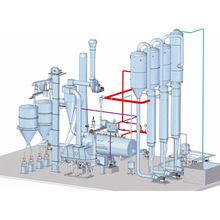

zero liquid discharge system

systems to treat such effluents, through evaporation & drying technologies. Stripper column is used to remove the solvent from High COD stream. With the help of this technology, effluent concentrate is dried to a baggable powder with 6 - 8% moisture content, which can be reused as a land filling / disposal. Grain Based Distilleries Molasses Based Distilleries Textile Dyeing Industry Pharmaceutical & Bulk Drug Industries Pulp & Paper Industries (Black Liquor Concentration)

...more

Yeast Plant

In this system bio-methanated effluent is concentrated in a multiple stage vacuum evaporator to 40-60% solid. The total process is under vacuum and the vapors generated in the system are recompressed in a TVR / MVR to economize steam consumption. Condensate water from the evaporation system is cleared and recyclable for the process.In scheme-Bio-Methanated Effluent: The concentrated Bio-Methanated Effluent is dried in a spray dryer. The powder generated from spray dryer is mixed with coal and the mixture is burnt in a boiler to generate steam. It can also be marketed as POTASH RICH FERTILIZER. The alternate system is to mix the concentrate with rice husk and bagasse and drying the same into a rotary dryer and the dried material is a mixed fuel that can be used in a boiler for the generation of steam.

...more

Waste Water Treatment Plant

Waste Water Treatment Plant is used for given below application: Oesein / Gelatin Industries Oil Refineries and Electroplating Industries Tannery Industries Caustic Recovery for Mercerizing Units Yeast Plant Dye / Dye Intermediates Industries

...more

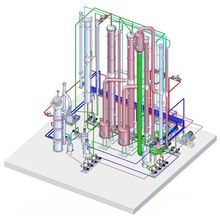

Vacuum Salt Refinery

The process involves dissolving of salt in water and making a saturated solution of salt. The saturated brine is pumped out to a brine clarifier, where the insoluble settles at the bottom of the clarifier and clear brine solution is taken to a brine tank. In the brine tank required chemicals are added to precipitate out magnesium and calcium salts present along with the salt. The brine is then filtered and taken to the final brine tank. From this tank saturated brine is fed to the continuous evaporation plant where Crystallization takes place and slurry is pumped out to a concentrate tank. This salt slurry is then pumped to a hydro-cyclone battery to get a slurry concentration up to 50-60%. This slurry is fed to a centrifuge, and from the centrifuge salt cakes with 4-5% moisture comes out. The salt with 4-5% moisture is fed to a fluid bed dryer through a screw conveyor where the iodization is completed.

...more

Spirulina Algae Powder Plant

Soya Protein Isolate Plant

Soya protein isolate is a highly purified form of soya protein with a minimum protein content of 90% on dry basis. It is made from de-oiled soya cake/defatted soya flour. Most of the non-protein component needs to be removed by the process to make the product.Soya protein isolate is prepared by dissolving the protein content of soya flour or flake by the addition of alkali. The dissolved protein is separated from the insoluble impurities using a decanter centrifuge. The protein in the clarified liquor is precipitated by the addition of acid and then recovered using a decanter centrifuge. The solid content of the recovered protein can be varied 15% to 20%. This solid is then passed through a spray drier to get protein isolate powder containing 90% protein on dry basis. SSP has developed this process technology after several pilot plant trial runs and are in a position to offer commercial scale plant starting from 1 TPD to 20 TPD capacities.

...more

Soya Milk Powder

offers suitable multiple effect Evaporator to concentrate soy milk upto 22% followed by Spray Dryer for manufacture of Soy milk powder.Instant Soy milk powder can be made by addition of lecithination system along with Spray Dryer.

...more

oil refineries

The effluent from the Oil Refineries and Electroplating Industries is generally low in solids content and contains metals like chromium and manganese.The effluent is preheated and then fed to the Multiple Effect Falling Film Evaporator for concentration. After concentration, the concentrate is dried using an Agitated Thin Film Dryer. This dried powder can be disposed of as solid waste for land fill. The condensate obtained from the evaporator is clean and colourless which can be used in the plant as process water.

...more

Natural Colours Extraction Plant

Brand Name : SSP

Type : Extractor

Application : Textile and Food Industry

...more

Mechanical Salt Refinery

Crude Salt is fed into the feeding hopper of suitable capacity and it is then transferred to a belt conveyor. This belt conveyor will be fitted with a magnet to remove rubbish metal and will also be provided with a belt weigher with totalizer. Crude salt is pre-washed in special washing system. This is then fed to the feed in hopper of the wet mill for grinding. Wet mill is used to grind the salt with the help of saturated brine solution. This mixture is then passed to the slurry tank that is fitted with a slow speed agitator.

...more

Malted Plant

Malted Milk is a powdered food product made from mixing of standardised milk, malt extract with wheat flour, and cereal grains in such manner as to secure complete hydrolysis of the starchy material, which is evaporated until it forms a high viscous solution. Which is then dried in a Vacuum Tray Dryer / Vacuum Band Dryer.The manufacturing process consists of the following stages Blending of ingredients like malt extract, milk or milk powder, grain flour etc in required proportion. Concentration of the slurry in evaporator. Vacuum Drying of the concentrate. Pulverization of the dried product. Packaging of malted food. Storage.

...more

Lactose Processing Plant

Whey comprises of 80-90% of the total volume of milk entering in the cheese making and casein manufacturing. Whey contains soluble proteins, lactose, vitamins & minerals. Sweet whey is produced when cheese or casein is precipitated by rennet. Acid whey is produced when mineral acid is used to precipitate cheese or casein

...more

Industries Effluent Plant

tannery effluent which is based on evaporation technology. The effluent is concentrated in Multiple Effect Evaporator where it is concentrated up to 40-45% of total solids and then passed through hydro cyclone and thickener. From bottom of thickener, slurry is passed through centrifuge for separation of salt.In this process we get solid waste and the condensate water. Condensate water can be recycled in the tannery and solid is sent to TSDF (Treatment, Storage and Disposal Facility)

...more

honey processing plant

Automatic Grade : Automatic

Condition : New

Brand Name : SSP

Certification : ISO

...more

Herbal Extraction Plant

Application : Herbal, Pharmaceuticals, food, Cosmetic

Gelatin Processing Plant

Brand Name : SSP PVT LIMITED

Egg Processing Plant

Eggs are an excellent food containing many essential nutrients. The higher nutrients density of eggs relative to their calorie content makes them excellent food. Two large chicken eggs contains about 12 gms of protein, 1.2 gms of carbohydrate 11 gms of lipids and substantial amount of iron, phosphorous, vitamin A, E, K and most of the B complex vitamins. White portion of the egg contains almost 90% water, but contributes about 50% protein, niacin and riboflavin. Most of the vitamins and minerals are found in egg yolk. The yellow color of egg yolk is due to the presence of xanthophylls pigment.

...more

Dairy whitener Plant

Non dairy creamer / coffee whitener normally consist of : Maltose syrup - 60 to 64.5% Corn / Palm Oil - 30.8 to 35% Sodium Caseinate - 2.1 to 2.5% Emulsifying agent - 0.05% Moisture - 2.5%

...more

Centrifugal Pumps

Water cooling arrangements. Suitable for use in vacuum Evaporators. These pumps can work under vacuum. Available with 1440 & 2800 RPM. These pumps have the capability to generate upto 80m head and capacity upto 160m3/Hr.

...more

Caustic Recovery for Mercerizing Units

Caustic Solution used in mercerizing unit can be recycled by concentrating weak caustic solution in Multiple Effect Evaporator. The initial concentration is normally in the range of 8% to 10% which can be concentrated up to 45-50%. Here steam is used as a heating source a thermos compression technology is applied for achieving better steam economy.

...more

Steam Tube Dryer

Be first to Rate

Rate ThisOpening Hours