Wash Fasteners Tester

Utility: It is designed to meet standard norms and specification generally followed in industry. It is ideal for checking fastness of coloured Textile samples to washing, dry cleaning and chlorinated water. Machine is compact floor model electrically heated water bath. MOC: SS 304 / 316 With Electronic Programmer

...more

Vertical Yarn Dyeing Machine

HTHP Vertical Yarn Dyeing Machine is designed for dyeing of fibers / yarns in production. Capacity of dyeing machine is calculated by the yarn to be dyed. The formula calculated i.e the receipe of the colour which is used to dye the different type of yarns, in Sample Dyeing Machine is used in this H. T. H. P. Vertical Yarn Dyeing Machines. H. T. H. P. Vertical Yarn Dyeing Machines are controlled by programmable controller The Dyeing Vessel available in market are in different forms like Vertical single vessel or Horizontal with no. of small tubes which vary according to the capacity of the yarn to be dyed. Features • Capacity up to 500 kg. • Reversible TURBO Pump. • Carriers for cone, hank, tapes etc. • Air pad or fully flooded versions available • Semi automatic facilities. • PLC assistance also available • Very small liquor ratio 1:5 to 1:8 • Energy efficient compact design of heat exchanger • has no heat loss to the ambient. • Open colour tank

...more

Vertical Padding Mangle

Utility: It is versatile M/C with wide applications in dyeing, printing and finishing process. Two Bowls vertical padding mangle has coated with synthetic rubber std. supply, shore Hardness 70 to 75 shore-hardness. Uniform pressure thro' pneumatic loading. MOC: SS 304 / 316

...more

Spry Type Hank Dyeing Machine

Spry Type Hank Dyeing Machine is designed for dyeing of loose fibers / Yarns. The heating to dye is provided and bundle of yarn is half deep and rotated at speed calculated. The rotating shaft also has veins to inject dye inner side of bundle. The machine is most suitable to avoid hazardous manual operations. The Machine can be designed with multiple shafts for higher production. Features • High efficient Circulation Pump made of SS316L. • Mirror polished perforated tubes with dish shaped front and rear disc for hassle free movement of the yarn. • Rotating hank displacing pipe is fit with Teflon bushes. • Inclined roof of special design, hence no dripping on the hanks. • Manual Ball valves at each tubes inlet. • AC inverter (optional) to regulate the flow of the liquor to maintain pressure. • Steam heating coil for quick heating with pneumatic operated valves and steam trap. • Water level indicator • Spot light inside the machine for inspection of material. • Dial pressure gauge to keep the check of the flow. • Programmer along with Digital temperature indicator • Fully Auto or Semi-Auto with PLC & Touch Screen & A/C Drive for main pump.

...more

space dyeing machine

Space Dyeing Machine is specially designed for multiple spot dyeing of fabric at a time. In Space Dyeing Machines the result of multi spot dyeing is achieved but may need to more process in Yarn Setting Machines. It can dye 8 different colours at the same time. Each colour has a different injection pump. It has got different mould systems for different cone sizes. The machine process is with cold dyeing system. The machine is controlled by the time relay system In the process multiple injections are provided to inject different dyes at a time and steam is forced in the vessel. Features • High productivity (1 package per min, time can vary as per yarn quality.) • Repeatability of design. • High vacuum. (730 mm) • Fully automatic operation. • Compact design, less floor space required. • No Foundation required. • Plastic tube, steel tube or dye spring can be used. • Suitable for various types of yarn. • Seperate injection pump for each colour • Variable system for different bobin size - optional • Facilited with drain tank

...more

Sample Soft Flow Dyeing Machine

Features • Wet parts are constructed in stainless steel • Process in high temperature or atmospheric condition is possible • Variable Reel Speed through drive • Mainly used to repeat and correct the recipe between lab and bulk production • Fabric turnaround time and liquor ratio similar to bulk production machine • Recipe developed can be applied directly • Machine is compact in size • SS Centrifugal pump for circulation

...more

ROTA DYER MACHINE

Utility: It is an ideal M/C for carring out sample dyeing under atmospheric conditions. Samples can be dyed in Fiber, Yarn or Fabric form. M/C. in table top model. Automation thro' PC O5 controller 1 to 50 programs. MOC: SS 304 / 316 With Electronic Programmer

...more

Open Bath Beaker Dyeing Machine

Ideal machine for dyeing of fabric, yarn & loose stock samples. • The rocking bars, apart from up-down motion, rotate at 70 RPM. • Direction reversal of rocking bars rotation after every 3 mins.This ensures proper contact between substrate & liquor due to constant agitation in liquor. • Number of beakers: 12. • S.S. Cover plates provided for all beakers to avoid oxidation during dyeing & to prevent spillage of liquor. • Automation through Microprocessors programmer PC-05 F/R. • Special Cages available as option for dyeing of loose stock. • Dyeing temperature upto 95°C is possible.

...more

MBTL Light Fastness Tester

Utility: It is an ideal instrument for evaluating colour fastness to light using standard 500W mercury Ballast Tungsten Filament Lamp and is internally phosphor coated. Thus it combines Tungsten Spectrum rich in red, with mercury spectrum and modified by fluorescent phosphor. Thus results of MBTL Light Fastness co-relative very well Xenon Arc and daylight results. MOC: SS 304 / 316 With Electronic Temperature Controller

...more

Infra Beaker Dyeing Machine

Infra Beaker Dyeing Machine is designed for dyeing of loose fibers / Yarns / samples in SS pot in very small quantity. It can be substitute for Glycerin Bath Beaker Dyeing Machine (H.T.H.P Beaker Dyeing Machine). As compare to Glycerin bath dyeing machine, Infra Beaker Dyeing Machine avoid the smell of heated Glycerin and heat is directly given to the potS and also measured from pot, so accuracy in process. It is less hazardous and convenient in working. infra dyeing machine heating enables efficient heating of beakers resulting in optimum dyeing conditions. as infrared radiations are used for heating there is no contamination of beakers with messy heating medium and hence the working is cleaner.more dyeing cycles are possible with infracolour as preparation and cleaning time is greatly reduced.injection dosing system is provided for making time to time additions to the beakers without opening the beakers. Variable speed roatation of beaker carriage assembly facilities dyeing of all types of fabric and yarn samples with all classes of dyes. Automation is through microprocessor programmer. Infra colour is environment friendly easy to use sample dyeing machine with infracolour there is no pollution, no smoke or bad smell in working area as is the case with conventional baths. Features • Crease - and spot -free sample dyeing. • Low liquar ratio: 1:5 fabric dyeing cotton. • Soda ash adding without opening the beakers. • No glycerin or coolong water needed. • Optional : Filling in the powder or liquid chemical to be added later on during the dye process. • Three - dimensional movement and 360° rotation (clockwise and counterclockwise) allow even and dyed through samples. • The multi functional beaker holder allows the use of different beaker sizes.

...more

Hydro Extractor

Hydro Extractor is designed for extracting moisture by centrifugal action at high speed. Om Sai Hydro Extractor is designed for high production capacity at very low power consumption that makes this machine must for every yarn dye house. Hydro Extractor is robust in structure and compact in size and occupies very less floor space compare to other textile processing machines Features • Quick and maximum hydro extraction at high speed & High productivity AC Inverter drive is used for soft start and dynamic braking. • For vibration free running it is provided with unique three point shock absorption system. • Compact design, less floor space required. • The machine is sturdily built and dynamically balanced to high accuracy.

...more

Hot Air Oven

Utility: It is used for drying the samples MOC: SS 304 / 316 With Electronic Temperature Controller

...more

HORIZONTAL YARN DYEING MACHINE

H.T H.P Horizontal Yarn Package Dyeing Machine was designed for dyeing the yarn with low liquor ratio. As well as the ceiling height required for the installation of the horizontal yarn dyeing machine as compare to vertical yarn dyeing machine is less for high capacity machine. H.T H.P Horizontal Package Yarn Dyeing Machine Is Used For Dyeing Acrylic Yarn, Texturised Polyester Yarn, Nylon Yarn And Other Narrow Fabrics. This Machine Is Ideally Suited For Large Scale Production. This Horizontal Package Yarn Dyeing Machine Is Available For Capacities 15 Kg / Batch To 540 Kg./Batch. Some Key Features Of This H.T H.P Horizontal Package Yarn Dyeing Machine Are As Follows: Features • Capacity from 15 kgs to 540 kgs • Very low liquor ratio from 1:4 to 1:5 • Variable loading i.e. Loading up to 30% possible. • Savings of water, chemical, heat & electrical energy thus low running cost. • Low ceiling height, only 3 meters required. • Overhead hoist and working platform not needed. • Locking/unlocking of all tube lids by electro-pneumatic devices. • Coil type heat exchanger for efficient and fast heat transfer. • Design ensures complete drain of liquor. • Large Saving of capital and operational cost. • Working Temp. up to 140°C,Working Pressure Up to 4 kg/cm2

...more

Heat Setting Machine

Features • Ideal production machine for spinners to achieve twist setting, yarn conditioning. • Stabilizes moisture content in the yarn. • Yarn is subjected to vacuum and pressure to the required levels in autoclave. • Improves efficiency in weaving, winding and dyeing due to conditioning of yarn. • Vacuum upto 730 mm. of mercury. Special pumps can be offered to achieve higher level of vacuum. • Customized Yarn Carrier. • Semi Automatic operation.

...more

H.T. Steamer

Utility: High temp. steaming at Atmospheric Pressure and temp. up to 200°C ideal for fixing disperse Dye on polyester Fabrics. Saturated steaming at atmospheric pressure & temp. 102° C ideal for cellulosic (like cotton, Rayon Viscose) Nylon. Flash ageing with high temp. steam at 130 °C. Drying, curing and Thermo soling up to 250°C, dry air temp. Ideal for drying, curing of pigment & finishing chemicals, & dye fixation of disperse on polyester. MOC: SS 304 / 316 With Electronic Programmer

...more

garment dyeing machine

Utility: It is ideal M/C for processing of garments in small quantity. M/C can be used for dyeing as well as finishing purpose and carrying out Bio-polishing of garment & Fabric samples. M/C. has S.S. 316 perforated drum for simulated heating action, baffles are provided models available 15 litres/45 litres/100 litres. MOC: SS 304 / 316 With Electronic Temperature Controller

...more

Digital Crock Meter

Utility: To determine the colour fastness of textiles to dry or wet rubbing provided with a crocking finger of 16mm diameter with a down ward force of Newton's and facility for mounting standard crocking fabric. A pinned acrylic sample holder ensures rapid sample mounting and repeatability of results. Available in various models MOC: SS 304 / 316

...more

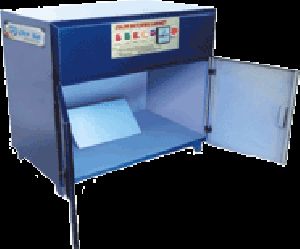

Color Matching Cabinet

Utility: It is an ideal M/C suitable for visual assessment of colours in different lights. MOC: SS 304 / 316 With Electronic Temperature Controller

...moreBe first to Rate

Rate ThisOpening Hours