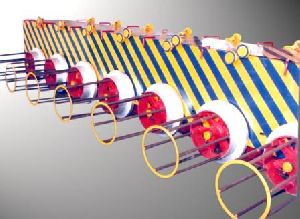

Wire Flattening Machine

We offer complete range of Wire Flattening Mills for both Ferrous and Non-Ferrous Wires. Though most features of our mills are standard, we can produce entire line as per the exact production requirements of the customers. Besides this, we also offer the complete line of accessories that are used with Wire Flattening Mills. Features : Mills Available in Single Stand, Two-Stand and Three-Stand Tandem. More Stands Can Also Be Added In Conjunction Turk Heads, Draw Blocks Etc. Custom Designed Tandem Line. Can Handle Inlet Diameters Up To Thousand of an Inch. Variable Speed.

...more

Wire Drawing Machines

Meenakshi Wire Products offers wide range of high speed state of the art study. O.T.O./ B.B. Type Wire Drawing Machines. The construction of the machine is such that it can withstand rugged workshop conditions of Wire Drawing Plant and can guarantee the performance and accuracy with least maintenance. These O.T.O./B.B. Type Dry Wire Drawing Machine have wide field applications in Stainless Steel, High Carbon Steel, Alloy Steel, Mild Steel, Copper Wire Drawing. The wire is drawn through a die which is fitted in independant Die Box and is accumulated on the Block, and later being taken through the OTO Pulley to the next Die. BB Block is Twist Free Type Machine with Free Bobbin Block for accumulation and transfer to next block and is better for higher speed & better finish materials. Salient features : 760/650/610/560/450/350/300mm Single / Multi Speed, Non-Slip, Block Type, Continuous Dry Wire Drawing Machines. Continues Type in Line Machine for Large Cross Sectional Reduction Inlet size up to 12mm. Wire Rods Combination with 'B.B.' Type Machines for High Speed Applications. AC fixed speed with Speed Change Gear Box or variable speed A C / D C Drive is offered Heavy Duty Worm and Worm Wheel type Fabricated Gear Boxes with Standard Greaves (RADICON) & NAW Gears. Combination of Heli-Worm or Bevel Helical Gear Reduction if required. Dry/Wet Lubricant Type Die Boxes with Optional Rotating Die and Motorized Soap Applicators Die Chamber with Forced Water Cooling Indirectly or Directly. Optional Pneumatic/Electro Magnetic, Brakes on Machines. Operator Consol provided on Independent Block or Common Floor Standing type Control Desk. Inching with Foot Operated Pedal Switch Reverse/Forward. Graded Cast Iron Drums with Chrome Carbide Hard Matrix at Drawing Portion. 1 Forced Water Cooled Drums for Longer Drum Life and Cooler Drawn Wire. Additionally Air Cooled Drums with specially Designed Uniform Cooling Air Jackets Wire Unloading Trough Stripper Blocks, Dead Block Coiler or Spooler.

...more

Wet Wire Plant

We offer state-of-the-art Wet Wire Drawing Machine to draw intermediate wires & fine wires from ferrous metals, Non Ferrous Metals and Metal Alloys. Suitable for high-speed drawing, all the machines consist of swivel Die Holders, Cone Rings, Lubricant Cooling System and adjustable exit Die Holders. Available in different Capstan Diameters and Spool Sizes, these machines have multi-spindle and multi-die contribution, which suit best with oil based lubricants. We also provide complete accessories and spares parts as well as custom designing to meet clients' needs. Salient features : Mild Steel, Carbon Steel, Stainless Steel, Copper, Aluminum and Alloys. Power Saving High Speed Timing Belts Transmission. Highly Efficient Alloy Steel Hardened. High Service Life due to Tungsten Carbide Cones. Options like Submerged Lubrication or Splash Lubrication. Cones Shaft Assemblies with Easily Removable Bolts. Dancer System for Synchronization of Wire Collection. Re-Circulation of Lubricant through Fluid Pump.

...more

Straight Line Wire Drawing Machines

Straight Line Wire Drawing Machines were developed for straight or deflection free drawing of wire to provide better drawability lower frictional contact and lower operator interference. Theoretically there is no limit as far as the wire material or wire diameter is concerned to be drawn on these machines. Meenakshi Wire Product has pioneered to indigenously develop the Straght-Line Wire Drawing Machine Technology in India. Presently the range available is capstan diameter 900mm, 750mm, 600mm, 550mm, 500mm, 460mm, 400mm and 300mm for inlet wire diameter 16mm down to 0.5mm. Line speeds upto 22 Mtrs / Sec. These heavy Straiht Line Wire Drawing Machines provide remarkable drawing performance for Low, Medium and High Carbon Steel Wire, Stainless Steel Wire and special Alloy Steel Wire and Non-Ferrous Alloy Steel Wire. This machine has a sensor roller between the drum and the next die such that the wire passes in contact with this roller. These rollers have sensors to detect the position of the arm and maintain tension on the wire by regulating speed of the drums. The drums of this machine are inclined to the vertical axis to effect fill on the drums. Principally this machine is best suited for thick wires.

...more

Specialized Die Boxes

Our Rotating Die Boxes are meant for improved performance, die life and wire quality. We offer the complete range of rotating die boxes, which cover a wide range of sizes and applications. Our rotating die boxes are available for both single and pressure dies. Wire Size Range : 16mm to 0.6mm Die Case Sizes : 43x28/53x35/70x40 Even Die Wear Even Product Concentricity & Finish Lower Drawing Temperatures Better Lubrication on Wire Increased Drawing Speeds

...more

rod break down machine

We offer a wide range of Rod Break Down Machines, which are highly effective in drawing and coiling aluminum and copper wires. Our machines are available in single or multi-block options that are designed to fulfill varied requirements of the user. In addition, there are ring type drawing capstans for convenience and low maintenance of the machine. Besides this, all the transmission gears and bearings are enforced with lubricants. We also offer customized designing and developing Rod Break Down Machines as per the client's requirements. Salient features : Designed for Multi-Die and Multi-Block Operation. Can work with Spooling Machine & Coiler. Power Efficient. Save Floor Space. AC & DC Drives.

...more

ms wire drawing machine

Meenakshi Wire Products offers wide range of high speed state of the art study. O.T.O. B.B. Type Wire Drawing Machines. The construction of the machine is such that it can withstand rugged workshop conditions of Wire Drawing Plant and can guarantee the performance and accuracy with least maintenance. These O.T.O.B.B. Type Dry Wire Drawing Machine have wide field applications in Stainless Steel, High Carbon Steel, Alloy Steel, Mild Steel, Copper Wire Drawing. The wire is drawn through a die which is fitted in independant Die Box and is accumulated on the Block, and later being taken through the OTO Pulley to the next Die. BB Block is Twist Free Type Machine with Free Bobbin Block for accumulation and transfer to next block and is better for higher speed & better finish materials.

...more

Galvanized Wire Plant

Meenakshi Wire Products provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups. By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires. MWP has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to ourcustomer's world wide. The plant consists of the following : Pay Off Stands: Revolving Turn Tables with brake tensioners for wire formers and spools, overhead Coil Opener type Payoff, Pintal Type Pay Off for Spools and Basket Type Pay Off for Coils. Open Hearth Furnace or Lead Bath Furnace with electric heating or Natural gas/LDO/FO combustion systems with top cover and recuparator for energy conservation. Online Fumeless Pickling System with water curtains to prevent any acid fumes form exiting the pickling system. The wires travel straight with lower tension and react with invigorated acid traveling against the wire, followed by triple stage water wash system. Intermediate wiping system in between chambers to prevent excessive carry over of fluids from one chamber to another. Vertical Gland / Seal Less Pumps for zero down time as no seal change over and routine maintence required. Stainless steel 316 fabricated Flux Tank with flue gas heating and temperature control system for energy efficiency and coating consistency. Option of Dipping type or straight path type with flux pumping system. Flux Dryer before the entry to the galvanizing bath hot plate assembly is provided for quick drying of flux which has heating through flue gases of the zinc bath furnace as rising energy costs has made conservation a prime criterion in today's plants. Zinc Bath furnace consisting of Structural Steel Frame. Which is completely lined using several layers of ceramic refractory. Best quality refractories ensure reliability and durability. Zinc Tank made out of low carbon low silicon steel plate with side bended at 90 degree welded with specialized electrodes and duly ultrasonic tested for any internal cracks. Options for Light/medium and heavy coating available. Finally wire is coiled on finishing Take ups where ASSOMAC offers several options depending on the industry use and coil weight requirements right from 25Kg. to 1000Kgs. Horizontal side winder take ups, Vertical dropcoiler with or without pattern lay and strip take ups in our manufacturing program.

...more

bull block wire drawing machine

We offer technically advanced Bull Block Wire Drawing Machine which are vertical or horizontal and gravity bull block wire drawing machines with multi speed. These are facilitated with variable drives and are ideal for ferrous and non-ferrous wires. Our range is available in various specifications ranging from 6mm to 25mm inlets and models of 750mm, 900, 1000 and 1200mm dia coils. Salient features : Application : For Drawing Stainless Steel / High Carbon Wire Twist free with High Torsion Values Specially for Spring Grades. Capstan : 560 / 460 / 400 / 350 / 300mm. Inlet : 5.5mm to 1.6mm. Finish : 4.0mm to 0.6mm. Speed : 5 to 15 meters /sec. Drive : State of the Art A.C Frequency Converter Variable Speed Control.

...moreBe first to Rate

Rate ThisOpening Hours