ROTOCONE VACUUM DRYER

Get Price Quote

1 Piece (MOQ)

VACUUM SPREY DRYER - 1500 DIA

Get Price Quote

technical specifications.sr. no.perticularstech. specs 1 capacity / volume 2000~2500 kgs/ batch 2 shell diameter 1500 mm & shell height - 2000 mm 3 main shell 10 mm thickness (s.s. 304 quality) 4 vacuum box 8 mm thickness (s.s. 304 quality) 5 top & bottom cone 8 mm thickness (s.s. 304 quality) 6 vacuum box 8 mm thickness (s.s. 304 quality) 7 bearing housing / cover ms / cast iron 8 gland pusher ms / cast iron 9 drive shaft en 8 series 10 bearings zkl make 11 center shaft (pipe) 141.3 o.d. pipe, s.s. 304 quality 12 worm gear & pinion p.b. & en-9 13 motor 12.5 hp , 760 rpm, hindustan make 14 vacuum 759 hg/mm 15 colling water flow rate not required 16 steam not required 17 electicity 12.5 hp 18 dimensions diameter: 1700 mm x height: 5500 mm note: customers scope - extra 2 tons/hr. neat soap transfer pump and 2 tons/hr. neat soap feed tank

Best Deals from Vacuum Dryers

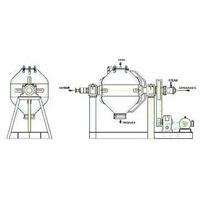

Double Cone Vacuum Dryer

Get Price Quote

1 Piece (MOQ)

Rotary Vacuum Dryer

250,000 Per Piece

1 Piece (MOQ)

Vacuum Tray Dryer

Get Price Quote

1 Piece (MOQ)

Rotary Vacuum Paddle Dryer

1,000,000 - 7,000,000 Per

1 Piece (MOQ)

Operation: Slurry/wet cake is charged through the charging door while keeping rotation of the agitator on. Vacuum is then applied to the dryer along with dust catcher (mounted on the dryer) condenser and receiver. Heating medium is passed through the jacket and agitator. Vigorous evaporation of moisture take place under vacuum. The vapor passes through the bag filters of the dust catcher, goes into the condenser and the condensate is collected in the receiver. Evaporation under high vacuum and low temperature results in faster recovery of maximum solvents. Adequate provision has been provided to cater for fluctuations in steam pressure / temperature, in condenser cooling water temperature, moisture content of feed etc. Dry product is discharged via the discharge valve by the reversing the agitator rotational direction to "discharge" direction. Salient Features: Ideal for temperature sensitive materials. Almost 100 per cent recovery of solvents. Low energy consumption.

Rotary Vacuum Dryer

Get Price Quote

1 Piece (MOQ)

We are counted as a distinguished Rotary Vacuum Dryer manufacturers in India. We are a capable manufacturer that uses cutting-edge production processes to create a Rotary Vacuum Dryer. Our vacuum dryers are used for drying various materials at very low temperatures. Our dryer has a contemporary design that incorporates discharge and charge openings, a jacketed cylinder, sealed stuffing boxes, an outboard bearing, a dust-tight housing, and an internal revolving agitator. These dryers allow heat-sensitive materials to be dried quickly below the boiling temperatures of water and solvents. Our vacuum drier incorporates cutting-edge technology to ensure that the drying process is completed correctly. We make every effort to deliver high-quality items to our clients. Features Of Products The valued customers can obtain a fantastic selection of Rotary Vacuum Dryer from us at reasonable prices. Even drying & Short cycle time No deterioration due to overexposure increased temperature, or time. Automated discharge, simplicity of use, condenser and receiver, solvent recovery. Heat is delivered to the jacket of a stationary cylindrical housing in these dryers. The material to be dried is kept agitated by a specifically constructed rotor. The dryer comes in capacities ranging from 100 to 20,000 liters gross capacity. How it Works A rotary vacuum dryer is a horizontal cylindrical jacketed shell with a hollow agitator that rotates close to the shell. A batch procedure in which drying is done under vacuum and heating is done through a jacket. The dryer is a simple but efficient way of drying wet cakes and occasionally slurries. Heat-sensitive items may be dried thanks to suction and agitation. While working in batch mode, the rotary vacuum drier effectively dries heat-sensitive materials while condensing and recovering solvents.

Rotary Vacuum Dryer

100,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

In order to ensure zero-defect quality, we conduct several tests on the products prior to final dispatch. Striving hard to provide the best in class Rotary Vacuum Dryer; we are established as renowned Suppliers in the market.

Rotary Vacuum Paddle Dryer

Get Price Quote

1 Piece (MOQ)

Vaccum Tray Dryer

Get Price Quote

1 Piece (MOQ)

The Vacuum Tray Dryer is a crucial piece of equipment utilized in industries requiring efficient drying processes. Its design incorporates trays stacked within a vacuum chamber, providing an optimal environment for drying materials. With its ability to operate under low pressure, this dryer offers enhanced drying capabilities, making it suitable for a wide range of applications.Description A Vacuum Tray Dryer consists of a vacuum-tight chamber housing multiple trays arranged one above the other. The trays are heated externally, and the vacuum inside the chamber facilitates the removal of moisture or solvents from the material being dried. This process ensures uniform drying, with minimal heat degradation, making it ideal for sensitive materials. Additionally, the vacuum environment reduces the boiling point of liquids, allowing for faster drying times.Where to use Pharmaceuticals: Drying of active pharmaceutical ingredients (APIs), granules, or powder formulations.Chemicals: Drying of various chemical substances, including solvents and intermediates.Food Processing: Used for drying food products such as fruits, vegetables, and snacks.Biotechnology: Drying of biotechnological products like enzymes, probiotics, and cultures.

Vacuum Tray Dryer

500,000 - 8,000,000 Per Piece

Vacuum Tray Dryer

rotary cone vacuum dryer

Get Price Quote

We offer secured online and offline payment processing methods. The transaction, done through online mode, is instantly forwarded to the payment system. We also accept bank account transfers, cash payments, etc. We have a team of qualified personnel to ensure proper quality control of products is done so that products are as per buyer's quality requirements. Features: High-performance Robust construction Easy operations & maintenance

ROTOCONE VACUUM DRYER

Get Price Quote

1 Piece (MOQ)

In RCVD, effective drying are achieved by uniform heat transfer throughout the batch and vacuum removes the moisture vapor rapidly. Specially designed filter removes passing of fine particles with moisture vapour in vacuum line. Steam / Hot water can be used as a heating media. cGMP model with flame proof / ATEX electricals. Different MOC options available for wetted parts.

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Double Cone Vacuum Dryer

Get Price Quote

In Double Cone Vacuum Dryer, heat is supplied to double conical shaped rotating jacket. The material to be dried is kept in continuous tumbling within the rotating housing. Conical shape facilitates easy drain out of material at the end of the batch. Features Configurations Heating Media: Steam, Hot Water/Oil, Thermic Fluid. Side Mounted Choppers. Solvent Recovery.

Vacuum Tray Dryer

500,000 - 100,000,000 Per Piece

1 Pieces (MOQ)

Vacuum Tray Dryer

Get Price Quote

1 Piece (MOQ)

Vacuum Tray Dryer (VTD) is suitable for drying of thermally sensitive materials easily resolved, polymerized, or deteriorated under higher temperature widely used in Herbal Extraction Plants and Pharmaceutical Plants. Sterilization can be conducted before the drying process, during which no matter is allowed to enter the product. Able Engineering manufactures the most qualitative Vacuum Tray Dryer that is well known for its high quality and efficiency levels. This gamut of products is in high demand in the market for heating and drying up of various items involved in the manufacturing processes of several industries.Inside the vacuum dryer materials to be dried are kept on the trays and pressure reduces through the vacuum pump. The dryer door is tightly shut and between trays and jacket steam passes through space so that the heat transfer occurs by conduction.Features Light and sight glass provided for checking the process of the material. Temperature gauge and vacuum gauge are provided for monitoring. Modified lock hinge for better grip and easily sealed the chamber. Gasket provided in the door for reducing the chances of leakage. Lower Drying Temperature. Due to the Large Surface Area, faster drying takes place. Dries Large Moisture as compared to Normal Dryers. Consume less power than other traditional drying technologies. Optional A Digital temperature meter can be provided. High mirror polish can be provided. 12 to 96 Trays.

Rotary Vacuum Dryer

300,000 Per Piece

1 Piece (MOQ)

Rotary Vacuum Dryer

Get Price Quote

Rotary Vacuum Dryer

Get Price Quote

The drying in a Rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.Rotary vacuum dryer has some typical applications in pharmaceuticals, organic chemicals, pasty materials, insecticides, pesticides, solvent recovery, dye intermediates, dyestuffs and in others industries.Material of Construction (MOC) Offered : - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, PP/FRP ETC.Features : Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying. Shaft sealing by mechanical seals is also available. N2 pulse jet dust filter (self cleaning type).

ROTOCONE VACUUM DRYER

300,000 - 4,000,000 Per Piece

1 Piece (MOQ)

Rotary Vacuum Dryer is suitable for drying of materials which cannot resist high temperature, material which are easily oxdised, volatile materials which should be retrieved, materials which are strong irritants and poisonous in nature. Rotary Vacuum Dryer with the improved technology integrates during operation under vacuum. The Rotary Vacuum Dryer facilitates enhanced drying efficiency, low temperature operations and economy of process by total solvent recovery. It helps cGMP based working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them (in single cone). The rotary action of the dryer together with mechanical action of the breakers, cuts down drying time and gives a lump free product.ADVANTAGES : (Pharmachem Cosmetics Industries) Reduces drying time Eliminates need for re-drying of lumps Handling and exposure of final product is avoided Gives uniformity size dry product System can process crystalline or amorphous powders which are prone for lumps Easy to clean internal surface, thus ensuring purity of product Optimum and continuous vacuum maintenance during process Uniform material shuffling over the heated contact surface of the cone

Rotary Vacuum Paddle Dryer

800,000 Per Piece

1 Piece (MOQ)

used ss rotocone vacuum dryer

Get Price Quote

Vacuum Tray Dryer

Get Price Quote

Is suitable for drying of thermal sensitive materials easily resolved, polymerized or deteriorated under higher temperature. Sterilization can be conducted prior to the drying process, during which no matter is allowed to enter the product. Static vacuum dryer eliminates the configuration damage of the drying materials, there fore widely used in pharmaceutical, chemicals and foodstuff etc,. vacuum Tray Dryer is the most commonly used batch dryer. They are box-shaped and loaded and unloaded via a door (two doors on the larger models). Vacuum Tray Dryers are used mainly for drying of high grade, temperature and oxygen sensitive products. Highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Frequently vacuum drying cabinets are the sole possibility for drying lumpy, glutinous products or products of low pomposity. Standard models range from 4,6,12,24,48 to 96 trays. Features of Vacuum Tray Dryer : All contact parts are made out of SS304 / SS316 / SS316L quality material in GMP models and mild steel externals with stainless steel internals in the standard model Hollow pad type heating shelves which are easily removable for maintenance Condenser and condensate receiver fixed on the dryer body or stand alone for remote installation Fully welded skirt on vacuum dryer body for flush mounting through the wall. External fluid heating of dryer with protective panels in stainless steel or mild steel powder-coated Dedicated fluid heating and circulating systems. These can be steam or electrically heated. Fluid heating systems are available for water as well as thermic fluid (for temperature requirements above 95 oC) Validation ports and nitrogen purge nozzles Can be designed to customers specification requirements Steam sterilisable models available Double door loading available for large models.

conical vacuum dryer

125,000 Per Piece

1 Piece (MOQ)

Vacuum Tray Dryer Machine (Vacuum Shelf Dryer)

Get Price Quote

Vacuum Tray Dryer - 6-16 Shelf Vacuum Tray Dryer Machine Manufacturer We are providing the Vacuum Tray Dryer Machine to our customers. Mostly used for drying of thermal sensitive materials, these tray dryers have a number of applications chemical and pharmaceutical industries. By procuring the quality assured stainless steel from our reliable and trusted vendors, the offered tray dryers are manufactured under the strict vigilance of our qualified professionals. Also, these tray dryers are known for their smooth finish and sturdy construction. Features:- Vacuum Tray Dryer Machine Smooth finish Sturdy construction Longer service life

ROTOCONE VACUUM FILTER DRYERS

250,000 Per Piece

Vacuum Tray Dryer

Get Price Quote

vacuum tray dryer (pbxvtd) is suitable for drying of thermal sensitive materials easily resolved, polymerized of deteriorated under higher temperature. Sterilization can be conducted prior to the drying process, during which no matter is allowed to enter the product. Static vacuum dryer eliminates the configuration damage of the drying materials therefore widely used in pharmaceutical, chemicals and foodstuff etc. salient features: mani body and door are made in ss 316 with rigid flange shelves(hollow type) in ss 316 with baffles trays(without back folding) in ss 316 condenser(shell & tube) and receiver in ss 304 for solvent recovery digital temperature indicator(flp) at h.w. Inlet and outlet digital temperature indicator(flp) at vacuume line dail type vacuume gauge in vacuum line dail type temperature guage in body glass view provided on door and receiver flow glass provided to monitor condensation between condensor and receiver validation port provision for nitrogen purging vacuum break valve provided in vacuum line construcion and finish as per cgmp standards optionals: condenser and receiver are made in ss 316 300 mm wide ss 304 skirting all along the flange 50 mm thick glass wool insulation on the vacuum chamber outer surface except door. The insulation is enclosed and covered with removable ss 304 angle frame digital temperature controller with pneumatic operated valve at hot water/steam inlet 2 stage water ring type vacuum pump (partial ss) run by flp motor hot water system with circulation pump testing: the vacuum dryer shelves are hydro-tested 5 kg/cm2 assembled condition. The vacuum chamber is tested for leaks under vacuum.

Vacuum Tray Dryer

Get Price Quote

Vacuum Tray Dryer is used mainly for drying of high grade, temperature and oxygen sensitive products. Vacuum Tray Dryer is highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level.

Rotary Vacuum Paddle Dryer

Get Price Quote

Rotary vacuum paddle dryer is a jacketed cylindrical vessel with a large diameter hollow shaft. Attached to the shaft are hollow paddles provided with specially designed scraper blades, which scrape the entire internal surface of the dryer and continuously move and rotate the material thereby precluding the possibility of material remaining in contact with hot surfaces for protracted periods of time. The jacket and hollow shaft with paddles can be heated with hot water, steam or any other thermal fluid capable of providing a large indirect heat transfer area. Cooling can be also be done by cold water, brine or any other refrigerant through the jacket and hollow shaft. Heating medium is passed through the jacket and agitator. Vigorous evaporation of moisture take place under vacuum. The vapor passes through the bag filters of the dust catcher, rotary paddle dryer machine, rotary paddle dryers exporters, rotary vacuum paddle dryer, vacuum paddle dryer manufacturers goes into the condenser and the condensate is collected in the receiver.