Stainless Steel Dye Spring

75 Per Piece

500 Piece (MOQ)

Based in Mumbai (India), we are the exclusive Manufacturer, Supplier and Exporter of Dye Springs in the world. Fabrication with stainless steel makes them durable while their precise dimensions result in excellent performance in many dyeing and bleaching operations. We can tailor-make them to match client’s requirements. Moreover, our large production capacity is the reason behind our ever-swift deliveries! Place large orders with us to fetch lucrative deals. Dye Springs Application : Used for dyeing and bleaching of yarn packages.Salient Features of Tex Fab Make Dye Springs : Made of high quality corrosion free stainless steel wire in AISI 304 & 316 grade. Main spring coil is made on fully automatic machine with high production capacity and lacing is done on advanced machines specially designed for this purpose. The spring coils are heat treated for stress release and shape retention. Large manufacturing capacity for quick delivery Dyesprings manufactuerd exactly as per customer as requirement with regard to size and weight. Radially compressible springs available for high shrinkage yarns like nylon & acrylic. Advantages of Dye-Spring : Yarn packages on dyesprings are pressed together to make a rigid column, thus equalizing the density variation within and between different packages facilitating uniform dyeing. The pressing of dyespring packages increases the loading capacity of machines up to 10%, resulting in higher production, and equivalent savings in water, chemicals, heat & electrical energy. The spring design optimizes the flow of dye liquor uniformly all over the yarn packages leading to excellent dyeing results. Dye springs are more durable & economical than plastic tubes. Stainless Steel Dyetubes : With perforations are used as package centres for bleaching & dyeing of yarn as well as heat setting & conditioning. The tubes are available in different sizes, and with a step on one end for stacking one above another. It is a superior alternative to plastic tubes (PP) and long lasting. Dyetubes facilitates easy winding & unwinding of yarn due to smooth finish and eliminates wastage of yarn at the bottom during unwinding as could happen with old dyesprings. Dyetubes with compressible packages are also.

Material : Iron, Stainless Steel, Steel

Certification : ISI Certified

Color : Grey, Silver

Type : Springs

Thickness : 5.5-6mm

Length : 600-700mm

...more

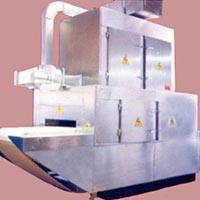

radio frequency dryer

2,200,000 Per

1 Piece (MOQ)

Get rid of excess water from different textile materials after bleaching, dyeing or other such processes with our supreme-quality Radio Frequency Dryer! We infuse them with latest technological features and best components, so that they yield uniform heating functions and user-friendly operations. Being a reputed Radio Frequency Dryer’s Manufacturer, Supplier and Exporter in India and overseas, we quote market-leading prices. Also, we execute prompt deliveries. Highlights : In a radio frequency heating/drying system, the RF generator creates an alternating electric field between two electrodes. The material to be heated /dried is conveyed between the electrodes, where an alternating energy field causes polar molecules in the material to continuously reorient them to face opposite electrodes much like the way bar magnets move to face opposite poles in an alternating magnetic field. Friction resulting from this molecular movement causes the material to rapidly heat throughout its entire mass. Features of RF Drying : Uniform heating resulting in level drying and controlled moisture content within ±1%. Environment friendly. Clean and safe. No effluents and No flues. Easy to feed, operate and maintain. No need of steam or hot air. Self contained unit. Superb consistent quality of dried material for feel and appearance. No chance of contamination, physical damage or colour migration. Instant drying process. No startup and shutdown cost. Application : The RF dryer is widely used in Textile industry all over the world for drying the materials after bleaching, dyeing, mercerizing or wet processing after the initial hydro extraction process in a centrifuge to remove excess water. Any textile material in the form of fibres, Cheeses, cones, hanks, tows & tops and fabrics can be dried in a RF dryer and over the years this technology has increasingly become an accepted and preferred method for drying.

Type : Dryer

Certification : CE Certified

Application : Industrial

Weight : 1000-2000kg

Color : Multi Colour

Voltage : 220V

Automatic Grade : Semi Automatic

Power : 1-3kw, 12-15kw, 15-18kw, 18-21kw, 3-6kw

Driven Type : Electric

Warranty : 1year

...more

radio frequency

In a radio frequency heating/drying system, the RF generator creates an alternating electric field between two electrodes. The material to be heated / dried is conveyed between the electrodes, where an alternating energy field causes polar molecules in the material to continuously reorient them to face opposite electrodes much like the way bar magnets move to face opposite poles in an alternating magnetic field. Friction resulting from this molecular movement causes the material to rapidly heat throughout its entire mass. Features of RF Drying : Uniform heating resulting in level drying and controlled moisture content within ±1%. Environment friendly. Clean and safe. No effluents and No flues. Easy to feed, operate and maintain. No need of steam or hot air. Self contained unit. Superb consistent quality of dried material for feel and appearance. No chance of contamination, physical damage or colour migration. Instant drying process. No startup and shutdown cost. Application :The RF dryer is widely used in Textile industry all over the world for drying the materials after bleaching, dyeing, mercerizing or wet processing after the initial hydro extraction process in a centrifuge to remove excess water.Any textile material in the form of fibres, Cheeses, cones, hanks, tows & tops and fabrics can be dried in a RF dryer and over the years this technology has increasingly become an accepted and preferred method for drying.

...more

Pneumatic Press

Pneumatic Press manufactured by us is extensively demanded in numerous textile industries in India and overseas for pressing yarn cheese. Designed to have superior quality, it’s efficient enough to handle even bulky carriers! Different capacities of Pneumatic Press is supplied and exported by us at cost-effective prices. Owing to our well-equipped production unit, we are capable of catering bulk orders within set time frame. Salient Features : Our pneumatic press consist of header with movement in X and Y axis. Pressing head and guide rods are provided as per the application to meet the particular needs of any pressing process. Gear motor is provided in the trolley for easy movement of the carrier.

Type : Pneumatic Machines

Usage : Packing Various Products

Certification : CE Certified

Overall Weight : 100-200kg

Color : Multi Colour

Voltage : 220V

Operating Type : Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Pneumatic

Warranty : 1year, 2years

...more

HTHP Vertical Dyeing Machines

700,000 Per Piece

1 Piece (MOQ)

Located in Mumbai (India), we are famed for manufacturing comprehensive line of HTHP Vertical Dyeing Machines having capacities up to 1000 kilograms per batch. It facilitates pretreatment and after-treatment of almost every fabric including cotton, polyester, wool, acrylic and many more. We can supply and export them in India and overseas within stipulated time. Besides that, we can custom-make HTHP Vertical Dyeing Machines for our esteemed clients. Application : Used for pretreatment, bleaching, dyeing and after treatment of packages, bobbins, beams loose fibre tops, muffs, hanks etc with appropriate material carriers. Salient Features of Tex Fab make HTHP Vertical Dyeing machines : Low liquor ratio 4 upwards. Offered in either airpad dyeing system or fully flooded dyeing system on customer demand. Variable loading facility at almost constant liquor rates without using dummies. High capacity , High efficiency circulation pump of low noise, directly coupled to the motor, and special reversing device fitted below the dyeing vessel for flow , -reversal which is carried out with pump’s motor in operation. The system avoids peak power absorption due to frequent motor restarting, eliminates water hamming effect on yarn packages, saves energy, minimizes break downs and gives better dyeing results with shorter dyeing cycles. Semi- Automatic or fully automatic mode of operation. Semi Auto operation includes auto fill & drain, programmed dosing and auto sequencing of operations. Fully auto operation includes, in addition, inverter (VFD) with differential pressure control, parallel operation of dyeing vessel & stock tank, remote programming through PC, graphic display of process parameters & process history in memory. The machines can be offered working directly on CNG ( compressed natural gas ) with burner fitted, for heating the dye liquor, so that no boiler or steam is required for running the machine. This revolutionary new idea has resulted in great savings in operating cost as well as capital cost of boiler, chimney & pipelines. Multiple level safety features to make the machine operation totally safe. Two machines of same capacity can be coupled to work as a single machine of double capacity.

Type : Yarn Dyeing Machine

Color : Silver

Warranty : 1year

Power : 1-3kw, 3-6kw, 6-9kw

Voltage : 220V

Certification : CE Certified

Driven Type : Electric

...more

HTHP Pilot Dyeing Machine

200,000 Per Piece

1 Piece (MOQ)

We are the Mumbai-based Manufacturer, Supplier and Exporter offering premium-quality HTHP Pilot Dyeing Machines that are used for dyeing all kinds of fibers & yarns. Our standard models have capacity of 200 grams to 5kgs/batch, but we can also custom-make for variegated clients’ needs! Every machine is duly examined before dispatch. We are known for reasonable pricing and prompt deliveries across India and overseas. Salient Features : The machines have all the features of any large capacity machine, including identical liquor ratio and other process control features for exact reproducibility of dyeing results in bulk. Steam, thermik fluid or electrical heating system or dual systems can be offered. Two or more machines can be offered on a common platform to save space. The machines are table top models with integrated electrical control panel for ease of operation.

Type : HTHP Pilot

Color : Silver

Warranty : 1year

Power : 1-3kw, 3-6kw, 6-9kw

Voltage : 220V

Certification : CE Certified

Driven Type : Electric

...more

HTHP Horizontal Dyeing Machine

600,000 Per Piece

1 Piece (MOQ)

Economical and eco-friendly HTHP Horizontal Dyeing Machine saves you from installation hassles by giving easing mounting facility even on mezzanine of higher floors. These Horizontal Tubular Type Dyeing Machines comes in standard capacities from 20 kgs to 320 kgs per batch, but we also provide with Made-to-Order Machines. Owing to our large distribution network across the world, we make quick deliveries! We are the Manufacturer, Supplier and Exporter of HTHP Horizontal Dyeing Machine from India. Application : The machine is suitable for dyeing all types of yarn in package form. It is also suitable for dyeing zippes tapes, small width fabrics & warp beams. Salient features of Texfab tubular dyeing machines : Works on very low liquor ratio of 1:3.5 upwards depending on nature of yarn & loading factor. Low liquor ratio results in proportionately large savings of water, heat energy, chemicals & effluent treatment cost. Variable loading possible from 50% upwards of the rated capacity without using dummies. Works on airpad dyeing system, resulting in saving cooling water, heat & electrical energy. Opening closing and locking/unlocking is done, simultaneously and automatically by electro pneumatic devices with complete safety. Many optional features are offered to suit varying requirements of the customers like pressure extraction of water, thermo flush, PH monitoring and more. Machines working on gas (CNG) with burner fitted ( without the need of steam or boiler) can also be offered. Advantage : Variable loading possible from 50 % upwards of the rated capacity with almost constant liquor ratio without using any dummies. Heat exchanger is coil type, directly fitted inside the color addition tank resulting in most efficient and fast heat transfer. The tubes are fully flooded but still works on air pad dyeing system. Thus saving cooling water, heat energy and electrical energy. Opening/closing and locking/unlocking of all tube lids is done simultaneously and automatically by electro-pneumatic devices. Design ensures complete drain of liquor from the machine every time. Thus, preventing accumulation of dye deposits inside the machine and contamination. Machines are available in semi-auto or fully-auto mode of operation. The operations automated include fill, circulation, color / chemical dosing, drain & uninterrupted sequence of operations, besides controlled heating & cooling. Specially developed dedicated PLC with microprocessor, live mimic and liquid crystal display (LCD) to indicate all process parameters, for better control and easy operation Many optional features are offered to suit the varying requirement of the customers like pressure extraction of water, thermo flush, ph monitoring, variable frequency drive and more.

Type : Yarn Dyeing Machine

Color : Brown, Grey

Warranty : 1year

Power : 1-3kw, 3-6kw

Voltage : 220V

Certification : CE Certified

Driven Type : Electric

...more

HTHP Beam Dyeing Machine

2,000,000 Per Piece

1 Piece (MOQ)

We offer a mighty range of Beam Dyeing Machines that are reckoned around the globe for their exemplary heat transfer efficiency. The range encompasses HTHP Beam Dyeing Machine and Economical Beam Dyeing Machine! These are designed at par with the international quality standards. Standard capacity of up to 500Kgs/batch or custom capacity can be availed from us at affordable prices. We are the Beam Dyeing Machine’s Manufacturer, Exporter and Supplier from Mumbai, India. Application : For dyeing and bleaching of all types of fabrics in open width form. Advantages: As the fabric wound on perforated beams is static, the even penetration of dye liquor ensures level dyeing and avoids damage to the fabrics. No wrinkles and crease marks on the fabrics. Suitable for delicate fabrics as well as heavy suiting’s. The machine is suitable for working pressure upto 5 bar and temperature upto 1350C Provided with ‘Airpad’ system for static pressure thus reducing the M:L ratio. (1:6 upwards) High capacity high efficiency centrifugal pump with flow reversal device for both into out and out to in flow for achieving uniform dyeing results. Internal heat exchanger of seamless tubes increases the heat transfer efficiency and causes least pressure drop in liquor flow. Machine with various diameters and width with one or two beam in series are available as per customer’s requirement.

Type : Dyeing Machine

Color : Multi Colour

Warranty : 1year

Power : 1-3kw, 3-6kw, 6-9kw

Voltage : 220V

Certification : CE Certified

Driven Type : Electric, Hydraulic, Mechanical

...more

HTHP Beaker Dyeing Machine

1 Piece (MOQ)

Based in Mumbai (India), we are renowned for manufacturing best HTHP Beaker Dyeing Machines having 6 or 12 beakers with capacity of 500cc or 250cc each! They come along with pressure tight caps having Teflon gaskets. Every Machine design is in adherence to the set industry guidelines. Moreover, we export and supply them in timely manner to different global destinations at affordable prices. Customization requests are accepted. Application : Used for sampling and shade matching of yarn and fabrics with temperatures up to 1350C. Salient Features : All the beakers (of 250 cc) are made from solid bar and hence here are no weld joints. These are not made from pipes y welding the bottom. This ensures long life and no leakages even after many years of use. The gear motor of 0.5HP/32rpm is from most reputed manufacturers for noise free and maintenance free operation. A choice of heating arrangements with either electrical, steam or thermik fluid system. Table top model for ease operation, without requirement of a platform. Machines with more or less number of beakers, of larger or smaller size can also be made as per customer’s requirement. Pneumatic press consist of header with a pneumatic cylinder with movement in X and Y axis. Pressing head and guide rods are provided as per the application to meet the particular needs of any pressing process. Gear motor is provided in the trolley for rotational movement of the carrier.

Type : HTHP Beaker

Certification : CE Certified

Application : For Dyeing And Fabric

Weight : 100-200kg, 200-300kg, 300-400kg

Color : Multi Colour

Voltage : 220V, 380V

Automatic Grade : Automatic, Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw

Driven Type : Electric

Warranty : 5years

...more

Hot Air Dryer

1,000,000 Per

1 Piece (MOQ)

We are the Mumbai-based Manufacturer, Supplier and Exporter of top-tier Hot Air Dryers in the global markets. This fully automatic machine gives higher thermal efficiency for drying dyed yarns etc at an economical cost. We provide them in capacity 25 to 500 Kgs /Batch. Higher capacities can be made available on client’s request! We safely and promptly deliver of every order, owing to our efficient logistics around the globe. Our recirculatory hot air dryer-chamber type for yarn in packages, is an economical alternative to RF dryer . It is recirculatory type for higher thermal efficiency. The machine is fully controlled via programmer. Drying cycle for cotton is 41/2 hours. The hot air dryer machine consists of : Cabinet: Fabricated from heavy duty angle Frame with gauge S.S.Sheet inside and M.S.Sheet from outside with powder coating and sliding door. Insulation : Cabinet and door are insulated Glass wool. Blower Fan : A centrifugal blower with motor. The blower force circulates hot air through the yarn packages and the exhaust is partly re circulated.(Optional) The blower motor is fitted with A.C. inverter drive for soft start and flow control. Radiator : Steam or thermik fluid Radiators are provided to heat the chamber temperature upto 120°C. Hot air generator working on LPG/CNG can also be supplied where required. Temperature Control : Microprocessor based time-temperature programmer is provided to control the inlet air temperature and temperature indicator for outlet air. S.S. rectangular Trolley carrier with poles and special locking nuts for loading the yarn packages into the chamber. Salient Features : Gives uniform drying results. Drying cycle for cotton with 45% residual moisture is 41/2 hours. Economical alternatives to RF dryer. Both capital and operating cost less. Almost no maintenance. Simple to operate and maintain.

Type : Dryer

Certification : CE Certified

Weight : 10-50kg

Voltage : 220V

Warranty : 1yrs

Color : Shiny Silver

Power : 6-9kw

...more

Effluent Waste Heat Recovery System

1,000,000 Per Piece

1 Piece (MOQ)

Texfab waste heat recovery from dyeing effluent system can recover upto 85% heat from effluent discharge by using a high efficiency heat exchanger for heating incoming process water or boiler feed water upto 85°C.Advantages: Cost savings due to reduced steam requirement upto 35% (varies according to difference in water temperature and water consumption). Due to reduced temperature of effluent discharge, no need to cool it before treatment. Hence savings on waste water treatment cost and cooling tower. By using hot water to wash, improvement in dyeing quality of yams and fabrics Using hot water in process increases productivity by reducing water heating time. Salient Features: All parts in contact with dye liquor/ water are made of stainless steel 316/316L High efficiency heat exchanger (upto 85%). Aeration device and filter cleans adhesion substances (manual/Automatic) to keep the system clean and efficiency high. The system consists of stainless steel vacuum containers, centrifugal pump, filter, electrical control panel, back purge cleaning system & master controller that controls the whole system and keeps record of heat energy recovered.

Power : 5 HP

Country of Origin : Made in India

...more

centrifuge hydro extractor

Application : Used for hydro extraction of dyed yarn packages in a short time and at low cost. Salient Features : Centrifuge hydro extractor rotates at very high speed which results in quick and maximum hydro extraction. AC Inverter drive is used for soft start and dynamic braking. For vibration free running it is provided with unique four point shock absorption system. The machine is sturdily built and dynamically balanced to high accuracy. Technical Specification: Model size : 24" 36" 48" 60" Approximate loading capacity (polyester) : 27 kg. 45 kg. 63 kg. 90 kg.

...more

centrifugal hydro extractor

300,000 Per Piece

1 Piece (MOQ)

Our Centrifugal Hydro Extractor makes a must have for every yarn dye house with its exceptional rotating speed for quick & maximum hydro extraction! Not just quick, but it also consumes less power. It is robust yet compact enough to occupy minimum spaces. Also, easy customization in different capacities can be done on customer’s demand. Being the prime Manufacturer, Supplier and Exporter of Centrifugal Hydro Extractor in India and overseas, we offer best prices! Application : Used for hydro extraction of dyed yarn packages in a short time and at low cost. Technical Specification: Model size : 24" 36" 48" 60" Approximate loading capacity (polyester) : 27 kg. 45 kg. 63 kg. 90 kg. Centrifuge Hydro Extractor for Fabrics & Fibre cake We offer our clients basket type hydro extractor that are either semi open or fully open. These machines are mostly used for hydro extraction of fabrics, hanks, tops and more. Our machines are easy to operate and facilitate direct loading and unloading of fabric in rope form in to the basket from overhead hoist. High in durability and functionality, these machines are sturdily built and dynamically balanced to high accuracy. Our Centrifuge Hydro Extractor is available in diverse specification as per the requirement of our esteemed customer. Salient Features : Centrifuge hydro extractor rotates at very high speed which results in quick and maximum hydro extraction. AC Inverter drive is used for soft start and dynamic braking. For vibration smooth operation, the machine is provided with unique four point shock absorption system. Opening and closing of lid done by pneumatic cylinder. The machine is sturdily built and dynamically balanced to high accuracy. . All parts coming in contact with water and textile are made from stainless steel. Available in different sizes and capacities according to customers' requirements from 24" to 72" diameter baskets.

Type : Hydro Extractor

Certification : CE Certified

Application : Textile Industry

Weight : 100-200kg

Color : Silver

Voltage : 220V

Automatic Grade : Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

Driven Type : Electric

Warranty : 1year

...more

Yarn Setting Autoclave

We make available hi-tech Yarn Setting Autoclave that provides lustrous and soft yarn by heat setting and conditioning it. This fully automatic Autoclave is sturdy and long lasting, courtesy its stainless-steel built! To add up, we custom make it in various loading capacities to suit user’s operations. Acquire it from us anywhere in India or overseas within prescribed time. We are Yarn Setting Autoclave’s Manufacturer, Supplier and Exporter belonging to Mumbai, India. The advantages of yarn heat setting : Yarn relaxation gives luster and soft feel. Twist setting and stabilization Better dye affinity Snarling and kinking during unwinding process can be eliminated. How does it work : Texfab make yarn steaming autoclaves for heat setting and conditioning of yarn. It is suitable to work on high temperature at 1350C and 3.5 bar pressure. The material of construction is S.S or M.S with optional S.s cladding inside for long life. The autoclave is provided with limpet coil on outside. A water ring vacuum pump is provided with the machine to give maximum vacuum inside up to 650mm of mercury. The autoclaves are supplied in various capacities from 50Kg to 1000kgs per batch of yarn in cheese or hank form. The yarn carrying and yarn charging trolleys are made as per customer’s requirement to accommodate the maximum material and different loading arrangements. Autoclave is fully automatic and controlled through microprocessor based programmer.

...more

Autoclaves

e advantages of yarn heat setting: Yarn relaxation gives luster and soft feel. Twist setting and stabilization Better dye affinity Snarling and kinking during unwinding process can be eliminated How does it work:Texfab make yarn steaming autoclaves for heat setting and conditioning of yarn. It is suitable to work on high temperature at 1350C and 3.5 bar pressure. The material of construction is S.S or M.S with optional S.s cladding inside for long life. The autoclave is provided with limpet coil on outside. A water ring vacuum pump is provided with the machine to give maximum vacuum inside up to 650mm of mercury. The autoclaves are supplied in various capacities from 50Kg to 1000kgs per batch of yarn in cheese or hank form. The yarn carrying and yarn charging trolleys are made as per customer’s requirement to accommodate the maximum material and different loading arrangements.Autoclave is fully automatic and controlled through microprocessor based programmer.

...moreOpening Hours