Welded Wire Mesh

We are main supplier of this product.

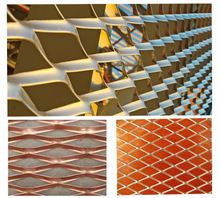

Brand Name : Expanded Metals

Steel Structure purline

Color : yellow

Material : Stainless Steel

Steel Structure (PEB)

Concrete filled steel column (CFSC) The CFSC system has many advantages compared with the ordinary steel or the reinforced concrete system. One of the main advantages is the interaction between the steel column and concrete, local buckling of the steel column is delayed by the restraint of the concrete and the strength of concrete is increased by the confining effect of the steel column. Advantages The CFSC column system has many advantages compared with ordinary steel or reinforced concrete systems. Interaction between steel column and concrete: Local buckling of the steel column is delayed and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. On the other hand, the strength of the concrete is increased due to the confining effect provided by the steel column. Drying shrinkage and creep of the concrete are much smaller than in ordinary reinforced concrete. Cross-sectional properties The steel ratio in the CFSC cross section is much large than in reinforced concrete and concrete-encased steel cross sections. The steel of the CFSC section is well plasticized under bending because it is located most outside the section. Construction efficiency Labor for forms and reinforcing bars is omitted, and concrete casting is done by tremie or pump-up method. This efficiency leads to a cleaner construction site and a reduction in manpower, construction cost, and project length. Fire resistance Concrete improves fire resistance so that fireproof material can be reduced or omitted. Cost performance Because of the merits listed above, better cost performance is obtained by replacing a steel structure with a CFSC structure. Ecology The environmental burden can be reduced by omitting the form work and by reusing steel column and using –quality concrete with recycled aggregates. 1. The concrete filled column system has many advantages compared with ordinary steel or reinforced concrete systems. The main advantages are listed below: 2. Interaction between steel tube and concrete: Local buckling of the steel tube is delayed, and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. On the other hand, the strength of the concrete is increased due to the confining effect provided by the steel tube, and the strength deterioration is not very severe, because concrete spalling is prevented by the tube. Drying shrinkage and creep of the concrete are much smaller than in ordinary reinforced concrete. 3.Cross-sectional properties: The steel ratio in the CFST cross section is much larger than in reinforced concrete and concrete-encased steel cross sections. The steel of the CFST section is well plastified under bending because it is located most outside the section. 4. Construction efficiency: Labor for forms and reinforcing bars is omitted, and concrete casting is done by Tremie tube or the pump-up method. This efficiency leads to a cleaner construction site and a reduction in manpower, construction cost, and project length. 5. Compared with the hollow steel sections, concrete filled steel sections will have a higher fire resistance, and the need less fire proof material around the steel tubes, because concrete has a larger thermal capacity than air which is enclosed in the hollow steel tubes. Even if the sustained loads carried by steel are decreased by heat, the column will not be crushed during the fire if the columns are designed to sustain the dead and live loads only by their concrete cores. So the structures will not surer great damage. Concrete improves fire resistance so that fire proof can be omitted interaction b/w steel tube and concrete: Local buckling of the steel tube is delayed, and the strength deterioration after the local buckling is moderated, both due to the restraining effect of the concrete. 6. Significant economic advantages over either pure structural steel or reinforced concrete alternatives. 7.Identical cross sections with different load and moment resistances can be produced by varying steel thickness, the concrete strength and reinforcement. This allows the outer dimensions of a column to be held constant over a number of floors in a building, thus simplifying the construction and architectural detailing. 8. Higher strength and stiffness compared with RC columns of the same materials properties. Cross section properties: Steel ratio into CFST is much larger than in RC sections. The steel of CFST sections is well plastified under bending because it is located most outside the sections. 9. Cost performance: Cost effective when we compared to steel structure because of composite effect (steel and concrete). 10.Environmental: Form work can be reduced so that production of steel will be less and using high quality concrete with recycled aggregates.

...more

Steel Structure decking sheets

Material : Stainless Steel

Pp Corrugated Sheet

Color : silver

Material : Aluminum Alloy

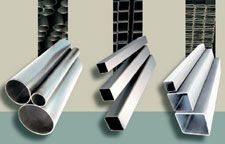

pipe forming

We are main supplier of this product.

Lead Time : Shipped in 0 days after payment

Brand Name : Metal Section

Supply Ability : 20,000 Kilogram/Kilograms per Week

Place of Origin : Karnataka, India

...more

metal section

Company established with the vision to develop sheet folding technology, which is first of its kind in India. Pioneered in high quality sheet folding of most of the metal ranging from cold rolled steel, stainless steel, galvanized steel, Bross, Aluminum to Polycarbonate. Sugam Engineers has been compatible and competitive to the growing demand for steel folding technology in automobile, civil engineering, building, electrical engineering, general engineering and heavy duty pelletized rocking systems. Our folding technology thickness ranging from 0.5mm to 12 mm and length up to 7 meters. With various kinds of surface finishes like painted, pre coated, Polished, stainless steel sheets, can be folded without scrotch. We are the only company specialized in Trapezoidal sections and manufadure according to desired specification in the country. Sugam Engineers dedicated professionals and manufacturing unit is wellequipped with highly modern machines, which is capable of producing quality produds. like Pipe Forming, Poly Carbonate Sheets, Heavy Thickness Plates, PEB Structural, Decking sheets, Door and Windows, Highway Crosh Barriers.

...more

metal poles for lighting

Material : Stainless Steel

Brand Name : steel

Galvanized Steel Z Purlin

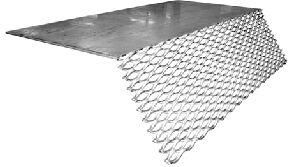

Expanded Metal utility trailers

Brand Name : Expanded Metals

Material : Stainless Steel

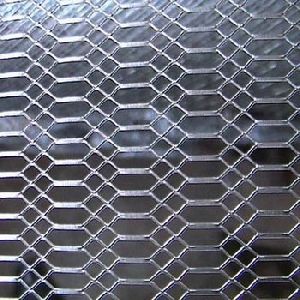

expanded metal lowes

Brand Name : Expanded Metals

Material : Stainless Steel

Expanded Metal

We are now entering this one of its kind product called the expaned metals. In the world the maximum availability is 6mm and maximum opening is 75mm width 200mm, we at SUGAM ENGINEERS are going to manufacture minimum thickness upto 12mm, the maximum which is 300mm and strand height is 600mm and we are able to produce in metal like steel, stainless steel, copper, Brass, Aluminum, Titanium and also polycarbonate with shapes like Hexagonal, square & Diamond shaped expanded Metals. Grills Heat treating baskets Walkaway & Stair treads Food Processing equipment Trays Ceiling lighting Containers Metal Grating Screening for fences Interior decorating screen Building industry Conditioning plants Skylight guards etc….,

...more

Decorative Aluminum Expanded Metal Mesh Panels

Decking Sheets

Composite metal deck is a cost-effective flooring system used in multi story buildings. Floors constructed of composite metal deck ate typically designed such that the corrugated of composite metal deck are typically designed such that the corrugated metal deck will support the weight of fresh concrete and some construction loads without requiring shoring. Once the concrete gains strength, the concrete and metal deck act together as a composite member. The metal deck acts as tensile reinforcement for the slab in resistance to positive moment stresses induced by dead and live loads. Traditional design practice dictates that minimum reinforcement is required in the transverse direction to control any cracks that may occur due to temperature and shrinkage movements. This minimum requirement for reinforcing has traditionally been addressed via the use of light-gauge welded wire mesh. Decking There are many advantages to using metal decking. Versatility Steel decks complying with Specifications are available in various depths and rib spacing’s, with and without stiffening elements. With and without stiffening elements, with and without acoustical material, cellular and non-cellular, and in varying material thicknesses. This extensive choice makes steel deck applicable to a wide range of projects and structural designs. Structural Strength with Less Weight The properties of steel are used with maximum efficiency in the design and fabrication of steel decks, resulting in products with a high strength – to weight ratio. As a result, delivery, erection, and structural framing costs can be lower than with other systems. Attractive Appearance Although steel decking is primarily a structural component, it is visually attractive when left exposed in other applications. With the properly specified factory and field coatings, steel deck is easy to maintain, durable, and esthetically pleasing. All Weather Construction Steel deck can be erected in most weather conditions, eliminating the costly delays that can occur with other types of floor and roof systems, Required Fire Ratings U.L. fire resistance ratings on standard roof and floor assemblies have been obtained by the Steel Deck Institute. Individual Sugam Steel Structures having ratings on their own products. Most fire resistance requirements can be met with products manufactured by Sugam Steel Structures. Uniform Quality Through engineering and continuously refined production techniques, Sugam Steel Structures produce decks that conform to specified standards. Proven Durability Steel deck in place and performing satisfactorily for more than a half century is indicative of the product’s durability. Economy and Value Value is determined by combining initial costs, life – cycle costs, and overall performance. Steel deck assemblies are the best value in floor and roof designs. They combine low cost with top performance.

...more

construction fencing

Material : Stainless Steel

Color : silver

Expanded Aluminum Foil Mesh

Expanded Metal False Ceiling

High Tensile Corrugated Sheet

industrial false ceiling

Steel Structure Multistore Building

Pre Engineered Building

hexagonal poles

Concrete Filed Steel Column

M.S. Formed Section

steel construction

Yoga Dhama Project - Building Construction Project

Design Process

Be first to Rate

Rate ThisOpening Hours