Screwed Forged Thredolet

Get Price Quote

10 Piece (MOQ)

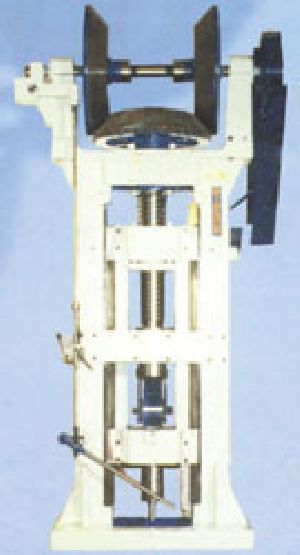

Up Stroke Forging Screw Press

756,000 Per piece

1 Piece (MOQ)

Best Deals from Forging Screw Press

Single Screw Press

Get Price Quote

We are engaged in the exporting, importing and supplying of the advanced single screw press. Our single screw press has gained us a lot of appreciation in the indian and international markets. We offer single screw press at the market leading prices. highlights variable diameter & variable pitch spiral : the stock is pressed in a slowly reducing space, so that the dewatering of the stock layer is almost same.low rotation speed : when there are bulky or hard substances (such as iron ware) in the stock the impurities will be automatically extruded in to the space between helical blades, so as to avoid the damages to the equipment.adjustable outlet consistency : the screw shaft with high compression ratio, to high concentration of stock and outlet consistency can be adjusted with pneumatic or manual plungers as per operator’s demandsspecial structure to prevent slipping of stock and to keep steady the outlet consistencyclosed design to prevent the overflow off flavorscompletely mechanical extruding dewatering without special requirements of installation heighthighly dewatering efficiency to deprive over 85% black liquor in the stock structure it is composed of driving unit, screw shaft and screen cylinderdriving unit : electric motor , gear box and couplerscrew shaft : the first section in contact with stock is the conveyer screw and the middle part is the conical variable diameter variable- pitch to increase the compression ratio the filter liquor extraction percentage and consistency of stock. At the end of the section blade-interruption is termed as interception section to prevent the impacts in outlet consistency due to uneven inlet consistency. The later part is conveyer screw sectionscreen cylinder : it is composed of four sections for input filtering compression and output, each section in the steel frame structure and supported with steel skeleton. The outside of filter is a screen plate with big holes to protect screen plate.

forging screw press

Get Price Quote

HP Singh Machinery Pvt. LTD is a renowned manufacturer, supplier and exporter of Friction screw presses. The Screw is made of high quality alloy Steel and is heat treated to have great hardness at the same time great elasticity. Commonly used in hot forming (forging) and cold coining, stamping, embossing, sizing non-ferrous metal. We have been providing quality machines to our clients at the most reasonable prices.

forging screw press

Get Price Quote

This Screw Press is also known as Forging Presses or Screw Presses. These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging.Vincent Presses are screw presses with friction drive on which the forging blow takes place in an upward direction, that is, from bottom towards top. On machines employing the Vincent principle, the screw nut is positioned in the top cross head of a frame type ram. Thus Ram is moved upwards in axial direction by rotation of longitudinally fixed screw.

forging screw press

Get Price Quote

These Friction Screw Presses are preferred for Hot Forming (Forging) and Cold Coining, Stamping, Embossing, Sizing non-ferrous metal.The press body is of steel welded construction, one piece box type design, The screw is made of high quality alloy steel and is heat treated to give hardness and elasticity.

forging screw press

Get Price Quote

Forging presses & Friction Screw Presses which are the essence of Technical ability and skill of Engineers. We are manufacturing all kind of presses i.e. Forging Presses, Friction Screw Presses and Power Presses. Needless to add the beauty of our designs are to incorporate maximum possible facilities to their users without incurring exorbitant investments.

forging screw press

Get Price Quote

A screw press is a forging machine that uses screws and nuts as drive mechanisms and transforms negative and positive rotary movement of fly wheel into upward and downward reciprocating movement of sliding block. At work, electric motor makes fly wheel rotate in an accelerating way and store energy, and push the sliding block to move downward through screw and nut. When the sliding block touches the workpiece, the fly wheel is forced to reduce speed till stop completely, and rotary kinetic energy that is stored is transformed into impact energy and strike the workpiece via the sliding block and make it be distorted. After strike is over, electric motor makes the fly wheel rotate in a reverse way and bring the sliding block to ascend and return to the original position. The specification of a screw press is shown with nominal work force.

forging screw press

800,000 Per Piece

forging screw press

Get Price Quote

These screw presses are specially designed to make bolt head of any kind of Nuts, Rivets, Motor Parts Axle half shaft, Engine valve and non-ferrous forging. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction i.e. from bottom to top. On machines employing the vincent principle the screw nut is positioned in the top cross head of a frame type ram. Thus ram being moved upward in exial direction by rotation of longitudinally fixed screw. The bottom die of the Forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frames but are sustained by the ram. Ejector is provided at lower part of the ram.

FRICTION SCREW FORGING PRESSES

Get Price Quote

FEATURES Hot Forgings. Investment costs low & Cost for foundations are minimal. The forging Dies have a long life. Costs of development, manufacturer & replacement of the dies are low. Great forging accuracy is achieved because of the free stroke. Additional energy can be applied to the same die impression by making several blows. The heat contact time considerably less than it with crank type forging presses & knuckle joint presses. Cost of repairs after years of hard usage is low. Only skilled labor should be employed for its usage. Our Friction Screw Presses are heavy duty fabricated construction and are suitable for endless variety of Non-Ferrous Stamping, Forgings and Piercing operations depending on the tooling employed on it. Even these are utilized for planership and finishing of articles which has been produced on Power Presses or by castings. These presses are being manufactured from 30 to 500 Tonnes Capacity. Their design beauty is that they can give 1/2" stroke with full press force. Moreover any type of ejection arrangement can be supplied along with the press against specific requirement.

forging screw press

Get Price Quote

These screw presses are specially designed to make bolt head of any kinds of nuts, rivets, motor parts, axle half shaft, engine valve and nonferrous forgings. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction i.e. from bottom towards top. On machines employing the vincent principle The screw nut is positioned in the top cross head of a frame type ram.Thus ram being moved upwards in exial direction by rotation of longitudinally fixed screw. The bottom die of the Forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frame but are sustained by the ram. Ejector is provided at the lower part of the ram.

Birson Forging Screw Presses

Get Price Quote

We offer birson forging screw presses. These screw presses are specially designed to make bolt head of any kind of nuts, rivets, motor parts axle half shaft, engine valve and non-ferrous forging. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction.i.e. From bottom to top. On machines employing the vincent principle the screw nut is positioned in the top cross head of a frame type ram. Thus ram being moved upward in exial direction by rotation of longitudinally fixed screw. The bottom die of the forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frames but are sustained by the ram. Ejector is provided at lower part of the ram.

Forging Screw Press (Up Stroke)

Get Price Quote

These screw presses are specially designed to make bolt head of any kinds of nuts, rivets, motor parts, axle half shaft, engine valve and nonferrous forgings. Vincent presses are screw presses with friction drive on which the forging blow takes place in an upward direction i.e. from bottom towards top. On machines employing the vincent principle The screw nut is positioned in the top cross head of a frame type ram. Thus ram being moved upwards in exial direction by rotation of longitudinally fixed screw. The bottom die of the Forging tools is secured to the lower cross head of the ram while the top die is fitted to a fixed bridge which is the part of the machine frame be employing this design, the forging forces do not act on the machine frame but are sustained by the ram. Ejector is provided at the lower part of the ram.

Friction Screw Forging Press

Get Price Quote

forging screw press

Get Price Quote

Forging of Hexagonal Square and Round headed Bolts- Forged parts for the Nuts, Rivets, Motor Parts , Cycle Parts- Capacity from 50 to 400 TonsForging Presses are a answer for the forging of Hexagonal Square and round headed bolts as well as for Nuts, rivets, Motor Parts, Cycle Parts and Verities of such other items. These Presses are very simple in operation and their stroke can be achieved depressing a lever provided on the left hand column on the front of the press. We provide a wide range in capacity from 50 to 400 Tons.

forging screw presses

Get Price Quote

Our FORGING SCREW PRESSES allow the production of large and small batches of all kinds of threads that can be cold formed, in the most economical way. The normal basic data stated in the table for each machine type are not limiting values. Practical tests in the areas of manufacturing techniques and material behaviour extend performance limits of our machines further and further. Our developments are being determined by and over increasing and move accurate knowledge which enable us to conceive tailor made designs for SPECIALS APPLICATIONS, MATERIAL SPECIALITIES, SPECIFIC DIMENSIONS & DIE-SHAPES.

forging screw press

Get Price Quote

Technical Specification The famous name in Down-Stroke Friction Screw Press,Up-stroke Forging Screw Presses, New Model Down-Stroke Forging Screw Presses (Steel Body) and Power Presses.1. These are manufactured under strict supervision of qualified technicians.2. These are most precise presses, smooth running, durable, strong in construction, accurately finished and very easy in installations.3. H.S.Birdi Industries minimize the cost of production, famous for trouble free performance and are fully guaranteed for service.Terms1. Delivery Ex – Factory Ludhiana.2. Packing Forwarding Extra.3. Sale Tax Charged Extra where applicable.4. Rates are valid for 10 days.5. Insurance will be charged extra.6. 30% Advance with confirmed order and balance against delivery of dispatch.7. All rates are without electrical.8. Subject to Ludhiana Jurisdiction only.Application:1. Forged gear, Bolts, Fasteners & Brick.2. Agricultural Tools, Hand Tools etc.3. Automobile, Motor Cycle & Bicycle Parts.4. Transmission Equipment.5. Engine Valve & parts, Watch Case, Cap.6. Wrist Band & Electric Equipment.

forging screw press

Get Price Quote

forging screw press

Get Price Quote

forging screw press, C-type Power Press, down stroke forging screw press