Condensate Flash Heat Recovery System

Get Price Quote

1 Piece (MOQ)

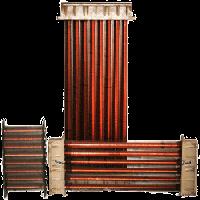

Flue Gas Heat Recovery System

Get Price Quote

We bring forth to our clients our efficient Flue Gas Heat Recovery System that is designed keeping the Industry requirements in mind. This system is used extensively in Industries due to its superior design and features. The Flue Gas Heat Recovery System implements the use of the latest technology to ensure that there is minimal waste and high energy efficiency. Our Flue Gas Heat Recovery System is offered at reasonable prices to clients. Details about the Flue Gas Heat Recovery System In Boiler Stations, fuel is burnt to heat water to produce steam. It is practically impossible to utilize all the heat energy given out. Flue Gas is a by-product of any combustion process. The Flue Gas is a mixture of water vapors, CO2, N2, O2 and traces of other gases. Approximately 4 to 5 times flue gas is produced by burning every one ton of bagasse, in similar boilers. When the heat transfer reaches the practical value, the Flue Gases are removed from the boiler. At temperatures of around 160-180"C and the specific heat around 0.3 kcal / kg, a lot of heat is wasted. This spent Flue Gases hold a lot of Thermal energy. This is the highest single heat loss in systems. To achieve energy efficiency, this heat energy loss must be recovered. What sets our Flue Gas Heat Recovery System apart? Our systems are designed to achieve maximum energy efficiency by arresting and using the energy in the Flue Gas. We make the Boiler economy better by recovering the waste heat in two techniques. Recovery upto dew point/sensible heat recovery : The spent flue gas energy is employed in condensate heating or pressurized heating upto 120 ΓΆ€“ 125 degree C depending on the quantity of flue gas. The heated condensate is flashed as per the low pressure heat requirement or is flashed to the evaporator trains and sent back to heat recovery units at the boiler station. In this way the vapors generated in flash tank are utilized for concentration purposes in the evaporator station. Recovery at dew point : Sulphur content of flue gas is negligible or almost nil in case of bagasse fired boiler, hence water content in flue gas can be condensed and used in the process to recover more heat energy.

Best Deals from Flue Gas Heat Recovery System