Vibro Sifter

1 Piece (MOQ)

The Vibro Sifter is a versatile and efficient sieving equipment used across various industries for separating particles of different sizes. Its unique vibratory motion ensures thorough sieving and accurate separation. With its robust construction and customizable features, this sifter offers reliable performance and consistent results.Description A Vibro Sifter consists of a circular sieve deck driven by a motor that causes it to vibrate. As the material is fed onto the sieve deck, the vibratory motion separates particles based on size. The larger particles are retained on the sieve, while the smaller particles pass through. The sifter is equipped with mesh screens of varying sizes to achieve the desired particle size distribution.Where to use Pharmaceuticals: Sieving of active pharmaceutical ingredients (APIs), granules, and powders.Chemicals: Separation of various chemical substances, pigments, and additives.Food Processing: Used for sieving food ingredients such as flour, sugar, spices, and grains.Cosmetics: Sieving of cosmetic powders, pigments, and additives in the cosmetics industry.

Material : Stainless Steel

Finishing : Polished

Shape : Round

Color : Silver

Voltage : 220V

Specialities : Durable, Easy To Use

Country of Origin : India

...more

Vaccum Tray Dryer

1 Piece (MOQ)

The Vacuum Tray Dryer is a crucial piece of equipment utilized in industries requiring efficient drying processes. Its design incorporates trays stacked within a vacuum chamber, providing an optimal environment for drying materials. With its ability to operate under low pressure, this dryer offers enhanced drying capabilities, making it suitable for a wide range of applications.Description A Vacuum Tray Dryer consists of a vacuum-tight chamber housing multiple trays arranged one above the other. The trays are heated externally, and the vacuum inside the chamber facilitates the removal of moisture or solvents from the material being dried. This process ensures uniform drying, with minimal heat degradation, making it ideal for sensitive materials. Additionally, the vacuum environment reduces the boiling point of liquids, allowing for faster drying times.Where to use Pharmaceuticals: Drying of active pharmaceutical ingredients (APIs), granules, or powder formulations.Chemicals: Drying of various chemical substances, including solvents and intermediates.Food Processing: Used for drying food products such as fruits, vegetables, and snacks.Biotechnology: Drying of biotechnological products like enzymes, probiotics, and cultures.

Material : Stainless Steel

Color : Silver

Application : Pharamaceutical

Voltage : 440V

Type : Vacuum Tray Dryer

Weight : 100-200kg

Country of Origin : India

...more

V Blender

1 Piece (MOQ)

The V Blender is a versatile and efficient mixing equipment used across various industries for blending dry powders, granules, and other materials. Its unique V-shaped design ensures thorough mixing and homogeneity in the blend. With its robust construction and customizable features, this blender offers reliable performance and consistent results.Description A V Blender consists of a V-shaped vessel with a central shaft and two side arms or paddles. The rotation of the shaft causes the paddles to move material both radially and axially, ensuring thorough mixing. The gentle mixing action prevents product degradation and ensures uniformity in the blend. The blender is equipped with a discharge valve for easy removal of the blended material.Where to use Pharmaceuticals: Blending of active pharmaceutical ingredients (APIs), excipients, granules, and powders.Chemicals: Mixing of various chemical powders, pigments, additives, and intermediates.Food Processing: Used for blending food ingredients such as powders, spices, flavorings, and nutritional supplements.Plastics: Blending of plastic resins, additives, colorants, and compounds in the plastics industry.

Color : Silver

Automatic Grade : Semi Automatic

Feature : Stable Performance, Rustproof

Voltage : 440V

Type : V Blender

Country of Origin : India

...more

Tray Dryer

1 piece (MOQ)

The Tray Dryer is a versatile and reliable drying equipment extensively used in industries requiring efficient drying processes. Its simple yet effective design makes it suitable for drying a wide range of materials, from pharmaceuticals and chemicals to food products. With its customizable temperature and airflow settings, this dryer offers precise control over the drying process, ensuring optimal results.Description A Tray Dryer comprises a stack of trays placed within a chamber, with hot air circulating through the trays for drying. The trays can be made of stainless steel or aluminum and are perforated to allow for airflow. The heating system, typically located at the bottom or rear of the chamber, heats the air, which then flows through the trays, evaporating moisture from the material being dried. Tray Dryers are available in various sizes and configurations to accommodate different production needs.Where to use Pharmaceuticals: Drying of tablets, capsules, powders, and granules.Chemicals: Drying of various chemical substances, intermediates, and pigments.Food Processing: Used for drying food products such as fruits, vegetables, grains, and snacks.Textiles: Drying of fabrics, yarns, and dyed materials in the textile industry.

Material : Stainless Steel

Finishing : Polished

Color : Silver

Power Source : Electric

Automatic : Semi Automatic

Usage : Pharmaceutical Industry

Type : Tray Dryer

Country of Origin : India

...more

syrup plant

1 Piece (MOQ)

A Syrup Plant is a specialized manufacturing facility used in both the pharmaceutical and food industries for the production of liquid syrups. It consists of various interconnected units for mixing, heating, cooling, filtration, and filling. Syrup Plants are designed to meet industry standards and regulatory requirements for product quality and safety.Description The Syrup Plant typically includes units such as syrup preparation vessel, storage vessel, heating system, cooling system, filtration system, and filling machine. Raw materials are first mixed in the preparation vessel and heated or cooled as required. The mixture is then transferred to the storage vessel for further processing. After filtration, the syrup is filled into bottles, jars, or containers using the filling machine.Where to use Pharmaceutical Industry: Production of liquid pharmaceutical formulations such as cough syrups, antacids, and vitamin syrups.Food Industry: Manufacturing of flavored syrups, fruit syrups, dessert syrups, and pancake syrups.Herbal Industry: Production of herbal syrups and medicinal syrups.Beverage Industry: Manufacturing of syrup bases for soft drinks, cocktails, and mocktails.

Color : Silver

Automatic Grade : Fully Automatic

Voltage : 440V

Type : Syrup Making Machine

Weight : 100-500kg

Country of Origin : India

...more

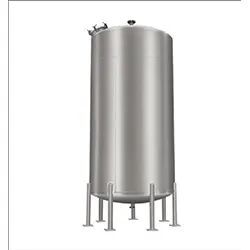

Storage Tank

1 Piece (MOQ)

A Storage Tank is a large container used for storing liquids or gases in various industries. These tanks are essential for holding raw materials, intermediate products, and finished goods in manufacturing processes, as well as for storing fuel, chemicals, and agricultural products. Storage Tanks come in different sizes, shapes, and materials to meet the specific requirements of different industries and applications.Description Storage Tanks are typically constructed from materials such as steel, fiberglass, or concrete, depending on the type of material being stored and the environmental conditions. They may be aboveground or underground, depending on space availability and regulatory requirements. Storage Tanks may also include features such as insulation, heating or cooling systems, level indicators, and safety devices to ensure safe and efficient storage of materials.Where to use Manufacturing Industry: Storage of raw materials, intermediate products, and finished goods in industries such as chemicals, pharmaceuticals, food and beverage, and electronics.Oil and Gas Industry: Storage of crude oil, refined petroleum products, natural gas, and liquefied gases in production, refining, and distribution facilities.Chemical Processing: Storage of chemicals, solvents, acids, and other hazardous materials in chemical manufacturing plants and storage terminals.Agriculture: Storage of fertilizers, pesticides, grains, and agricultural chemicals on farms, ranches, and agricultural facilities.

Material : Stainless Steel

Shape : Round

Color : Silver

Feature : Anti Corrosive, Anti Leakage, Good Strength

Capacity : 1000-2000ltr

Country of Origin : India

...more

ROTOCONE VACUUM DRYER

1 Piece (MOQ)

A Rotocone Vacuum Dryer is a type of equipment used for drying heat-sensitive materials under vacuum. It is widely used in industries such as pharmaceuticals, chemicals, food processing, and more for drying powders, granules, and pastes.Description The Rotocone Vacuum Dryer consists of a cone-shaped vessel that rotates slowly while being heated from the outside. The vacuum inside the vessel lowers the boiling point of the liquid in the material, allowing for gentle drying at low temperatures. The rotating action ensures uniform drying and prevents material buildup on the vessel walls. The dried product is then discharged from the dryer for further processing or packaging.Where to use Pharmaceutical Industry: Drying of active pharmaceutical ingredients (APIs), intermediates, and formulations.Chemical Industry: Ideal for drying chemicals, especially those sensitive to heat or oxidation.Food Processing Industry: Used for drying various food products such as powders, granules, and pastes.Other Industries: Suitable for drying materials in industries such as cosmetics, nutraceuticals, and agricultural chemicals.

Driven Type : Electric

Color : Silver

Automatic Grade : Semi Automatic

Application : Vacuum Drying

Type : Rotocone Vaccum Dryer

Country of Origin : India

...more

Ribbon Blender

1 Piece (MOQ)

The Ribbon Blender is a versatile and efficient mixing equipment used across various industries for blending dry powders, granules, and other materials. Its unique ribbon design ensures thorough mixing and homogeneity in the blend. With its robust construction and customizable features, this blender offers reliable performance and consistent results.Description A Ribbon Blender consists of a U-shaped horizontal trough and a set of inner and outer helical ribbons mounted on a central shaft. The rotation of the shaft causes the ribbons to move material both radially and axially, ensuring thorough mixing. The gentle mixing action prevents product degradation and ensures uniformity in the blend. The blender is equipped with a discharge valve for easy removal of the blended material.Where to use Pharmaceuticals: Blending of active pharmaceutical ingredients (APIs), excipients, granules, and powders.Chemicals: Mixing of various chemical powders, pigments, additives, and intermediates.Food Processing: Used for blending food ingredients such as powders, spices, flavorings, and nutritional supplements.Plastics: Blending of plastic resins, additives, colorants, and compounds in the plastics industry.

Material : Stainless Steel

Color : Silver

Automatic Grade : Semi Automatic

Power : 750W

Feature : Stable Performance, Rustproof

Voltage : 440V

Type : Ribbon Blender Machine

Country of Origin : India

...more

receiver tank

1 Piece (MOQ)

A Receiver Tank, also known as a storage tank or receiver vessel, is a crucial component in various industrial processes for storing and distributing liquids or gases. It serves as a buffer between different stages of a process, allowing for smooth operation and ensuring a continuous supply of materials. Receiver Tanks come in different sizes and configurations to meet the specific storage and distribution requirements of different industries.Description The Receiver Tank typically consists of a cylindrical vessel with inlet and outlet connections, pressure relief valves, level indicators, and other accessories. It may be constructed from materials such as stainless steel, carbon steel, or fiberglass, depending on the application and the properties of the stored material. Receiver Tanks are designed to withstand the operating conditions and pressures encountered in industrial processes.Where to use Manufacturing Industry: Storage and distribution of raw materials, intermediate products, and finished goods.Oil and Gas Industry: Holding tanks for crude oil, natural gas, and refined petroleum products in production, refining, and distribution processes.Chemical Processing: Storage of chemicals, solvents, reagents, and intermediates in chemical manufacturing plants.Food and Beverage Industry: Holding tanks for ingredients, beverages, and food products in processing and packaging facilities.

Material : Mild Steel

Shape : Round

Application : Air Storage

Type : Air Receiver Tank

Country of Origin : India

...more

Rapid Mixer Granulation

1 Piece (MOQ)

Rapid Mixer Granulation is a highly efficient process used in pharmaceutical and chemical industries for mixing and granulating powders. It involves rapid mixing of dry powders with a liquid binder to form granules of uniform size and density. With its rapid and controlled mixing capabilities, this equipment ensures consistent granulation results with minimal processing time.Description In Rapid Mixer Granulation, dry powders and a liquid binder are fed into a mixing chamber equipped with high-speed impellers or choppers. The impellers rapidly mix the powders while simultaneously spraying the liquid binder onto the particles. The granulation process results in the formation of spherical granules with improved flow properties and compressibility. The equipment is designed to provide precise control over mixing parameters such as mixing time, impeller speed, and binder addition rate.Where to usePharmaceuticals: Granulation of active pharmaceutical ingredients (APIs) to produce tablets or capsules.Chemicals: Granulation of various chemical powders, pigments, and additives.Food Processing: Used for granulating food ingredients such as sugar, salt, and spices.Nutraceuticals: Granulation of nutritional supplements and health products.

Material : Stainless Steel

Color : Silver

Automation Grade : Semi Automatic

Voltage : 220V

Type : Rapid Mixer Granulation

Country of Origin : India

...more

paste kettle

A Paste Kettle is a versatile mixing vessel used in various industries for heating, mixing, and blending pasty or viscous materials. It consists of a jacketed kettle with a tilting mechanism for easy pouring and cleaning. Paste Kettles are designed to handle a wide range of materials, from pharmaceutical creams and ointments to food products like sauces, jams, and confectionery fillings.Description The Paste Kettle features a steam jacketed vessel that heats the contents using indirect heat transfer, preventing burning or scorching. The kettle is equipped with an agitator or scraper blade that continuously mixes the material to ensure uniform heating and blending. The tilting mechanism allows for easy discharge of the finished product. Paste Kettles come in various sizes and configurations to suit different production requirements.Where to use Pharmaceuticals: Mixing and blending of creams, ointments, and gels.Food Processing: Heating and mixing of sauces, jams, confectionery fillings, and other food products.Chemicals: Blending of adhesives, sealants, and other viscous chemical formulations.

Material : Stainless Steel

Color : Silver

Automatic Grade : Semi Automatic

Voltage : 220V

Type : Paste Kettle

Country of Origin : India

...more

Ointment Cream Plant

1 Piece (MOQ)

An Ointment Cream Plant is a specialized manufacturing facility used in the pharmaceutical industry for the production of ointments, creams, gels, and lotions. It consists of various interconnected units for mixing, heating, cooling, emulsifying, and filling. Ointment Cream Plants are designed to meet cGMP (current Good Manufacturing Practice) standards and regulatory requirements for pharmaceutical manufacturing.Description The Ointment Cream Plant typically includes units such as a preparation vessel, storage vessel, heating system, cooling system, vacuum emulsifying mixer, homogenizer, filtration system, and filling machine. Raw materials are first mixed in the preparation vessel and heated or cooled as required. The mixture is then transferred to the vacuum emulsifying mixer for emulsification and homogenization. After filtration, the product is filled into tubes, jars, or bottles using the filling machine.Where to use Pharmaceutical Industry: Production of topical pharmaceutical formulations such as ointments, creams, gels, and lotions.Cosmetics Industry: Manufacturing of cosmetic creams, lotions, and gels.Personal Care Industry: Production of skincare products, moisturizers, and emollients.Veterinary Medicine: Manufacturing of topical medications and ointments for animals.

Color : Silver

Automatic Grade : Semi Automatic

Voltage : 220V

Type : Ointment Cream Plant

Weight : 1000-2000kg

Country of Origin : India

...more

Octagonal Blender

The Octagonal Dryer is a robust and efficient drying equipment utilized in industries requiring effective drying processes. Its unique octagonal shape allows for maximum heat transfer and uniform drying of materials. With its durable construction and customizable features, this dryer offers reliable performance and consistent results.Description An Octagonal Dryer consists of a chamber with an octagonal-shaped body and a central shaft. The chamber is jacketed for heating or cooling, and the material to be dried is loaded into the chamber. As the chamber rotates, the material tumbles, ensuring uniform exposure to the heated surfaces. The efficient heat transfer and uniform drying make it suitable for a wide range of applications.Where to use Pharmaceuticals: Drying of granules, powders, and formulations in the pharmaceutical industry.Chemicals: Used for drying various chemical substances, intermediates, and catalysts.Food Processing: Drying of food products such as grains, nuts, and spices.Minerals: Drying of minerals and ores in the mining and mineral processing industries.

Driven Type : Electric

Color : Silver

Automatic Grade : Semi Automatic

Feature : Rustproof, High Performance

Voltage : 440V

Type : Octagonal Blender

Country of Origin : India

...more

IPC Bin

1 Piece (MOQ)

IPC (Intermediate Bulk Container) Bins are specialized containers designed for storing, transporting, and handling bulk materials in various industries. These bins are commonly used in pharmaceuticals, chemicals, and food processing industries due to their efficiency and versatility. IPC Bins come in different sizes and configurations to accommodate different types of materials and storage requirements.Description An IPC Bin typically consists of a sturdy plastic or stainless steel container with a lid and integrated pallet base for easy handling with forklifts or pallet jacks. The bins are designed to meet industry standards for cleanliness, durability, and safety. They may feature features such as smooth surfaces for easy cleaning, ergonomic handles for lifting, and secure locking mechanisms to prevent tampering.Where to use Pharmaceuticals: Storage and transportation of active pharmaceutical ingredients (APIs), excipients, and intermediates.Chemicals: Handling of chemical powders, granules, liquids, and solids in manufacturing and distribution facilities.Food Processing: Storage and handling of food ingredients, additives, and finished products in food processing plants and warehouses.Cosmetics: Transporting and storing cosmetic ingredients, formulations, and finished products in cosmetics manufacturing facilities.

Material : Stainless Steel

Color : Silver

Automation Grade : Semi Automatic

Application : Pharma Industry

Feature : Good Quality, Good Strength

Type : IPC Bin

Country of Origin : India

...more

Heat Exchanger

1 Piece (MOQ)

A Heat Exchanger is a device used to transfer heat between two or more fluids or between a solid surface and a fluid. Heat Exchangers are essential equipment in various industries for heating, cooling, and condensing processes. They come in different types and configurations to suit different applications, from simple shell-and-tube exchangers to complex plate-and-frame exchangers.Description A Heat Exchanger consists of two fluid circuits separated by a solid wall or surface, through which heat is transferred from one fluid to the other. The fluids may be in direct contact with each other or separated by the solid wall, depending on the type of exchanger. Heat Exchangers may use different heat transfer mechanisms such as conduction, convection, and radiation to transfer heat efficiently.Where to use Manufacturing Industry: Heating and cooling of process fluids in chemical processing, petroleum refining, and metal fabrication.Energy Industry: Heat recovery and energy conservation in power plants, cogeneration systems, and district heating and cooling networks.HVAC Industry: Air conditioning, refrigeration, and heat pump systems for commercial buildings, residential complexes, and industrial facilities.Food Processing Industry: Pasteurization, sterilization, and cooling of food products such as dairy, beverages, and processed foods.

Material : Stainless Steel

Shape : Cylindrical

Color : Sliver

Automatic Grade : Semi Automatic

Medium used : Air

Weight : 500-1000 Kg

Country of Origin : India

...more

Fluid Bed Dryer

1 Piece (MOQ)

A Fluid Bed Dryer is a type of equipment used for drying granular materials by fluidizing them with hot air. It is widely used in industries such as pharmaceuticals, food processing, chemicals, and minerals for drying powders, granules, crystals, and aggregates.Description The Fluid Bed Dryer consists of a bed of solid particles through which air is passed at a high velocity to create a fluidized state. The material to be dried is fed into the fluidized bed, where it is suspended and agitated by the flowing air. This results in efficient heat and mass transfer, leading to rapid drying of the material. The dried product is then discharged from the dryer for further processing or packaging.Where to use Pharmaceutical Industry: Drying of granules, powders, and particles in the production of tablets, capsules, and granules.Food Processing Industry: Drying of food products such as grains, cereals, fruits, and vegetables for preservation and packaging.Chemical Industry: Drying of chemical powders, pigments, catalysts, and intermediates in chemical manufacturing processes.Mineral Industry: Drying of minerals, aggregates, ores, and ceramics for processing and refinement.

Material : Stainless Steel

Finishing : Polished

Color : Silver

Power Source : Electric

Usage : Pharmaceutical Industry

Voltage : 440V

Type : Fluid Bed Dryer

...more

Double Cone Blender

1 Piece (MOQ)

The Double Cone Blender is a versatile and efficient mixing equipment used across various industries for blending dry powders and granules. Its unique double cone design allows for gentle yet thorough mixing, ensuring uniformity in the blend. With its simple operation and ease of cleaning, this blender is a popular choice for applications requiring precise and consistent mixing.Description A Double Cone Blender consists of two conical-shaped vessels joined at their apexes, mounted on a central shaft. The rotation of the shaft causes the powders or granules inside the cones to tumble and mix thoroughly. The gentle tumbling action prevents product degradation and ensures homogeneity in the blend. The blender is equipped with a discharge valve for easy removal of the blended material. Where to use Pharmaceuticals: Blending of active pharmaceutical ingredients (APIs), excipients, and granules.Chemicals: Mixing of various chemical powders, pigments, and additives.Food Processing: Used for blending food ingredients such as powders, spices, and flavorings.Cosmetics: Blending of cosmetic powders, pigments, and additives in the cosmetics industry.

Material : Stainless Steel

Driven Type : Electric

Color : Silver

Automatic Grade : Semi Automatic

Feature : Rustproof, High Performance, Durable

Voltage : 440V

Type : Double Cone Blender

Country of Origin : India

...more

Distillation Column

1 Piece (MOQ)

A Distillation Column is a key component in the process of distillation, which is used to separate liquid mixtures into their individual components based on differences in boiling points. Distillation Columns are widely used in industries such as petroleum refining, chemical processing, pharmaceuticals, and beverage production.Description A Distillation Column consists of a tall vertical vessel with multiple trays or plates arranged at intervals along its height. The liquid mixture to be separated enters the column at the bottom and is heated, causing the components with lower boiling points to vaporize. The vapor rises through the column, coming into contact with the descending liquid on the trays. As the vapor cools, it condenses back into liquid form, and the separated components are collected at different tray levels or in separate compartments.Where to use Petroleum Refining: Separation of crude oil into various fractions such as gasoline, diesel, kerosene, and lubricating oils.Chemical Processing: Purification of chemical intermediates, solvents, and specialty chemicals in chemical manufacturing plants.Pharmaceutical Industry: Separation and purification of drug compounds, active pharmaceutical ingredients (APIs), and pharmaceutical intermediates.Beverage Production: Distillation of alcoholic beverages such as vodka, whiskey, rum, and brandy in distilleries and breweries.

Surface Finishing : Polished

Application : Industrial Use

Feature : Accuracy Durable, Corrosion Resistance

Capacity : 1000-2000L

Type : Distillation Columns

Country of Origin : India

...more

Contra Rotary Mixer

1 Piece (MOQ)

A Contra Rotary Mixer is a specialized mixing equipment used in various industries for blending dry powders and granules. It features two contra-rotating shafts with mixing elements that move the materials in opposite directions, ensuring thorough mixing and blending. With its efficient mixing action and customizable features, this mixer offers reliable performance and consistent results.Description The Contra Rotary Mixer consists of two shafts with mixing elements such as paddles, ribbons, or screws that rotate in opposite directions. This contra-rotating motion creates a fluidized zone within the mixing chamber, where the materials are continuously mixed and blended. The mixer is equipped with a discharge valve for easy removal of the blended material. Contra Rotary Mixers come in various sizes and configurations to suit different mixing requirements.Where to use Pharmaceuticals: Mixing of active pharmaceutical ingredients (APIs), excipients, granules, and powders.Chemicals: Blending of chemical powders, pigments, additives, and intermediates.Food Processing: Mixing of food ingredients such as powders, spices, flavorings, and nutritional supplements.Cosmetics: Blending of cosmetic powders, pigments, and additives in the cosmetics industry.

Material : Stainless Steel

Finishing : Polished

Color : Silver

Application : Industrial Use

Voltage : 220V

Type : Contra Rotary Mixer

Country of Origin : India

...more

Chemical Reactor

1 Piece (MOQ)

A Chemical Reactor is a specialized vessel used in chemical processing industries for the production of chemicals, pharmaceuticals, polymers, and petrochemicals. It facilitates chemical reactions by providing an environment where raw materials can react to produce desired products. Chemical Reactors come in various sizes and configurations to accommodate different reaction processes and production requirements.Description The Chemical Reactor consists of a vessel or tank where the chemical reaction takes place, along with ancillary equipment such as heating or cooling systems, agitators, and instrumentation. The reactor may be operated under different conditions such as batch, continuous, or semi-batch mode, depending on the nature of the reaction and the desired product. Reactors are designed to withstand high temperatures, pressures, and corrosive chemicals encountered in chemical processing.Where to use Chemical Processing Industries: Production of specialty chemicals, fine chemicals, intermediates, and bulk chemicals.Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs), pharmaceutical intermediates, and drug formulations.Polymer Industry: Polymerization reactions for the production of plastics, resins, elastomers, and synthetic fibers.Petrochemical Industry: Processing of crude oil and natural gas into refined products such as fuels, lubricants, and petrochemical intermediates.

Color : Grey

Automatic Grade : Semi Automatic

Voltage : 220V

Type : Chemical Reactors

Weight : 0-100kg

Country of Origin : India

...more

cage blender

1 Piece (MOQ)

The Cage Blender is a versatile and efficient mixing equipment utilized in industries requiring thorough blending of dry powders and granules. Its unique cage design ensures uniform mixing and homogeneity in the blend. With its robust construction and customizable features, this blender offers reliable performance and consistent results.Description A Cage Blender consists of a cylindrical vessel with a rotating cage assembly mounted inside. The cage assembly contains multiple arms or paddles that rotate independently, ensuring thorough mixing of the materials. The cylindrical vessel is jacketed for heating or cooling, allowing for temperature control during the blending process. The blender is equipped with a discharge valve for easy removal of the blended material.Where to use Pharmaceuticals: Blending of active pharmaceutical ingredients (APIs), excipients, granules, and powders.Chemicals: Mixing of various chemical powders, pigments, additives, and intermediates.Food Processing: Used for blending food ingredients such as powders, spices, flavorings, and nutritional supplements.Cosmetics: Blending of cosmetic powders, pigments, and additives in the cosmetics industry.

Driven Type : Electric

Color : Silver

Automatic Grade : Semi Automatic

Power : 750W

Feature : Stable Performance, Rustproof

Voltage : 440V

Type : Cage Blender

Country of Origin : India

...more

Autoclave Processor

1 Piece (MOQ)

An Autoclave Processor is a specialized sterilization equipment used in both the pharmaceutical and food industries for the sterilization of liquids, solids, and instruments. It uses steam under pressure to kill microorganisms and pathogens, ensuring product safety and quality. Autoclave Processors come in various sizes and configurations to meet the specific sterilization requirements of different industries.Description The Autoclave Processor consists of a pressure vessel, heating system, control system, and safety features. The items to be sterilized are placed inside the chamber, and steam is injected under pressure to raise the temperature and pressure inside the chamber. The items are exposed to the steam for a predetermined time to ensure complete sterilization. After sterilization, the pressure is released, and the items are cooled before removal from the chamber.Where to use Pharmaceutical Industry: Sterilization of pharmaceutical formulations, medical devices, and laboratory instruments.Food Industry: Sterilization of food products, ingredients, and packaging materials to extend shelf life and ensure safety.Laboratories: Sterilization of laboratory equipment, glassware, and media for microbiological studies.Biotechnology: Sterilization of biopharmaceutical products, cell culture media, and fermentation vessels.

Material : Stainless Steel

Shape : Horizontal

Color : Silver

Pressure : High Pressure

Usage : Laboratory Use

Country of Origin : India

...moreBe first to Rate

Rate ThisOpening Hours

Nisha Engineering

Established in the year 2007, we at Nisha Engineering are one of the fastest-growing organizations in Industrial Rotary equipment. We professionally deal in Industrial Dryers, Industrial Blenders, Industrial Tanks, Industrial Plants, Vibro Sifter, Rapid Mixer Granulation, Paste Kettles, IPC Bin, Contra Rotary Mixer, Autoclave Processor, Chemical Reactor, Heat Exchanger and Distillation Column. Now, you can get the best quality of the product at the best price.

Our Team

Our professional engineers finish their work with full precision and responsibility. To confirm that you get the best quality products every time, stick to global standards.

Mission

We maintain our mission to give clients access to ace-grade, pioneering technologies from renowned machine makers by building proficiency.

Vision

We aim to lead the food and chemical processing equipment industry through the best product quality, innovations, timely delivery and mutual reliance.

Our mission is to please our customers by giving the outmost solutions to their requirements. We know the reality that each customer has a unique obligation which can be answered by a special design.

Additionally, we give effective after-sales service to our valued clients to make sure for the convenient functioning of the tools.

Based in Ankleshwar, Gujarat, India, Nisha Engineering is professionally managed by Mr. Sandeep Yadav. He has years of experience and practice in the market.