Y Type Strainer

Our Y-Strainers have compact design and full flow, with large filtration area for low pressure drop and more solid collection. They are available with stainless steel body & stainless steel filter element of perforated sheet and wire mesh as per the client requirement. High grade raw material is used to fabricate this stream.The valves are provided with drain Plug that can be replaced with ball valve for frequent blow off. Moreover, the element is strengthened for rigidity and long life and fitted in machined seats. We provide a range of Y-type strainers that are designed in compliance with international quality standard. These are designed in accordance with the specifications of our clients, also following engineering standards of industry.Our Y Strainers are reliable, durable and accessible at highly reasonable rates.This y strainer is important for proper functioning of the pump. They are designed for longer service life and high performance even after consistent use in extreme and testing environments of high temperature and pressure. Butt weld Type:- Application: Filtration of liquids, Lube & fuel oil, Chemicals etc. in the pipe line. Construction: Close Grain Cast Iron, Bronze, Cast Steel, Stainless Steel and Fabricated Construction.Connections: Flanged, Screwed, S.W Ends. Flanges in DIN, ASA or to customer's specifications.Range: Pressure: 150#, 300# and above. Sizes: NB 50 NB and upwards. Element/Screen : Stainless Steel, Brass, Monel. From coarse say 8 mm to as fine as 0.5 micron. Features: Easily removable fitted without fasteners to seat. Easily removable cover with hinged bolt design or fixed type cover. High Filtration Ratio. Streamline design for low pressure drop. Fabricated Y Type Strainer:- Application: Filtration of liquids, Lube & fuel oil, Chemicals etc.Construction: Close Grain Cast Iron, Cast Steel, Stainless Steel and Fabricated Construction. Connections: Flanged, Screwed, S.W Ends. Flanges in DIN, ASA Range: Pressure: 150#, 300#, 600# Sizes: NB 50 NB and upwards. Element/Screen : Stainless Steel, Brass, Monel. From coarse say 8 mm to as fine as 0.5 micron.Features: sEasily removable fitted without fasteners to seat. Easily removable cover with hinged bolt design or fixed type cover. High Filtration Ratio. Streamline design for low pressure drop.

...more

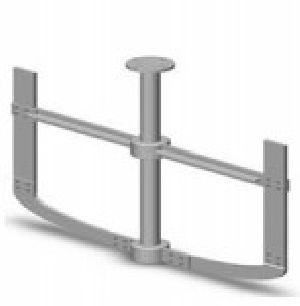

TWO BLADED ANCHOR FOR HIGHER VISCOSITY APPLICATIONS

The Two bladed anchor for higher viscosity applications. is a contoured two bladed anchor. It has applications in blending and particularly, heat transfer, where the viscosities range from 10000 to 100000 centipoise.

...more

T Type Strainer

We are sole design, manufacture and supplier of Tee Type Strainers, Steel Tee Strainers, and Vertical Tee Strainers. These are manufactured from one piece. 'T' or fabricated Tee with bath tub type element is suitable for horizontal flowing medium or 90 flowing medium. Design of the element may be of Bath Tub Type, Conical Type or Partition Type depending on flow direction. 'T' strainers are recommended where there are limitations of space to accommodate Basket Type strainer. 'T' Type strainers with Butt Weld ends can be directly welded to piping.Our Strainers are highly compact and applicable, where space is restricted. Unlike most other Strainers, Tee Type Strainers are ideal to use in either vertical or horizontal installations. There are some different arrangement are available for the Cover as per the below. Hinged Cover Type (For Quick Opening) Bolted Cover Type (For high Pressure) Application: Filtration of liquids, Lube & fuel oil, Chemicals etc. Construction: Cast Iron, Cast Steel, Stainless Steel and Fabricated Construction. Connections: Flanged, Screwed, S.W Ends. Flanges in DIN, ASA Range: Pressure: 150#, 300#, 600# Sizes: NB 50 NB and upwards. Element/Screen : Stainless Steel, Brass, Monel. From coarse say 8 mm to as fine as 0.5 micron. ‘Features: Easily removable fitted without fasteners to seat. Easily removable cover with hinged bolt design or fixed type cover. High Filtration Ratio. Streamline design for low pressure drop.

...more

Storage Tanks

SS Storage Tanks / Vessels :- We provide an exclusive range of storage tanks that are widely used in various industries. As we use quality material and cutting edge technology in manufacturing process, therefore, the end products are capable of sustaining high pressure and tension. Our products are also durable, non-corrosive, leak proof and low in maintenance. Designed with precision, our range of storage tanks is available in various shapes like elliptical, dished, flat or conical head and can be customized as per the requirements of clients. MS Storage Tanks / Vessels :- With thorough industry knowledge, we are engaged in manufacturing and supplying quality range of MS Storage Tanks. These tanks are manufactured under the supervision of our experts, using qualityapproved material and modern machines.

...more

spiral agitators

We are engaged in offering quality range of spiral agitators such as HDPE lining agitators and fluid agitators. Quality tested in line with the international quality standards, these agitators find application in food, chemical and dye industries. Low on maintenance, these can be availed by our customers at competitive prices.We are instrumental in offering or customers with finest quality of HDPE lining agitators that is used as components for reaction vessels. Popularly known as anchor agitators, these HDPE Lining Agitator are fabricated using metal, HDPE or P.P. plastic. Offered in different shapes and designs such as anchor type and pedestal type, these HDPE Lining Agitator can be custom-built as per our client’s requirements

...more

HDPE lining agitators

We are instrumental in offering or customers with finest quality of HDPE lining agitators that is used as components for reaction vessels. Popularly known as anchor agitators, this HDPE Lining Agitator are fabricated using metal, HDPE or P.P. plastic. Offered in different shapes and designs such as anchor type and pedestal type, this HDPE Lining Agitator can be custom-built as per our client’s requirements

...more

PHARMACEUTICAL TANKS AND VESSELS

We are engaged in manufacturing Storage tanks which is known for effective functioning among our valued clients. These storage tanks are extensively used in pharmaceutical and chemical industries for the processing and the storage of their products. Drive system is also optional as per client requirement.A storage tank is a container, usually for holding liquids. Storage tanks operate under no (or very little) pressure, distinguishing them from pressure vessels. Storage tanks are often cylindrical in shape, perpendicular to the ground with flat & Chronicle bottoms. Storage tanks are available in many shapes vertical and horizontal cylindrical, open top and closed top, flat bottom, cone bottom, slope bottom and dish bottom. Large tanks tend to be vertical, cylindrical, or to have rounded corners (transition from vertical side wall to bottom profile), which help in withstanding hydraulic hydrostatically induced pressure of contained liquid.Most container tanks are used for handling liquids during transportation and are designed to handle varying degrees of pressure. We also offer precision-designed chemical blenders that are usually tanks provided with stirrer. Chemical blenders are extensively used for blending chemicals. Chemical blenders are made of certified material. Our range of chemical blenders is highly durable and resistant to wear and tear.

...more

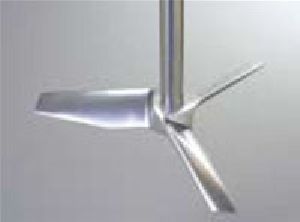

LOW VISCOSITY AND FLOW CONTROLLED APPLICATIONS IMPELLER

The Low viscosity and flow-controlled applications provides a combination of performance characteristics and high flow efficiency not available from other types of axial flow impellersThe Low viscosity and flow-controlled applications can produce the same flow and process results at a lower power than other axial flow impellers thus reducing operating and capital costs.

...more

LOW AND MEDIUM VISCOSITY IMPELLER

The traditional impeller for larger volume applications. Largely superceded by the Low/medium viscosity, flowcontrolled applications, it still has a specific role in applications where a degree of fluid shear is beneficial to the overall process result.

...more

Industrial Agitator

Our dynamic range of Agitator has gained immense popularity in the industry. We fabricate these as per technical specifications, which are in compliance with the industry standards. These are robustly constructed to enhance their life and offer high performance. We are providing a range of Agitators, which is utilized for agitating, beating, and stirring of various emulsions, liquids, suspensions, and similar mixtures. Agitators are designed using sophisticated technology to assure corrosion resistance and durability. Due to these high-end features, Agitators are utilized in: Food industry Chemical industry Paper & pulp industry Agitators can also be designed as per the specific requirements of our clients

...more

High Shear Impeller

The High shear, typically used for difficult to disperse pigments provides high shear rates. It is generally used in conjunction with a high flow impeller in applications involving a combination of blending and a need for physical change created by fluid shear

...more

Rushton Turbine Impellers

The High shear mixing and gasliquid Applications rushton turbine is the traditional impeller for gas - liquid mass transfer controlled systems. It is also used where higher shear is needed. The High shear mixing and gasliquid applications shown above has similar characteristics to the High shear mixing and gasliquid applications but gives: A higher power input in the gassed condition (reduced ‘K’ factor effect) Lower power in the ungassed condition

...more

HIGH FLOW IMPELLER FOR HIGHER VISCOSITY APPLICATIONS

The High flow impeller for higher viscosity applications. is designed to operate in higher viscosity fluids. The effectiveness of many high efficiency impeller systems which are designed to operate in the turbulent flow regime is impaired as the viscosity of the fluid increases and the Reynolds Number decreases. This is not the case with the High flow impeller for higher viscosity applications. The unique design of the impeller reduces both capital and operating costs. Blend times are also reduced compared to other ‘open’ impellers used at low Reynolds numbers.

...more

GAS AND LIQUID APPLICATIONS IMPELLER

The Gas/ liquid applications with uppumping characteristics with up-pumping axial flow is the most recent development for gas/liquid applications. The Gas/ liquid applications with uppumping characteristics can be used for coalescing and non-coalescing systems and allows better. Mass Transfer Heat Transfer Shorter Mixing Times

...more

FLOCULATORS

SVE flocculators provide engineers and water treatment facilities with well designed, well crafted, flocculator systems engineered for long life and minimal maintenance. Our Flocculator provides gentle agitation by slow moving paddles. This action serves to break up the mass rotation of liquid and promote mixing. The specially designed flocculating paddles enhance flocculation of the feed solids. Agglomeration of the destabilised colloids is achieved as a result of particulate transport in the flocculation compartment. Increased particle contact will promote floc growth and aids faster settling. Our flocculators are available in your choice of horizontal or vertical configurations for all water applications.

...more

Flash Mixer

We are engaged in offering a wide range of Flash Mixer that is fabricated by using quality-tested material bases that is sourced from reliable vendors of the market. Specifically designed and fabricated for the process requirement of water and wastewater treatment. The design of Flash mixer water treatment plants ensures efficient, minimum energy consumption and long life. These are available in various designs and models and can be customized as per the details provided by the client. The entire range of Flash Mixer delivered by us is highly acknowledge for their durability, reliability, accurate finish, precision engineered and optimum performance.

...more

ELECTRIC DRYER/ TUMBLER MACHINE

The main function of this machine is removing the moisture/powders form the product. The rotating drum is mounted in the machine which is rotate clockwise direction in nominal speed. Drum is connected with motor with pulley and sprocket chain arrangement. There are electric heaters are available to maintain the temperature level in the machine. All electric heaters are controlled by Panel. In the panel we can adjust the temperature limits for the electric heater. A Cross-Flow Blower is mounted on the top of machine which is continuously & equally blow the air on rotating drum. The air is passing through electric heater. Cross-Flow Blower is very compact and generates very low noise level compare to centrifugal blower. As per the requirement different size of cross-flow blowers are available. Stainless steel rotary drum with internal baffles create tumbling action to expose all surfaces to heating air. A machine is totally controlled by the control penal. Auto cutoff function for the heater and overload alarm functions are available. At the bottom of the machine duct are available with filter cloth which is used to hold the extra powder/material which is removed form the material. There is no requirement of cyclone or other equipments for the filter the powders from air

...more

Duplex Strainer

We are one of the highly established designers, manufacturers and suppliers of Duplex Type Strainers,Duplex Basket Strainer and Duplex Filters Strainers. Which are used wherever continuous operation is required and flow is not interrupted for cleaning of filter element. It consists of two filtration chambers,each rated for 100% capacity connected in parallel by means of 3 way ball valve, Butterfly Valve, Gate Valve & NRV. Diversion of fluid flows without interruption of flow with manual change over valve or automatically operated. Its higher flow rates handled by disc type change over system possess large filtration area for raw water/sea water, etc.It can be fabricated in casting/fabrication as per requirement and can also be available with steam jacketing for fluid like (L.D.O./H.F.O./Bitumen, etc.). We offer a wide range of Duplex Types Strainer filtration from 2 micron to 500 microns. Our Duplex Type Strainers are highly economic, handy and easily accessible in the market. We have highly experienced professionals, who are master of Strainers manufacturing industry. Types of Covers Design: Bolted Cover – For Low & High Pressure Application. Eye Bolt Cover - For Quick Opening. Hinged Cover -- For Quick Opening. (TC Connection) Clamp Type – For Low Pressure Application. Construction: Fabricated Carbon Steel or Fabricated SS 304, SS 316 Element: SS 304, SS 316 model or as per customers requirement.Basket strainer applications: Petrochemical Industries & Refinery Projects Cement plant Chemical Industries, Pharmaceutical industries Power Plants Sugar Industries Pulp & Paper Mill Fertilizer plant & Allied Industries Basket type strainer Design & Testing International Standard Design Std : ASME 16.34 / ASME SECTION VIII Pressure Testing : API 598 Face to Face : Mfg. Standard Flange Drilling : ANSI B16.5 / BS 10 Table / DIN / IS 6392 Pressure Rating : 125#, 150#, 300#, 600#, 900# Size Range : 50NB to 2000NB Other Assembly: Other assemblies provided along with the Basket like as Flanged Or NPT Drain & Air Vent Connection, Davit assembly, Legs/Skids & Differentials Pressure assembly are Optional & Provide on Customer request.Features: High Filtration Ratio. Streamline design for low pressure drop. Threaded / Flanged Drain Plug Valve & Air Vent Valve (Optional). For the Higher Size Davit assembly for Cover. Strainer Arrangement Design 1 (Model No: DMBS/11) Features: Four individual Butterfly Valve, Ball Valve or Gate Valves are used to isolate & Divert the Flow. For Quick opening Clamped Cover, Hinged Connection Or Eye-Bolt type Connection are available. Inexpensive Construction & Fast Delivery. Bottom / Side threaded drain plug are available. Inlet & Outlet Connection are Available as per the Standard. Standard Sizes are Available for 5" - 12 ". Pneumatic operated Butterfly valve available (optional). At Outlet we can provide the NRV Instead of the Butterfly or Ball Valve which help to reduce the equipment cost and make the automatic open & Close the outlet Valve without any Manual/Pneumatic operation. Strainer Arrangement Design 2(Model No: DMBS/21) Features: Four individual Butterfly Valves, Ball Valves or Gate Valves are used to isolate & Divert the Flow. For Quick opening Clamped Cover, Hinged Connection Or Eye-Bolt type Connection are available. Inexpensive Construction & Fast Delivery. Bottom / Side threaded drain plug are available. Inlet & Outlet Connection are Available as per the Standard. Standard Sizes are Available for 6" - 24 ". Pneumatic operated Butterfly valve available (optional). Custom Modification is available as per customer requirement. For High Pressure design Bolt Cover Design are Available. SS Perforated Sheet is Standards. Easy to install in the Horizontal Pipeline. Davit assembly Available.(Optional) At Outlet we can provide the NRV Instead of the Butterfly or Ball Valve which help to reduce the equipment cost and make the automatic open & Close the outlet Valve without any Manual/Pneumatic operation. Strainer Arrangement Design 3 (Model No: DMBS/31) Features: Four individual Butterfly Valves, Ball Valves or Gate Valves are used to isolate & Divert the Flow. For Quick opening Clamped Cover, Hinged Connection Or Eye-Bolt type Connection are available. Inexpensive Construction & Fast Delivery. Bottom / Side threaded drain plug are available. Inlet & Outlet Connection are Available as per the Standard. Standard Sizes are Available for 6" - 24 ". Pneumatic operated Butterfly valve available (optional). Custom Modification is available as per customer requirement. For High Pressure design Bolt Cover Design are Available. SS Perforated Sheet is Standards. Easy to install in the Horizontal Pipeline. Davit assembly Available. (Optional) At Outlet we can provide the NRV Instead of the Butterfly or Ball Valve which help to reduce the equipment cost and make the automatic open & Close the outlet Valve without any Manual/Pneumatic operation. Strainer Arrangement Design 4 (Model No: DMBS/41) Features: Four individual Butterfly Valve, Ball Valve or Gate Valve are used to isolate & Divert the Flow. For Quick opening Clamped Cover, Hinged Connection Or Eye-Bolt type Connection are available. Inexpensive Construction & Fast Delivery. Bottom / Side threaded drain plug are available. Inlet & Outlet Connection are Available as per the Standard. Standard Sizes are Available for 6" - 24 ". Pneumatic operated Butterfly valve available (optional). Custom Modification is available as per customer requirement. For High Pressure design Bolt Cover Design are Available. SS Perforated Sheet is Standards. Easy to install in the Horizontal Pipeline. Davit assembly Available. (Optional) Lower Space requirement. At Outlet we can provide the NRV Instead of the Butterfly or Ball Valve which help to reduce the equipment cost and make the automatic open & Close the outlet Valve without any Manual/Pneumatic operation.

...more

DRAFT TUBE CIRCULATORS

Designed specifically for dependable draft tube service, the Draft-tube circulators. has a true airfoil shape and provides high flow, even in unstable process conditions, whilst minimising power requirements. A specific family of impellers (unique to Lightnin) based upon the Draft-tube circulators. design is available for use in draft tubes. Processes include alumina, gold, uranium and potash.

...more

CUSTOM STRAINER

Our company designs, manufactures and supplies excellent Temporary Strainers or Conical Strainers,Conical Filters. Which are mounted between two flanges as permanent protection of pipelines and plants. We design and develop world-class stainless steel Conical Strainers in fully welded design. They are made from perforated plate or perforated plate with fabric filter medium related to the filter rate. The compact design of Strainers guarantees a minimal space requirement. These Temporary Strainers are often applied when a new plant is put into operation or by repairs of existing plants. We offer these products at highly customized prices. They are mostly used for the initial start up of any filtration system or in the places where the requirement is short term. Temporary plate strainers provide a short term solution for filtrating debris and other solid impurities. Features: Hassle free performance Easy installation Low maintenance

...more

BASKET AND BUCKET STRAINER

We are leading company engaged in designing, manufacturing and supplying of the best quality Basket Strainers that permit the straining & filtering of a wide variety of fluids, to retain solids of almost any size. All baskets are easily removable & cleanable. The ranges of basket strainers offered by us are precision designed to meet the specific requirements of removing foreign particles in the flowing applications or services. Basket strainers flawless functionality standards also help in increasing the overall service life of the pumps, valves and other flow control equipment Bucket Strainer is a closed vessel with cleanable or removable screen or element for removing particles from liquids Drain connection provided to remove accumulated particles or solids.Simplex Basket Strainer / Basket strainer is used where cleaning may occur frequently; it stands to reason that the basket should be able to be removed and replaced as simply as possible.We offer Multi Basket/Cartridge Filters in fabricated construction for high filtration ratio that can be supplied for very large filtration area. Our company manufactures and supplies Stream Flow Design available in fabricated construction, which reduces the pressure losses. Types of Covers Design: Bolted Cover – For Low & High Pressure Application. Eye Bolt Cover - For Quick Opening. Hinged Cover -- For Quick Opening. (TC Connection) Clamp Type – For Low Pressure Application Construction: Fabricated Carbon Steel or Fabricated SS 304, SS 316Element: SS 304, SS 316 model or as per customers requirement.Basket strainer applications: Petrochemical Industries & Refinery Projects Cement plant Chemical Industries, Pharmaceutical industries Power Plants Sugar Industries Pulp & Paper Mill Fertilizer plant & Allied Industries Basket type strainer Design & Testing International Standard Design Std : ASME 16.34 / ASME SECTION VIIIFlange Drilling : ANSI B16.5 / BS 10 Table / DIN / IS 6392Pressure Rating : 150#, 300#, 600#, 900#Size Range : 50NB to 1000NBOther Assembly: Other assemblies provided along with the Basket like as Flanged Or NPT Drain & Air Vent Connection, Davit assembly, Legs/Skids & Differentials Pressure assembly are Optional & Provide on Customer request. Features: High Filtration Ratio. Streamline design for low pressure drop. Threaded / Flanged Drain Plug Valve & Air Vent Valve (Optional). For the Higher Size Davit assembly for Cover. Nozzle Arrangement: There are some Different Arrangement of Nozzles are available as per the Customers requirements.

...more

AXIAL FLOW IMPELLER FOR SIDE ENTRY APPLICATIONS

The Axial flow impeller for side entry applications is designed for the arduous requirements of pulp and paper applications. It is also used in other side entry applications such as oil storage and FGD (Flue Gas Desulphurisation). It is an axial flow impeller with a minimal radial flow component, unlike other conventional side entry mixer impellers.

...more

AXIAL FLOW IMPELLER FOR GAS / LIQUID APPLICATIONS

The Axial flow impeller for gas/ liquid applications is capable of dispersing gas and controlling flow patterns at significantly higher gas rates than other axial flow impellers. Compared to conventional Rushton type radial flow turbines, the Axial flow impeller for gas/ liquid applications can provide up to 30% greater mass transfer at equal torque and power consumption. Good axial flow patterns from the Axial flow impeller for gas/ liquid applications give good solids suspension and significantly reduce power requirements.

...more

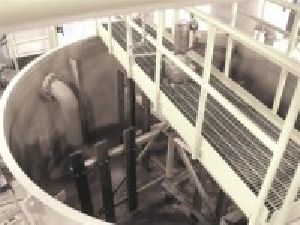

AGITATOR TANKS AND VESSELS

With the help of our state-of-the-art manufacturing unit, we are capable of manufacturing a range of quality Agitator Tank. Our range of agitator tank is available with impeller of propeller turbine, paddle and anchor type configuration.Our range of agitator tanks is manufactured using carbon steel and stainless steel with jacketing and internal coil for heating or cooling. Known for durability, less maintenance, easy operation and corrosion resistance, our range is in adherence with defined industry standards. Features: Durability Less maintenance Easy operation Corrosion resistance

...moreBe first to Rate

Rate ThisOpening Hours