AUTOMATIC TUNNEL TYPE LINEAR VIAL WASHING MACHINE

1,100,000 - 2,200,000 Per Piece

1 Piece (MOQ)

Multi Jet Ampoule Vial Washing Machine

125,000 - 450,000 Per Piece

1 Piece (MOQ)

Best Deals from Vial Washing Machine

Automatic External Filled Vial Washing Machine

Get Price Quote

We are offering automatic external filled vial washing machine. Complete cgmp construction & design can handle vial sizes from 5 ml (ø 25mm) to 100 ml (ø 54mm) with only change part of vial separators for proper positive feeding with required intervals 'no vial no washing' & 'no vial no air' system eliminates wastage of water & air. Machine is equipped with plc system. Has polycarbonate guards on machine. Machine stops if water in storage tanks's level goes below minimum & there is no inflow triggering alarms. Machine stops if the compressed air pressure drops below the set pressure and triggers alarms. Machine stops if any toppled vial inserts the track of the machine

Vial Washing Machine

Get Price Quote

we are offering automatic linear vial washing machine. description:- automatic linear vial washing machine is suitable to wash injectable glass tubular vials. machine equipped with seven washing stations can be interchangeable as per specific customer’s requirements. this linear vial washer provides 4 water wash & 3 air wash for positive & pressurizing washes of vials. all contact parts made from aisi ss 316l and non-contact parts from aisi ss 304 materials. vials invert into neck down position and nozzles enters into vial during washing cycle to meet gmp requirements. automatic linear vial washing machine is ideal and economic choice for online sterile vial filling line. salient features:- * a complete cgmp model * all contact parts made from s.s. 316l * entire frame covers & non contact parts made out from ss 304 * easy cleanable & inter changing facility * machine provides 4 water washers & 3 air washers * complete flexibility with user for washing cycle * feeding online vial transferring chain through turn table * "no vial - no washing” system * “no washing - no water supply” system * nozzles enter into the container during washing cycle to meet cgmp requirement * low water consumption * quick change over with minimum use of tools * microprocessor based variable ac frequency drive for speed control * vial counter for counting the final production output process operation:- containers feed from the de-cartooning station are received on an infeed turn table through visual inspection unit. an in feed worm inverts container to neck down position and feeds them through a specially designed indexing device. the device carries the container forward and stops. nozzles carrier enters into the container and activities the jet of waterair. the airwater flow is deactivated after the washing cycle is over. device indexes the vials for next wash. a separate pumping station gives the right quantum of water at the desired pressure. washed containers are again inverted to neck upward position to collect in trays or directly feed to sterilizing tunnel. washing cycle:- 1st wash recycled water 2nd wash compressed air 3rd wash dm water 4th wash dm water 5th wash compressed air 6th wash distilled water (wfi) 7th wash compressed air 8th wash (optional) silicon (optional)

Automatic External Vial Washing Machine

Get Price Quote

The External Vial Washing Machine is designed to wash the outer surface of round shaped Vials [5ml to 100ml Vials]. This machine washes the outer sides of Vials and eliminates the particles that are formed on the vials, which are previously filled and sealed. Vial external washer machine is fitted with after capper machine is injectable vial external washer machine / injection vial external washer machine, oncology vial external washer machine and aseptic processing lines, speed up to 120vpm , vial surfaces involves the destruction or removal of any possible product residual so as to prevent them infecting the operators and cross contamination between containers and machine, as well. From the infeed Turn Table the vials are fed into the External Vial Washing Machine conveyors. The machine consists of two conveyors on which the vials are properly fed and transported from in feed Turn Table for the washing operation. Two operations are carried out on this machine. First the vials are washed by water jet and then dried by air jet. On the sides of the conveyor a set of spray nozzles are fitted on each conveyor for water jet. One set of knifes blocks are provided on each conveyor for air jet The air is sprayed through this knifes. The Knifes are fitted in a inclined manner which ensures that the air that is sprayed reaches each corner of the vial which are previously washed. After washing and drying the vials are guided to the outfeed Turn Table. Before reaching the outfeed Turn Table a special arrangement is provided to dry the vial from the bottom side. A set of syringes are provided on the sides of each conveyor at the exit end which sprays the air jet on the bottom part of the vial resulting in the drying of the vials This machine is completely operated by PLC. A covering of Acrylic cabinet is provided in the machine which when opened up during the operation immediately stops the supply of water & air and shows the indication with alarm in the PLC.

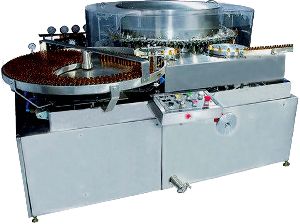

Automatic High Speed Rotary External Vial Washing Machines

450,000 - 750,000 Per Unit

1 Unit (MOQ)

Linear Vial Washing Machine

Get Price Quote

Riddhi high speed vial washing machine with Grippers for washing of vials Having dimensions comprised in the specification. The in-line tunnel design is such that separation is maintained between feeding zone and discharge zone of the cleaned containers. All the mechanical drives are separated and isolated from the washing zone. A Top class materials only are used for manufacturing, with careful choice of components, thereby taking in to consideration of all aspects of sanitation and complying with the pharmaceuticals cGMP requirements.Salient Features The machine is suitable for washing of 2 ml to 100 ml vials. High Pressure spray nozzles enter in to the vials & ensure perfect wash Totally fabricated from S.S. Materials Including the basic frame. The entire washing process can be seen. No Change of Parts required for washing of vials - saving time of Change over All Parts coming in contact with washing zones / jets are made from S.S.316 material Water re-cycling arrangement is possible as per customer’s requirements Machine is totally sturdy and withstand continuous operation for long working hours without any trouble. Machine is with PLC system & Printing facility with passwords.

Auto. Rotary Vial Washing Machine

Get Price Quote

AUTOMATIC ROTARY VIAL WASHING MACHINE, MODEL: HRVW-120/240 WASHING SYSTEM Machine provides 3 water washes & 3 air washes Complete flexibility with user for washing cycle Suitable for washing of Vials (2ml to 100ml) (dia. 14mm to 52mm) All Contact parts made out from SS 316 Entire covers & non contact parts made out from SS 304 Needles enter in to the container during washing cycle to meet cGMP requirement Low water consumption Quick change over of parts for other size of containers The Grippers provided ensure efficient holding of different sizes of vials.

Linear Vial Washing Machine

Get Price Quote

Linear Vial Washing Machine is suitable for all kinds of bottles, vials, jars etc. It consists of following units. Brushing unit: Available in 2 or 4 heads. Have SS covered body and robust construction. Rotating Chucks are provided to hold the brushes of suitable size for brushing the bottles. Rinsing unit: each unit is made out of SS304, consists of 12 SS rinsers . valve is provided for controlling flow of water. Leak proof construction. Whole unit is constructed over a drainage tray to avoid spillage of water out of tank. Rubber corks are provided over rinsing tray to avoid chipping of bottles. SS tank with sink: Brushing and rinsing units are fitted on the SS tank. Waste water is stored or can be drained out by using sink. The whole structure is made out of 16 gauge SS. Motor Drive: 1HP, single phase. Output: up to 30 bottles with 2head, 1 rinsing unit.

Automatic Linear Vial Washing Machine

300,000 - 1,200,000 Per Piece

1 Piece (MOQ)

Linear Vial Washing Machine

Get Price Quote

The Linear Vial Washing Machine is specially designed to wash Vial with minimum contact of machine parts with Vials. We are an experienced organization engaged in offering our customers a perfectly designed Linear Vial Washing Machine. We customise our product as per client requirement.

Automatic Linear Tunnel type Vial Washing Machine

Get Price Quote

AUTOMATIC ROTARY VIAL WASHING MACHINE

Get Price Quote

The Automatic Rotary Vial Washing Machine is specially designed to wash Vial with minimum contact of machine parts with Vials. Machine with specially designed Inverter system changes the direction to reverse / invert the vial and is feed to the infeed main star wheel, till the washing operation completed and again after washing release the vial on out feed Star wheel system in vertical position ensures positive wash of vials. Machine, is suitable for 2ml to 50ml Vials with the help of change parts, In special design it can be used for 100ml Vial Size also. Vial feeds through Turn Table to infeed Star Wheel and specially designed inverter wheel, that invert the vial and move it further on rotary moving system for Washing process. Machine suitable for application in Pharmaceutical Industries, The Vials traveling in neck down position in continuous motion above and along Washing Needles spraying by continuous jet for different washing cycles with the Needle bar ensures maximum time for washing. Machine with Standard Six or ten Different Washing Stations each of 6/10 Needle for optimum Washing and the sequence can be change as per customers requirement. Machine also having external wash for optimum washing of Vials. SPECIAL FEATURES: All contact parts made of SS 316 material Machine construction in SS 304 Material Suitable for 2ml to 50ml and in special design up to 100ml size Washing sequence can be made as per customer requirements. Pumps with tank (60 liters each) 2 nos. Each washing zone with independent circuit to avoid contamination Automatic Infeed and Exit of Vials

Automatic External Vial Washing Machine

Get Price Quote

Automatic External Vial Washing Machine is designed to wash the outer surface of round shaped Vials. Machine washes the outer sides of Vials and eliminates the particles that are formed on the vials, which are previously filled and sealed. FeaturesComplete cGMP modelSuitable for vial sizes from 5ml to 100ml without any change parts (No change parts required)“No Vial – No Washing” system eliminates wastage of water & airEasy cleaning & maintainingMachine is equipped with PLC system.Stops supply of water & air when acrylic doors opened during operation.Indication & alarm in PLC.Normal water required for washing & no hot water requiredWhen there is no vial on conveyor, it stops the water & air supply. Infeed & outfeed Turn Tables.Imported Gear motor for main drive, unscrarnbler and scramblerVariable A.C frequency drive for main drive, unscrambler and scrambler Acrylic cabinet for machine. Form the in feed Turn Table the vials are fed into the External the Vial Washing Machine conveyors. The machine consists of two conveyors on which the vials are properly fed and transported from in feed Turn table for the washing operation. Two Operations are carried out on this machine. First the vials are washed by water jet and then dried by air jet. On the conveyor a set of spray nozzles are fitted on each on each conveyor for water Jet. One set of knife blocks are provided on each conveyor for air. The air sprayed through this knifes . The knifes are fitted in a inclined manner which ensures that is sprayed reaches each corner of the vial which are previously washer. After washing and drying the vials are guided to the out feed turn Table. Before reaching the out feed Turn Table a special arrangement is provided to dry the vial from the bottom side . A set of Syringes are provided on the sides of each conveyor at the exit end which sprays the air jet on the bottom part of vial resulting in the drying of the vials This machine is completely operated by PLC . A covering of Acrylic cabinet is provided in the machine which when opened up during the operation immediately stops the supply of water &air and shows the indication which alarm in the PLC.

Automatic Linear Vial Washing Machine

Get Price Quote

our company offers high quality automatic linear vial washing machines in india. These machines are sturdy and durable giving flawless performance for year�s tom come. The vials of these machines are vertically discharged with the neck opening upwards and then automatically reordered in to a tray or progressed directly to a drying and sterilizing tunnel. Quick change over with minimum maintenance, these are easy to clean with on-line inspection with the machine. High pressure spray nozzles enter in to the vials during washing time technical specification total cgmp model s.s. Frame structure special pocket system ensures easy and trouble free washing of vials from outer and inner side indexing motion makes easier for syringes to move inside vial, when it is in stationery motion no change parts are required from 5ml to 30ml vial washing cycles can be adjusted as per customer requirement user friendly machine, even semi skilled operator can operate the machine vary easily a special clutch device is incorporated for stoppage of machine in the event; vial is over turned or over diameter low rpm but high output imported pumps are provided in the machine, which gives a good pressure to wash vials properly machine will be able to handle vial size from 2ml to 100m l (with the help of change parts) machine speed can be adjustable with the help of a.c. Frequency drive two models available for high production speed up to 120 vials/min. & 240 vials/min properties long lasting rust resistant strong sturdy design abrasion resistant flawless performance

High Speed Automatic Rotary Ampoule AND Vial Washing Machine

Get Price Quote

high speed automatic rotary ampoule & vial washing machine is specially designed to wash ampoule & vial with minimum contact of machine parts with container. Machine with specially designed gripper system holds the container from neck and invert till the washing operation completed and again after washing release the container on outfeed feedworm system in vertical position ensures positive wash of containers. Machine is suitable to wash various sizes of containers with the help of change parts. Automatic rotary ampoule & vial washing machine is widely uses in pharmaceutical, veterinary & biotech industry for performance & cgmp demanding customers. salient features all contact parts with the internal surface of ampoules/vials and the wash media are made of aisi ss 316l stainless steel other parts are made from engineering plastic, fda approved or aisi ss 304 stainless steel all finishes, welding joints are processed, treated & equipment selected in accordance with cgmp standards 18 jets for 6 internal washing zones 15 cassette of grippers each having 2 grippers suitable for 1ml to 25ml ampoule & 2ml to 100ml vials washing sequence can be made as per customer’s requirements 3 pumps and 3 tanks of 25 liters each each washing zone with independent circuit to avoid contamination automatic infeed and exit of ampoules/vials output capacity of up to 240 ampoules/vials per minute process operation ampoules/vials feed from the infeed tray are received on an infeed feedworm then moves on infeed starwheel. The grippers picks up the ampoule/vial from infeed star wheel and invert it in neck down position over washing needles and move along with the needle bar for washing. On completion of a cycle, washed ampoules/vials are again inverted to neck upward position and feed to output star wheel. Washed ampoules/vials received from output starwheel can be collected on output tray or can be pushed to tunnel

High Speed Rotary Vial Washing Machine

Get Price Quote

Automatic Linear Tunnel type Vial Washing Machine

Get Price Quote

Application: Our Machine suitable for Pharmaceuticals, Dairy, Distilleries & Breweries, Cosmetics & Food & Ancillaries Industries etc. Description: ‘Bhagwati High Speed Linear Vial Washing Machine is used for washing of Vials and finds wide application in Pharmaceuticals Industries. The automatic loading arrangement facilities loading of Vials on to SS wire mesh conveyor through feed conveyor or Vials are pushed manually from feed table. This saves manpower as Vials are feed into pockets automatically. The automatic unloading mechanism consists of unloading Vial continues on to turn table (Optional). Operation: Vials will be pushed from in feed tray and then move on wire woven conveyor belt, which align the Vial in correct position, to enter in to the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the Vial inside pocket in mouth down position over spraying nozzles. Multijet sprayers fixed at the top cause the total external and internal surface to be washed. To avoid any possible cross contamination between two different waters. Each washing station is provided with an independent circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the Vials, spraying jets of water or compressed air then return down. The baskets movement then advances by one station. Each station of Vials passes through the washing cycles selected. The duly washed Vials then delivered to the out feed tray with neck opening upward and then automatically re ordered to a drying and sterilizing tunnel with back pressure.Salient Features: Special Pocket system ensures easy and trouble free washing of Vials from outer and inner side. Indexing motion makes easier for syringes to move inside Vial, when it is in stationery motion. No Change parts are required from 2 ml to 100 ml Vial. (Change parts are required 2 ml & 50,100 ml Vials) Washing cycles can be adjusted as per customer requirement. User friendly machine, even semi skilled operator can operate the machine very easily. A Special clutch device is incorporated for Stoppage of Machine in the event; Vial is over turned or over diameter. Low RPM but High out/put. Imported Gear Motor for +Main drive and conveyor. A.C. Frequency drives for Main drive and conveyor. Pumps with tank (60 litres each) 3 nos. In feed conveyor belt system. Suitable for 2 ml to 100 ml (. (Change parts are required 2 ml & 50,100 ml Vials) S.S. cGMP Model. S.S. 304 Frame Structure. Suitable for 2ml to 100ml at Output Speed of 40 to 120 Vials/Min. Imported Gear Box for Main Drive & Conveyor Drive. All contact parts will be of S.S. 316 material In feed Wire Woven Belt for feeding of Vials. HDPE material Vial pockets. Grand force Pump having S.S. 316 contact surface – 3 Nos. 10 Nos. Different Washing Stations and can change as per customer requirement. Outer wash of Air & Water both. Loading & Unloading of Vials will be through mechanical Cams. S.S. Filter Housing for Water & Air and machine consist of 3 Nos. Water Filter & 1 No. Air Filter Water Filter & Air Filter will be supplied with Nylon Cartage. Recalculated Water Filter will be of 10 Micron. D.M. & W.F.I. Water Filter will be of 5 Micron. Air Filter will be of 0.22 Micron. Total 40 Rows & each Row is having 12 Pockets. Total No. of Pockets is: 480 Nos.

Pharmaceutical Vial Washing Machine

Get Price Quote

Linear Vial Washing Machine

Get Price Quote

Harsiddh engineering Co. is a recognized brand in the supply vial washing machines. The two popular automatic linear vial washing machines are the HLVW-150 and the HLVW-80 model. The HLVW- 150 has a throughput of 60-150 vials per minute while the HLVW-80 model has capacity of 40 to 80 vials per minute depending on vial size that ranges from 2ml to 20ml. Our vial washing machine has CE certification. The loading, cleaning and exit mechanisms are automatic and this increases the cleaning throughput and ensures minimum handling and contamination. The machines have a specially designed in-feed worm wheel that inverts vials and holds them on an indexing device ready for the first wash. The washing cycle is achieved through water and air nozzles that are directed on the inverted vials for maximum cleaning. The specially designed pumps supply water to nozzles at high pressure to effect the cleaning. The devices are specially designed to perform 7 washing cycles depending on the user preferences and type of vial be cleaned. The machines have an automatic system to exit the bottle after cleaning ready for further processing. Parts that come into contact with the vials are manufactured from stainless steel SS316 and meet the cGMP standards for pharmaceutical and chemical manufacturing processes. These machines have low water and electrical power consumption. In addition, the input and exit feed worm, in feed and exit star wheel can be easily changed to clean larger or smaller vials. This increases the machine flexibility and reduces the changeover time. Silent Features Linear left to right direction. Indexing linear chain mechanism. Automatic in feed of vials through un-scrambler. Machine Provides 4 Water Washes & 3 Air Washes. Suitable for siliconization (Optional). Separate pumping systems provide high pressure jets. Complete Flexibility with user for washing cycle. All contact parts made from SS316L. Entire Frame Covers & Non-contact parts made out from SS 304. Nozzles Enter into the container during washing cycle to meet cGMP Requirement. Low water consumption. Quick change over with minimum use of tools.

Linear Vial Washing Machine

Get Price Quote

The Automatic Linear Vial Washing System consists of main structure, covered with SS cabinet safety acrylic doors (OPTIONAL), in-feed turntable, washingnozzles, out-feed conveyor, pumps with tank, filter housing & cartridge, pneumatic components, motors & gear box, and electrical panel,AC Drive, PLC & HMI (OPTIONAL).

AUTOMATIC ROTARY VIAL WASHING MACHINE

Get Price Quote

DESCRIPTION Harsiddh Sterilepack (India) Pvt Ltd. offers the best-quality Rotary Vial Washing Machine complying with the cGMP standards. With this particular equipment, you will receive an amazing output capacity of producing 240 vials in a minute. All the contact parts, wash media, and internal container surfaces are manufactured from AISI 316L-grade Stainless Steel. The product offers thorough washing for your vials with 3-air and 3-water washes. And this particular tool provides suitable washing for 2ml to 100ml ampoules and vials. A unique benefit of the equipment is that it is customizable according to your washing requirements. With as many as three 25-liter tanks, this washing device features separate washing zones. Each of these washing zones has independent circuits that offer the perfect flexibility of operation. Because of this particular characteristic, operators are capable of avoiding contamination while washing. Almost all the welding joints and finishes are treated and processed in compliance with the cGMP standards. And this washing tool also operates via the in-feed of ampoules. The device also offers easy height adjustments from 900 to 950mm. Our machines have CE certifications. With rotary vial washing machine, operators will have the opportunity of performing external washes. Six distinguished washing stations ensure complete and optimum washing for several vials and ampoules through a unique process. SALIENT FEATURES Complete cGMP Model Higher production output capacity of 120 &240 Vials per Minute All contact parts with the internal surface of Container and the wash media are made from AISI 316L Stainless Steel. Other parts are made from engineering plastic, FDA approved or AISI SS 304 Stainless Steel. All finishes, welding joints are processed, treated & equipment selected in accordance with cGMP standards. Machine provides 3 water washes & 3 Air washes. Complete flexibility with user for washing cycle. Suitable for 2ml to 100ml Glass Vials. Washing sequence can be made as per customer’s requirements. 3 Pumps and 3 Tanks of 25 liters each. Each washing zone with independent circuit to avoid contamination. Infeed and Exit of Ampoules/Vials. TECHNICAL SPECIFICATION Model No. HRW – 120 VHRW – 240 V Output / Hour 7200 / Hour (Depend on size)14000 / Hour (Depend on size) Direction RotaryRotary Vial Dia. 16mm to 56mm16mm to 56mm Vial sizes 2ml to 100ml2ml to 100ml Contact Parts Stainless Steel 316L Stainless Steel 316L Electrical Input 380 V, 3 Phase, 50 Hz380 V, 3 Phase, 50 Hz Power Requirements 1.5 H.P. For Main Machine1.5 H.P. For Main Machine Working Height 900 to 950mm adjustable900 to 950mm adjustable Dimension 1800mm (L) X 1950mm (W)2050mm (L) X 2000mm (W)

AUTOMATIC ROTARY VIAL WASHING MACHINE

Get Price Quote

Vials feed from the Infeed Turn Table are received on an Infeed Star Wheel. The Grippers picks up the Vials from Infeed Star Wheel and invert it in neck down position over washing needles and move along with the needle bar for Washing. On completion of a cycle, washed vials are again inverted to neck upward position and feed to output star wheel. Washed Vials received from output star wheel can be collected on Output Tray or can be pushed to tunnel. Salient Features: All Contact parts made out from SS 316. Entire frame covers & non Contact parts made out from SS 304. All finishes, welding joints are processed, treated & equipment selected in accordance with cGMP standards. Suitable for 2ml to 100ml vials. Low Water Consumption. Quick Change over of parts for other size of Vial. 3 Pumps and 3 Tanks of 25 liters Each. Washing sequence can be made as per customer’s requirements.

Vial Washing Machine

Get Price Quote

Vial washing machine Model SCQ – ll, the automatic ampoule vial washing machine is latest spermatic process highly suitable for both ampoule bottles and oral liquid bottles.Remaining water can be easily removed from automatic ampoule vial washing machine.Load the tray full of ampules inside machine and water will be sprayed out aver them automatically. As soon you notice start – up signal then press PLC control button. Now tray loaded with ampules will be poured inside machine and it will be washed by ultrasonic ware for around 25 seconds.

Vial Washing Machine

Get Price Quote

The semi automatic multijet ampoule washing machine is used in the Pharmaceutical industry for the washing of vials and ampoules. Semi automatic ampoule washer is a compact and versatile machine made according to the latest cGMP standards. The semi automatic ampoule cleaning machine is suitable for washing of 1 ml to 20 ml ampoules and 2 ml to 100 ml glass vials. Different size of vials and ampoules can be washed with the help of change parts. It has multiple pressure jets to wash the ampoules hence the name semi automatic multijet vial washing machine. It s equipped with a motorized cam operated valve system which is used to monitor the washing process. The ampoule rinsing machine comes with optional solenoid valve system which is offered on the customer request. Multi jet vial washer machine is widely used in small and medium Pharmaceutical industries. Process of operation The dump loading feature is used for the loading of vials or ampoules in the vial washing machine. Alternatively, every ampoule needs to be arranged into the loading tray. Then the loading tray is placed in the vial cleaning machine. Automatic centering of the washing nozzles in the vials is achieved by lowering down the handle. The top cover is also lowered down & the switch is used for automatic sequential washing. Vials or ampoules are washed both from inside and outside. The machine automatically stops after the completion of washing cycle. The machine automatically stops and restart on lifting and pushing down the Acrylic top cover. Salient Features: Positive & Pressurized jets Washing of ampoules from inside ad outside Clear view of washing through Acrylic top cover All contact parts made of SS 304 or Poly Propylene Simple and robust design for long life

Vial Washing Machine

Get Price Quote

We are providing vial change Parts for all make Cap sealing Machine.We are providing Vial Holding Pockets for all Size of Vials and Bottles.

Vial Washing Machine

Get Price Quote

Positive & pressurised jets through washing needle for pressure cleaning at minimum usages of washing media. sound design concept of pressure tanks for reverses & continuous supply of washes medias both internal & external washing ensuring absolutely & continuous ampoule & vial after sequential washing. acrylic top cover for clear view of washing events taking place in the machine. on-line poly carbonates housing with p.p. Replaceable filter cartridge of 10 microns for water & 5 microns for air for best possible washing. All contact parts of washing media & compressed are of s.s 316 or hdpe of poly carbonate or p.p. in the event of acrylic cover lifted during cycle operation, the machine will automatically stop and re-start from the point when cover is pushed down.

rotary vial washing machine

Get Price Quote

Salient Features: Geneva Mechanism. Four inner (Included one air wash) & one outer. Sequence of washes to customer’s choice. Easy operation. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading.

Automatic Linear Tunnel type Bottle Washing Machine

Get Price Quote

Automatic Linear Vial Washing Machine

Get Price Quote

Input Specification:- Std. 30m1 to 200m1 Bottles without any major change parts. Can accommodate different size of Bottles with the help of minimal change Parts. Special machines are available for other Size & Type of containers on request.