wet grinding machines

25 piece (MOQ)

Type : Wet Grinding Mill

Application : Industry Grinding Use

Weight : 100-1000kg, 3000-4000kg

Color : Blue, Green, Silver

Voltage : 440v

Automatic Grade : Manual, Semi Automatic

Power : 1-3kw, 22

Driven Type : Electric

Warranty : 1year

Brand Name : TECHNOFAB

Type : SANDMILL

After-Sales Service Provided : YES

Capacity(t/h) : LAB.SCALE. (5 LITERS)AND 300 LITERS

Motor Type : 4P,ELECTRICAL FLANGE MOUNTED

...more

Vertical Conical Dryer (Nauta Dryer)

The vertical conical or Nauta dryer is an efficient method of drying process equipment. As the name suggest it is a conical bottom and top Dish end equipment with coaxial siirrer arrangement The stirrer rotates in the plenatary motion giving very effective belnding and drying The material of construction can be Stainless steel, Duplex steel ,or any high Nickle alloy steel

Brand Name : TECHNOFAB

Material : SS

Finishing : Polished

Condition : New

Power : 5kW, 10kW, 15kW

Power Source : Electric

Automatic : Semi Automatic

Usage : Chemical Industry

Voltage : 440V

Display Type : Digital

Overall Length : AVAILABLE IN VARIOUS SIZES

Specialities : Precise Design, Fine Finish

Dryer Capacity : 250 TO 1000 KG/BATCH

Type : Conical Vacuum Dryer

Frequency : 40-50Hz

Working Temperature : 150

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

...more

Large storage tanks

25 piece (MOQ)

The Extractor is specially designed High Vacuum Distillation Unit that comprises multi-bladed stirrer design with a set of fixed & moving blades. The bottom set is specially designed blades, one set having pin-type construction & another sweeper profile to match the bottom dish profile in closed proximity. The distillation is done under high vacuum condition to achieve effective separation by distillation at relatively low temperature, especially to suit the heat sensitive product. Since the extraction is achieved up to the last drop one can get rid of the effluent problem during the operation. The total operation is carried out in an enclosed environment there is no environmental adverse effect. You can achieve zero discharge process.

Color : Customize

Condition : New, Good

...more

Screw Conveyors

25 piece (MOQ)

Shafted screw conveyors are used in thousands of industrial applications every day for efficiently conveying a variety of bulk materials. A screw conveyor’s main function is to transfer bulk materials from one process to another. Screw conveyors are very cost-effective and require minimal maintenance to operate.Screw Conveyors are available in many configurations and are designed based on industrial standards They can be modular in construction providing flexibility for a variety of applications.Advantages of Using Screw Conveyors Ideal for handling dry to semi-fluid materials - free-flowing to sluggish Cost-effective when compared to other conveying devices such as belt, pneumatic or aero-mechanical conveyors Efficiently distributes bulk materials to various locations using multiple inlet and discharge points Totally enclosed for corrosive or hazardous requirements Available Features / Options Custom engineered for your specific application Wide range of construction materials (carbon steel,SS316,SS316L,SS304,) Flight configurations available for mixing and chopping Designs available for cooling and heating products utilizing jacketed housings

Condition : New

Loading Capacity : Up to 25 tph

Material : Stainless Steel

Voltage : 220V/380V/440

Specialities : Custom design as per specific applications, Efficiently conveys dry to semi-fluid materials – free-flowing to sluggish

...more

Rotary Vacuum Dryer

The drying operation is achieved under high vacuum conditions using a horizontal, cylindrical agitated blender cum dryer. The core of the rotor has multiple blades, and live steam enters through one end and circulates throughout the dryer length and across the cross-section. Additional heat is given through the limpet coil. The main advantage of this dryer is that it provides a very high heat transfer area up to the center of the dryer. Additionally, the drying is done under high vacuum conditions, which helps maintain the quality of the product1.

Brand Name : TECHNOFAB

Material : SS

Finishing : Polished

Condition : New

Power : 5kW, 10kW, 15kW

Power Source : STEAM

Automatic : Semi Automatic

Usage : Chemical Industry

Voltage : 440V

Display Type : Digital

Specialities : Precise Design, Fine Finish

Dryer Capacity : 100 - 1000 KG/BATCH

Type : Rotary Vacuum Dryer

...more

ribbon blander

25 piece (MOQ)

Horizontal ribbon mixer is widely used in chemical, pharmaceuticals, food, and construction line. It can be used to mix powder with powder, powder with liquid, and powder with granule. Under the driven of motor, the double ribbon agitator mix the material quickly. This ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customer should choose the model according to the output per batch. Horizontal ribbon mixer is mainly combined with mixing barrel, agitator, driven unit.Untwist double ribbon are swirled with the main shaft in the U shape barrel. The outer ribbon push the material from the two ends to the centre, inner ribbon push the material from center to the two ends.Thus to achieve material convention The discharging port is set in the bottom centre, with the help of the outer ribbon,the material can be discharged completely, and no dead zone.

...more

PTFE OVEN (TRAY DRYER)

THIS IS A MODIFIED VERSION OF THE TRAY DRYER AND IS ALSO AVAILABLE IN VACUUM DRYER tOTAL HYGENIC PRODUCT , FULLY POLOSHED INSIDE OUT WITH INSULATED WALL WIDELY USED IN THE PHARMACEUTICAL UNIT OPERATIONS

Brand Name : TECHNOFAB

Condition : New

Power : 6-9kw

Power Source : STEAM/ELECTRIC

Certification : CE Certified

Voltage : 440V

Type : CLOSED TRAY DRYER

Frequency : 50Hz

Warranty : 1year

Country of Origin : India

...more

Pneumatic Conveying System

25 piece (MOQ)

The pneumatic conveying system is a method of conveying dry material in a pipeline through air without any moving parts. The pneumatic conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Each pneumatic conveying system is designed & customized as per the application popularly known as custom conveyor system. The provided solution is assured to be the best pneumatic conveying system solution for the application.Prime Mover can be Roots blower, Centrifugal blower, Centrifugal fan, Radial blower.The motive force for the transfer of materials comes from a combination of pressure differential and the flow of a gas, such as air or nitrogen.Application : For transferring powders, granules, and other dry bulk materials.

Weight : 16 kg (35.3 lb)

Color : Any

Condition : New

Application : Transfer dust

Warranty : 1 Year

...more

PET Recycling System

25 piece (MOQ)

We are into Designing Manufacturing and Exporting PET Recycling System, which is engineered with precision to match the high industrial standards. We offer wash line equipment with total design. We provide the layout details / drawing along with the design to the clients. The Pet Recycling System is widely used for recycling pet bottles by converting used bottles into flakes. Equipment we can supply : Pre wash tank and Reactor with agitator Sink float Tanks, Screw conveyor Bale breaker Trommel Spin dryer Hot air Generator Drying cum Pneumatic converging set up Salient Features : Longer working life High performance Low maintenance cost Robust structure Uses : Recycling of PET bottles Converting the used PET bottles in to flakes

Type : Automatic

Certification : Ce Certified

Weight : 100-500kg

Voltage : 380V

Condition : New

Power : 3-5kw

Driven Type : Hydraulic

After-Sales Service Provided : Spare Parts

...more

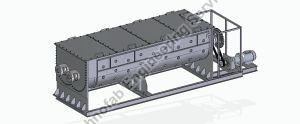

paddle dryers

25 piece (MOQ)

Paddle Dryer is a highly efficient, mechanically agitated, indirect heat transfer device that adds or removes heat from a process mass. It is used for indirect drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.Dual counter-rotating shafts with unique intermeshing wedge shape paddles produce intimate mixing and optimize heat transfer. The use of hollow paddles for heat transfer results in a compact machine. The heat transfer medium: steam, oil, thermal fluid, water, or glycol is isolated from the process mass.Advantages High thermal efficiency Heat transfer medium does not come into contact with the product. Gas is not used to convey the product. Off-gas flow is minimal. Precise control of temperature Uniform product quality, through mixing and movement of the product Continuous process on a once-through basis High heat transfer area to process volume ratio - reduced floor space Pre-conditioning with recycle is typically not required. Easy to operate, requires minimal attention Safer than direct drying when processing combustible material Simple durable design for easy and low maintenance Enclosed process contains odors and hazardous materials Application Drying Heating & cooling Process Chemical: salts, catalyst, brominated organics, cellulose, starch Polymer and plastic: polypropylene, polycarbonate, poly phenyl sulfide, PET, PTA Mineral and metal: metal powders, metal carbonates, sulfates and hydroxides

Condition : New

Power Source : Electric

Material : Stainless Steel

Weight : 5 T

...more

Paddle Dryer

25 piece (MOQ)

Paddle Dryer is a highly efficient, mechanically agitated, indirect heat transfer device that adds or removes heat from a process mass. It is used for indirect drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules. Dual counter-rotating shafts with unique intermeshing wedge shape paddles produce intimate mixing and optimize heat transfer. The use of hollow paddles for heat transfer results in a compact machine. The heat transfer medium: steam, oil, thermal fluid, water, or glycol is isolated from the process mass. Advantages • High thermal efficiency • Heat transfer medium does not come into contact with the product. • Gas is not used to convey the product. Off-gas flow is minimal. • Precise control of temperature • Uniform product quality, through mixing and movement of the product • Continuous process on a once-through basis • High heat transfer area to process volume ratio - reduced floor space • Pre-conditioning with recycle is typically not required. • Easy to operate, requires minimal attention • Safer than direct drying when processing combustible material • Simple durable design for easy and low maintenance • Enclosed process contains odors and hazardous materials Application • Drying Heating & cooling Process for • Chemical: salts, catalyst, brominated organics, cellulose, starch • Polymer and plastic: polypropylene, polycarbonate, polyphenylsulfide, PET, PTA • Mineral and metal: metal powders, metal carbonates, sulfates and hydroxides

...more

Horizontal PADDLE DRYER

Brand Name : TECHNOFAB

Material : SS

Finishing : Polished

Color : Silver

Condition : New

Power : 50 TO 90 KW

Power Source : Electric

Motor Power : 50HP,100HP

Automatic : Semi Automatic

Usage : Chemical Industry

Voltage : 440V

Display Type : Digital

Packaging Type : PLASTIC WRAPPING

Specialities : Fine Finish,Precisely Designed

Type : Dryers

Frequency : 40-50Hz

Working Temperature : 100-200 C

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Max Temperature : 200

Steam Pressure : 9 KG/CM2

Heating Media : STEAM

Output Moisture : 5-%

...more

Heat Recovery Unit

25 piece (MOQ)

We are a prominent Manufacturer and Exporter of Heat Recovery Unit. We offer waste heat recovery system for harnessing all types of waste heat originating from various fuels as well as from various industrial sources. Our Heat Recovery Unit is well acclaimed for high performance among the buyers across the globe. Sources : Exhaust recovery from captive power generator and gas turbine exhaust Drying units Jacket heat recovery Incinerator, Kiln, process waste gases industrial furnaces etc. Heat recovered is converted into various forms of energy such as : Steam Hot water Refrigeration Features : Improves equipment performance Improves productivity through process machine performance enhancements Enhances capacity High efficiency Reduces operating costs with heat recovery

Voltage : 380V

Power : 3-5kw

...more

Heat Exchangers

25 piece (MOQ)

We are one of the leading Manufacturers and Exporters of Heat Exchanger, which comprises equipment for the reduction process, condenser, chillers, Falling Film Evaporator and High Vacuum Solvent extraction System. Our industrial Heat Transfer Equipment gives an edge over conventional method. Tough compound can thus be handled easily since the entire process is carried out in high Vacuum System. Our High Temperature Heat Transfer Equipment does not required any direct human contact hence it is completely safe and convenient to us.All heat exchangers are designed and engineered in accordance with international standards of design and constructions including TEMA, ASME, and HEI etc. Thermal design is carried out with the help of customized software, HTRI and with our expert design engineers to meet custom requirements.Advantage Over Conventional Method Totally enclosed operation No direct contact of human body completely safe Most efficient & faster operation Water used in reduction process can be reused in the next batch, hence no liquid effluent also no mess up around the work place Material of Construction : Carbon Steel, Stainless Steel 304, 304 L, 316, 316 L, C22,C276, Inconel 600.625,800,825, Copper ,TI Applications Shell & Tube Heat Exchangers Multiple Effect Evaporators Re-boilers U – Bundle Finned Tube Heat Exchangers Heat Recovery Unit

Material : Stainless Steel

Color : Customize

Condition : New

Automatic Grade : Automatic

Usage : Water, Oil, Air, Organic Matter

Grade : AISI, ASTM, DIN

Voltage : 440V, 460V Or 230V

Operating Temperature : 0-50Deg C

Type : Heat Exchangers

Warranty : 1 Year

...more

fractional distillation columns

25 piece (MOQ)

We provide efficient Fractional Distillation Column. We design and supply total System including Re-boiler, Column, Condenser, Reflux device & Receiver. Industrial Fractional Distillation Columns are Systems for continuous as well as batch distillation. We also erect and commission Fractional Distillation Columns as required by the client.As a Part of the system, we design and supply vacuum system for Batch/Continuous Distillation, which Includes water combined with Steam jet vacuum system to produce vacuum up to 1 torr. This system does not require any barometric leg thus can be placed even on the ground floor.Raw material used :· Carbon steel· SS 304· SS 316· Incolloy· HastalloyFeatures :· Re- boiler or Distillation Kettle· Packed column or Bubble cap Column· Condenser conventional or Stand alone with integral reflux device· Reflux device· Receiver Column packing offered are : · Structured packing· Raschig ring· Pall ring· Intallox saddles· Bubble cap design

...more

Flaker

25 piece (MOQ)

We are engaged in Manufacturing and Exporting Flaker, which converts molten mass into solid flakes. The Flaker is specially designed with utmost precision for the continuous duty. We can also offer variable speed drive system as per client’s requirement. We supply high performing Flaker in the foreign markets. Material of construction : · Stainless steel Special Features : · Trouble free economical operation · Continuous Process · High thermal efficiency · Controlled thermal degradation · Single step operation · Uniform flakes Process : · Forming thin layer of the molten mass on the outer surface of the drum rotating at very low RPM · The layer is cooled by the water circulation through the drum · Adjustable scrapper continuously scraps the solidified flakes from the drum and the flakes are collected into bags or the containers

...more

Fin Tube Heat Exchangers

25 piece (MOQ)

We present an exclusive range of Finned Tube Heat Exchangers to our clients. These are fabricated using best grade raw materials and advanced technology, which ensures less time and power consumption while functioning. Our offered ranges of these exchanges are appreciated for superior quality and high performance. Clients can avail these from us at reasonable prices. Some of its features are: � High durability � Low maintenance cost � Trouble free operation Applications of finned tube heat exchangers: � Steam air heater / steam radiator � Thermic fluid air heater / thermic fluid radiator � Hot water air heater / hot water radiator � Air heater for fluid bed dryers � Air heater for spray dryers � Air heater for flash dryers � Air heater for dryers

...more

Hydro Extractor

25 piece (MOQ)

The Extractor is specially designed High Vacuum Distillation Unit that comprises multi bladed stirrer design with set of fixed & moving blades. The bottom set is specially designed blades, one set having pin type construction & another sweeper profile to match the bottom dish profile in closed .The distillation is done at near absolute vacuum to achieve effective separation by distillation at relatively low temperature ,especially to suit the heat sensitive product. Since the extraction is achieved up to the last drop one can get rid of effluent problem during the operation ,we mean to say one can claim the process as zero effluent discharge process.

...more

DRAG CONVEYOR

25 piece (MOQ)

Drag conveyors are a great complement to screw conveyors and belt conveyors and a requirement of many bulk material handling applications. Drag conveyors can be used to meter or transfer bulk materials from one process to another. The compact and versatile design allows drag conveyors to fit almost any plant layout. Drag conveyors are available in many configurations. Screw conveyors are designed based on industry standards and are modular in construction providing flexibility for a variety of applications. Advantages of using drag conveyors • ideal for handling dry, free-flowing materials • materials are static and move en-masse by paddles or chain • minimal product degradation during conveying • require less horsepower than other types of conveyors available features options • drop-forged chain and paddles for increased equipment life • easily replaceable wear liners for minimal down time • high torque drive units to power through upset conditions

...more

Contra Rotary Mixer

Material : Stainless Steel

Finishing : Polished

Color : Metallic

Condition : New

Power : 15-20Kw

Application : Industrial Use

Grade : ASTM

Voltage : 220V,440V

Capacity : 1000-2000L,2000-4000L

Type : Contra Rotary Mixer

Warranty : 1 Yr

Country of Origin : India

Orientation : Vertical

...more

Contra Rotary Mixer

25 piece (MOQ)

Contra Mixer as the name suggests works on the principle of Contra rotation of Blades for simultaneous beating and scraping operation. The mixer is highly versatile and mostly used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.The contra rotary mixture is so designed to withstand high vacuum applied during the process for optimum mixing. The mixer is provided with a jacket for cooling or heating as per the application.We offer Contra mixer suitable for manufacturing Tooth Paste, High viscous Creams, viscous Cosmetics products and other viscous products mix.Salient Features Compact design requires comparatively smaller floor space. Product container mounted on mounting lugs or legs as required by customer. Hydraulic power pack with cylinders are provided for lowering and lifting movement of top cover with stirrer's drive assembly. Lowering and lifting movement of drive assembly will be achieved through hydraulic lifting system for easy of cleaning and changeover of products. (OPTIONAL - Provided On Demand). Fixed product container for safe operation during mixing. As stirrer is a top driven and sealing doesn't comes in contact with product, there isn't any black particle contamination problem. Steam circulation jacket for mixing bowl, to heat the product during operation & water circulation facility to cool the product during or after mixing. (made out of mild steel or SS304, as per customer requirement). Material discharge from bottom. Flush bottom valve provided for material discharge. M/C provided with Light glass, Sight glass, material inlet, water inlet, steam & washing water inlet, air suction valve for vacuum, vacuum gauge etc. Mixing assembly have two speed facility. Variable speed drive facility for mixing assembly will be provided on extra cost, as an OPTIONAL facility. Spray ball assembly to effectively SIP.

Type : Contra Rotary Mixer

Material : Stainless Steel

Application : Industrial Use

Grade : AISI, ASTM, DIN, Automatic

Voltage : 440V, 230V

Condition : New

Capacity : 2000-4000L, 000 Liters

Finishing : Polished

Power : 15-20Kw

Warranty : 1 Yr, 1 Year

Orientation : Vertical

...more

closed loop cooling tower

The closed-loop cooling tower is a hybrid of a counter-current forced-draught cooling tower and a water-to-water heat exchanger tube bundle. This cooling tower has several advantages over other types of cooling towers. Firstly, the cooling water never gets contaminated with dusty atmospheric air, which helps maintain the quality of the water. Secondly, since the cooling water circulates in a closed loop, there is no evaporation loss, which makes it an energy-efficient option1. Jacket cooling in reactors is a beneficial feature as it prevents scaling and accumulation of mud, ensuring a very clean operation1.

Material : FRP, Stainless Steel

Driven Type : Electric, Hydraulic

Color : Blue

Condition : New

Automatic Grade : Semi Automatic

Power : 9-12kw

Application : Process Cooling

Certification : CE Certified

Voltage : 440V.580V

Capacity : 100TR To 300TR

Type : Closed Circuit Cooling Tower

Warranty : 2years

After-Sales Service Provided : Yes

Country of Origin : India

Temperature : 0-50℃

...more

Chemical Reactors

25 piece (MOQ)

a chemical reactor or reaction vessel are vessels design to facilitate chemical reaction using various chemicals, known as reactants. Reaction vessels are also used for other processes such as solids dissolution, product mixing, distillation, crystallization, liquid-liquid extraction and polymerization. Reactors are also identified based on the process for which it will be used. (such as blender or crystallizer). We are a chemical reactor manufacturer for chemical, pharmaceutical, polymers, fine chemicals, polyester, dyes and other industries. As per your process demand we fabricate jacketed vessel, limpet coil reactor, dimple type reactor, high-pressure reactor(autoclave). salient features • complete range of chemical reactors as per your specifications • adheres to asme and other standards with special attention to argon and arc welding procedures • different types of agitator design • registered with leading consultants and third-party inspection agency. • reliable after-sales support • on-time delivery material of construction • stainless steel(sa 240 gr.316,316l,304,304l) • carbon steel • incoloy • hastalloy

Type : AGITATED REACTORS

Brand Name : TECHNOFAB

Certification : ASME SEC VIII

Application : FOR CHEMICAL PROCESS

Voltage : 410

Condition : BRAND NEW,TAILOR MADE

Warranty : 12 MONTS FOR THE MECHANICAL DESIGN

After-Sales Service Provided : YES

...more

Chemical Reactor

25 piece (MOQ)

Reactor for the chemical process is an art along with the science. Years of in-depth industrial experience at various level raw chemicals resulted in meticulously designing the reactor with the correct specifications. It requires vision to understand the chemical process thoroughly. The amalgamation of various process in a proper manner is the key to perfect reactor design We offer design fabrication, testing and commissioning of the agitation system which can be a part of the complex chemical reaction. Solid suspension, solid dissolution in the liquid, Heat and mass transfer, product mixing, distillation, crystallization, liquid/liquid extraction, Reduction, Helogenations polymerization. are the few process for which we designthe reactors We also offer skid mounted self-contained pilot plants with automation. We cater to Pharmaceutical, Fine chemicals, Dyes, Chemicals, Polyester plants As per your process requirements, we fabricate Jacketed vessel, limpet coil reactor, dimple type reactor, high-pressure reactor or autoclave. Reactors with internal coils and various combinations of agitators We also offer reactors with stuffing box, Mechanical seal and Magnetic drive for the sealing Salient Features Complete range of chemical reactors as per your specifications Stainless steel and all ally steel Adheres to ASME and other standards Special attention to Argon and Arc welding procedures100 % RTD Different types of agitator design Registered with leading consultants and third-party inspection agency. Reliable After-sales support On-time delivery Material Of Construction Stainless Steel(Sa 240 Gr.316,316L,304,304L,310,321) Carbon Steel Incoloy Hastalloy TI

Type : Stainless Steel Chemical Reactor

Voltage : 220-380 V

Condition : New

Warranty : 1 Year

Material : Stainless Steel

...moreOpening Hours