Semi Automatic Grid Casting Machine

This machine is best suited for small scale & medium scale battery plate & battery manufacturers or for longer Industrial negative grid where the grid mould are heavy & manual casting are not possible. It is a simple equipment which consists of a main frame on which the grid mould mounting block with grid mould opening / closing & grid ejection mechanism is mounted. Various grid type moulds could be mounted on this. Grid mould opening & closing is continuous & the timing could be set. When the mould opens, the grid is ejected automatically. Trimming is not necessary since dropping legs are not provided & the gate portion is made for manual cutting. Lead pouring could be manual or by a pneumatic operated laddle. Lead is generally poured either directly into the mould or into the laddle from the furnace. Grid moulds are provided with water cooling lines & cartridge heater brackets. Temperature of grid mould is controlled by Automatic Digital Controller. The machine is semi-automatic in nature. Only trimming is manual operation. Suitable for Antimonial & Selenium Alloys for any type of Grids. Most suitable to cast Twin Tubular Spine Grids of size 165mm spine length x 145mm width Digital Temperature Controllers for better Monitoring & Control Power : 415V, 31KW (Electrically Heated Furnace) / 12KW (Diesel or LPG heated Furnace) Capacity : 6 to 10 Grid Pannels Per Minute Furnace : 800 Kg

...more

Pasting Machine

This one side pasting machine is suitable for battery manufacturers looking for an economical substitute to tedious manual pasting. Consistent weight and thickness can be maintained from plate to plate and with less wastage of oxide. The machine can be used to paste different thickness of plates. The plate thickness is maintained by a rubber stripper. Independent drive is provided for the hopper and the pasting belt. This aids in running the belt while cleaning without operating the hopper. Hopper can be lifted pneumatically in case of a plate jams and for easy cleaning. The equipment is a semi-automatic one and requires manual feeding and collecting of grid panels. (Auto-Feeding could be supplied on demand). The structural construction is rugged and is built to last. Suitable for Automotive & Industrial Negative Grids Belt Pasting with good finish Auto Feeder for Automotive Girds Manual feeding for plates with hanging legs feature available Pasting Speed : 20 to 80 Grid Panels Per Minute Power : 415V, 14KW Pasting Thickness : 1.4 mm to 4.0 mm

...more

Mixers SigmPressure Die Casting Machine

Suitable for Positive Tubular Spine Grids Maximum Length : 15 spine x 500mm Twin Cavity casting upto 250mm Length Spines Capacity : 2 to 4 Grids Per Minute Operating Pressure : 110 Bar Power: 415V, 33KW (Electrically Heated Furnace) / 15KW (Diesel or LPG heated Furnace) Digital Temperature Controllers for better Monitoring & Control Furnace : 1000 Kg

...more

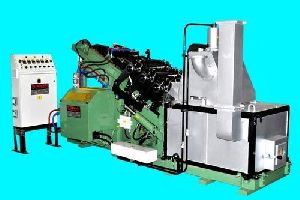

Hydraulic Pressure Die Casting Machine

Power : 415V, 33KW (Electrically Heated Furnace) / 15KW (Diesel or LPG heated Furnace)

battery making machine

Battery making machine Suitable for Positive Tubular Spine Grids, Twin Cavity casting upto 250mm Length Spines, Digital Temperature Controllers for better Monitoring & Control.

Capacity : 2 to 4 Grids Per Minute

...more

Automatic Grid Casting Machine

the machine is fully automatic and can produce up to 10 trimmed grid panels per minute depending upon the lead alloy and the grid design. This equipment is ideal for high volume production battery and battery plate manufactures. The construction of machine is rugged and built for low maintenance. The grid mould opening – cum closing cum grid ejection and ladle tilting is pneumatically operated. Grid alinging chute, grid-trimming device, grid stacking mechanism are all operated by mechanical cams. Heating is by electrical resistance heaters (also given provision for additional heating by lpg at the gate of the ladle). The operations are simple and easy. the machine is fully automatic and suitable for any alloy. built in trim scrap conveyor trimmed grids are stacked for easy removal digital temperature controllers for better monitoring & control casting thickness 1.4 to 4 mm maximum casting size including lugs – 350 x 150 mm power : 415v, 33kw (electrically heated furnace) / 15kw (diesel or lpg heated furnace) capacity : 8 to 14 grid pannels per minute furnace : 800 kg

Power : 415V, 31KW

...more

Carton Box Pasting Machine

Intercell welding machine

Be first to Rate

Rate ThisOpening Hours