Cement Grouting Machine

Get Price Quote

1 Container (MOQ)

Mild Steel Tile Adhesive Mixing Plant

150,000 Per Unit

1 Unit (MOQ)

Best Deals from Cement Plant Parts

Hydraulic Cement Brick Making Machine

1,280,000 Per Set

1 Set (MOQ)

Semi-Automatic Cement Road Paver Machine

375,000 Per Piece

1 Piece (MOQ)

Cement Plant Spare Parts

Get Price Quote

we are engaged in offering a quality range of cement plant spare parts to the clients. Cement plant spare parts, offered by us, are easy to install and have longer service life. Our cement plant spare parts have sturdy construction and, are resistant to corrosion. We offer these cement plant spare parts in corrugated box packaging.

Cement Silo

Get Price Quote

01 Set(s) (MOQ)

We are a manufacturer of cement silo as per customer requirement all of size and capacity are also as per requirement..

Cement Storage Silo

750,000 Per Piece

cement rotary kilns

Get Price Quote

Rotary kiln cement plant - manufacturing process cement manufacturing process crushing & proportioning : - in cement manufacturing process the main raw material is limestone grinding, which is crushed and transported to the pre-blending stockpile by means of a belt conveyor. After reclaiming it is stored into the respective hoppers along with other raw materials. These raw materials then extracted in desired proportion with the help of electronic weigh feeder & transported to the raw mill for fine grinding. Cement manufacturing process raw milling & blending : - the raw mill is a closed circuit ball mill equipped with high efficiency separator. After grinding to 90 microns size the raw meal is send to the continuous blending silos (cfc) for homogenization & extracted by means of load cell hopper for feeding to the kiln pre heaters. Cement manufacturing process pyro processing : - it consists of series of low-pressure drop, pre heater cyclones generally with fluidized bed calciner, where the calcinations begin and material goes into the rotary kiln and after clinkerization the hot material is sent to the cooler for its cooling. The cooler is efficiently designed to recover maximize heat while cooling the hot clinker which is then crushed & sent to the stock pile for intermediate storage. Cement manufacturing process burning :- the required temperature for the clinkerisation is about 1500oc, which can be attained either by coal, gas or oil. The burner is fuel-efficient specially designed multi channel type for uniform burning. cement manufacturing process cement milling, storage & packing:- the clinker mixed with app. 5% of gypsum is sent to the cement mill (ball mill) for fine grinding to produce cement. It is then transported to cfc silo for blending & storage and is packed in the bags with helps of auto packers & transported to the market for sale

Cement Feeding System

310,000 Per Units

1 Units (MOQ)

Dry Mix Mortar Plant

5,000,000 Per Piece

1 Piece (MOQ)

Clinker Breaker Roater

Get Price Quote

Highly praised for presenting high-grade quality Clinker Breaker Roater, we are a celebrated Supplier in the market. We have superior storage capacity to safely store the extensive product range that we offer. Our massive and well-maintained storage space is well-connected with the shipping unit. Features: Precision made High strength Industrial application

Rotary Kiln

Get Price Quote

1 Piece (MOQ)

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or “firing pipe”) which acts like a large Bunsen burner. The fuel for this may be gas, oil or pulverized coal.

Adhesive Making Plant

2,500,000 Per Piece

Adhesive Coating Lamination Plant

3,251,000 Per Piece

1 Piece (MOQ)

Cement Feeding System

580,000 Per Piece

1 Piece(s) (MOQ)

cement mixture machine

Get Price Quote

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Cement Block Making Machine

Get Price Quote

This Machine Can Produce Cement Brick,Concrete Block Like Solid Block, Hollow Block & Paver Block as per your requirement.

cement grinding plant

1,000,000 Per Unit

1 Unit (MOQ)

Plaster Of Paris Powder

Get Price Quote

Cement Feeding System

Get Price Quote

1 Piece(s) (MOQ)

Rotart kiln

2,500,000 Per Unit

Cement Feeding System

Get Price Quote

Exporter, Manufacturer and Supplier of Cement Feeding System, Pneumatic Cement Feeding System, Cement Silo Feeding System, Feeding System, Cement Conveying System, Silo Feeding System, Aggregate Feeding System, Cement Handling System, Powder Feeding System, Cement Feeding Machine..Batching Plant, Batching Plant Silo Accessories, Silo Fabrication, Fly Ash Storage Silo, Grain Storage Silo, Powder Storage Silo, Storage Hopper, Feeding System, Cement Silo, Fly Ash Silo, Cement Storage Silo, Storage Silo, Silo, Mild Steel Silo, Steel Silo, Stainless Steel Silo, Rmc Plant Silo, Batching Plant Silo, Grain Silo, Cement Feeding System..

Rotary Kiln

4,200,000 Per Piece

Vertical Silo

Get Price Quote

Salient Features • Available in 20/30/40/60/80/100 ton capacity. • Horizontal and vertical screw conveyor with hopper arrangement for silo feeding system. • Seamless pipe for feeding material in silo. • Aeration System at bottom of cone & with other necessary filaments.

Cement Feeding System

Get Price Quote

Pneucon is considered as one of the very well trusted and leading Cement feeding system manufacturer that supplies huge range of Cement Feeding Systems. We provide finest quality products made out of superior components and raw materials acquired from the best suppliers in the market. To avoid complaints regarding the defects in the product the manufacturer severely keep check of the various parameters before the delivery of the product. These cement feeding system are known for their durability, strong construction with minimum maintenance cost and high performance.

Cement Brick Machine

Get Price Quote

We provide an exclusive range of cement bricks making machine. Our employees possess in-depth knowledge of the process and operating the machine in order to produce supreme quality of cement bricks. These are made of best grade material, technology like cutting-edge and according to the industrial standards. Our machines are known for their high performance, production in bulk quantity and less maintenance. The machine is made up of various parts like mixer, hydraulic block, mechanical tile making press, curing tanks and pump set. As cement and fly ash bricks machine manufacturer we offer some specification like power required, production capacity and the maintenance required. The main materials required in the process are cement, sand, gravels and water. Our machine process all the ingredients to make a uniform mixture and strong and durable cement bricks in least time.

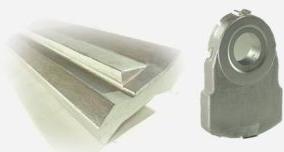

cement plant parts

Get Price Quote

Whether using cone crushers, hammer crushers, impellor crushers or vertical shaft impact crushers; The Group can supply wear parts that offer significant cost benefits when compared to conventionally formulated and manufactured components. This has been achieved through the use of alloys and techniques that can produce higher tensile, higher stiffness and extended fatigue strength characteristics – in fact increasing the fatigue strength by a factor of 2 or even more is not uncommon.

Rotary Kilns

Get Price Quote

A Rotary kiln is a processing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: Cement Lime Refractories Metakaolin Titanium dioxide Alumina Vermiculite Iron ore pellets

Cement Plant

Get Price Quote

Shree Krishna Induction Pvt. Ltd. has gained a rich experience in understanding and delivering excellent products to the cement industry. We offer a wide range of products to service the needs of the Cement manufacturing plants. Our high quality product-line and customized service has helped customers gain from reduced maintenance costs and improved cost-effectiveness. Our products have inherently high wear-resistance rates, required toughness and deliver long-term enhanced performance.