Automatic Cashew Nut Filling

Get Price Quote

Bagging Machine

Get Price Quote

We are regarded as the most trusted Exporter and Supplier of the finest range of Bagging Machines. Our Bagging Machine range includes Semi Pneumatic Auger Based Filling Machines, Semi Pneumatic Cup Filler and Collar Type Filling Machines. The Bagging Machine, which we provide, is procured from reliable Manufacturers and Vendors; these Vendors manufacture this machinery by using the latest technology and adhering to the international quality standards and guidelines. Bagging Machine is used for the purpose of packing different kind of products. These Bagging Machines are widely appreciated for their robust construction, flawless performance and easy operation. The machine gets approved and stamped by Department of Legal Metrology before the final dispatch. Specifications : Packing Capacity : 300 Bags Per Hour for 25 kg bags Weighing accuracy : 50 g Machine will be complete in all respects, factory assembled and ready for installation under your hopper. Machine will include : Filling assembly (Gravity Feeder for coarse, medium and fine feeding) with single flap valves mounted on structure. Net-weigher (Weigh Hopper) with discharge flap Dumper Hopper with pneumatically operated bag clamps Load cell of 110 kg capacity Electronic Weighing system including microprocessor computer controller Pneumatic arrangements including the filter regulator lubricator All contact parts shall be fabricated in mild steel Koyka Automatic Packing Machine with single spout for weighing and filling in standard open mouth bags : Model : GF 02E Packing Capacity : 600 Bags Per Hour for 5 kg bags Weighing accuracy : 50 g Features : Double Thread Heavy duty Bag Closing Machine complete with sewer head mounted on a tubular pedestal column with hand wheel and rack & pinion arrangement for height adjustment with 0.5 hp motor Slat Conveyor 4000 long and 350 mm wide with 1 hp geared drive Control Panel Double action foot switch Dual thread cone mount Heavy duty base Hand operated centralized lubrication unit

Best Deals from Filling Line

Air Intake Manifold

Get Price Quote

We offer Air Intake Manifold that is heavily demanded for automotive applications. With a precision design and accurately made intake runner surface, our air intake manifold is ideal for reduction of turbulence that affects the speed and efficiency of the engine.

Bopp Labeling Machine

Get Price Quote

1 Piece (MOQ)

1-2 Color Beverage Caps Printing Machine

Get Price Quote

1 Piece(s) (MOQ)

We offer 1-2 color beverage caps printing machine. • model no.:rpm-2c-cap • plate size:100*200mm • printing area:φ28-30mm top of caps • print model: • printing color:1 color (with speed 21600pcs each hour) 2 color(with speed 10800pcs each hour) • products size:φ28-30mm caps • speed:900cyclehour=900*8*2=14000pcshour 22color • power:single-phase 220v 5060hz 7kw • air source:6bar • machine size:1800*1220*2000mm • weight:320kg • delivery time: 60 days once get the deposit.

Automatic Pneumatic Form-Fill-Seal Collar Type Packing Machine

375,000 - 450,000 Per Piece

1 Piece (MOQ)

Dry Form Fill Seal Machine

250,000 Per Piece

1 Piece(s) (MOQ)

We are proud to offer premium quality Dry Form Fill Seal Machines that are specially designed by experts keeping in mind the needs and requirements of our clients. The glitch free operations which our Dry Form Fill Seal Machine offers make them the best available option available for Dry packing in the market. Attributes : Fully automatic Compact and Robust machine Photoelectric mark registration system for precise cutting and sealing of the sachets / pouches Counter for number of pouches packed Machine mounted on castor wheels for easy movement Simplified operation Wear resistant spares made of Stainless steel Fast changeover of pouch/sachet size and filling volume Customization option Low maintenance Top quality components Best workmanship Optional Accessories : Mechanical Flexographic Coding Unit ( MFCU) Electronic Flexographic Coding Unit (EFCU) Emboss Coding Unit (ECU) Pneumatic Batch cutting device (PBCD) Nitrogen Flushing Unit Filled Pouch Conveyers (Take off conveyors) Moving Adjustable Disc (MAD) Acrylic Made enclosure to avoid product contamination and dusting Auger filling system for non-free-flowing powders Hopper level sensor device (Minimum Material Level Sensor Device) Rat tail cutting device (Only for Liquid Packing Machine) Widely used to pack Powder Granules Tea dust Ground Coffee Tablets Candies Pan Masala Tobacco Curry powder Beans Salt Pepper Cereals Spices Detergent Powder Peanuts Sugar Soft drink concentrates O.R.S. Powder Other medical powders Talcum powder Milk Powder Hair dye powder Henna The pouches shown in the photographare meant to indicate the applicationof machine only

Paste Filling Machine

Get Price Quote

Paste Packing Machine

Get Price Quote

We are offering liquids and pastes packing machine. Provision for two rolls on unwind sealers are both end supported end roll detection synchronized with plc & filling provision for batch cutting & counting temperature control and heater failure indication is through plc hence, eliminating the need for temperature controller paper break detection sensor joint detection sensor (optional) hopper level controller

Intermittent Form Fill Seal Machine

Get Price Quote

Sand Blasting Machine

Get Price Quote

Being an established brand in the industry we are offering Sand Blasting Machine to our valued clients. The product we offer is excellent in quality, as it is manufactured by using the excellent quality materials along with the latest technology. The product is designed for precision and excellence by our experienced team of professionals. Our product is highly demanded, as it is used for various applications like cleaning of molds, putting grains on the molds, preparing the surface for painting, coating, and much more. We are offering this machine at a very marketable rate. Portable Abrasive Blaster The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone. The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.

Auger Filler Form Fill Seal Machine

350,000 - 450,000 Per Set

1 Set(s) (MOQ)

pick fill seal machine

550,000 - 750,000 Per unit

Pick ,fill and Sealing Machine with weight filler for filling & sealing of preformed pouches of snack foods , dry fruits, Seeds, Chips, Mixtures etc. The machine works automatically in picking, filling and sealing of pouches. It offers flexibility of using pouches in different forms such as stand-up pouches, pouches with spouts, zippers and many more.

Sewage Treatment Plant

Get Price Quote

The Sewage Treatment Plant offered by us is the best example of the latest development of technology. The Industrial Sewage Treatment is manufactured strictly adhering to the international guidelines so that it ensures total freedom from pollution. The Sewage Treatment Plant is available in different capacities to meet the specific requirements of the industry. We are among the prominent Manufacturers of Sewage Treatment Plant in India whose products are widely accepted in industries. The Sewage Water Treatment Plant is fit for all kinds of biological and chemical treatments. Treatment Techniques The basic technology generally used for the treatment of Sewage is activated sludge process. This applies to both small and large processing plants and the difference lies in the arrangement and enhancement of the various sections of the process. The activated sludge process is a natural process and nature offers us a unique solution to treat sewage. Nature has provided a special balance in this process in that the micro organisms present when the food levels are high, will also consume the largest amount. This allows the quick breakdown of the BOD levels to more reasonable levels. Once these levels are reached, other microorganisms, which are heavier and less mobile, will reduce the BOD levels further, until the final acceptable standards are obtained The fact that the last organisms are large and heavy, allows us in practical terms to settle these organisms out very efficiently, producing a clear liquor. To balance the process, we can identify four major sections in a activated sewage plant system: Collection and anaerobic storage Aeration of the Sludge Setting of the sludge removing all solids Chlorination and phosphor removal to bring the final effluent up to the required standard Biological Treatment Biological treatment is the process of utilizing naturally occurring living organisms to degrade, stabilize and destroy organic contaminants. These microorganisms use the waste as their source of energy and carbon. Biological treatment technologies are restricted to organic wastes, and therefore have limited application. It is appropriate at this point to review some principles of biological process. All living organisms require a source of energy and carbon to be able to develop and reproduce. Many organisms (autographic) get their carbon from inorganic compounds (such as CO2), while other organisms (heterotrophic) use organic compounds to get their carbon. Aerobic and anaerobic metabolic pathways are used by microorganisms to degrade organic waste. During aerobic respiration, the organism utilizes oxygen to break down complex organic compounds into simple in organic salts, carbon dioxide and water. These microorganisms require an electron acceptor (oxygen in the case of aerobic), nutrients such as nitrogen (N) and phosphorous (P), and other trace elements. One of the most important characteristics of the waste is its biodegradability. Microorganisms can either directly use the contaminated waste and gain energy and carbon from it; or, with the help of another substance they can co-metabolically break down the contaminated waste. The biodegradability of a waste can be measured in the laboratory through BOD (5) / COD tests. BOD (biological oxygen demand) is a test through which contaminants can be categorized according to their biodegradability. COD (chemical oxygen demand) is a measure of the oxygen required to oxidize all compounds in water, both organic and inorganic. Chemical Treatment The technologies described in this section are chemical treatment technologies that are used for the cleanup of uncontrolled hazardous waste sites. In general, chemical treatments alter the structure of the waste constitutions to render them less hazardous than their original form. The objectives in using chemicals and chemical reaction are to either immobilize, mobilize for extraction, or detoxify the contaminants. A chemical technology may achieve one or all of the above tasks. Before describing any of the treatments in detail, a few points must be emphasized. The feasibility of chemical treatment is dependent on site and waste characteristics. Therefore, a careful study of site hydrology and geology must be performed before choosing teleology. Many chemical treatments involve delivery of a fluid to the subsurface. Care must be taken to avoid the migration of treatment reagents since they can be toxic themselves. Chemical treatment can be applied to both organic and inorganic wastes. However, a detailed study of the waste must be done, so that the wrong reagents are not mixed with the waster resulting in increased toxicity. Sequential Batch Reactor The Sequential Batch Reactor combines. The efficiency of activated sludge aeration with batch. Treatment to provide exceptional efficient quality even. Under extreme loadings. Benefits And Features Reduces main pollutants including ammonia by 95% Reduces phosphates by 99% Batching system eliminates peak surges Fully recyclable All components easily accessible The SBR uses an aeration process known as activated sludge but operates on a storage and batch treatment cycle Which ensures full treatment of all the effluent � even under pack flow conditions. Crucle sewage enters the primary Settlement Tank where gross solids settle out and the supernatant liquor. remaining near the surface can be drawn off. Substantial buffer storage volume is provided to cope with even the most extreme peak flow loadings and aerated by a powerful air bubble diffusers for a period of 4 to 6 hours. During this aeration cycle efficient Oxygen transfer cultures of bacteria (the active sludge) which feeds on the sewage liquor thereby removing most of the organic pollutants. After carnation, the bubble diffuser is switched off and three is a setting period of two hours during which the dense activated sludge sinks to the bottom leaving behind the clarified effluent, which is then discharged in to the drain. The SBR is an advanced biological aeration type treatment plant designed to produce a very high quality of final effluent in addition to overcoming several of the common problems Common problems, which normally occur, in other treatment plants are : Peak surges flow (i.e. Mornings and evenings) can force effluent through the Plant before it has had sufficient treatment time. Fixed film, types, which have a media matrix, can suffer from media blockage because of excessive bacteria growth. Replacement / maintenance of the media material may be required at regular intervals. Mechanical / electrical components within the tanks are difficult to maintain and can be a safety risk. The liquor is not spread evenly over the available bacteria preventing an adequate Oxygen supply.

Candy Pillow Pack Machine

Get Price Quote

Candy, Chewing gum, Chocolates. Packing Material: Heat Sealable Laminated Films, Type of seal: Center Seal Pouch, Pouch Dimensions: Width : 50mm to 200mm, Height: 65mm to 300mm. Electrical Supply: 230V A.C. Single phase 50 Hz. Power Consumption: 2.5Kw, Single phase. Production Out Put: 300-450 per minute (Depend upon size of product). Weight: 600 kg (Approx.). Machine Dimension: L: 1800mm, W: 100mm, H: 1360mm (Approx.).

Liquid Filling Stick Packing Machine

Get Price Quote

We are offering Liquid Filling Stick Packing Machine. Rollatainers-Toyo Machine - Japan Offer fully automatic, most accurate, stick packing machine to fill LIQUID products in sticks.

bag packing machine

Get Price Quote

5-50kg bag packing machine, that fills on the basis of weight. Empty bag is clamped in the machine. The material is weighed and then discharged in the bag. Once the bag is released from the machine it falls on the optional conveyor which takes it to the stitching head where the mouth of the bag is stitched and it then falls out of the machine. This machine is ideal for 10kg, 25kg Rice Bags. Applications Rice Grains Fertilizers Granular free flowing Products Sugar, etc.

Auger Doser

Get Price Quote

Milk Chilling Plant

Get Price Quote

Sewage Treatment Plant

Get Price Quote

Sewage treatment plant Water treatment plant Oil and grease trep Effluent treatment plant Air pollution control plant

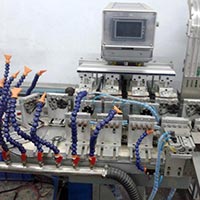

Intermittent Machine Auger Filler

Get Price Quote

Best for Namkeen & Powder Products. The fully automatic Form Fill & Sealing Machine is an intermittent machine designed for the efficient packing of product in seal pouch upto 500 gms. Ease of operation & Maintenance. The Machine is versatile & can be easily changed over from one pouch size to another. Horizontal Sealer is driven by pneumatic cylinders. Vertical seal is done by rotating die rollers through clutch & brakes.

Pyramid Tea Bag Packing Machine

Get Price Quote

We are successfully ranked amongst the top traders and suppliers of Pyramid Tea Bag Packing Machine

Automatic High Speed Bitumen Drum Filling System

Get Price Quote

The first company in India to develop & manufacture Fully Automatic High Speed Electronic Bitumen Drum Filling Automatic Bitumen Drum Filling Equipment INSTALLED AT ALL MAJOR REFINERIES OF INDIA CONTROLLED THROUGH PROGRAMMABLE LOGIC CONTROLLERS (PLC) WITH ALL THE SOFTWARE DEVELOPED IN-HOUSE ROBUST DESIGN FOR HAZARDOUS ENVIRONMENT PROGRAMMABLE FEATURES AS REQUIRED NET WEIGHT FILLING AIR FAIL SAFE POWER FAIL SAFE PROPORTIONAL CONTROL TECHNOLOGY BY ELECTRO-PNEUMATIC POSITIONER PNEUMATIC :- HIGH TEMPERATURE RESISTANT CONTROLS PROGRAMMABLE:- TOUCH SCREEN MIS FACILITY :- LAN PROVIDED (OPTIONAL) AUTO / MANUAL FILLING PROVISION

Liquid Filling Machine

100,000 - 110,000 Per Piece

Multi Head Weigher

Get Price Quote

LIQUID PASTE Machine

Get Price Quote

Sand Blasting Machine

250,000 Per Units

Auger Filler Machine

Get Price Quote

Single Phase Power Load : 5KW Motor : Servo Auger S Screw & Pipe Power Supplied : 220V/50Hz, 110V/60Hz

Plastic Cap Making Machine

1,600,000 Per Piece

cosmetic packaging machine

Get Price Quote