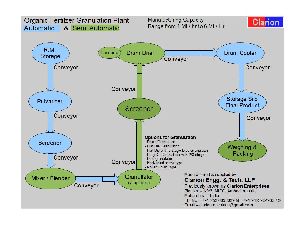

Organic fertilizer granulation plant and machines

975,000 Per Set

1 Set(s) (MOQ)

We are manufacturers & suppliers of Organic fertlizer granulation plant & machines along with technical know how. Capacity range from 10 kg hr. To 10000 kg hr.

Mineral Gypsum Granulation Plant

Get Price Quote

1 Piece(s) (MOQ)

With thorough expertise and understanding of this industry, we are enormously involved in offering Mineral Gypsum Granulation Plant. The Mineral Gypsum or Phospho Gypsum is screened for lumps. The lumps are crushed fine. The powder is mixed with the binder and hardener and transferred to the granulator. In the granulation drum a very fine spray of water is done on rolling material at its angle of repose. Some coating of powder over the small nuclei / particles takes place. The size of granules are controlled as more spray, bigger granule. Less spray small granule. This duration of this process is controlled as per requirement. The material is then taken to dryer drum where the hot air generated in the furnace is passed through it. The dried material is cooled in cooler drum by passing ambient air through it. The ID fans connected to dryer & cooler sucks air from the drums so some dust also comes with it. The dust is separated in the cyclones and finally scrubbed in wet scrubber. The cooled material is screened through under size & over size screens. The product of 1 – 4 mm size is separated and packed in 50 kg. Bags. The oversize material after crushing and the under size are recycled and work as nucleus for next cycle.

Best Deals from Granulation Plant

High Shear Granulation

Get Price Quote

The system allows full integration with upstream and downstream equipment, and even includes a wet mill between the granulator and dryer. With modern control systems it is easy to load, mix and granulate a second batch in the high shear granulator whilst drying the previous batch in the fluid bed prior to discharge. All equipment can be CIP in a single automatic process. Where as a single shaker might be acceptable for drying application. A twin shaker or blow back filter should be used for granulation processes.

Mild Steel Granulation Plant

225,000 Per unit

Granules Plant

Get Price Quote

Our advanced packaging system assists us in meeting the bulk and customized packaging requirements of the clients. In addition, our packing experts ensure safe packaging of the products. Our prime interest is to deliver a flawless range of products to the buyers. And in this concern, we make all arrangements in order to store the entire lot under safe environment.

granulation plant

Get Price Quote

granulation plant

Get Price Quote

We source only qualitative raw material from the reliable places only. Our professionals conduct strict quality checks as a result of which, finished products stand high on the clients' expectations. Our company stocks the product in mass. Thus, we can cater to bulk/retail requirements with easy and ensure fast delivery of product. Product Details : Eminent design Heavy duty Durable Tested OK Quality assured Smooth functioning

Granulation Reprocessing Plant

600,000 Per Piece

Granulation Fertilizer Plant

5,500,000 Per unit

granulation plant

Get Price Quote

We are offering Granulation Plant, Wire & Cable Plant.

Fluid Bed Top Spray Granulation

Get Price Quote

Fluid Bed Equpment-Processor- Top Spray Granulation High Precision Fluidize Drying, Granulating, Agglomerating & Coating Process Technic Application & Process : Prism Fluid Bed Processing involves drying, cooling, agglomeration, granulation and coating of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Biotech, Nutraceuticals, Cosmetic, Chemicals, Biochemical, Food, Dairy, Confectionery, Agrochemical, Herbals, Ceramics, Detergents and Pharma Institutes. Depending on the application required Prism fluid bed Equipment can be configured into designs as follows: 1. The Fluid Bed Mixing and Drying Process : The Fluid Bed system have a bed of solid particles which are fluidized by passing a stream of air upward through a specially designed perforated sheet. The upward velocity of air is so maintained so as to slightly lift the solid particles and set them in motion. This motion can be utilized to bring about mixing as well as forward movement of the solids particles. The air is heated and the process hot air evaporates the fluid and dries the solids. Fines get agglomerated to larger granules particles thus providing large size 2. The Fluid Bed Processor with Top spraying system for Agglomeration and Granulation Process :The process is used in fluid beds to form granules form a fine powder. The fluidized powder is wetted with fluid / binder / starch pest by using top spraying system. The top spraying system provided with spraying nozzle and precise dosing peristaltic pump. The fluidized powder is wetted until liquid bridges are formed between particles. Segregation of powder doesn't take place as different powder is glued together on a micro scale. Since there is no impinging force in fluid bed equipments the granules are weak and having good solubility. Once the granules are made they are dried in the equipment using hot air. This technology used for formed granules for Tabletting, capsule, dust free process, free flow properties, good dispensability and excellent solubility due to porous structure. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. High Mixing Precision, Short Batch Time, Problem free Cleaning and Residue Free Discharge. Single piece construction & Integrated retarding chamber cum filter bag housing Top Spraying system for Granulation. Different Batch size capacity model available. Granulation system with advance PLC controls system with MMI Touch screen. Spraying system with atomized spraying gun and high precise flow peristaltic pump. Sampling pot on product container. Pneumatic Sealing of Filter Bag and Product container by inflatable silicon rubber tube. Inlet Air handler with Air Filter- Micro and HEPA and Heat Exchanger. Dual speed mixing impeller for mixing and intensify chopper for granulating. Optional Features : Combo model with Granulator and Pellets Coater. Flame Proof Electrical. Safety Features : Explosion flap ensures that there no damage to the person operating the machine if there is an explosion inside caused by mixture of air and dust. Blower stops if the air pressure in filter bag locking gasket drops below the set value.

Plastic Granulation Plant

Get Price Quote

Plastic Granulation Plant, plastic high speed mixer, Screw Extruder

granulation plant

Get Price Quote

granulation plant, HDPE Scrap, plastic regrind

Industrial Plastic Granulation Plant

Get Price Quote

Industrial Plastic Granulation Plant, LDPE Film Plants

granulation plant

Get Price Quote

granulation plant, Air Compressor Parts, engineering patterns

granulation plant

Get Price Quote

granulation plant, industrial spray dryers, rotary vacuum dryers

granulation plant

Get Price Quote

granulation plant, Floor Self Supporting Chimney, venturi valve

granulating plants

Get Price Quote

granulating plants

Roto-Pe-Colouring Granulation Plant

Get Price Quote

Roto-Pe-Colouring Granulation Plant

Slag Granulation Plant

Get Price Quote

Slag Granulation Plant, clinker cooler, gas cleaning plant

Calcium Chloride Granulation Plant

Get Price Quote

Calcium Chloride Granulation Plant, vibratory dryer, Spray Cooler