on the largest sprocket in the drive system. It is good practice to have the sum of teeth not less than 50 where both the driver and the driven sprockets are operated by the same chain, e.g. on a 1:1 ratio drive. Both sprockets should have 25 teeth each. Centre Distance For optimum wear life, centre distance between two sprockets should normally be within the range 30 to 50 times the chain pitch. On drive proposals with centre distances below 30 pitches or greater than 2 metres, we would recommend that the drive details are discussed with our technical staff. The minimum centre distance is sometimes governed by the amount of chain lap on the driver sprocket, our normal recommendation in this circumstance being not less than six teeth in engagement with the chain. The centre distance is also governed by the desirability of using a chain with an uneven number of pitches to avoid the use of a cranked link, a practice that is not recommended except in special circumstances. For a drive in the horizontal plane, the shortest centre distance possible should be used consonant with recommended chain lap (maximum six teeth) on the driver sprocket.

...more

Spiderjaw and Spiderwrap Coupling

This medium power torsionally flexible coupling combines shock absorbing and misalignment capacity, used in the widest range of industries and applications. Coupling Capacity Maximum power @ 100RPM - 45kW Maximum torque - 4308Nm Features & Benefits Torsionally flexible - shock absorbing, extending machine life. Maintenance free - minimum number of wearing parts. Misalignment capabilities allowing flexibility in installation. Jaw wrap allows external wrap fitting of elastomeric element. Cost effective - offering low cost product with a high quality design. Jaw wrap ensures machinery downtime kept to a minimum so ensuring continued process. Dimensionally interchangeable with other Spider Jaw couplings - Lovejoy, Browning & Fenner Taper bush bores available for ease of maintenance Compact design - small, with high torque capacity. Applications Bulk handling Compressors Generator sets Metals manufacture Pumps Conveyor drives Paper converting Logging General industrial applications Standard Range Comprise Shaft to shaft Taper Bush Pilot bored Bored and keywayed to customers requirements General Details Coupling materials available include: Cast iron half bodies Sintered iron half bodies Aluminium half bodies Elements available include: Nitrile (standard) Urethane Hytrel Bronze

...more

Spiderflex Coupling

A medium power torsionally flexible coupling combining shock absorbing and misalignment capacity, used in the widest range of industries and applications. Coupling Capacity Maximum power @ 100RPM - 33kW Maximum Torque - 3150Nm Features & Benefits Torsionally flexible - shock absorbing, extending machine life Dimensionally similar to other spider couplings - interchangeable Maintenance free - minimum number of wearing parts Misalignment capabilities allowing flexibility in installation Cost effective - offering a low cost product with high quality design Optional fire retardant anti-static elements for use in flameproof environments Taperbush bores available for ease of maintenance Compact design - small, but with high torque capacity Blind assembly Applications Bulk handling Compressors Generator Sets Metal Manufacture Pumps General Industrial Applications Construction Details Cast iron half bodies - Grade G220 Standard element - Shore Hardness A90 FRAS element - Shore Hardness A78 Temperature Range -30+100°C Standard Range Comprises Shaft to shaft Taper Bush or Parallel Bore

...more

SO Sprag Clutches

Features All clutches are fitted with high precision heavy duty bearings for arduous duty applications Clutch sizes 300 to 700 are fitted with ARO sprags to resist vibration and high transient torques and overloads SO series clutches, oil lubricated suitable for overrunning, backstopping and medium duty indexing (up to 150 indexed/minute) Grease lubrication is available where high inner race overrunning speeds are required or maintenance is difficult SO series clutches, grease lubricated for use on general purpose overrunning and backstopping applications SX series clutches, oil lubricated designed for medium to heavy indexing applications (over 150 indexes/minute) Applications Pump drives Paper Machinery Textile Machinery Light duty hammer mills Fan Drives General industrial applications

...more

SH Sprag Clutch

Renold Sprag clutch Holdbacks with Central Torque Arms are self contained units ready for mounting on the headshafts, or other suitable driving shafts, of inclined conveyors or elevators to prevent run back. Features High precision sprags create instantaneous action with ZERO BACKLASH High quality, high precision heavy duty bearings for arduous applications SH clutches designed for LONGLIFE and lower overall operating cost Able to accommodate LARGE BORES (up to 20") and HIGH TORQUE CAPACITY within compact design Dimensionally INTERCHANGEABLE one piece central torque arm design for ease of replacement against other brands Quick disconnect mounting pins for fast torque arm removal Enhanced labyrinth sealing for use in hostile environments Grease or oil filled options available Axial retaining collars available for all sizes Renold Sprag Clutch RE-CONDITIONING SERVICE TO NEW available on all sizes Typical Applications Inclined belt conveyor Bucket elevator If reverse rotation occurs serious safety problems would be created and possible machinery failure. To overcome the problem of drive reversal a Renold Sprag Clutch holdback is fitted to the conveyor headshaft and held with a torque arm against stops fitted to the framework of the conveyor. Aggregates Industry Renold SH Sprag Clutch Holdbacks are used in the aggregates industries Worldwide, often in conjunction with high quality RENOLD GEARBOXES, typically on inclined conveyors. The SH Sprag Clutch Holdback is positioned on the end of the conveyor headshaft. If the drive fails or is stopped when the conveyor is loaded the SH Sprag Clutch Holdback instantaneously prevents any runback. This is due to the sprag elements of the clutch being in constant contact at all times with the inner and outer races of the clutch element of the holdback. Resultant downtime is prevented and also any potential accident risk to personnel. Renold SH Sprag Clutch Holdbacks are ideal for use in the aggregates industry being equipped with high quality seals that prevent contaminants from reaching internal parts and ensuring long unit lifetime. Mining Renold SH Sprag Clutch Holdbacks are fitted to inclined conveyors used to transport bulk materials in many coal or iron ore mines around the World. A typical example of a mine application is shown on the right. Fitted to an apron feeder drive in an iron ore mining plant in Canada the SH Sprag Clutch Holdback with Central Torque Arm prevents any runback in the drive, if the drive fails or is stopped. This is due to the sprag elements of the clutch being in constant contact at all times with the inner and outer races of the clutch element of the holdback. Resultant downtime is prevented and also any potential accident risk to personnel. The high quality components and overall robustness of the Renold SH Sprag Clutch Holdback with Central Torque Arm design is ideally suited to the heavy duty and hostile environment that apron feeders operate in ensuring long unit lifetimes. Material Handling Renold SH Sprag Clutch Holdbacks are fitted to many inclined conveyors and bucket elevators that transport bulk handling materials around steel works, such as coking coal and iron ore, major docks, moving bulk materials to storage and many other sites around the World. Whenever a Renold SH Series Sprag Clutch Holdback is fitted it provides the user with complete peace of mind knowing that not only have they purchased a holdback that provides instant runback protection every time when needed, but is also of the highest quality and the knowledge that a superb back up service is available to enhance their investment even further.

...more

SCPF and SCGF Sprag Clutches

Features SO series clutch combined with Pinflex coupling allowing for angular, parallel and axial misalignment Absorbs vibration and shock loads SO series clutch with two flexible half Gearflex couplings forming a short cardan shaft accommodating parallel and angular misalignment Flexible shaft connection for overrunning barring drive applications Grease lubricated clutch used as standard for high overrunning speeds and infrequent maintenance Allows larger shaft sizes to be used Construction Pinflex clutch uses all steel coupling half bodies for compactness combined with strength Gearflex clutch uses all steel double engagement coupling for maximum flexibility Applications Barring drives Dual drive systems - overrunning Power generator sets Packaging machinery Textile industry Fan drives Steel works Mining industry General industrial applications

...more

Sb Sprag Clutches

Features: Extended spigot at one side to allow direct mounting of chain pinions gears, index arms etc - design flexibility Sleeve bearing inside the extended spigot - greater strength Dimensionally identical to other manufacturers - interchangeability SB3 clutches are supplied greased and sealed for life - no maintenance is required SB5 to SB16 clutches can supplied suitable for oil or grease lubrication or without seals for use in oil bath applications All SB Series clutches are optionally left or right hand Applications: Centrifugal pumps Textile Machinery Instrumentation Mixer Drives Blowers and fan drives Light duty general industrial applications

...moreBe first to Rate

Rate ThisOpening Hours