Vacuum Furnace

Get Price Quote

1 Set(s) (MOQ)

Induction Vacuum Furnace Refining of high purity metals and alloys Casting of aircraft engine components For Titanium and Reactive metals melting and casting, used in fields like Aerospace, Automotive and Medical Melting of Lanthanum Melting and casting of Ferrous Metals (steel, cast iron) and their powder production. For melting precious metals (gold, silver, platinum group) and making of metal ingots, sheets, rods and grains production in batch production. For the homogenization of steel samples coming from a scrap batch. Master alloy stick for processes such as investment casting etc.

Vacuum Furnace

Get Price Quote

We pleased to get this opportunities to introduce our firm specialized for undertaking refractory Installation work. We involve in this field since long back time and executed several new projects as well as rebuild/ repairing work in India and abroad with excellent quality of work performance within a stipulated time frame. Our company is registered and developed with all infrastructures i.e. equipments, tools-tackles, organized workmen team. So, we are capable to undertake any quantum of related work in any industry and for your kind information, we have our own EPF code, ESIC code no, GST, PAN and manpower holding with valid passport. So, we can comply all statutory liabilities and fulfill all obligations. Assuring you that we shall always be at the best service in future and all your enquiries will receive our best attention, we request you for your kind consideration for us.

Best Deals from Vacuum Furnace

Vacuum Furnace

Get Price Quote

Our company shares glorious credentials with the successful Manufacturers and Suppliers of Vacuum Furnaces. The Vacuum Furnaces we make available are manufactured in compliance with set industrial norms. Few words that better describe our Furnaces are easy to install, durable and reliable. Bulk orders of these are processed by us as per the specific requirements of the buyers. One can obtain these at reasonable rates from us.

High Vacuum Furnaces

Get Price Quote

High vacuum furnaces, The furnace has effective hot zone size 350x250x450 mm (14”x10”x18”) & load capacity of 100 Kgs. (200 lbs).Treated parts are heated very homogeneously in a temperature range between 150 °C (300°F) and 1315 °C(2400°F) and under vacuum level of 10-5 Torr range. With advanced PLCHMI control system , furnace complies to NADCAP requirement “ Furnace is highly flexible since it can be used for hardening with high pressure gas quench and brazing application under high vacuum for complex aerospace parts” Mr. Oguzhan Kocaman Quality Manager, quoted after completing the production trials.

Vacuum Furnace

2,500,000 Per Piece

1 Piece(s) (MOQ)

Vacuum melting furnaces FIM

Get Price Quote

Vacuum melting furnaces FIM / FPt (Alloys Palladium, Platinum) The oven is used for the vacuum melting of platinum, palladium, dental alloys. The induction furnaces Italimpianti Orafi are all equipped with static converters medium frequency (4 to 15 kHz), which guarantee the homogeneity of the alloys. The high technical level achieved in the design of the inductors, also combined with a modular construction technique and the use of high quality materials, guarantees maximum production even in the harshest conditions. The furnace is composed of a completely stainless steel casing rafreddato water wheel in which the crate with the crucible and mold for casting or cylinder for tilting casting. The case is done by tilting motor with inverter and proportional joystick. The oven is equipped with vacuum pump 65 m 3 / h and an optical pyrometer for temperature control. All the step of melting, casting and homogenisation takes place in a protective atmosphere, which can be, optionally, composed of gas Argon or Nitrogen. monitoring of the display of the converter operating parameters, such as voltage and power consumption; computerized alarm diagnostic for the detection of alarms or warnings of which the operator must take into account for the proper functioning of the system. Instructions and tips on what to do are displayed on the display; of closed loop power control which allows to absorb the power system set regardless of the amount and type of metal to be melted; the internal environment of the converter is conditioned by an air-water heat exchanger.

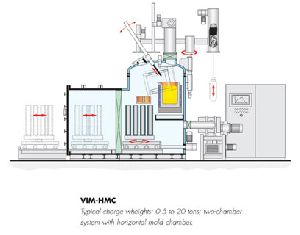

Vacuum Induction Melting Plants

Get Price Quote

Applications : Melting, Alloying and casting under vacuum of oxidation prone metals and alloys. Main uses are in R&D, Electronic Industry, Dental Applications, Aerospace and Precious Metal Industry.

Induction Vacuum Furnace

Get Price Quote

Refining of high purity metals and alloys Casting of aircraft engine components For Titanium and Reactive metals melting and casting, used in fields like Aerospace, Automotive and Medical Melting of Lanthanum Melting and casting of Ferrous Metals (steel, cast iron) and their powder production. For melting precious metals (gold, silver, platinum group) and making of metal ingots, sheets, rods and grains production in batch production. For the homogenization of steel samples coming from a scrap batch. Master alloy stick for processes such as investment casting etc.

vacuum furnaces

Get Price Quote

vacuum furnaces, atmosphere furnaces

Vacuum Furnace

Get Price Quote

Vacuum Furnace

Vacuum Induction Melting Plants

Get Price Quote

Vacuum Induction Melting Plants, metal forming, Vacuum Arc Remelting Plants

Vacuum Furnace

Get Price Quote

Vacuum Furnace, Drying Plants