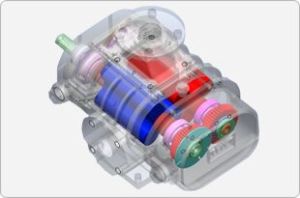

Twin Lobe Roots Blower

Salient Features of TMVT Compressors: TMVT make Twin Lobe Compressors (MTLK / MP / ETP Series) are enjoying tremendous reputation in the market since about 3 decades. Complete range of 18 Models of MTLK type covers requirements of various industries of divers nature. Suitable for different pressure up to 1 Kg/cm2 in Single Stage and up to 2.2 Kg/cm2 in Double Stage. Also suitable for Gas Duty as well as Vacuum Duty (Up to 600 mbar). Blower : The Main Body, Side Covers are manufactured from Graded Cast Iron as per CI IS 210 FG 260. Castings are procured from Foundries of repute like Bhagwati Spherocast, Ductile Iron Foundry, etc. etc. Rotors : The Rotors are of S. G. Iron as per grade 400 / 015 of smaller capacities up to 1500 M3/ Hr. For larger capacities of Twin Lobe Compressors, Rotors are having Lobes in Graded Cast Iron IS 210 FG 260 Construction. All types of Rotors are with EN-8 Shafts. For corrosive gases we supply blower in C.I. construction with electro less nickel plating on contact parts or complete blower in stainless steel construction. Machining : All components are machined to very accurate dimensions with extremely tight tolerance with guaranteed interchangeability. The Castings of Casing and Main Covers (Bearing Housing) are stress relieved after pre- machining for dimensional stability at elevated temperature. Lobe Profiles : The Lobes of Rotors are having involute profile ensuring Uniform clearances between rotor to rotor in any position of two rotors. The profile also ensures uniform clearances between Casing and Lobes unlike providing PTFE strips which is usually done as a cheap method of manufacturing for maintaining clearances. The Rotor profiles are machined on CNC machines and imported Copy Shaping/Planning Equipment ensuring profile with high accuracy/finish which result in power saving. MTLK type blower main chamber is sealed by labyrinth seal. Four numbers piston rings are fitted on each side of rotor. Lubrication : Both side of side casings are oil filled. All bearings and gears are splash lubricated. This increases life of bearings and gears. Timing Gears : The Timing Gears are wide for more load bearing, and having helical teeth, hardened and ground, maintaining backlash within the limit of 0.03 to 0.06 mm to ensure low noise level. Same are either Press-fit on rotor shafts by Tensioning Element or having taper locking on rotor shaft by hydraulic system making mounting and dismounting of Gears much easier. Bearings : In case of Air Cooled Compressors model MTLK, Bearings on the drive shafts have Spherical Taper Roller Bearings to take axial as well as thrust load whereas the gear Shafts have Angular contact Ball Bearings. In case of Water Cooled Compressors Model MP, all bearings are cylindrical Roller Bearings. Cooling : .Air Cooled as well as Water cooled models are available for specific requirements .In case of air cooling, housing surface is cooled by convection cooling. Making fins on the housing surface increases convection. In case of Water Cooling, water is flown in the casing constantly at the specific rate which cools the blower, lobes and oil.. Testing : All the Blower are individually tested with Test Procedure based on IS-10431/IS-5456-Rev. (BANGALORES-726/BS-1571-Part-II-Rev) for capacity, power consumption, temperature rise noise level as well as vibration level. MTLK Models : They are suitable for vertical as well as horizontal flow. In case of vertical flow compact assembly requiring no additional internal piping is being given. MP Models : In this design, for gas duty, there is special arrangement of shaft sealing. In this arrangement FOUR OIL SEALS are provided on Lobe shaft to ensure no leakage of gas to oil chamber. For additional reinforcement to this arrangement, Oil Seal, ‘O’ Ring and after space ring are provided on main shaft. This type of shaft sealing arrangement arrest gas leakage to great extent. LDB Models : They are used for low pressure duty in which gears are cooled by oil on one side and on the other side, bearings are cooled by grease. ETP Models : They are suitable for pressure upto 5000 mm WG. They are good for Water Treatment Plants. They can also used for other duties using Non Return Valves. Blower Unit: The Twin Lobe Compressors as well as various accessories like Two Silencers (for Suction and Discharge), Suction Filters, Safety Valves, Non Return Valves, Anti Vibration Pads, Flexible Bellows, etc. are having robust construction being as per conservative SWISS design. This ensures extremely reliable/trouble free operation and long life for critical process industries like Cement where low speed machines are usually preferred. Accoustic Hood :A drastic reduction of the noise level to 10 to 12 db(A) at 1 M distance is possible by employing a sound insulating hood, which can be opened to allow inspection. This hood can also be retrofitted without modifying the insulation

...more

Turbo Blower

Turbo Blower : TMVT introduces Turbo Blowers. The machine is equipped with high pressure AIR Bearings and Computer Assisted Energy Efficient Axial Impeller. The machine is driven with Latest Energy Efficient Permanent Magnet Synchronous Motor and Variable Speed Inverter Drive. Due to its design features the machine has very Low Power Consumption and also Low Noise Level. The biggest advantage of this machine is almost ZERO Maintenance over a period of many years. Salient Features of our Turbo Blower as follows: High profitability through energy-saving and cost-saving. The best in efficiency, performance and quality. The best choice for a more pleasant industrial environment. Customer satisfaction through ZERO Break Down.

...more

Roots Blower

Three Lobe Roots Blower : TMVT Three Lobe Roots Blower are new 3MTL series Roots type Blower. Rotors are manufactured on high precision CNC machines ensuring high performance. Owing to ‘THREE LOBES' Rotor design, the reverse flow pressure variation period is only 2/3 of that of a conventional ‘TWO LOBES' rotor, the peak pressure is also lower. So the noise and pressure pulsation are greatly limited. Features Of Three Lobe Roots Blower : Discharge pressure pulsation is reduced, so lighter loading of bearings and timing gears ensures the long servicing life. Oil Chamber is separated from main chamber. Hence air is oil free. Bearings on drive and driven sides are lubricated by oil Construction simple and hence easy maintenance. Less back flow. Hence Volumetric Efficiency increased. Stable air flow rate Lower vibration. Less vibration transmitted through the lobe results approximately 20% longer bearing life Three lobes design efficiently reduce noise by approximately 5dB

...more

mechanical vacuum boosters

Mechanical Vacuum Boosters: TMVT Vacuum Boosters dramatically reduce process time by achieving faster evacuation. They also reduce power requirements. It can also achieve higher values of vacuum, if required. TMVT manufactures wide range of capacity Booster pumps in India. Capacities range from 270 to 5240 M³/Hr. TMVT Industries Pvt. Ltd. is an ISO 9001-2008 company. Salient Features of TMVT Boosters: Very high volumetric pumping efficiency and capable of moving large quantity of gas at low pressures. Provide significant savings in time and power. Can be used in combination with variety of backing vacuum pumps to achieve higher speeds and lower ultimate pressures. As an oil free pump, the mechanical booster delivers clean and dry gas. Backing pumps to achieve low pressures with high pumping speeds. Rotors are made on CNC machines to close tolerances and are dynamically balanced. High quality bearings for longer life and trouble free operation. All units are leak tested. Suited to a wide range of applications.

...more

Liquid Ring Vacuum Pump

The Liquid Ring Vacuum Pump has certain advantages such as : Material Of Construction: Considering corrosive conditions of gas to be handled, construction of vacuum pump is selected. It is available in complete cast iron, complete S.S., partial S.S. or partial bronze construction. Vacuum: Up to 50 mm Hg. Absolute using service liquid as water at 30°C. and higher (with water having less than 30°C) Higher Vacuum: Higher vacuum can be obtained by using special oil or other service liquid. Also high vacuum can be achieved by using Liquid Ring Vacuum Pump as backing pump in series with mechanical booster. Long Life and Low Maintenance Cost. : Pumps are robust in construction. Impeller with shaft is only moving part. Impeller has no contact with casing. Hence wear is negligible. These machines require very little maintenance and easy overhauling. Vibration- free and Noiseless Operation: The sealant ring acts as a sound damper. Gas flow is non-pulsation type. Hence machines are comparatively noiseless and vibration-free. Liquid and Vapor Handling: Liquid Ring Vacuum Pumps are capable of handling large quantities of vapor. It has also ability to handle small amount of liquid in the suction stream without causing damage. Handling solid particles: Continuous flushing action permits handling of certain fibrous materials Low Starting Torque : No Internal Lubrication Sealing: Sealing is generally by water lubricated asbestos rope while mechanical seal may be used for special application. Circulation Of Service Liquid: As per requirement , service liquid can be circulated in the pump in open system, partially closed system or completely closed system. Condensing Effect: When handling gas saturated with water vapor advantage can be taken of the condensing effect of the sealing ring. As Compressor: Liquid Ring Pump can work as compressor. Oil Free Gas : When pump is used as compressor, delivery of gas is absolutely oil free.

...more

high vacuum system

TMVT Mechanical Booster Vacuum Systems are designed engineered and manufactured in our State-of-the – art modern manufacturing facility. Systems are suited to a wide range of applications. A vacuum Booster can be backed by various types of Vacuum pumps such as Liquid Ring Vacuum Pump, Rotary oil sealed, Rotary piston, Reciprocating piston pump, Dry screw pumps, water/steam ejectors etc. Liquid Ring Vacuum systems can be configured with Lobe type Boosters to maximize flow at lower vacuum levels. Equipped with single stage liquid ring backing pumps, the systems are offered as air cooled models. These are available in Direct Driven versions with or without VFD Drive wherein capacity can be varied as per the choice. Each system is specifically designed to meet customer’s requirements for capacity, final vacuum and material of construction. The systems operate initially with the vacuum pump pulling down to maximum vacuum, followed by the cut in of the booster to maximize the flow. The key advantage of systems using booster is that they provide high flow rate with minimum power. TMVT Industries Pvt. Ltd. is an ISO 9001-2008 companyCapacity : 270 to 5000 M³/Hr. Pressure Range : Booster - Water Ring Pump combination - Up to 10 Torr

...more

three lobe roots blower

TMVT Three Lobe Roots Blower are new 3MTL series Roots type Blower.

...moreBe first to Rate

Rate ThisOpening Hours