Hydraulic Plate Rolling Machine Manufacturer Supplier and Exporter from Maharastra

100,000 - 500,000 Per piece

1 Piece (MOQ)

Knifing Unit

Get Price Quote

we are offering knifing unit. knifing unit for babit metal line.

Best Deals from Rolling Machine

PURLIN FORMIG MACHINE

Get Price Quote

1 Container (MOQ)

PURLIN FORMING MACHINE C AND Z SECTION WITH SPECIFIC LENGTH,WIDTH AND THICKNESS

Manual Roll Marking Machine

Get Price Quote

We are the one stop shop in market for availing precision engineered Manual Roll Marking Machine. The offered Manual Roll Marking Machine is fabricated with the highest level of perfection, using top grade components. Manual Roll Marking Machine, available with us, is in conformity with the highest quality standards. Model No. : RH10 / RH15 Features Ideal for marking cyclindrical (Solid or hollow ) components of Steel, Aluminium, Brass, etc. using Bradma interchangeable Steel Types and marking Dies. Perfect for marking such specific components as drills, taps, engine valves, spark plugs, cutting tools, diamond tools, bushes, nozzles, sanitary fittings, hose end fittings, gas lighters and studs. Outstanding benefits : Low set -up time. Easy opertion. High output rates. Robust construction low costs (uses standard tooling). The Steel Types or stamp marks are mounted in holder fixed to the machine carriage. A simple hand lever operates the carriage producing a uniform, legible marking. Marking depth is precisely set by adjusting the vertical dove-tail slide, which cant then be locked any position for for repetitive work. Note : The length of inscription, size of characters number of lines and depth of impression are interrelated and also depend on the hardness of the material being marked. Accessories : Anvil, Roller Cradle, Stud Arbour, Type Holder. Anvil : Components to be marked can be placed either on the Anvil or directly on the Bed Roller Cradles These support and position Solid, round components or thick-walled tubing for peripheral marking During the marking operation, the type holder or marking die rolls over the periphery of the component, causing it to rotate in the cradle. Lubricanted rollers assure free movement of components while marking Stud Arbour This provides internal support to hollow, round components allowing them to rotate freely during marking. Generally, thin- walled components require close-fitting studs to avoid distortion due to marking while thick-walled components do not necessarily require close-fitting studs. Hollow, round components with stepped outer diameters can also be marked with the Stud Arbour. Type Holders : These guarantee accurate type position, positive locking and durability. Specifications Type Character Size Marking Die to Anvil �A� Marking Die to Bed �B� Marking Die to Anvil �A� Marking Die to �B� - - Max. Mm Min. Mm Max. mm Min. mm Max. Mm Min. mm Max. mm Min. mm T010 1 34 0 69 29 84 50 119 79 T062 1.59 (1/16�) 43 0 78 38 93 50 128 88 T020 2 34 0 69 29 84 50 119 79 T093 2.40 (3/32�) 40 0 75 35 90 50 125 85 T030 3 34 0 69 29 84 50 119 79 T125 3.18 (1/18�) 40 0 75 35 90 50 125 85 T040 4 34 0 69 29 84 50 119 79 Used for Marking Dia. Ranging BetweenUsed for Marking Dia. Ranging Between Roller Cradle Code No. Model RH 10 Model Rh 15 - Min Max Min Max RC 1 6 mm 20 mm - - RC 2 12 mm 35 mm - - RC 3 - - 25 mm 55 mm 11.59 (1/16�)22.40 (3/32�)33.18 (1/18�)4 Holder Code No. Type Size (mm) 8 R 10 20 20 - 10 - 6 - 5 8 R 10 40 40 - 20 - 13 - 10 R R 10 60 - - 30 - 20 - 15 125 R 10 1000 - 16 - - - - - 125 R 10 2000 - 32 - - - - - 250 R 10 1000 - - - 10 - 8 - 250 R 10 2000 - - - 21 - 16 - 250 R 102 L1000 - *24 - - - - - 250 R 102 L 2000 - *56 - - - - -

Roller Embossing Machine

10,000 Per Piece

We are reckoned among the established Manufacturers and Supplier of Roller Embossing Machine. The Embossing Machines we make available are manufactured using quality-tested components and the latest technology. We maintain a large stock of the machines in our warehouse in order to meet the bulk and urgent requirements of the buyers. The entire range of the Roller Embossing Machine is reasonably priced by us.

Guide Forming Machine

Get Price Quote

Are you looking for the guide forming machine,best guide forming machine manufacturer in Mumbai? Panchal Engineering Works has known as the best company for sourcing these machines. Our company supplies certified products to customers all around the globe. We have built a huge clientele all around the world. Our customers and clients appreciate our products and are happy with our customer service.Why Choose Products From Us?Quality Assurance Quality is the biggest priority and we never comprise with it. We always make sure that the products of our company have unmatched quality and our customers get machines that meet their requirements. We check our products at every stage to make sure that it meets the international standard quality.Affordable Pricing The products of our company are listed at an affordable price for our customers. All our machines are sold at competitive pricing in the market.For more details call us. We will answer all your questions and will make sure that you get the best products for your use.

Paper Roll To Sheet Cutting Machine

Get Price Quote

Thermal Paper Roll Printing Machine

Get Price Quote

Roll Forming Machine

Get Price Quote

We are reputed Exporter, Importer and Supplier of Roll Forming Machine in Maharashtra. Our Roll Forming Machine is obtained from trusted vendors. Flawless in delivering high performance, our Roll Forming Machine is considered the best in the market. Also, before purchasing Roll Forming Machine from manufacturers, we conduct several quality-tests before delivering to the customers. We offer variety of Roll Forming Machine, Pipe Bending machine of different capacities suitable to bend and form Angle, Channel, Flat, Rod etc. Details : Make : AmadaModel : B-100HCatagory : Ring FormerLocation : Navi MumbaiStock : STK0001456Origin : Japan Technical Specifications : Axis Diameter : 170mmTable Outside Diameter : 1800mmUpper Side Support Movement : HydraulicDown Side Support Movement: ElectricCenter Roller Up down Movement : By HandTable Rotation: 1.5,2.3,3.9,1.8,2.7,4.7 RPMTable Height from the Floor Surface : 830mmMax Table Length :3204mmMachine Height : 1353mmMachine Wight along with Table : 3500KG

ROLL PACKING MACHINES

Get Price Quote

The B-Tex Packing Machine, BPM-PC is fully automatic fabric roll packing machine. It produces presentable packed rolls with high production rate and low cost. BPM-PC can be incorporated with number of inspection machine using conveyor system. After packing fabric rolls are transported to a shrinking unit to shrink pack the rolls which again is doffed on trolley. Features Automatically nylon film wrapping up to 500 mm diameter fabric roll Packing capacity is 60 - 80 fabric roll/hour PLC controlled command system Thickness of nylon film is 70-120 micron Tailor-made machine width from 150 cms to 400 cms Edge closing made by thermic system Shrink operation by passing through the hot air tunnel Automatic entering to machine from more than one machine by conveyor system.

Slip-Out type Bending Rollers

Get Price Quote

This is two roll driven three roll slip-out type plate bending rollers. Slip-out type beding rollers have all three rolls of same diameter and is ideal machine to take out rapidly formed small diameter cylinders without deformation. The machine is available in various sizes from 300 x 1.0mm capacity upto 1250 x 1.0mm in mild steel capacites.

Eye Rolling Machine

Get Price Quote

Features: - All fabricated design - Supplied with quick lifting centre pin arrangement with hand operated lever - Capacity maximum of leaf eye rolling 100 x 12 mm Installation: - The machine should be installed on a concrete foundation close to the heating furnace. Hot end chambers / pre-bending of leaf spring should be done. - After Hot end chamfering of lead on press, hot flat end should be reheated. Two Eye Rolling diameter pins should kept ready. One pin is used for eye rolling while the other pin cools in the water tank kept below the eye rolling machine. Corresponding to the pin size, the required bush is to be mounted on the Eye Rolling Machine. Please make all size pins and corresponding bushes as per your requirement. Brief Operation: Put eye rolling pin in its position. Place the pre-bent portion of the hot leaf into the machine, tighten the clamping screw and manually push the pivot end of the machine using a long pipe. After completing 3/4th bend / eye, release the clamping screw and pull the pivot end of the machine to the starting point. Again clamp the screw and push the pivot end again to complete the eye. Release the screw and pull the pin upwards. Remove the eye using a hammer and die correct the eye size and Inside Diameter. Put this eye rolling pin in the water tank for cooling and use the other pin for the next rolling operation.

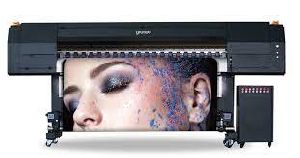

UV LED Roll to Roll Printing Machine

1,450,000 - 2,250,000 Per Set

Flute Roll Corrugation Machine

200,000 Per Set

1 Set(s) (MOQ)

To furnish the varying desires of our customers, we are immersed in offering a world class consignment of Flute Roll Corrugation Machine. Features: Customized Reliable Fine finish Tough construction Durable

Automatic Roll Fed Machines For Forming & Punching Operations

Get Price Quote

Vacuum and pressure forming machines working from roll-stock for separate forming and punching on RV, RDKP, RDK 3rd Generation Thermoformers. > RDK series automatic pressure forming machines were developed as independent machine series featuring high availability, optimum customer benefits and easy operability. > RV machines – vacuum forming with different forming areas, expansion levels and automation levels Formings can be produced economically and efficiently, even in small batch sizes, using the vacuum forming technology in combination with simple tools.

fabric roll counting machine

Get Price Quote

1 Piece (MOQ)

fabric roll couting machine with reverse forward option.

Cable Tray Roll Forming Machine

Get Price Quote

In the industry, we offer cable trays & forming machines such as cable tray forming machines and cable trays roll forming machines from india. Custome made tray we are forming on it there different type of cable tray are there custome made tray easy to formed

Single Shaft Auto Roll Cutting Machine

1,230,000 Per Set

Features : Main driving part: Taiwan AC motor with inverter is employed. Central control unit: programmable central control is used and 20 sizes can be set on the same shaft for auto transfer and cutting. Operating panel: all functions are operated on the 10.4" Taiwan EVIEW LCD touch panel. Motor control system: the central control system is PLC programmable controller. Cutting positioning system: cutting positioning is controlled by Mitsubishi servo motor. The imported high precision ball screw is applied to set the size and the linear slide rail is to bear the load of the cutter seat. Blade feeding positioning system: blade feeding is controlled by Mitsubishi servo motor, and the cutting speed is adjustable in three stages. Auto angle adjustment of circular blade: Mitsubishi servo motor is used to calculate the circular blade angle and the angle change is subject to different materials (the angle change range is ±8°). Quick shaft change system: three kinds of shafts are available and quick change of shafts is applied for different materials.

cloth rolling machine

38,500 - 84,500 Per piece

Wire Rolling Machine

100,000 Per Piece

1 Piece(s) (MOQ)

We are offering our wire and sheet rolling machine 3.5" x 2" are extensively used in workshops that manufacture & design jewelry. These rolling machine consist of steel rollers between which the metal is passed for compression or shape changes. The wire machines have the capability to roll wires for a tapered or shaped effect. Features: hassle-free performance low maintenance high efficiency rugged construction