Wire Coiler Machine

On the other side of the machine, we find the rotor that is composed of coiling forms that can be opened automatically with the help of Pneumatic system. The coil forms are interchangeable depending on the coil size and cable size.The machine is also equipped a meter counts that checks precisely the length on the coil, When the preset length is achieved, the roter forms 1800 and the operation in cut the wire length a cutting device placed in front of him.Automatic coiling cable from an extrusionline or a payoff rewinding line.

...more

mounting flanges

Sai Extrumech Private Limited manufactures all the relevant accessories for the extrusion industry like mounting flanges, all type of replacement parts, By- pass/bleed port system, Jelly injection guns, Corrugation rollers, Armouring tools for optical fibre cable etc.

...more

Tip & Dies

Sai manufactures tips and dies with precision unmatched in the industry today. Settling for less will lead to compromised product quality. All tools are produced using certified and documented quality steel material specifically qualified for the polymer to be extruded. Sai designs tip & dies for any application that you need, whether it is multi-layers, stripe and multiple stripe, wire & cable, hose, pipe, tube, fibre optic.

...more

Screw & Barrel

we offer premium grade extruder series that includes machine size with screw diameter of 30, 40, 50, 65, 80, 100, 120, and 150mm. in addition, we also engaged in supplying various versions with alternative generative driving powers and torques with maximum specifications with high efficiency. thus, these are suitable for a specific industrial application. following are the main features of (screw / barrels): * we provide single screw extruder that is used for the production of cables from typical thermoplastics such as pe, hdpe, pp, xlpe, pvc materials and special types for high output applications * these screw and barrels are manufactured from special nitro alloy steel nitrided with mirror finish. the barrel is honed with spiral grooved in feeding zone to enable forced feedings * we offer high grade alloys for bimetallic barrals, which are used in general and also specific high demand applications to prevent the effects of wear and corrosion. drive / gears these high grade extruders are driven by ac motors. the control of the driving motor enables to control the speed. further, the dual-reduction gears are capable of withstanding great thrust and torque loads and helical gearing. the superior quality materials help in noiseless functioning and enhance the durability of the mechanisms.

...more

Screw and Barrel

Sai offers standard application finished screws through flight tipping as well as fully encapsulated screws. This combined with corporate research and development, has enabled Sai to offer barrel material, screw finishes and screw geometries for nearly every extrusion machine and plastics processing application. Screw designs within the Sai have evolved over several decades from simple single flight Geometries to sophisticated barrier/mixing designs. State-of-the-art advances in screw design have improved the melting and solids conveying capabilities of the single screw extruder, leading to higher productivity. The most significant advances in melting are being realised due to our patented barrier screw geometriesSai can supply almost any size of extrusion screw for almost any application, and also offer a comprehensive rebuilding service too. Just remember the most important element in any extrusion system is the feedscrew and is responsible for the critical functions of feeding, solid conveying, melting, mixing and pumping. Feedscrew Technology Our ability to design and manufacture some of the industry's most advanced and efficient feedscrews is one reason we have been an extrusion leader for more than 10 years. With our R&D facilities and team of experienced polymer process engineers, we offer customers world class screw design and technical capabilities. R&D Capabilities Our primary research and development center in Pawcatuck, Connecticut, USA, enables us to research, test, and supply custom feedscrew designs. Quality Materials Feedscrews manufactured from a variety of metals for corrosion and wear resistance. Screws for Every Application Screw sizes range from ½ inch (13mm) to 12 inches (300mm) for single screw, and 40mm to 140mm for counter-rotating twin screw. Screws, including smooth and groove feed designs, can be customized for specific applications. Proven Technology Barrier screw technologies are known worldwide for consistently higher output rates, process stability, venting and devolatilization capabilities, distributive and dispersive mixing properties, and minimized polymer degradation. Process Technology Our experienced team of process engineers work with our customers on unique features. Barrels Our primary manufacturing facility is in the single screw production, service, and support. We build one piece barrels ranging in bore size from 1 to 20 inches (25 to 500mm) in diameter and up to 185 inches (4,700mm) long. Two piece barrels are available in lengths ranging from 185 to 295 inches (4,700 to 7,500mm). Quality Our alloys provide dramatically enhanced abrasion and corrosion resistance to barrels operating under severe conditions, especially those using filled materials including glass, titanium, dioxide, quartz, talc, mineral oxides and others. Selection We can manufacture virtually any barrel including vented, groove-feed, nitrided, jacketed, and re-sleeved. Durability New barrels for plastics and rubber applications are designed to last four to five times longer than equivalent nitrided products. Quick Turn Around With knowledge of virtually every extruder brand in operation today, we have the expertise, people, and production facilities to supply you with barrels anywhere in the world. Barrel Alignment The purchase of a new barrel or screw can often be a considerable expenditure for an organisation, not perhaps in the initial purchase price of the replacement part but in the time, planning and lost production in making the change. It is essential that companies therefore protect that investment and ensure that their new components are installed in the appropriate manner. The alignment of the barrel, feed housing and gearbox drive shaft are critical in the installation to avoid premature wearing of the components and subsequent loss in production rates in the future. Sai understands these issues and offers a laser alignment service to ensure that these components are in their optimum condition before production restarts. Our visiting engineer will measure the initial deflection and then assist your production staff in making the simple adjustments until the positioning of the components are as near to nominal as possible, thus protecting your investment for the future. Inspection & Measuring Screws and barrels used in plastics/rubber processing naturally wear over time and companies often don't realize the consequences that this wear process can have on the quality and quantity of production from their machinery. Sai understands implicitly these issues and offers an Inspection and Measuring Service to help customers determine how to maintain their machinery in peak condition. Our visiting engineer will inspect both barrel and screw conditions and submit to the client a written report on the condition of the components and the recommended remedial action required, if any. Again, Sai will work with you to protect your production equipment from the consequences of worn and/or deteriorating components.

...more

ring plunger

We provide Automotive Ring Plunger Set manufactured using nitro alloy material. These are available in various sizes and designs for our customers to choose from depending on their specific requirement. High tensile strength characterizes the set which is obtained by toughening the material in the raw state. The machining is done after this stage, to provide exact dimensions to the Plunger set according to the specifications provided.

...more

Powder Applicator

The Sai Powder on the product and the size of the product. The brushes are smoothening the through passing product and are taking away the surplus of the powder material which is continuously fed back into the powder storage chamber by means of a step less speed adjustable rotating screw (AC-Drive converter). The brush set rotation speed is driven by a chain transmission from the screw Applicator is design to apply powder e.g. Chalk, Talc, Calciumstearat or Graphit on cables, profieles or hoses. The application of powder on the through passing product is done by means of a rotating bridge preventor spring as well as by an adjustable set of 3 counter rotating brushes. The brush set is adjusted according to the needed amount of powder. There is an inspection hole above the brush set in order to supervise the brushes during operation so that the rotation speed of the screw/brush set can be adjusted accordingly. Also available is a provision on the outlet side after the brushes to connect a vacuum suction device to remove even more powder from the product if necessary. Refill of powder is done during continuos operation by pouring powder into a funnel directly over the powder chamber. The powder chamber is electrically heated, preventing the powder from clogging and absorbing humidity. The complete unit is movable on wheels, adjustable to line height and can be used for continuous application of powder to cables, hoses, profiles a.s.o.. All parts in direct contact with powder are made out of stainless steel. The operator panel is easy reachable above the machine and can be swivelled around to adjust to the line direction.The Powder Applicator acc. to draw. no. 3-300041-02 corresponds to the new European regulations and is delivered with the CE-label and a conformity certificate.

...more

Piggy Extruder

The space saving mobile extruders usually operators in conjunction with the fixed horizontal extruder. Thus in combination provides extra flexibility to insulate automotive wires, optical fibre buffering etc. And also employed as an auxiliary extruder for skin insulation, striping & colouring. It is grounded by the foundation bolt & provides mobility in all four directions. I.e. Backward, forward and both sideways. It ensure that its mobility leaves no impact on the quality of the products and provide the clearing, changing of screw & cross head as well and manages the thermal expansion of main extruders. sepl offers following piggy back extruders * 25mm extruder * 30mm extruder * 40mm extruder * 45mm extruder * 50mm extruder

...more

Pay Off And takeup

This traversing type unit allows to keep the cable straight at all times during the haul off process. Bobbin load/unload, locking/unlocking and traversing operations are fully motorized. When using dual pay off/take up, the front stand can be moved aside from the machine's center line, allowing to used the rear stand thus getting a continuous run. The machine is provided with MMI+PLC control system for pre-setting traversing pitch and for drum speed control. When using large cable, the pay off can be equipped with a speed detecting dancer for speed synchronization. The pay off system is a necessity for continuous production. Two housings made of mild steel iron are so placed that the out let of the wire comes in the centre. The inner end of the wire and the starting endof the full reel are led out of a horizontal slot of the housing and welded together, thus ensuring a continuousrun. Each housing is equipped with a reel lifting carriage containing the mandrel for the reels, the flyer disk and the AC motor. The wire is paid off via the flange of the non-rotating reel which is lifted on the spindle driven by a reversible three phase AC motor. The motor is fed via a plug-in cable from the control board. Reel lifting by electro lifting spindle. Activation by switch A flexible connection allows a traveling path of 2.5m Each reel carriage is equipped with a braked wheel, which allows blocking the trolley. Travel drive for reel carriages movable by an AC motor. At the Pay off housing a wire change detection is mounted. The device gives a signal if a reel change is necessary to have continuous production.

...more

MULTIPASS COOLING TROUGH

The trough is made of S.S. 304 and design consists of Telescopic Trough, Fix trough &Multipass trough. The telescopic trough is movable and its movements are adjusted by hand wheel. There is one way circuit of water between reservoir box and telescopic trough. The cable is guided over the special designed tray and water is sprayed over wire. There is height adjustment system for the tray meant for different size of wires.

...more

Lab Extrusion Line

We offer highly advanced lab extrusion line which are primarily used for tubes, stripe, compound and cables. With small amount of raw material it helps in producing extrudates with the simple cross section. The predictions by the plasticating extrusion software have been given on the geometry of the screws. Furthermore, these are fabricated in accordance with international standards and are delivered on time.

...more

Lab Extruder

We provide fully instrumented laboratory and pilot extruders for testing and formulating of recipe. Millions of trials are made in labs all over the world to analyze the extrusion condition and extrusion status which help people decide the influence and parameters of each factor during the extrusion process. We have both twin screw lab extruder and single screw lab extruder. Our twin screw lab extruder is mainly used for: compounding high filling reactive process color master batches other extrusions Our single screw lab extruder is mainly used for: sheet pipe/tube profile fiber other extrusions

...more

Haul Off Machine

haul-off caterpillar is fully guarded and has good accessibility of mechanical, electrical and pneumatic parts. It provides automatic absorption of cable irregularities by mean of independent gripping roller system. High number of gripping rollers ensures even distribution of pressure on the length of cable to be pressed. The belts are pressed and tensed pneumatically ensuring low specific pressure on cable due to great contact length of Caterpillar. Line Seed can be adjusted as required by means of three speed gear box. A built in control incorporates all necessary pressure gauges. Safety elements and push buttons. Sai Extrumech Haul-off Caterpillars has adjustable gripping force independent of the opening and can be used as entry Caterpillar and Exit Caterpillar.

...more

Haul Off Caterpillar

SAI EXTRUMECH haul-off caterpillar is fully guarded and has good accessibility of mechanical, electrical and pneumatic parts. It provides automatic absorption of cable irregularities by mean of independent gripping roller system. High number of gripping rollers ensures even distribution of pressure on the length of cable to be pressed. The belts are pressed and tensed pneumatically ensuring low specific pressure on cable due to great contact length of Caterpillar. Line Seed can be adjusted as required by means of three speed gear box. A built in control incorporates all necessary pressure gauges. Safety elements and push buttons. Sai Extrumech Haul-off Caterpillars has adjustable gripping force independent of the opening and can be used as entry Caterpillar and Exit Caterpillar

...more

Extrusion Line

The Sai Extrumech Pvt. Ltd.have created a powerful force in the wire and cable marketplace. We manufacture complete wire and cable systems for building and communication wire, construction wire, automotive wire, high temperature wire, and specialty wire applications. Systems are available with a wide range of extruders, payoffs and tension brakes, take-ups, and auxiliary equipment including cooling troughs, capstans, caterpillars, and accumulator systems. Laboratory equipment, customized feed screws, and control systems are also available. Extrusion Line Components Extrusion lines can be built with a wide range of extruders, payoffs and tension brakes, take-ups and auxiliary equipment including cooling troughs, capstans and accumulator systems. Laboratory equipment, customized feedscrews, and control systems are also available. Complete Extrusion Systems We supply complete wire and cable extrusion systems for communication, construction/building, telephone, and automotive wire, high temperature wire, optical fiber and specialty wire. Capabilities include communication cable systems, automotive cable systems, power cable systems, construction cable systems, fiber optic systems and coaxial cable systems. All wire and cable extrusion systems are available with Clipper take-ups, payoffs and spoolers, customized feedscrews and patented micro-processor based control systems. Wire Handling Equipment We offer high performance wire handling equipment including capstans, payoffs and take-ups, and linear caterpillars. CapstansBelt wrap capstans are available from 6 to 84 inches (150 to 2,133mm) in diameter, dual wheel multi-pass configurations from 12 to 32 inches (300 to 813mm) in diameter, with lengths to 40 feet (12 meters) in dry and wet arrangements. Linear capstans (caterpillar) from 14 to 80 inches.

...more

Single Screw Extruder

The Sai single screw extruder is a product of heavy research & development. This confirms the dominance of Sai in extrusion field. The Gear Box is designed for transmitting the high torques & for coping up with the maximum thrust load. It has space saving construction. High efficiency is achieved with helical gears of high quality forged steel, hardened & ground. The Thrust housing is designed for bearing the maximum force and not allowing the thrust pressure to damage the reduction gears as Sai provides high quality Thrust Roller Bearing.The screw is combined with a special grooved barrel having a properly equilibrated geometry.The melting process is determined by the barrier zone. Separation between the solid and liquid phase is achieved, maintaining the solid bed up to the complete melting.The role of metering zone is to homogenize the molten material and give high output without pulsation. The space saving Mobile Extruders usually operators in conjunction with the fixed horizontal extruder. Thus in combination provides extra flexibility to insulate automotive wires, optical fibre buffering etc. and also employed as an auxiliary extruder for skin insulation, striping &colouring.

Certification : CE Certified

Application : Industrial

Weight : 200-400kg

Voltage : 220V

Condition : New

Power : 1-3kw

Driven Type : Electric

...more

dual take up

The Automatic Dual Take up is a robust structure enabling the continuous production of wire without stopping for change over of bobbin. The complete structure is guarded for operator protection. The complete system is Pintle type and bobbin loading & unloading system is taken care by sensor actuatedcarriage system which is motor driven. The locking & unlocking of bobbin is also actuated by sensors. The smooth automatic changeover of wire winding from one bobbin to another bobbin ensures that no time is wasted in changing the loaded bobbin and placing the empty bobbin. The accurate catcher system along with effective cutter provides Customer an unmatched ease of operation at all speed and for all wire range. The system is driven by high torque AC frequency motors which take care of wide range of torque required to run different wires product mix. The smooth braking system ensures that wire tension does not get disturbed while stopping the driven bobbin. The precision traversing system ensures the perfect winding of wire on bobbin of any pitch. The entire system is actuated and protected through sensors at every stage.

...more

dancer

We are engaged in offering the Dancer Unit, which is a mechanical interface between post and printer equipment. The different paper movement of post and printer equipment is equilibrate by the unit and the web tension is created at the printer outlet. It is simple in handling and the dancer weight is controllable for different paper weights. Appreciated for low maintenance, durability and high performance, the unit finds application in industries like construction, heavy engineering and mining.

...more

Cross Heads

we offer a wide range of cross heads in various designs like fixed center and manual centering for double and triple coating. manufacture with premium quality of raw material, meet client’s specifics and industry standards. sant engineers were emerging as a leder of cross-heads in indian market for durability and high tolerance. We manufactures fixed centre, manual centre, single layer, multi layer (skin layer) stripe/marking and custom designed cross-heads for various types of plastics such as pvc, pe, pp, xlpe, nylon etc. we use good quality alloy steel to manufacture the cross-heads and guarantee a concentricity of 0.01 mm (.0005”) in all our cross-heads. sec cross-heads have found applications in practically all the fields like; house wiring, power & control cables, jelly filled telecom cables, optional fibre cables, special cables, shaped/profile cables (coil cord cables), submersible cables, lift cables, flat cables etc. features of cross head: * reduce scrap material by 50% * reduce raw material consumption by 10% * reduce set-up and changeover time by 50% * increase productivity manifol * cut eccentricit * totally eliminate the need for a skilled operator we provides two types of cross heads * fixed center cross head * manual center cross head

...more

Capstan

The Capstans offered by us are available in different sizes of pulley and diameter that vary as per the small & medium size of cables and line speed. Capstan role in extrusion line is to pull the wire from Extruder and offering it to take-up in a synchrony form of speed. For this, these are provided with a three speed transmission to avoid by passing of wire from capstan in pulling operations in thick size or wire conductor. The Capstans are offered with main drive options in DC & AC frequency drives.

...more

Breaker Plates

Sai Breaker Plates are renowned among our valued clients for its effective functioning. These plates are primarily used for increasing the output by stopping the compound leakage and removing the dead spots. Our highly skilled tool specialists work efficiently with the production engineers to offer good quality of breaker plate design. Furthermore, these can be easily modified in compliance with client requirement and is delivered within stipulated time frame.

...more

Auxiliary Piggy Extruder

We are the quality manufacturer of piggyback extruder having wide range of advance technology option which you can opt from from us. Our piggyback extruder comes with best quality delivery and best price you can get that is for sure. We also offer time warranty for our high quality piggyback extruder and extrusion crossheads. The space saving Mobile Extruders usually operators in conjunction with the fixed horizontal extruder. Thus in combination provides extra flexibility to insulate automotive wires, optical fibre buffering etc. and also employed as an auxiliary extruder for skin insulation, striping &colouring. It is grounded by the foundation bolt & provides mobility in all four directions. i.e. backward, forward and both sideways. It ensure that its mobility leaves no impact on the quality of the products and provide the clearing, changing of screw & cross head as well and manages the thermal expansion of main extruders. SEC offers following piggy back extruders 25mm Piggyback Extruder 30mm Piggyback Extruder 40mm Piggyback Extruder 45mm Piggyback Extruder 50mm Piggyback Extruder

...more

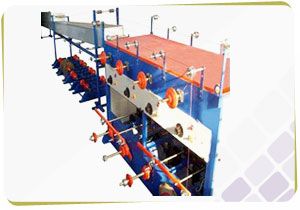

Automatic Coiling Machine

The SAI automatic coiling machine is designed to fulfill a wide variety of different coil with very simple operating process, our coiling machine is of a basic frame is electro welded steel that ensure a perfect base for the rest of the equipment. On the other side of the machine, we find the rotor that is composed of coiling forms that can be opened automatically with the help of Pneumatic system. The coil forms are interchangeable depending on the coil size and cable size. The machine is also equipped a meter counts that checks precisely the length on the coil, When the preset length is achieved, the roter forms 1800 and the operation in cut the wire length a cutting device placed in front of him. Automatic coiling cable from an extrusionline or a payoff rewinding line. The activating a push button the line starts coiling by ramping up and down and stop at the exact length. During the coiling process, the finished coil can be extracted manually or automatically. PLC+ touch screen control for easy operating system. The Complete line is composed of a single driven pay off that receives the cable to be coiled along with the payoff, a dancer accumulator regulates the speed and ramping phases of the pay off. The winder is powered by a A/c motor with A/c frequency drives. Traversing, through ball screw. Features Cable diameter max : 0.75 sq.mm to 10 sq.m. Coil outside diameter max : 350 mm Winding height adjustable : 150 mm Operating height : 1000 mm Total Power : 7.5 Kw Pass through direction : Right to left or left to right Air Pressure supply : 6 bar (10 kg. /cm2) Weight(Approx.) : 2.2 Ton(approx.) Average Speed : 2.0 coils/min of 100 meter Color : Blue L x W x H : 3600mm x 1200mm x 2300 mm Coil Size : Height 60-100 mm Outside diameter 150 to 350mm Inside diameter 100 to 150 mm Cable diameter 0.75 sq. mm to 10 sq. mm.

...more

Annealing Machine

We also specialize in manufacturing and exporting offline annealing machine. As its name suggests, it is suitable for annealing many strands of copper wire in a single process. Our annealing machine is built with extreme technical and quality control processes to ensure high performance from them. This annealing machine also involves an off line annealing process. This annealing machine is capable of annealing 24 spools of wire at a time that assists in saving cost, resources and most importantly the precious time. The spools fitted in the take up stands of these annealing machinery are either driven together by group drive motors or through a individual torque motor dedicated to drive each of the 8/12 spools. Each spool can hold the maximum weight of 100/150 kgs. These annealing machine offers many advantages that are : Wires are free from color variation Energy efficient No leakage of vacuum No effect of weather

...moreBe first to Rate

Rate ThisOpening Hours