Soybean Meal

32,500 Per Ton

25 Ton (MOQ)

Soybean meal is used in food and animal feeds, principally as a protein supplement, but also as a source of metabolizable energy. Typically 1 bushel (i.e. 60 lbs. or 27.2 kg) of soybeans yields 48 lbs. (21.8 kg) of soybean meal. Some, but not all, soybean meal is produced from the residue left after oil extraction. (Removal of the oil, which is used mostly in food, but also for industrial oils, soaps and biodiesel, involves crushing and either pressing or solvent extraction.) Some, but not all, soybean meal contains ground soybean hulls. Soybean meal is heat-treated during production, to denature the trypsin inhibitors of soybeans, which would otherwise interfere with protein digestion. Major kinds of soybean meal full-fat soybean meal, made from whole soybeans defatted soybean meal, containing no hulls defatted soybean meal, containing soybean hulls Uses · Mainly used in animal feed

Moisture : Less than 12%

Application : Cattle,chicken,dog,fish,horse

...more

Silica Sand Powder

Application : Glass

Al2O3 Content (%) : 0.25-0.35

Color : White

Brand Name : Phenix

...more

Silica Sand

SiliSilica sand is a granular material that contains quartz and minute amounts of coal, clay and other minerals. It is also known as quartz sand and industrial sand, and is largely used in several construction applications. Silica is another name for silicon dioxide, of which quartz is a specific latticed structure. So, silica sand is quartz that over the years , through the work of water and wind , has been broken down into tiny granules. Industrial sand is a term normally applied to high purity silica sand products with closely controlled sizing. It is a more precise product than common concrete and asphalt gravels. From water filtration, to glass manufacture, to industrial casting, to sand blasting, to producing concrete, to adding texture to slick roads, silica sandimpacts every aspect of daily life. Uses of silica sand Used in making concrete mix as a partial replacement of fine aggregate. Used in manufacturing bricks. Used in industrial processing, to make glass, as fill, in castings, synthetic foundry moldingcatalysts. In water filtration. In adding texture to slick roads. In beaches. In sand blasting. Used for acid heat resistant ceramics, refractories, pottery glaze, enamel etc. Used in sawing stone, grinding and surfacing glass. Used as a filter in paints. The presence of silica sand on metal materials can be a source of crevice corrosion on those metals Used for abrasive blasting. Used in hydraulic fracturing of oil wells. In sports. ca Sand

...more

Refined Salt

Color : White

Form : Powder

Brand Name : Phenix

Packaging Type : Bag

...more

pozzolanic material fly ash for concrete

Color : Brown, Grey

Brand Name : Phenix

montmorillonite clay desiccant

Brand Name : Phenix

Color : Grey, cream

Laterite

Laterite is a soil layer that is rich in iron oxide and derived from a wide variety of rocks weathering under strongly oxidizing and leaching conditions. It forms in tropical and sub tropical regions where the climate is humid. It is a reddish weathering product of basalt. Laterites are rusty-red in color because of high iron oxide content. Laterite is well known in Asian countries as a building material for more than 1000 years. It was excavated from the soil and cut in form of large blocks. Uses and benefits of laterite Uses : Used as a building material. Strong, hardened varieties of laterite are sometimes cut into blocks and used as brickstones for building houses. Laterites are economically most important for ore deposits, such as bauxite. Hardened laterite varieties are also applied for the construction of simple roads. Nowadays solid lateritic gravel is readily put in aquaria where it favours the growth of tropical plants. In artifacts, monuments, sculpture, oil and gas reservoir, decoration etc. Laterite- cement blocks are more economical building units for walling units. Benefits: More economical Durability Strength Sustainability

...more

Ground Granulated Blast Furnace Slag

2,600 Per Ton

5000 Ton (MOQ)

Granulated blast furnace slag or gbfsis the residue of combustion in the furnace of the steel refining process. It is obtained by quenching molten iron slag from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. Ggbfs or ground granulated blast furnace slag is formed when gbfs is further processed or ground using conventional cement clinker grinding technology. Uses and benefits of gbfsggbfs uses : ã�â· ggbfs or gbfs is the most used raw material in cement industry to make slag cement. Ã�â· lightweight fill ã�â· raw material for the manufacture of glass ã�â· gbfs can be used as a substitute for sand in building materials ã�â· ggbfs can be used as a replacement for portland cement benefits : ã�â· reduced chloride permeability ã�â· improved resistance to sulphate attack ã�â· reduced heat of hydration in mass concrete ã�â· better workability ã�â· environmental friendly ã�â· improved compressive and flexural strength ã�â· reduced alkali-silica reaction ã�â· less bleeding ã�â· long slump retention ã�â· better reflectance ã�â· greater durability and thermal resistance ã�â· brighter color and reduced electricity

Color : White

Color : white

...more

granulated blast furnace

2,600 Per Ton

5000 Ton (MOQ)

Granulated Blast Furnace Slag or GBFSis the residue of combustion in the furnace of the steel refining process. It is obtained by quenching molten iron slag from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. GGBFS or Ground Granulated Blast Furnace Slag is formed when GBFS is further processed or ground using conventional cement clinker grinding technology. Uses and Benefits of GBFSGGBFS Uses : �· GGBFS or GBFS is the most used raw material in cement industry to make slag cement. �· Lightweight fill �· Raw material for the manufacture of glass �· GBFS can be used as a substitute for sand in building materials �· GGBFS can be used as a replacement for Portland cement Benefits : �· Reduced chloride permeability �· Improved resistance to sulphate attack �· Reduced heat of hydration in mass concrete �· Better workability �· Environmental friendly �· Improved compressive and flexural strength �· Reduced alkali-silica reaction �· Less bleeding �· Long slump retention �· Better reflectance �· Greater durability and thermal resistance �· Brighter color and reduced electricity

Brand Name : Phenix

Certification : ISO 9001-9002

Application : Construction

Color : brown

...more

Garnet Sand

Brand Name : Phenix

Abrasive Grain Sizes : 80 mesh

Application : water jet cutting , sand blasting , water filtration

Color : reddish and shades of red

...more

Fly Ash Powder

2,275 Per Ton

28 Ton (MOQ)

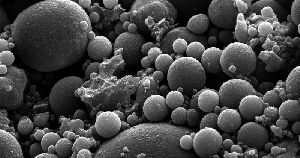

Fly ash is produced from the burning of pulverized coal in a coal-fired boiler. It is a fine-grained, powdery particulate material that is carried off in the flue gas and normally collected from the flue gas by means of electrostatic precipitators , baghouses, or mechanical collection devices such as cyclones. Fly ash is commonly used in production of concrete. It is applied as a supplementary cementing material. Initially the idea was to use fly ash for economical reasons ����¯�¿�½������¢������¯������¿������½������¯������¿������½ on one hand to utilize fly ash which is an industrial by product, on the other to reduce the amount of costly cement. However, it appears that application of fly ash in concrete has a lot of benefits, mainly by reduction of unwanted hydration heat. Cement can be replaced with fly ash in concrete. It reacts (Si) with Ca(OH)2 and produces more CSH gel which contributes to strength. With reduced cement, hydration heat will be reduced and hence there is strength gain. Type : Cement clinker Heat of hydration : Moderate Heat Hardening Feature : Rapid hardening Brand name : Phenix Standard : ASTM C618BS 3892 color : browngrey Retention : Less than 20 and less than 12 Moisture : Less than 0.10 Grade : A Quantity and rates - Minimum order quantity : 28 tontons per month Price in US dollars : $30-$40 per ton Supply ability : 10000 tons per month Packaging : jumbo bags , 5040 kg bags as per client requirement Delivery time : 10-12 days Payment : LC,DA,DP,TT Port : Mundra,Kandla,Vizag,Navasheva

Brand Name : Phenix

Certification : ISO 9001-9002

Color : Brown/grey

Hardening Feature : Rapid hardening

Type : cement clinker

...more

Fly Ash/ Coal Ash

Fly ash is produced from the burning of pulverized coal in a coal-fired boiler. It is a fine-grained, powdery particulate material that is carried off in the flue gas and normally collected from the flue gas by means of electrostatic precipitators , baghouses, or mechanical collection devices such as cyclones. Fly ash is commonly used in production of concrete. It is applied as a supplementary cementing material. Initially the idea was to use fly ash for economical reasons – on one hand to utilize fly ash which is an industrial by product, on the other to reduce the amount of costly cement. However, it appears that application of fly ash in concrete has a lot of benefits, mainly by reduction of unwanted hydration heat. Cement can be replaced with fly ash in concrete. It reacts (Si) with Ca(OH)2 and produces more CSH gel which contributes to strength. With reduced cement, hydration heat will be reduced and hence there is strength gain. Uses: The most common use of fly ash is as a partial replacement for Portland cement used in producing concrete. Replacement rates normally run between 20% to 30%, but can be higher. Fly ash produced by coal-fired power plants provides an excellent prime material used in blended cement, mosaic tiles, and hollow blocks among others. Fly ash can be an expensive replacement for Portland cement in concrete although using it improves strength, segregation and ease of pumping concrete. The rate of substitution typically specified is 1 to 1 and a half pounds of fly ash to 1 pound of cement. Fly ash can be used as prime material in blocks, paving or bricks; however, one of the most important applications is PCC pavement. PCC pavements use a large amount of concrete and substituting fly ash provides significant economic benefits. Fly ash has also been used for paving roads and as embankment and mine fills, and its gaining acceptance by the government , specifically the Highway Administration. Fly ash reacts as a pozzolan with the lime in cement as it hydrates, creating more of the durable binder that holds concrete together. As a result concrete made with fly ash is stronger and more durable than traditional concrete made exclusively with Portland cement.Benefits : Fly ash can be a cost-effective substitute for Portland cement. In addition, fly ash could be recognized as an environmentally friendly product because it is a byproduct and has low embodied energy. It is also available in 2 colors, and coloring agents can be added at the job site. In addition, fly ash also requires less water than Portland cement and it is easier to use in cold weather. Other benefits include : Can withstand harsher service environments Less susceptible to chemical attacks and mitigates the negative impact of deleterious aggregates. Improved flowability, reduced hydration temperatures and delayed setting time of fly ash concrete Longer service life Used to mitigate a problem called alkali silica reaction which occurs when concrete deteriorates early due to issues with aggregate quality. Costs less Has positive environmental impacts, as it conserves landfill space, reduces energy and water consumption, and helps reduce greenhouse gases Produces various set times Cold weather resistance Higher strength gains, depending on its use. Can substitute Portland cement Considered a non-shrink material Produces denser concrete and a smoother surface with sharper detail Great workability Reduces crack problems, permeability and bleeding Reduces heat of hydration Produces lower water/cement ratio for similar slumps when compared to no fly ash mixes. Reduces CO2 emissions. Types of fly ash : There are different types of fly ash , depending on its chemical properties, including Class F and Class C , generated by burning black coal and brown coal respectively. Class F and Class C are being utilized in making building materials such as concrete, lightweight aggregate, bricks etc. Also fly ash is used as a material for road construction and earth filled dam construction. Class F fly ash is available in larger quantities , which is generally low in lime , less than 15%, and contains greater combination of silica , alumina and iron(more than 70%) compared to Class C fly ash. Class F is a solution to a wide range of summer concreting problems and it is often recommended for using where concrete may be exposed to sulphate ions in soil and ground water. Class C fly ash normally comes from coal which produces an ash with higher lime content, generally more than 15%, often as high as 30%. Also, high Calcium Oxide(CaO) gives Class C unique self hardening characteristics. Class C is mostly used in situations where higher early strengths are important.

...more

Fly Ash

Feature : Acid Proof,Anti-algae,expansive,radiation resistant,refractory

Type : Cement Clinker

Brand Name : Phenix

Hardening Feature : Rapid Hardening

Color : Grey, Brown

...more

Fly Ash

2,275 Per Ton

28 Ton (MOQ)

Fly ash is produced from the burning of pulverized coal in a coal-fired boiler. It is a fine-grained, powdery particulate material that is carried off in the flue gas and normally collected from the flue gas by means of electrostatic precipitators , baghouses, or mechanical collection devices such as cyclones. Fly ash is commonly used in production of concrete. It is applied as a supplementary cementing material. Initially the idea was to use fly ash for economical reasons ���¢�¯�¿�½�¯�¿�½ on one hand to utilize fly ash which is an industrial by product, on the other to reduce the amount of costly cement. However, it appears that application of fly ash in concrete has a lot of benefits, mainly by reduction of unwanted hydration heat. Cement can be replaced with fly ash in concrete. It reacts (Si) with Ca(OH)2 and produces more CSH gel which contributes to strength. With reduced cement, hydration heat will be reduced and hence there is strength gain. Type : Cement clinker Heat of hydration : Moderate Heat Hardening Feature : Rapid hardening Brand name : Phenix Standard : ASTM C618BS 3892 color : browngrey Retention : Less than 20 and less than 12 Moisture : Less than 0.10 Grade : A Quantity and rates - Minimum order quantity : 28 tontons per month Price in US dollars : $30-$40 per ton Supply ability : 10000 tons per month Packaging : jumbo bags , 5040 kg bags as per client requirement Delivery time : 10-12 days Payment : LC,DA,DP,TT Port : Mundra,Kandla,Vizag,Navasheva

Brand Name : Phenix

Certification : ISO 9001-9002

Color : Grey/brown

Type : Cement clinker

Hardening Feature : Rapid hardening

...more

Construction Aggregates

650 Per Ton

10000 Ton (MOQ)

Construction aggregate or aggregate is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Crushed stone or Stone or angular rock is a construction aggregate. It is created by mining a suitable rock formation and then using a crusher to break down the stone into different sizes. Crushed stone differs from gravel in that gravel has a more rounded shape and is made by the natural processes of weathering and erosion. Crushed stone has continuously been used for a variety of construction needs because of its versatility. It is one of the most common and accessible natural resources on the planet. It is one of our most abundant and basic of raw materials.

Color : Black

Size : 10mm,20mm,45mm,60mm

...more

Biryani Rice

55 Per Ton

17 Ton (MOQ)

Packaging Size : 1Kg to 50Kg

Type : Punjab Basmati

Color : White

Brand Name : Phenix Rice

Speciality : White Long Grain Sixe

Cuisine Type : Biryani

...more

Cement Grade Laterite

Color : Brown

Shape : Lump

Bentonite

all cast iron, steel & malleable iron foundries are almost using bentonite with cost efficient results, kutch region is famous for a very good sodium bentonite for casting industries. For continuous mould making also kutch bentonite is used successfully. Our foundry grade bentonite powder gives good flow ability. Compact ability and thermal stability for the production of high quality castings following parameters help to make high quality castings high gelling time which gives high strength in less mulling time ph maintaining active clay maintaining high strength on good compatibility

...more

Basmati rice

55,000 Per Ton

Packaging Size : 1Kg to 50Kg

Type : Punjab Basmati

Color : White

Brand Name : Phenix Rice

Variety : Long-Grain Rice

Feature : White Long Grain Sixe

...more

Aggregate Stone

Type : Gravel & Crushed Stone

Size : 10mm, 20mm, 45mm, 60mm

Color : Black

...more

Aggregate

Construction aggregate or aggregate is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Crushed stone or Stone or angular rock is a construction aggregate. It is created by mining a suitable rock formation and then using a crusher to break down the stone into different sizes. Crushed stone differs from gravel in that gravel has a more rounded shape and is made by the natural processes of weathering and erosion. Crushed stone has continuously been used for a variety of construction needs because of its versatility. It is one of the most common and accessible natural resources on the planet. It is one of our most abundant and basic of raw materials. Uses of stone aggregates Stones are used in various industries from construction to agriculture. Their uses are: Used in paving blocks and concrete for sidewalks, driveways, patios, homes, office buildings and paved roads as a base or sub – base material or in the process of cement manufacture. Used as a flux in blast furnaces to create liquid slag which, when cooled, becomes a stone material that is crushed and used as a construction aggregate. Placed on the ground in landscapes around trees, drains and as tracking pads on construction sites. A road construction technique called Macadam uses stones in which the strength of the road depends upon the interlocking of the stones due to their angular shapes. Used with a binding material in walls for shorelines in order to protect against erosion from water or ice. Used in railroad construction Used in sewage treatment systems Used in the manufacture of agricultural lime Types Types of crushed stone are categorized by the size of the stone after it has been crushed. 6mm 10mm 20mm 45 – 65 mm Railway Ballast Boulders ( As per client’s requirement ) Quarry Dust

...more

White Silica Sand

Bentonite Powder

Bentonite clay

merchant exporter services

Be first to Rate

Rate ThisOpening Hours