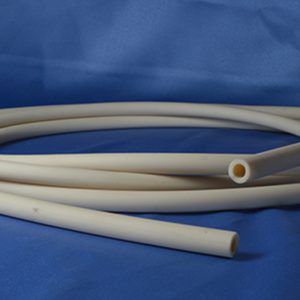

peristaltic pump tubing

Get Price Quote

Used in A peristaltic pump is called positive displacement pump used for pumping a variety of fluids. The fluid is contained within a flexible western polyrub flexible rubber tube with excellent strength fitted inside a circular pump casing (though linear peristaltic pumps have been made). A _rotor with a number of “rollers”, “shoes”, “wipers”, or “lobes” attached to the external circumference of the rotor press the flexible tube. As the rotor turns, the part of the tube under compression is pinched closed (or “occludes”) thus forcing the fluid to be pumped to move through the tube. Additionally, as the tube opens to its natural state after the passing of the cam fluid flow is induced to the pump. This process is called peristalsis and machine called pump

Peristaltic Pump Tubings

Get Price Quote

The compatibility of a peristaltic pump with a certain type of fluid is almost completely dependent on the designof the tubing. This is why, when selecting a peristaltic pump, it is important not to overlook the selection of thepump tubing. Silicone tubing will normally give the highest dispensing accuracy. Most commonly used fordispensing applications silicone tubing meets USP and NFS Class VI standards.Food and medical quality and Autoclavable.There are many factors that should be considered in this selection process. Chemical compatibility – the tubing material must be chemically compatible with the pumped fluid. Engineers should use a chemical compatibility chart designed specifically for pump tubing (not a general use chart) to aid in this decision.When a chart is not sufficient, immersion tests may be used to determine its compatibility or resistance to corrosion. Pressure – the tubing material must be able to withstand the system pressure without leakage or failure. It must also be able to adequately handle abrasive media and suspended solids. Temperature – the tubing material must be able to operate within the temperature range of the system. Users should identify the minimum and maximum temperatures reached in the system and select a material with an appropriate corresponding temperature range. Size – the tubing must be correctly sized in order to fit within the pump head and operate effectively. Closer dimensional tolerances will result in more consistent and repeatable performance. Life expectancy – the tubing material must have a tolerable rated life expectancy to reduce downtime and costs associated with replacement. Transparency – if the media needs to be viewed during pumping, the tubing material should be transparent Digital Analytical Instruments Spectrophotometer Variable Angle Ellipsometer Polarimeter Contact Angle Meter Reflectometer Laser Raman Spectro Photometer Refractometers Hand-Held Refractometer Digital Pocket Refractometer Digital Laboratory Refractometer Peristaltic Pump Peristaltic Filling Pump Peristaltic Pump Tubings Telescopic Conveyor Industrial Belts Vision Inspection Systems for Plastic Sheet Headspace/Package gas analyzer Model 200 Model 901 Model 902D Model 902P Model 905P Model 905V Model 906 Model 907 Portable XRF Analyzer TrueX-Hand-held-Gold-Analyzer Truex Handheld alloy Analyzer Cooking Oil Tester Beverage Gas Monitoring System Bev-Alert System Acetaldehyde, Methanol, & Benzene in CO2 Applications Total Sulfur in CO2 Applications

Best Deals from Peristaltic Pump Tubing

peristaltic pump tubing

Get Price Quote

Peristaltic pump tubing is used in specialized applications of pharmaceutical, biotechnology and laboratory. Some of the types of tubing are Silicone tubing, Viton® tubing, Thermoplastic elastomer tubing( TPE/ TPV tubing). In these applications, the fluid will only be in contact with tubing thereby avoiding any contamination. This peristaltic pump tubing is highly durable, resistant to fatigue, ozone, ultraviolet, acids, alkalies, water, and most oils and lubricants. Therefore becoming one of the best suited tubings for critical applications of biopharma industry. Transparent silicone tubing offers the transparency and having one of the least extractables. Viton® tubing offers excellent chemical resistance to the majority of the chemicals due to fluorine atoms in the chemical chain. This allows it to be used with most of the corrosive liquids where other tubings would fail. Westoprene® tubing is used for special applications where long life and resistance to certain types of chemicals is required.