Sigma Mixer

Get Price Quote

Sigma Mixer

Get Price Quote

1 Piece (MOQ)

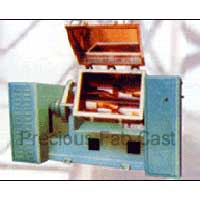

A Z-shaped blades made of hardened cast steel polished & finished. The stuffing box can be heated electronically or by steam. The tilting of the stuffing box is automated.

Best Deals from Sigma Mixer

Sigma Mixer

Get Price Quote

Sigma Mixer

Get Price Quote

The Sigma Mixer is used for mixing and kneading for mixing, kneading of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses. The sigma kneader is a double arm mixer, the two “Z” blade rotate towards each others at same or different speed inside a W- shaped product container. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally.

Sigma Mixer

Get Price Quote

As a leading manufacturer, exporter and supplier from Ahmedabad, Gujarat, we offer optimal quality Sigma Mixer which is widely used in pharmaceuticals, chemical, food industries etc. It comprises of high grade stainless steel and carbon steel that makes it durable and provides smooth blending of high viscosity materials. The kneaders of the Sigma Mixer along with efficient blades help in perfect blending. These are highly demanded by our customers for economical pricing and less power consumption.

Laboratory Sigma mixer

Get Price Quote

Sigma Mixer The Laboratory Z Blade mixer , Sigma mixer is ideal for mixing, kneading and blending of materials for development. The lab mixers sizes, ease of use, and quality of mixing makes the development of new formulations a simplified process. laboratory Sigma mixer machines for all your laboratory mixing needs. Applications- Laboratory mixing machines, perfect for product research and development. Ideal for developing: Adhesives, Sugar pastes, Rubber solutions, Mastics, Soaps, Metal powders, Energetics, Detergents, Ceramics, Confectionery Pharmaceuticals, Fibreglass doughs, Chewing gums, Brake linings, Sealants, Flavour development. Please contact us and we will assist you in developing the right solution for you. Process Equipment Sigma Kneader, Reaction Vessel, Horizontal Ribbon Blender, High Speed Paint Disperser, Three Roller Grinding Mill ,Stainless steel Colloid Grinder, Complete Unsaturated Polyester Resin Production Line

Double Sigma Mixer Machine

Get Price Quote

Extruder Screw Sigma Mixer

Get Price Quote

Sigma Mixer with Extruder Screw Uniform Kneading, Mixing and Extruding Process Application & Process : The Sigma Mixer with extruder is used for mixing, kneading and extruding of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses. The extruder mixer is designed to handle difficult to discharge products such as hot melts and butyl sealants, as well as other medium to high viscosity pastes. This type of mixer combines the action of the Double Arm Sigma Blade Mixer with an extrusion screw placed in the lower part of the mix trough. During mixing, the extrusion screw is run in reverse which imparts a third mixing action on the product, increasing mixing efficiency. The sigma kneader is a double arm mixer with extruder, the two "Z" blade rotate towards each others at same or different speed inside a W- shaped product container and extruder screw is located between the two blade with separate gear motor drive. The extruder screw is rotates in forward direction for extruding process and rotate in reverse direction during mixing process. Speed of the extruder to be adjustable by VFD. The twin screw basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. The extrusion screw is located in the saddle section and runs in a cylindrical trough tangential to and below the 2 mixing blades. When the product has finished the mixing cycle, discharge/extrusion is performed simply by running the extrusion screw in a forward direction. The double arm sigma blades normally continue to run throughout the extrusion process providing a thoroughly mixed product at all stages of the production cycle. By changing the extrusion die heads, the product can be discharged in round, square, "spaghetti", or any form desired. Speed variation of the extrusion screw allows adjustment of the product flow, depending on the viscosity. Salient Features : Designed as per cGMP - Current Good Manufacturing Practices & Non GMP Standard Model. Contact parts in AISI 316, AISI 304 or MS as desired by customer. Capability to pass from mix phase to extrusion phase without interruption. Lateral discharge of product through the extrusion screw without operator interaction. Shape of extruded material is adaptable to customer's requirements. Mixing, Blending and kneading of high Viscosity Materials, with a combined action of Bulk Movement, Kneading, stretching folding, dividing and Recombining. High Mixing Precision, Short Batch Time, Problem free Cleaning and Residue Free Discharge. Automated mixing and granulating process in single bowl. Available in Capacity from up to 1000 Kg Industrial Productions. There are different types of blades: Sigma-"Z" blade, Spiral blade, and Naben blade. Selection of appropriate blade shape and speeds result in excellent mixing. Optional Features : PLC Controls with HMI touch screen Binder spraying system Product Bowl with Jacketing for heating and cooling. Flame Proof Electrical. Vacuum or pressure designs Automatic control of blade speed based on product viscosity. Safety Features : Enclosed mixing and discharge provides protection from product contamination and greater operator safety. Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Overload relay Protection and Emergency stop button

Sigma Mixer (kneader)

Get Price Quote

Sigma Mixer : SIGMA MIXING MACHINE is a heavy-duty mixer specially designed to produce uniform mixing, blending & kneading of highly viscous, paste & dough type materials. Sigma mixer is used for kneading of putty, epoxy, paints, pigments, adhesives, gums, battery pastes, welding electrode flux, catalysts paste, plastic compounds, rubber compounds, papad, chocolate, bubble gum, etc. The tangential action of mixing and kneading is thoroughly obtained by two 'Z' shaped kneading blades, which rotates very accurately at different speed towards each other causing the product to be transferred from one blade to the other. The mixing action is a combination of bulk movement, stretching, folding, dividing, and recombining of the material. The shearing & tearing action of the material against blades and the side walls causes size reduction of the solids. Sigma Mixer Operation Sigma mixer, the tangential action of mixing and kneading is thoroughly obtained by 'Z' (SIGMA) shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided Sigma Mixer Options GMP / Non GMP / models. Discharge in sigma mixers is done by tilting container / bottom sliding valves / bottom gates / flush bottom gate valves. Tilting in sigma mixers is done by hand liver / hand wheel with lead screw / electrical arrangements / hydraulic systems. Lifting of lead either manually, with help of counter weights or hydraulically. 'Z' Type Spiral blade / Naben / double naben blades to circulate hot / cold water in cases of heavy masses. Jacketed shell for heating or cooling by steam, oil, water etc. with fiber glass insulation over the jacket. Spray system for liquid addition / gas purge. Flame proof / Non-flame proof electrical controls. Salient Features Sigma Mixer is a Batch type Mixer In sigma mixer, Mixing Trough and Blades are fabricated from mild steel, stainless steel 304 and 316 grade. Blades of sigma mixers are designed to obtain thorough mixing of high viscosity materials. Sigma Mixers Blades are machined to keep minimum equal gap between through walls and blades. Sigma mixers have fixed with Heavy-duty gears to sustaion of load of Kneading. Shaft sealing into the stuffing boxes is provided by Teflon Chevron Rings / PTFE breaded gland rope to prevent leaking from blade ends. Safety Guards and Grills are provided for maximum safety in sigma mixers.

Sigma Mixer

Get Price Quote

This is a mixing machine provided with the arrangement of two z-shaped arms (blades) which blend the mass inside the trough machine in a dough making manner. It has the application to blend or process highly viscous materials such as adhesives, Dyes & Pigments, Food products, Fiber glass, Grease, Polymer plastics, Rubber , Soap, detergents and so on. The necessary additives or other kinds of filler additives can be added and mixed to prepare the required stub. Features; Available in MS, SS-304, SS-316 with or combination of them in material of construction. Available with or without cooling/heating jacketed arrangement. Can be easily discharged the material by tilting by manually or Auto system. Various Blades’ Profile and their Application;

Double Sigma Mixer Machine

Get Price Quote

We are the main supplier of this product.

Sigma Type Battery Mixer Machine

145,000 Per Piece

10 Piece (MOQ)

Sigma Mixer Machine

Get Price Quote

Being a customer-focused organization, we are engaged in offering a wide assortment of Sigma Mixer Machine. The offered are extensively used in laundry soaps, detergent cakes and toilet soaps industry. These machines solve the purpose of mixing and kneading highly viscous material. Moreover, customization of our offered machines is provided by us in order to meet the needs of clients. We offer these machines to the valued customers at market-leading prices.

Z-blade mixers

Get Price Quote

Z-blade mixers are used in a number of food and commercial adhesive applications. Ingredients are blended until the consistency is correct. The ingredient is then tipped out of the mixer and forwarded to the next step in the process. These types of machines are available in M.S. And S.S. construction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate. Applications: Double Arm Sigma Blade Mixers are suitable for many applications, including: Sealing compounds, asphaltic derivatives, mastics, hot-melts, floor coverings, colorings, rubber base, master-batches, chewing gum, rubber compounds, silicone, lubricating greases, dispersed pigments, butyl, gums and adhesives, ceramic paste, polyester compounds, greasy inks, pencil leads, explosives, powders to granulate, PVC coatings, resins, soap, brake linings, carbon electrodes, celluloid, Bakelite, battery paste, polishing pastes, … LABORATORY DOUBLE ARM SIGMA BLADE MIXERS Laboratory Mixers are available in sizes ranging from 3 Liters to 10 liter working capacity. Variable speed drive on the blades standard. Stainless steel construction standard, jacketed is standard.

Soap Sigma Mixer Machine

200,000 Per Piece

1 Piece (MOQ)

Sigma Mixer Machine

Get Price Quote

We manufacture Laundry Soap Mixer Machines which are used in the manufacture of detergent cakes and toilet soaps.

Biscuit Plant Sigma Mixer

650,000 Per Piece

Sigma Mixer

Get Price Quote

Sigma Mixer that we provide is suitable for uniformly mixing thick material, pasty. There are two shafts that consist of �Z� shaped blades which moves at different speeds in opposite directions. The Sigma Mixer that we offer is available at industry leading prices. Available In : Also in stainless steel construction Jacketing for heating or cooling provided Suitable for : MineralAgro ProductsAgricultural ProductsMixing of ChemicalScreen of Powder StoneCeramic RefractoryOreSpicesCoalSandChemicalGyratoryMineralSpiceAyurvedicPharmacyCeramicTobaccoSaltCattle FeedPoultry Feed

Sigma Mixer

1,500,000 Per Units

Sigma Mixer Machine

200,000 Per Set

Product Description:With sincerity and hard work of our experts, we have carved a niche for ourselves in this domain by manufacturing and supplying Rotor Removal Type Mixer. Use: Used in various industrial application. Features: Long working life Minimum maintenance Rugged construction

Sigma Mixer

Get Price Quote

Sigma Mixer, Packing Conveyor, Sigma Mixer- Z Blade- Dough Mixer

Sigma Mixer

Get Price Quote

Sigma Mixer, Ship Loader Conveyor, Drag Chain Conveyor, Overhead Conveyor

Used Sigma mixer machine

Get Price Quote

Used Sigma mixer machine