transformer steel

The Quality of CRGO is measured in terms of lower losses of electrical current, which flow in the core. The proper design of core and good quality of core material do a best job in combination. Mainly the core losses are measured in Watts per Kg.

...more

steel metal components

Metal component parts can be stamped for lowest cost and greater efficiency. Very intricate and complex products can be produced using a metal stamping die. This is due to advances in die design and build technologies. Products can be cut, formed, drawn, twisted, coined, extruded, welded, and tapped. Also, parts can be assembled in the die by employing a variety of technologies. As a result, the metal stamping process economically competes with other processes such as chemical etching, laser cutting, screw machining and die casting, even at low production quantities. Very intricate and complex products can be produced using a metal stamping die. This is due to advances in die design and build technologies. Products can be cut, formed, drawn, twisted, coined, extruded, welded, and tapped. Also, parts can be assembled in the die by employing a variety of technologies. As a result, the metal stamping process economically competes with other processes such as chemical etching, laser cutting, screw machining and die casting, even at low production quantities.

...more

Stamped Steel Parts

Metal component parts can be stamped for lowest cost and greater efficiency. Very intricate and complex products can be produced using a metal stamping die. This is due to advances in die design and build technologies. Products can be cut, formed, drawn, twisted, coined, extruded, welded, and tapped. Also, parts can be assembled in the die by employing a variety of technologies. As a result, the metal stamping process economically competes with other processes such as chemical etching, laser cutting, screw machining and die casting, even at low production quantities. Very intricate and complex products can be produced using a metal stamping die. This is due to advances in die design and build technologies. Products can be cut, formed, drawn, twisted, coined, extruded, welded, and tapped. Also, parts can be assembled in the die by employing a variety of technologies. As a result, the metal stamping process economically competes with other processes such as chemical etching, laser cutting, screw machining and die casting, even at low production quantities.

...more

Spiral Welded Pipes

Uncoiler 1 - Pinch and delivery 5 - Motored guide rollers 1 - Shear end welder 2 - Edge miller 2 - Plate sweeper 1 - Delivery machine 1 - Pre-bending 1 - Forming machine 1 - Front bridge 1 - IO welding machine 1 - Rear bridge 1 - Centering device 1 - Flying cut-off cart 9 - Pipe flipper 1 - Buried parts 1 - Host hydraulic system 1 - Host electric system 1 - Flux electric stage 2 - Welder - Lincoln DC1500 2 - Welder - Lincoln AC1200 2 - LGK250 Plasma cutter 1 - Shear welder cart 1 - Flux recycle system 1 - Flux process system

...more

shredded steel scrap

ISRI Code 202 Wrought iron andor steel scrap 14 inch and over in thickness. Individual pieces not over 60 x 18 inches (charging box size) prepared in a manner to insure compact charging.

...more

scrap steel

ISRI Code 204 205 206 Wrought iron and steel scrap, black and galvanized, maximum size 36 x 18 inches. May include all automobile scrap properly prepared.

...more

prepainted steel

POLYESTER PAINTED STEEL SHEET General Application High Formability A variety of usages such as interior exterior construction materials APPLICATION Building: Exterior Material (Roofing, Wall) industrial, commercial, public utility, housing, etc Building: Interior Material interior wall, ceiling, partition, fireproof door etc Accessories: shutter, signboard Home Appliances: oil and gas boiler, rice box, portable gas range, etc Other: electric device, steel furniture, agricultural equipment 2. POS-PSP SUPER POLYESTER PAINTED STEEL SHEET Corrsion Resistance Weather Resistance A variety of usages such as interior exterior construction materials High durability compated to the POS-PGS series

...more

Plate Cutting Scrap

ISRI Code 211 Homogeneous iron and steel scrap magnetically separated, originating from automobiles, unprepared No. 1 and No. 2 steel, miscellaneous baling and sheet scrap. Average density 70 pounds per cubic foot

...more

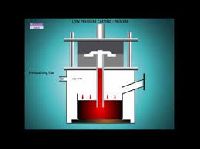

low pressure die casting

n die casting, molten metal is injected into a mold at high pressure. The pressure can range from about 1,400 psi to as high as 30,000 psi. By pressurizing the mold, the cast object will be more uniform and will display an attractive finish. In many cases very little or no post-casting machining is needed to complete the item. Pressure molding also provides for precise dimensional accuracy that is critical for parts used in products with interchangeable parts. Low pressure die casting is commonly used for larger non-critical parts. Whereas high pressure castings which are used for tight tolerance detailed geometry. High pressure die castings are able to maintain tighter tolerances and more detail than low pressure die casting because the extra pressure utilized is able to push the metal into more detailed features in the mold. High Pressure die castings have excellent surface finishes that are consistent dimensionally with precision features and minimum draft. There are two main die casting processes, and their use is dependent on the type of metal being cast:

...more

hot rolling mill plant

Plant Year : 2005 Brand : Mill – Wonil & Hyundai, Korea Reducer & Motor – Japan Electric part – Korea Others- Korea 1. Basic Specification - Raw material: Billet - Billet Size: 120mmsg(160mmsg) - Billet length: 1.8m ~ 4.8m - Steel grade: Low carbon steel - Products: Angle 40x 3mm~75x 9mm - Product capacity: 35~40TonHr 2. Reheating furnace - Capacity: 35TonHr - W x L: 5200W x 18,000l - Type: Pusher type - Burner: 13pcs x 3 zone 3. Roughing mill - Roll stand: 5set(2-high closed) Roll size: 500Ø x 1050l Bearing: Roller Bearing(24052) Roll balance: Hyd type - Universal joint: 12pcs swing dia -350Ø - Pinion stand with reducer : 3set (2put reducer-2set, single reducer-1set, pinion-5set) pcd -480, single helical gear - Motor: 3pcs (AC500kwx 2, AC300kwx 1)

...more

High Melting Scrap

ISRI Code 231 Cut structural and plate scrap, 5 feet and under. Clean open hearth steel plates, structural shapes, crop ends, shearings, or broken steel tires. Dimensions not less than 14 inch thickness, not over 5 feet in length and 18 inches in width. Phosphorus or sulphur not over 0.05 percent.

...more

Electrical Laminations

Core laminations are the main part of an electrical transformer, and this attribute to 70% of a transformer cost. These core laminations are required to be cut from special steel called as Cold Rolled Grain Oriented Electrical Steel or popularly known as CRGO. The CRGO is a special quality of steel which have a special grain surface and comes in a thickness of 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm. (generally called M3, M4, M5 & M6). Lower the thickness of material better is the quality of material. The Quality of CRGO is measured in terms of lower losses of electrical current, which flow in the core. The proper design of core and good quality of core material do a best job in combination. Mainly the core losses are measured in Watts per Kg. Every type of steel has "grains" which consist of "domains". These "domains" are nothing but electrical charges oriented in any random direction. Therefore if a transformer were to be made of Mild Steel used as core material, the core loss would be approx. 16 to 17 wkg at 1.5T50Hz and the size of the transformer would be approx. 18 to 20 times the size of a transformer manufactured with GO steels.

...more

CRNGO Steel

Every type of steel has "grains" which consist of "domains". These "domains" are nothing but electrical charges oriented in any random direction. Therefore if a transformer were to be made of Mild Steel used as core material, the core loss would be approx. 16 to 17 wkg at 1.5T50Hz and the size of the transformer would be approx. 18 to 20 times the size of a transformer manufactured with GO steels.

...more

CRGO Transformer Lamination Core

Every type of steel has "grains" which consist of "domains". These "domains" are nothing but electrical charges oriented in any random direction. Therefore if a transformer were to be made of Mild Steel used as core material, the core loss would be approx. 16 to 17 wkg at 1.5T50Hz and the size of the transformer would be approx. 18 to 20 times the size of a transformer manufactured with GO steels.

...more

crgo steel

ELECTRICAL STEEL : Electrical Steel, also called lamination steel, silicon electrical steel, silicon steel or transformer steel is speciality steel tailored to produce certain magnetic poperties, such as small hysteresis area (small energy dissipation per cycle, or low core loss) and high permeability. PRODUCTION PROCESS 1) Hot Rolled Coil-> Pre-Annealing and Pickling -> High Temperature Annealing -> Insulation Coating -> PH-Core & PG-Core 2) Hot Rolled Coil-> Pickling -> Cold Rolling -> Annealing -> Tempreture Rollling -> Insulation Coating -> PN- Core & PNS Core 1) CRGO: Core laminations are the main part of an electrical transformer, and this attribute to 70% of a transformer cost. These core laminations are required to be cut from special steel called as Cold Rolled Grain Oriented Electrical Steel or popularly known as CRGO. The CRGO is a special quality of steel which have a special grain surface and comes in a thickness of 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm. (generally called M3, M4, M5 & M6). Lower the thickness of material better is the quality of material.

...more

CRGO Sheet

The Quality of CRGO is measured in terms of lower losses of electrical current, which flow in the core. The proper design of core and good quality of core material do a best job in combination. Mainly the core losses are measured in Watts per Kg. Every type of steel has "grains" which consist of "domains". These "domains" are nothing but electrical charges oriented in any random direction. Therefore if a transformer were to be made of Mild Steel used as core material, the core loss would be approx. 16 to 17 wkg at 1.5T50Hz and the size of the transformer would be approx. 18 to 20 times the size of a transformer manufactured with GO steels.

...more

crgo core

CRGO: Core laminations are the main part of an electrical transformer, and this attribute to 70% of a transformer cost. These core laminations are required to be cut from special steel called as Cold Rolled Grain Oriented Electrical Steel or popularly known as CRGO. The CRGO is a special quality of steel which have a special grain surface and comes in a thickness of 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm. (generally called M3, M4, M5 & M6). Lower the thickness of material better is the quality of material.

...more

aluminium sheet coil

Aluminium SheetsCoils are manufactured in a range of alloys in varying tempers for usage in cooking holloware, insulation, air-conditioning fin, reflector, bus body, profiled building products for roof and cladding, false ceiling, fascia, paneling, packaging, general engineering purposes and more. Features of Aluminium - High Strength-to-weight ratio - Corrosion resistance - Modulus of Elasticity - Non-toxicity - Formability and workability - Thermal Conductivity

...more

SAIL TMT Bars

Be first to Rate

Rate This