Waste Refinery Plant

WyunaSep Hydro cyclone separators are one of the best ways to separate two non-mixing liquids. Almost any hydrocarbon oil and most non-hydrocarbon oils such as corn, orange, or other vegetable oils may be separated from water in a satisfactory manner. We manufacture our Waste Refinery Plant, as per the leading industrial norms and standards. High Performance : WyunaSep liquid /liquid hydro cyclones can treat emulsions with oil droplets below 15 microns. (50 to 100 microns for competitor's systems) The most reliable oil separation performance. Units are not affected by debris build up or inadequate maintenance, as can occur with other systems. The treatment system is closed hence there is no equipment smells or vapour emissions. Low Maintenance : No plates, or Hopper to clean leading to lower yearly maintenance costs. No closely packed plates to block. No algae chemical dose required. No large stagnant volumes. All our systems use high quality stainless steel piping and frames. No occupational health & safety issues like with plate pack cleaning. Easy Installation/Use : Our most models are easily manoeuvrable and will fit into confined or hazardous spaces. Pressurized oil and water discharge allows flexibility in site location and savings because re-pumping is not required. Standard systems are fully pneumatic with no electrical connections. This greatly simplifies and reduces the cost of installation. Operational Flexibility : Has the ability (via recycle option) to batch treat very difficult emulsions, and discharge water when oil content is below limits. With low cost recycle option, equipment has the ability to meet future oil discharge limits without additional capital expenditure. Removed oil is stored in large above (or below) ground decanting containers, extending the time between oil waste collections. Because our systems use skimmers, oil layers do not accumulate in the effluent pit so little or no oil will escape if the pit accidentally floods. Specifications : Separate oil from wastewater as an industrial pre-treatment system prior to directing the water to sewer or other disposal. Separate oil from circulating water or other aqueous phase systems to remove the oils so that the stream can more economically be reused or so that the oil in the water stream does not cause problems elsewhere in the system by fouling heat exchangers or catalysts. Separate oil from water so that the water may be purified and reused or recycled. Can be used either internally in chemical plants or oil refineries or in plant or refinery outfall streams. Industrial pre-treatment of waste streams prior to disposal to sanitary sewer systems Features : Foot Print - Compact, 10% the size and weight of conventional systems. -2 to 24 m3 = 1 to 1.5 m2 area. Oil content – single cycle <20 ppm or recycle + DHRR <5ppm in two stage Clean water with no chemicals. Effluent can be recycled for continuous treatment. Lowest cleaning & maintenance bills. Lowest repair & parts replacement bills. Lowest total ownership cost over 2 to 4 years. Ensure discharge compliance. Satisfies Regulatory authorities. More likely to meet tougher new Regulations. You can get on with your business. Fully pneumatic. Complies with Standards for hazardous Waste Zones.

...more

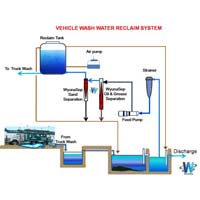

Vehicle Wash Water Reclaim System

We are a trusted Manufacturer, Supplier, and Exporter of the Vehicle Wash Water Reclaim System. We carry out our operations from Gujarat, India. We use the best quality components and pioneering techniques in building our Vehicle Wash Water Reclaim System. We offer it to the leading industries for specific applications. We are backed by a team of meritorious professionals, which engineers this system with a high level of precision. Process Description : Water from the wash enters the first collection pit where the large heavy solids drop out. Water is drawn from beneath the oil layer in the first pit then overflows to the second pit. The feed to the WyunaSep Separator is from this second pit. The water is first drawn through a coarse 3 mm debris strainer on the separator skid by a low shear helical rotor pump. The pump is self-priming and also provides the pressure to drive the fluid through the four stage separation process. Stage 1 WyunaSep Oil SeparatorRemoves the “light contaminants” : The WyunaSep Separator works on a very simple principle. The oily water is pumped tangentially into the spinning vortex. This spinning vortex is accelerated as it moves down the tapered separation tube flinging the heavier water to the outside walls while the lighter oil moves to the centre. The separated oil is removed via a hole in the separator end face, and the treated water is discharged out the other end of the tube. Why is it such a powerful separator of oil and wax? : Unlike plate pack style or gravity style separators the WyunaSep Separator does not rely on weak gravity forces for separation. The centrifugal force generated inside the vortex of the WyunaSep Separator is of the order of 1,000 times the force of gravity. With such force even emulsified oil droplets can be separated in the de-oiling separator. Stage 2 - WyunaSep Solids Separator -Removes the “heavy contaminants” : This separator uses the same high strength vortex separation principle except that the treated water is removed via the hole in the separator end face while the lesser flow containing heavier than water solids is discharged out the tapered end. The WyunaSep Separators do not require back flushing and have no moving parts. Stage 3 - Re-Use Tank - Removes “neutrally buoyant contaminants” : Separation of particles takes place by floatation as the air bubbles attach to the contaminants and float out. Fine foam generated in the “top part” of the Re-Use Tank attaches the small contaminants, which are discharged back to the pit for collection. The treated and aerated water is stored in the lower section of the re-use tank ready for use. The three debris streams are combined into one line and returned to the first collection pit for storage. Stage 4 Air Blower The injection of clean air into the water entering the Re-Use tank, via an air blower, increases the oxygen content of the water. The oxygen keeps the water smelling fresh by keeping it aerobic. Aerating the water prevents anaerobic conditions from developing. Aeration is achieved by dispersing air into the water. Tiny air bubbles are created to maximize the surface area of the air bubble, which ensures the maximum amount of oxygen in the water. Treated Water to Vehicle Wash - The vehicle wash equipment (supplied by others) can draw the treated reclaim water as required from the reuse tank. The treated water is stored at atmospheric pressure and as a result a pressure pump will be required to transfer the reclaim water to the vehicle wash process. Fresh Water Make-Up - A low-level fresh water makeup valve is installed in the reuse tank to allow continued use of the car wash if the WyunaSep Water Reclaim System has been turned off for maintenance or if car wash demand exceeds the WyunaSep Water Reclaim System capacity. A water meter has been installed to enable the user to meter and monitor the quantity of fresh water being used in the process. If checked regularly, the water meter will help identify excessive use of fresh water

...more

Stream Filtration Cooling Tower

We are counted amongst the predominant Manufacturers, Suppliers, and Exporters of the Stream Filtration Cooling Tower. Our well-reputed entity is based in Gujarat, India. We manufacture it by using the premium grade of raw materials and pioneering techniques. We are backed by a team of adept professionals, which designs these towers with a high level of precision. Our offered Stream Filtration Cooling Towers are well-appreciated in the market for their high durability, optimum functionality, robust construction, and long service life. Details : Cost-effectiveness Reliability Hassle free management

...more

Solids Separation Unit

180,000 Per Units

1 Units (MOQ)

Features : Optimum running time , High performance . Reliable and safe

Type of Machine : Automatic

Brand Name : Yamini

Material : Stainless Steel

Power Source : Electric

Surface Treatment : Color Coated

Frequency : 50 Hz

...more

Side Stream Filtration System

160,000 Per Units

Application : Industrial

Brand Name : Yamini

Body Material : Mild Steel

Filter Type : Hydraulic Filter

Filter Medium Material : Activated Carbon

Frequency : 50 Hz

Voltage : 220 V

...more

Raw Water Clarification

Frequency : 50-60 Hz

Oil Water Separators

150,000 Per Units

20 Units (MOQ)

Voltage : 220 V

Brand Name : WyunaSep

Surface Treatment : Powder Coated

Capacity : 60-150 L/Hr

Frequency : 50 Hz

Ambient Temperature Range : 5-60 Deg C

Power Consumption : 0.2 KW/ Hr

...more

Oil Water Separator

We are counted amongst the leading Manufacturers, Suppliers, and Exporters of Oil Water Separator. We carry out our operations from Gujarat, India. We use the superior grade of raw materials and updated techniques in manufacturing our Oil Water Separator. The entire range of our separators passes through various quality check, so as to deliver a matchless quality to our clients. Specifications : Most efficient and cost-effective solution to water treatment problems Clean water with no chemicals - 95% of 20 microns / up to 20 ppm oil droplets removed in a single pass. Foot Print: 10% the size and weight of conventional systems. From 2 to 24 m3 = 1 to 1.5 m2 area. Weatherproof MOC closed loop system. Effluent can be recycled for continuous treatment. Low maintenance – Hydro cyclone has no moving parts. Modular add-on features allow customers to achieve higher production efficiencies -cleaner environmental outcomes while meeting government regulations, compact design for reduced footprint and weight, wear resistant materials of construction for increased reliability and low maintenance. Flexible operation for variations in flow rates Manual or fully automated Fixed or portable systems available Can be installed vertically or horizontally Very short residence time (in the order of seconds)-Quicker separation of oil solids reduces many issues like odour, dissolved hydrocarbon process and bacterial fungi generation etc. Highly consistent performance 8 Power supply - only one motor for Pump-Pneumatic version up to 1om3 available Features : Electric and pneumatic options available SS 316 Flameproof and non-flame proof options available Trolley mounted system also available

...more

Oil Recovery System

365,000 Per Units

Voltage : 240 V

Power : 50-300 KW

Features : Easy to operate , High performance, Longer service life

Brand Name : Yamini

Material : Stainless Steel

Medium used : Oil

Frequency : 50 Hz

Temperature Range : 5-80 Degree C

Phase : 1

...more

Oil Fat Recovery System

We are counted amongst the prominent Manufacturers, Suppliers, and Exporters of Oil Fat Recovery System. Our well-reckoned organisation is based in Gujarat, India. It is well- appreciated by the clients for its non-corrosive body, ruggedness, and long operational life. We thoroughly examine our Oil Fat Recovery System on the basis of the stringent quality parameters, to bring about an exceptional quality in our offered system.Specifications : Increases good quality of recovered oil, as it is recovered from any treatments in ETP Reduces load on ETP further treatment. Increases the cooling tower efficiency, by removing the oil from its water Reduces Cooling tower maintenance requirement. Saves operators time and efforts to handle dirty water With the help of ETP Pre- treatment system – you can reduce the solids load on your ETP. Due to the reduction in solids prior to ETP reduces the load on pumps and chemical dosing in further treatments. It also helps in downsizing the further treatments and filter presses for solids handling. Features : Non corrosive body Ruggedness Maintenance free

...more

Hydrocyclone Cluster

2,500,000 Per Units

Material : Plastic

Brand : WyunaSep

grease separator

350,000 Per Piece

1 Piece (MOQ)

Material : Mild Steel

Country of Origin : Made in India

Color : Grey

...more

Effluent Water Treatment Plant

Owing to a vast experience and in-depth knowledge, we have emerged as the leading Manufacturers, Suppliers, and Exporters of Effluent Water Treatment Plant. We carry out our operations from Gujarat, India. It is a unique filter system that has no moving parts and is used for the removal of unwanted solids within water systems. This system can remove a variety of undesirable solids that are often found in water systems from natural debris. Undesirable solids can cause numerous problems within all manner of water systems. Advantages of Using WyunaSep System : No filter elements, screens, bags or media Less space required doing the similar job with conventional systems Lesser chemicals required in further treatments Efficiency of the further treatments improves, as it reduces the solids load & in some cases BOD as well No cleaning costs No down time – continuous filtration Low water loss when purging Low-pressure loss No backwash Specifications : The total suspended solid (TSS) concentration is defined as the mass of particles above 1 μm in diameter occurring in known volume of water. Suspended solids have both Inorganic and organic component. The organic portion, known as volatile suspended solids (VSS), contributes to oxygen consumption and bio fouling problem (BOD particles) the inorganic components contribute to formation of sludge deposits Physically suspended solids partitioned further into Settle able solid (>100 μm), Supra colloidal ( <100 μm and >1 μm), colloidal and dissolved. Features : No filter elements, screens, bags or media No cleaning costs No down time–continuous filtration Low water loss when purging Low pressure loss No backwash

...more

Dairy Waste Recovery Machine

430,000 Per Units

Voltage : 50 Hz

Features : Long operational life, Trouble-free functionality ,Easy maintenance

Application : Industrial

Material : Stainless Steel

Power Source : Electric

Automatic Grade : Automatic

Frequency : 50 Hz

Treatment Capacity : 50 - 200 Kg / Day

...more

Cutting Oil Purification System

Our trustworthy entity is rigorously engaged in manufacturing, supplying, and exporting an exclusive range of Cutting Oil Purification System. We carry out our operations from Gujarat, India. Our Cutting Oil Purification System is designed and developed in sync with the contemporary industrial standards and norms. Our offered system is proficient in oils, solids, and metal liquids from the cooling liquid. The hydro cyclone provides huge cost savings through : Longer coolant and fluid life Longer cutting tool life Reducing scratches and production failure rate Reducing the frequency of scheduled tank maintenance Minimizing other maintenance and downtime Eliminating or prolonging the life of paper and cartridge filtration Eliminating expensive pump, rotary joints, and system repair Details : Robust design Trouble-free system Easy to install

...more

Coalescing Filters

500,000 Per Units

1 Units (MOQ)

Voltage : 320-440V

Efficiency : 99.99%

Frequency : 50 Hz

Flow Rate : Up to 2500 CFM

Brand Name : Yamini

Power Source : Electric

Pressure : 13 bar

Max Residual Aerosal Oil Content : 0.07mg/m3

...moreBe first to Rate

Rate ThisOpening Hours