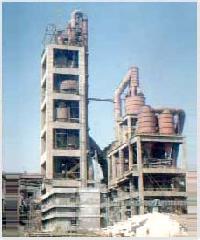

mini cement plant machinery

Get Price Quote

We are engaged in catering to the emerging requirements of valued customers by offering Mini Cement Plants Manufacturers. These mini cement plants are developed by our proficient engineers, who ensure to utilize supreme grade raw material. Along with this, these mini cement plants are designed in accordance with the demands of the clients. The offered mini cement plants are developed using modern machinery and sophisticated technology in adherence with the industry laid norms and standards.

Fly ash Feeding System

Get Price Quote

Melco manufacture and supply complete range of Fly ash equipments for both dry ash conveying and wet ash mode evacuation. Dust Extraction Valves, Dust Isolation Valves, Vacuum Breakers, Hydraulic Exhauster, Wetting Head, Collector Tanks, Air Washers.

Best Deals from Mini Cement Plant Machinery

Fly ash Feeding System

Get Price Quote

Fly Ash storage system is widely used to store loose fly ash. The Silo comes with a complete set of accessories including Level indicators, Dust collectors, Pressure safety relief valves, Bin aerator, Fludisation nozzles and options for feeding system.

Fly ash Feeding System

Get Price Quote

he structure of the silo is made from IS 2062 B grade material and it's a air tight with having top man hole provision and bottom butterfly valve provision. Silo comes with inner and outer ladder which is used to clean or inspect the silo when required. In some special cases silo can be made from SS material or as per the client's requirement.

Fly ash Feeding System

Get Price Quote

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by offering Automatic Weighing System. Designed with utmost precision, the offered weighing system is manufactured using high quality components and innovative technology. In addition to this, our provided weighing system is stringently checked under the supervision of quality experts in order to ensure its flawless performance. Our esteemed clients can avail this weighing system from us at market-leading prices.

mini cement plant machinery

Get Price Quote

Consultancy Services and repair jobs for optimisation and stabilisation of Mini Cement Plant at Karampudi of Ms. Goldstar Cements Limited, Hyderabad Consultancy Services for establishing a 200 TPD Cement Grinding Unit at Ratnagiri for Ms. Ratnagiri Building Products Ltd., Bombay Project Consultancy for expansion of the Mini Cement Plant of 1000 TPD Plant at Karampudi, Andhra Pradesh for Ms Goldstar Cements Limited, Hyderabad Consultancy Services for establishing a new 300 TPD Cement Grinding Unit near Thogaimalai, Karur District Consultancy Services for Installing a Garnet Micronising Unit for Ms Chettinad Quartz Products Project Consultancy Services for establishing a new 1000 TPD Cement Plant near Srinagar, Jammu and Kashmir, for Ms Khyber Industries Private Ltd. – Under Execution Assisting in R & D Activities of Ms Madras Hydraulic Hose (P) Ltd. and Development & Commissioning of Special Purpose Machines

Fly ash Feeding System

Get Price Quote

Fly ash Feeding System

Get Price Quote

As shown in above figure, all pneumatic conveying systems, whether they are of the positive or negative pressure type mainly consist of a feeding system and a separation system. The system requires gas, usually air to convey materials. For hygroscopic materials, dry air can be used and for potentially explosive materials, an inert gas such as nitrogen can be employed. Information on fundamentals for conveying material pneumatically is given in this chapter.

Fly ash Feeding System

Get Price Quote

The conveying rate achieved is 30 - 32 Tons per hour. When cement fly ash is received at site in Bags, then they are manually taken to a hopper. Bags are slit and loose material is dumped in to the hopper. A specially, designed screw feeder and low pressure air insertion ensures measured flow of material in to the discharge pipe line The cement fly ash dropped in discharge pipe are pushed ahead to main silo with the pressure of 1 KgCm2. The transfer rate achieved is 12 to 15 Tons Hour forthis mode The same operational procedures remain common for lime handling systems also.

Fly ash Feeding System

Get Price Quote

Twin lobe roots blower with accessories, electric motor & electric control panel.Type : POSITIVE DISPLACEMENT, Air cooled, both sides bearings and timing gears oil lubricated.

Fly ash Feeding System

Get Price Quote

Energo boasts of providing the state of the art vacuum system largely owing to its hugely successful Zero Leakage Endivac valves which play a major role in isolating the branch line from the hoppers. Energo provided systems have low Capital and Operation Cost, are ideal for situations where room for equipment is limited under the hoppers, are easy to maintain & provide long wear life, and are more effective mode of transport where material is collected from multiple discharge points. Lean Phase Pressure System designs go the distance to cleanly and safely convey material from hoppers to the silo. Energo’s easy-to-maintain equipment can handle the transport of significant quantities of material to the silo.

Fly ash Feeding System

Get Price Quote

Timely execution of mega-projects in construction Industries has led to paradigm shift with introduction of Batching plant and its product viz; RMC However two basic inputs to RMC viz cement and Fly ash are received at site in Bulkers or in bags The optimum productivity of Batching plant depends on how fast the cement fly ash is received at site and is transferred to Batching Silo. PNEUCON has designed, manufactured and supplied user friendly system mounted on a skid; it will have options to both modes of Cement fly ash input i.e. loose in Bulkers or material received in Bags. Conveying from Bulker to Main Silo is achieved by diverting the voluminous air flow at around 1 Kg Cm2 Pressure. The bulker is aerated and pressurized. Opening of Bottom Valve allows cement fly ash to fall directly in dispatch pipe. The air flow carries the material to the main Silo.

mini cement plant machinery

Get Price Quote

mini cement plant machinery, heavy gear machinery parts

mini cement plant machinery

Get Price Quote

mini cement plant machinery, Cement Plant Machinery

mini cement plant machinery

Get Price Quote

mini cement plant machinery, suction drums, Mini Cement Plant, Jaw crusher

Fly ash Feeding System

Get Price Quote

Fly ash Feeding System, twin lobe rotary compressors

mini cement plant machinery

Get Price Quote

mini cement plant machinery, Wall Putty Making Machine, waste heat boilers

Cement Fly Ash Pneumatic Feeding System

Get Price Quote

Cement Fly Ash Pneumatic Feeding System, mobile concrete batching mixing plant